Table of Contents

Advertisement

Quick Links

PROFESSIONAL PRESSURE WASHER

INSTRUCTION

MANUAL

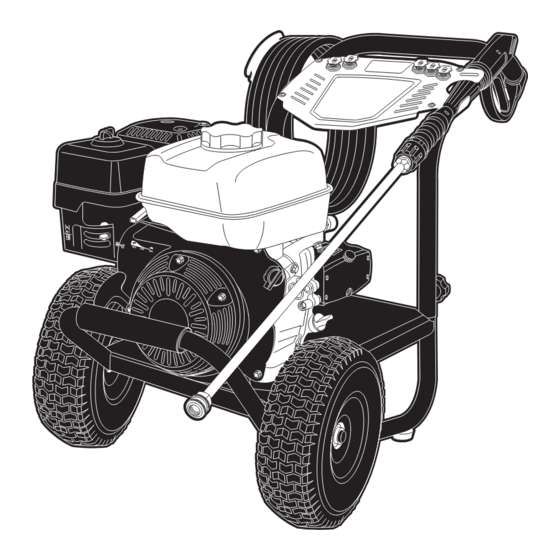

NOTE: Photographs and line drawings used in this manual are for reference only and do

not represent a specific model.

If your pressure washer is not working properly or if there are parts missing or

broken, please

CONTACT THE PLACE YOU PURCHASED YOUR ITEM - PLEASE ENSURE THAT

YOU HAVE THE MODEL AND SERIAL NUMBER OF THE PRODUCT FOR REFERENCE

IMPORTANT: Please make certain that the person who is to use this equipment carefully reads

and understands these instructions before operating.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Part No. 7110896 Rev.A MAR2018

Advertisement

Table of Contents

Summary of Contents for Simpson PRO3800PW

- Page 1 PROFESSIONAL PRESSURE WASHER INSTRUCTION MANUAL NOTE: Photographs and line drawings used in this manual are for reference only and do not represent a specific model. If your pressure washer is not working properly or if there are parts missing or broken, please CONTACT THE PLACE YOU PURCHASED YOUR ITEM - PLEASE ENSURE THAT YOU HAVE THE MODEL AND SERIAL NUMBER OF THE PRODUCT FOR REFERENCE IMPORTANT: Please make certain that the person who is to use this equipment carefully reads...

-

Page 2: Safety Guidelines - Definitions

SAFETY GUIDELINES - DEFINITIONS This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the symbols below. Please read the manual and pay attention to these symbols. DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury. - Page 3 WARNING: This product may not be equipped with a spark-arresting muffler. If the product is not equipped and will be used around flammable materials or on land covered with materials such as agricultural crops, forest, brush, grass or other similar items, then an approved spark arrester must be installed. SAVE THESE INSTRUCTIONS DANGER: RISK OF EXPLOSION OR FIRE WHAT CAN HAPPEN...

- Page 4 DANGER: RISK TO BREATHING (ASPHYXIATION) WHAT CAN HAPPEN HOW TO PREVENT IT • Breathing exhaust fumes will cause • Operate pressure washer in a well- serious injury or death! Engine ventilated area. Avoid enclosed areas exhaust contains carbon monoxide, such as garages, basements, etc. an odorless and deadly gas.

- Page 5 DANGER: RISK OF INJURY FROM SPRAY WHAT CAN HAPPEN HOW TO PREVENT IT • High-velocity fluid spray can cause • Always wear ANSI-approved Z87.1 objects to break, projecting particles safety glasses. Wear protective clothing at high speed. to protect against accidental spraying. •...

- Page 6 DANGER: RISK OF INJURY OR PROPERTY DAMAGE WHEN TRANSPORTING OR STORING WHAT CAN HAPPEN HOW TO PREVENT IT • Fuel or oil can leak or spill and could • If pressure washer is equipped with result in fire or breathing hazard. a fuel shut-off valve, turn the valve to Serious injury or death can result.

- Page 7 WARNING: RISK OF BURSTING WHAT CAN HAPPEN HOW TO PREVENT IT • Over inflation of tires could result in • Use a tire pressure gauge to check the serious injury and property damage. tires pressure before each use and while inflating tires;...

- Page 8 QUICK SETUP GUIDE WARNING: To reduce the risk of injury, read the pressure washer instruction manual and the engine instruction manual before operating pressure washer. Install the Add/Check Oil Add Gasoline Handle The engine In a well Slide the handle is shipped ventilated assembly onto the...

- Page 9 Connect Garden Connect High Connect High Hose to Pump Pressure Hose Pressure Hose to Pump to Spray Gun Thread the garden hose to Connect the high Thread the other end the pump inlet. pressure hose to of the high pressure the pump outlet.

- Page 10 GET TO KNOW THE PRESSURE WASHER NOTE: Photographs and line drawings used in this manual are for reference only and do not represent a specific model. Compare the illustrations with your unit to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference. BASIC ELEMENTS OF A PRESSURE WASHER (FIG.

- Page 11 Pump Inlet K. Quick Connect Nozzles Nozzle Holder BASIC ELEMENTS OF AN ENGINE Refer to the Engine Owner's Manual for location and operation of engine controls. Choke Control: Opens and closes carburetor choke valve. Starter Grip: Pulling starter grip operates recoil starter to crank engine. Engine Switch: Enables and disables ignition system.

-

Page 12: Operation

Attach high pressure hose (C) to gun (D). Tighten securely. NOTICE: The engine is shipped without oil. Before starting engine, add the oil provided. Damage to the engine will occur if the engine is run without oil, this damage will not be covered under warranty. NOTICE: The high-pressure pump was filled with oil at the factory. -

Page 13: Pressure Washer Operating Features

PRESSURE WASHER OPERATING FEATURES PRESSURE ADJUSTMENTS (FIG. 6) The pressure setting is preset at the factory to achieve optimum pressure and cleaning. If you need to lower the pressure, it can be accomplished by these methods. Back away from the surface to be cleaned. The further away you are, the less the pressure will be on the surface to be cleaned. - Page 14 HOW TO USE SPRAY WAND The nozzles for the spray wand are stored in the nozzle holder on the panel assembly. Colors on the panel identify nozzle location and spray pattern. Refer to the following chart to choose the correct nozzle for the job to be performed. CHANGING NOZZLES ON SPRAY WAND (FIG.

- Page 15 **NOTICE: The high pressure spray from your pressure washer is capable of causing damage to surfaces such as wood, glass, automobile paint, auto striping and trim, and delicate objects such as flowers and shrubs. Before spraying, check the item to be cleaned to assure yourself that it is strong enough to resist damage from the force of the spray.

- Page 16 WARNING: Risk of Fire, Asphyxiation and Burn. Never fill fuel tank when engine is running or hot. Do not smoke when filling fuel tank. • Never fill fuel tank completely. Fill tank to 1/2" (12.7 mm) below bottom of filler neck to provide space for fuel expansion. Wipe any fuel spillage from engine and equipment before starting engine.

-

Page 17: Shutting Down

Choose the correct nozzle for the job to be performed. See How To Use spray Wand instructions in this section. NOTE: If applying a chemical or cleaning solution, see How To Apply Chemicals/Cleaning Solvents instructions in this section. Turn water source on. NOTICE: Risk of property damage. -

Page 18: Maintenance

NOTE: The engine drain plug is located at the rear of the unit. PUMP (FIG. 15) NOTE: The Pump was filled with oil at the factory. The preferred oil is SIMPSON ® Premium Pump Crankcase Oil. If this oil is not available, an SAE 15W-40 oil may be used. - Page 19 ® is environmentally friendly. NOTE: Using pump guard helps provide proper lubrication to the internal seals of the pump regardless of temperature or environment. NOTICE: Risk of property damage. Use only SIMPSON / POWERWASHER ® ® Pump Guard or equivalent. Other products could be corrosive and/or contain alco- hol which may cause pump damage.

-

Page 20: Service Information

Unscrew bottle valve from Pump Guard bottle and remove seal. Screw bottle valve back onto bottle. Attach bottle to water inlet of pump. Squeeze bottle to inject contents into pump. With ignition switch off, simultaneously pull starter rope and squeeze bottle. Repeat until protector fluid exits pump outlet. NOTE: This step may require two people. -

Page 21: Troubleshooting Guide

Warranty Periods: ENGINE Covered by engine manufacturer warranty. See engine manual. HIGH PRESSURE PUMP (DEFECTS IN MATERIAL AND WORKMANSHIP) - Five (5) years from date of purchase. CAT Pumps - Two (2) years from date of purchase. FRAME (DEFECTS IN MATERIAL AND WORKMANSHIP) Ten (10) years from date of purchase. - Page 22 OPERATIONAL POSSIBLE CAUSE SOLUTION ISSUE See How to Use Spray No or low Spray wand not in pressure high pressure Wand instructions in the (initial use) Operation Section Low water supply Water supply must be at least 5 gpm @ 20 PSI Leak at high pressure Repair leak.

- Page 23 OPERATIONAL POSSIBLE CAUSE SOLUTION ISSUE Please contact the original place No or low Worn seal or packing of purchase. Quote the MODEL pressure and SERIAL NUMBER (after period of normal use) Worn or obstructed valves Please contact the original place of purchase.

- Page 26 Distributed in the United Kingdom By HSC Machinery Spares & Consumables www.hscmsc.co.uk Copyright. All Rights Reserved FNA Group, Inc. 7152 99th Street Pleasant Prairie, WI 53158 Internet Address: www.simpsoncleaning.com Assembled in U.S.A with domestic and foreign components Assemblé aux États-Unis avec des composants nationaux et étrangers Ensamblado en los EE.UU.