Honeywell ST 3000 Specification And Model Selection Manual

Series 100 remote diaphragm seals models smart transmitter

Hide thumbs

Also See for ST 3000:

- User manual (338 pages) ,

- Installation manual (126 pages) ,

- Addendum (6 pages)

Advertisement

Quick Links

ST 3000 Smart Transmitter

Series 100 Remote Diaphragm Seals Models

STR12D

0-10 to 0-400 inH

STR13D

0-5 to 0-100 psid

STR14G

0-5 to 0-500 psig

STR17G

0-100 to 0-3000 psig

STR14A

0-5 to 0-500 psia

Introduction

In 1983, Honeywell introduced the first

Smart Pressure Transmitter― the ST

®

3000

. In 1989, Honeywell launched

the first all digital, bi-directional protocol

for smart field devices. Today, its ST

3000 Series 100 Remote Seal

Transmitters continue to bring proven

"smart" technology to a wide spectrum

of measurement applications. Typical

applications include high accuracy level

measurement in pressurized vessels in

the chemical and hydrocarbon

processing industries. A second

application consists of accurate flow

measurement for slurries and high

viscosity fluids in the chemical industry.

Honeywell remote seal transmitters

demonstrate proven reliability in

hundreds on installations in a wide

variety of industries and applications

with a wide variety of secondary fill

fluids for corrosive or high temperature

process fluids.

All ST 3000 transmitters can provide a

4-20 mA output, Honeywell Digitally

Enhanced (DE) output, HART

or F

Fieldbus output.

OUNDATION™

When digitally integrated with

Honeywell's Process Knowledge

System™, EXPERION PKS™,

ST 3000 instruments provide a more

accurate process variable as well as

advanced diagnostics.

Honeywell's high-performance ST 3000

S100 transmitters lead the industry in:

•

Accuracy

•

Stability

•

Reliability

•

Rangeability

•

Warranty

Includes Lifetime™ Transmitters:

•

Total Accuracy = ±0.0375%

•

Stability = ±0.01% per year

•

Reliability = 470 years MTBF

•

Rangeability = 400 to 1

•

Lifetime Warranty = 15 years

O

0-25 to 0-1000 mbar

2

0-0.35 to 0-7 bar

0-0.35 to 0-35 bar

0-7 to 0-210 bar

0-0.35 to 0-35 bar

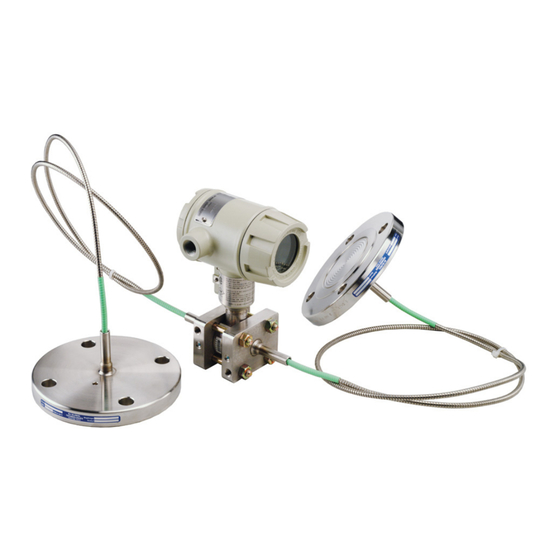

Figure 1—Series 100 Remote Seal Pressure Transmitters feature proven

*

output,

piezoresistive sensors and advanced seal technology with standard weld

connections.

The devices provide comprehensive self-diagnostics to help users

maintain high uptime, meet regulatory requirements, and attain high

quality standards. S100 transmitters are ideal for critical applications,

such as custody transfer of natural gas and energy and material

balances, where accuracy and stability are of the utmost importance.

"Our commitment to Honeywell field instruments is based on

seamless integration with our Honeywell system and the enhanced

fault detection that the Honeywell DE protocol offers. Honeywell

instruments also offer us a better way of ensuring database integrity

over simple analog instruments. In addition, Honeywell's high-quality

support has enabled us to better implement solutions to some of our

more difficult problems. We have used Honeywell differential pressure

smart transmitters for the past eight years. Based on their accuracy

and low failure rates, we are now targeting critical flow applications

that require the robustness that these transmitters bring."

Specification and

Model Selection

DCS Systems Engineer

International Integrated Oil Company

34-ST-03-64

2/08

Guide

Advertisement

Summary of Contents for Honeywell ST 3000

- Page 1 Honeywell’s high-performance ST 3000 "Our commitment to Honeywell field instruments is based on S100 transmitters lead the industry in: seamless integration with our Honeywell system and the enhanced •...

- Page 2 • Measuring Instrument Requires Remote Mounting The following diaphragm seals are standard from Honeywell (please call your local salesperson if you do not see the product you need for your application): Figure 2 - Flush Flange Seals can be used with differential, gauge and absolute pressure transmitters and are available with 3”...

- Page 3 ½”) are available with calibration rings. Figure 9 Figure 10 - Stainless Steel Armor and PVC Coated Stainless Steel Armor Capillaries are available with Honeywell Remote Seal Solutions. Figure 10 Figure 11 - 2” Stainless Steel Nipples are available for Close-Coupled remote seal solutions.

- Page 4 Figure 12 Description Features • Choice of linear or square root The ST 3000 transmitter can replace any 4 to 20 mA output output conformity is a simple transmitter in use today and operates over a standard two-wire configuration selection. system.

-

Page 5: Specifications

34-ST-03-64 Page 5 Specifications Operating Conditions – All Models Parameter Reference Condition Rated Condition Operative Limits Transportation and Storage °C °F °C °F °C °F °C °F Ambient Temperature * 25 ±1 77 ±2 — — — –55 to 90 –67 to 194 —... - Page 6 34-ST-03-64 Page 6 Performance Under Rated Conditions * - Model STR12D (0-10 to 0-400 inH Parameter Description Upper Range Limit ** inH2O 400 (39.2°F/4°C is standard reference temperature for inH 2 O range.) mbar 1000 Minimum Span inH2O 10 Note: Recommended minimum span in square root mode is 20 inH 2 O (50 mbar). mbar Turndown Ratio 40 to 1...

- Page 7 34-ST-03-64 Page 7 Performance Under Rated Conditions * - Model STR13D (0-5 to 0-100 psid) Parameter Description Upper Range Limit ** psid Minimum Span psid 0.35 Turndown Ratio 20 to 1 Zero Elevation and Suppression No limit except minimum span within –18% and +100% of URL. Specifications valid from –5% to 100% of URL.

- Page 8 34-ST-03-64 Page 8 Performance Under Rated Conditions * - Model STR14G (0-5 to 0-500 psig) Parameter Description Upper Range Limit ** psig Minimum Span psig 0.35 Turndown Ratio 100 to 1 Zero Elevation and Suppression No limit except minimum span from absolute zero to 100% of URL. Specifications valid over this range.

- Page 9 34-ST-03-64 Page 9 Performance Under Rated Conditions * - Model STR17G (0-100 to 0-3000 psig) Parameter Description Upper Range Limit ** psig 3000 Minimum Span psig Turndown Ratio 30 to 1 Zero Elevation and Suppression No limit except minimum span from absolute zero to 100% of URL. Specifications valid over this range.

-

Page 10: Parameter Description

34-ST-03-64 Page 10 Performance Under Rated Conditions * - Model STR14A (0-5 to 0-500 psia) Parameter Description Upper Range Limit ** psia bar absolute Minimum Span psia bar absolute 0.35 Turndown Ratio 100 to 1 Zero Elevation and Suppression No limit except minimum span from 0 to 100% URL. Accuracy (Reference –... - Page 11 Intrincically Safe: Approved as Intrinsically Safe for Class I, II, III, Division 1, Groups A, B, C, D, E, F, G locations. Canadian Registration All ST 3000 model designs, except SATG19L, STG99L, STG170 and STG180 have Number (CRN) been registered in all provinces and territories in Canada and are marked CRN:0F8914.5c.

- Page 12 Parameter Description Pressure Equipment Directive The ST 3000 pressure transmitters listed in this Specification have no pressurized (97/23/EC) internal volume or have a pressurized internal volume rated less than 1,000 bar (14,500 psig) and/or have a maximum volume of less than 0.1 liter. Therefore, these transmitters are either;...

- Page 13 34-ST-03-64 Page 13 Figure 15—ST 3000 Remote Seals operable limits for pressure vs. temperature.

- Page 14 The combination of tank vacuum and high pressure capillary head effect should not exceed 9 psi vacuum (300 mmHg absolute). Consult Honeywell for installation of STR13D. Figure 17—The ST 3000 transmitter with remote diaphragm seals shown mounted on a tank.

-

Page 15: Application Data

34-ST-03-64 Page 15 Application Data* Level Liquid Level: Closed Tank Determine the minimum and maximum pressure differentials to be measured (Figure 18). P Min = (SG p x a) – (SG f x d) = LRV when HP at bottom Level of tank = –URV when LP at... - Page 16 34-ST-03-64 Page 16 Density or Interface* Calculate the minimum and maximum pressure differentials to be measured. P min = (SG min - SG f ) x (d); minimum density, 4mA output P max = (SG max - SG f ) x (d); maximum density, 20mA output Where:...

- Page 17 34-ST-03-64 Page 17 82.9 94.9 With Smart meter With Analog 3.26 3.74 meter 53.1 65.1 Reference 45.7 2.09 Removal 2.56 5.32 0.14 Dimensions: Without Without Clearance Plug meter meter for All Caps millimeters 55.3 inches 2.18 Optional meters 23.5 .925 Rotational Optional external STR12D, STR13D...

- Page 18 34-ST-03-64 Page 18 82.9 94.9 With Smart meter With Analog 3.26 3.74 meter 53.1 Reference 65.1 45.7 2.09 Removal 2.56 Dimensions: 5.32 0.14 Without Without Clearance millimeters Plug meter meter for All Caps inches 55.3 2.18 Optional meters 23.5 .925 LP seal Rotational omitted...

-

Page 19: Ordering Information

(50 ≤ 3.6 mA and ≥ 21.0 mA. The In Canada: millimeter) pipe mounting. normal ST 3000 ranges are ≤ 3.8 The Honeywell Centre mA and ≥ 20.5 mA. Indicating Meter 155 Gordon Baker Rd. - Page 20 34-ST-03-64 Page 20 Model Selection Guide (34-ST-16-32) Model Selection Guide 34-ST-16-32 Issue 39 Instructions ● Select the desired Key Number. The arrow to the right marks the selection available. ● Make one selection from each Table I and II using the column below the proper arrow. ●...

- Page 21 34-ST-03-64 Page 21 TABLE II - SEALS Format for Seal Selection: Specify 12 characters _ _ _ _ _ _ _ _ _ _ _ _ Common Required Seal 12D & 13D 14G&17G Note: The first 3 characters are common to all seals. When selecting required seal, you must specify Selection only the 9 selections within the required seal.

- Page 22 34-ST-03-64 Page 22 STR14A STR12D & 13D 14G & 17G Selection TABLE II - SEALS (continued) Flushing None ● ● ● _ _ _ _ _ _ _ _ _ _ _ 0 Flush Flanged Connections One 1/4" with plastic plug _ _ _ _ _ _ _ _ _ _ _ H Seal and Plugs****...

- Page 23 34-ST-03-64 Page 23 STR14A STR12D & 13D 14G & 17G TABLE II - SEALS (continued) Selection Diaphragm Lower 316L SS 316 SS _ _ _ _ _ _ BA _ _ _ _ ● ● ● Hastelloy C 316 SS _ _ _ _ _ _ BB _ _ _ _ ●...

- Page 24 34-ST-03-64 Page 24 STR14A TABLE II - SEALS (continued) STR12D & 13D 14G & 17G Flange Flange Pressure Rating Diaphragm Selection Diameter Size Dependent on Customer Flange ANSI Class 150/300/600 3.5" 3" _ _ _ GFA _ _ _ _ _ _ ●...

- Page 25 34-ST-03-64 Page 25 TABLE II - SEALS (continued) STR14A Pressure Rating Threaded Process STR12D & 13D 14G & 17G Diaphragm Connection Size 304 SS Diameter Selection CS Bolts (NPT Female) Bolts 1/2" NPT _ _ _ JJG _ _ _ _ _ _ ●...

- Page 26 34-ST-03-64 Page 26 STR14A 14G & 17G TABLE II - SEALS (continued) STR12D & 13D Flange Diaphragm Selection Pressure Rating Diameter Size 1.9" 2" _ _ _ MD0 _ _ _ _ _ _ ● 2.4" 2-1/2" _ _ _ NE0 _ _ _ _ _ _ ●...

- Page 27 34-ST-03-64 Page 27 STR14A STR12D & 13D 14G & 17G TABLE III - OPTIONS Communication Options (Must choose a communications option) Analog only (can be configured using appropriate Honeywell DE tool) ● ● ● DE Protocol communications ● ● ●...

-

Page 28: Warranty Options

● (Brazil) *See ATEX installation requirements in the ST 3000 User's Manual **The user must determine the type of protection required for installation of the equipment. The user shall then check the box [√] adjacent to the type of protection used on the equipment certification nameplate. - Page 29 34-ST-03-64 Page 29 RESTRICTIONS Restriction Available Only With Not Available With Selection Letter Table Table Selection 3D or 3H Select only one option from this group _ _ _ _ _ _ BF _ _ _ _, _ _ _ _ _ _ BG _ _ _ _, _ _ _ _ _ _ JF _ _ _ _, _ _ _ _ _ _ JG _ _ _ _, _ _ _ _ _ _ BF _ _ _ _,...

- Page 30 34-ST-03-64 Page 30 RESTRICTIONS (continued) Restriction Available Only With Not Available With Letter Selection Table Table Selection 1C, 2J 2 _ _ _ _ _ _ _ _ JA _ _ _ _ FF, SM 2 _ _ MB, SB, FB _ 2 _ _ _ _ _ _ _ _ _ _ _ _ D 5 _ _...

-

Page 31: Dimensions And Drawings

34-ST-03-64 Page 31 Dimensions and Drawings Figure 20a. Flush Flanged Seal Figure 21a. Flush Flanged Seal Figure 20b. Flush Flanged Seal Figure 21b. Flush Flanged Seal... - Page 32 34-ST-03-64 Page 32 Dimensions and Drawings, cont. Figure 21 Figure 22 Figure 22 Figure 23...

- Page 33 34-ST-03-64 Page 33 Dimensions and Drawings, cont. Figure 23 Figure 24 Figure 24 Figure 25 Figure 25 Figure 26...

- Page 34 34-ST-03-64 Page 34 Dimensions and Drawings, cont. Figure 26 Figure 27 Figure 27 Figure 28...

- Page 35 34-ST-03-64 Page 35 Dimensions and Drawings, cont. Figure 28 Figure 29 Figure 29 Figure 30 Figure 20 Figure 20 Figure 20 Figure 20 Figure 30 Figure 31...

- Page 36 34-ST-03-64 Page 36 THIS PAGE INTENTIONALLY BLANK ST 3000® is a registered trademark of Honeywell International Inc. HART* is a trademark of the Hart Communication Foundation. ™ is a trademark of the Fieldbus Foundation. FOUNDATION Honeywell Field Solutions Honeywell International Inc.