Advertisement

SWAINS

OWNER'S

MANUAL

MODEL NO.

315.108241

CAUTION:

Read Rules for

Safe Operation

and All Instruc-

tions Carefully

,i.

Thank

You for Buying

A

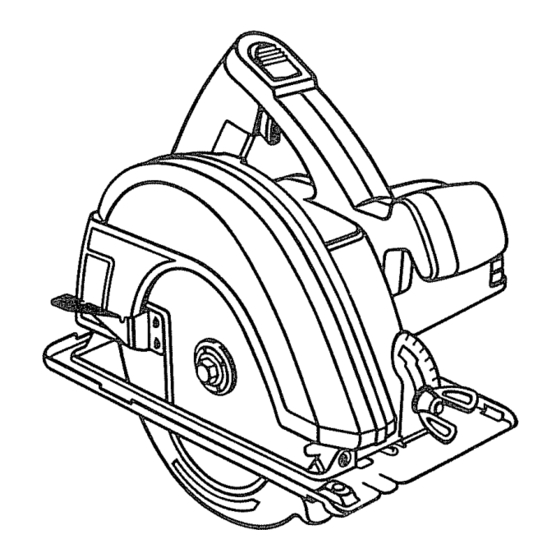

Craftsman

Circular

Saw

r

7-1/4 iNCH CIRCULAR

SAW

DOUBLE iNSULATED

Warranty

Introduction

Operation

Maintenance

Repair Parts

Sold by SEARS, ROEBUCK AND CO, Hoffman Estates, IL 60179 U.SA

®

972000-211

9-94

Printed In U SrA

Advertisement

Table of Contents

Summary of Contents for Craftsman 315.108241

- Page 1 7-1/4 iNCH CIRCULAR and All Instruc- DOUBLE iNSULATED tions Carefully Warranty Introduction ® Operation Thank You for Buying Maintenance Craftsman Circular Repair Parts Sold by SEARS, ROEBUCK AND CO, Hoffman Estates, IL 60179 U.SA 972000-211 9-94 Printed In U SrA...

-

Page 2: Rules For Safe Operation

FULL ONE YEAR WARRANTY ON CRAFTSMAN CIRCULAR SAW If this Craftsman Circular Saw fails to give complete satisfaction within one year from the date of purchase RETURN IT 'ro THE NEAREST SEARS SERVICE CENTER / DEPARTMENT THROUGHOUT THE UNITED STATES and... - Page 3 Do not rush, 4& When servicing use only identical Craftsman CHECK DAMAGED PARTS. Before further use of the placement parts. tool, a guard or other part that is damaged should be SAVE THESE INSTRUCTIONS.

- Page 4 FEATURES Features include easily operated bevel cut and depth of cut APPLICATIONS adjustment mechanisms; positive 0 ° bevel stop; directed air (Use only for the purpose listed below) flow for keeping line of cut clear; blade wrench storage; and 1_ Cutting all types of wood products (lumber, plywood, / lock-off switch, See Figure 1_ paneling).

- Page 5 ERATiON TO ASSEMBLE OR REMOVE BLADE See Figures 2 and & 1 Unplug your saw. 2, Place your saw on a piece of scrap wood as shown in figure 3 and remove blade screw, NOTE: With blade teeth embedded in the wood, turn blade screw counterclockwise to remove, 3_ Remove spring washer and outer blade washer ("D"...

- Page 6 ERATION BLADES The best of saw blades will not cut efficiently if they are not kept ctead, sharp, and properly seL Using a dull blade will place a heavy load on your saw and increase the danger of kickback. Keep extra blades on hand, so that sharp blades are always available.

-

Page 7: Operation

OPERATION TO LESSEN THE CHANCE OF KICKBACK: 1. Always keep the correct blade depth setting - the correct blade depth setting for all cuts should not exceed 1/4 inch below the material to be cut See Figure 7. 2, Inspect the work for knots or nails before beginning a cut Never saw into a knot or nail, 3r Make straight cuts, Always use a straight edge guide... - Page 8 O ERATION TO HELP MAINTAIN CONTROL: 1 Always support your work near the cut 2 Support your work so the cut will be on your right 3_ Clamp your work so it will not move during the cut, Place your work with its good side down NOTE: The good side is the side on which appearance is importanL Before beginning a cut, draw a guide line along the desired...

-

Page 9: Cross Cut And Rip Cut

OPERATION TO CROSS OR RIP CUT TOP VIEW OF SAW When making a cross cut or rip cut, align yeur line of cut with the outer blade guide notch on the saw base as shown in FRONT OF SAW figure 13 Since blade thicknesses vary, always make a trial cut in scrap material along a guideline to determine how much, if any, the guideline must be offset to produce an accurate cut. -

Page 10: Bevel Stop

O EFIATION TO ADJUST BEVEL SETTING 1. Unplug your saw. 2, Loosen wing nut. See Figure 15_ 3 Raise motor housing end of saw until you reach desired angle setting on bevel scale, See Figure 15. 4, Tighten wing nut securely. POSITIVE 0 °... - Page 11 OPERATION TO POCKET See Figure 18, Adjust the bevel setting to zero, set blade to correct blade depth setting, and swing the lower blade guard up using the lower blade guard handle. ALWAYS RAISE THE LOWER BLADE GUARD WITH THE HANDLE TO AVOID SERIOUS INJURY.

- Page 12 NTENANCE GENERAL Only the parts shown on parts list, page fifteen, are intended When electric tools are used on fiberglass boats, sports cars, to be repaired or replaced by the customer. All other parts wallboard, spackling compounds, or plaster, it has been represent an important part of the double insulation system found that they are subject to accelerated wear' and possible and should be serviced only by a qualified Sears service...

- Page 13 NOTES Page 13...

- Page 14 CRAFTSMAN CIRCULAR SAW- MODEL NUMBER 315.108241 pa_.14...

-

Page 15: Parts Ust

CRAFTSMAN CIRCULAR SAW- MODEL NUMBER 315.108241 The Model Number wilt be found on a plate attached to the Motor Housing. Always mention the Model Number in all correspondence regarding your CIRCULAR SAW or when ordering repafr parts. Only the parts listed below are intended to be repaired or replaced. -

Page 16: How To Order Repair Parts

S_ JRS 7ol/4 INCH CIRCULAR OWNER'S MANUAL DOUBLE iNSULATED SERVICE Now that you have purchased your Circular Saw, should a need ever exist for repair parts or service, simply contact any Sears Service Center and most Sears, Roebuck and Co. stores. Be sure to provide all pertinent facts when you call or visit.