Advertisement

Quick Links

Specialist in Fluid Transfer

致力于流体输送

This manual contains warnings and caution.

本手册包含警告和注意事项

READ AND RETAIN FOR REFERENCE

阅读和保留以供参考

INSTRUCTIONS

操作指南

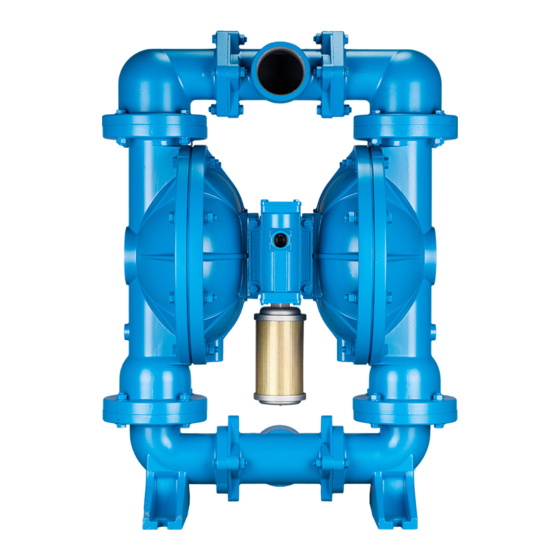

SK80

Skylink Fluid Technology

Operation and

Maintenance Manual

操作维护手册

Diaphragm Pump隔膜泵

2

Edition 7 Issue 2

SKY-SK-SE-03-2016

SKY-SK-E-03

Advertisement

Summary of Contents for SkyLink SK80

- Page 1 Edition 7 Issue 2 SKY-SK-SE-03-2016 Specialist in Fluid Transfer 致力于流体输送 This manual contains warnings and caution. 本手册包含警告和注意事项 READ AND RETAIN FOR REFERENCE 阅读和保留以供参考 INSTRUCTIONS 操作指南 Operation and SK80 Maintenance Manual 操作维护手册 Diaphragm Pump隔膜泵 Skylink Fluid Technology SKY-SK-E-03...

-

Page 2: Safety Information

27.1 N · m(20 ft-lb) 外腔体/内腔体,铝合金螺栓 Outer Pistons,Rubber & PTTE, Inner Pistons 22 N · m(16 ft-lb) 外压板,橡胶和聚四氟乙烯隔膜,内压板 109 N · m(16 ft-lb) Center Shaft & Inner Pistons中间轴与内压板 Bumper Plung & Center Block顶针座与中间体 5 N · m(45 in-lb) Skylink Fluid Technology SKY-SK-E-03... - Page 3 进口 进口 进口 Skylink AODD pumps adopt compressed air for power source and depend on diaphragms which move left and right to reach the volume sealed working chamber to achieve loading and discharging. 斯凯力气动隔膜泵采用压缩空气作为动力源,依靠向左和向右移动的膜片改变密封的腔体容积来实现进料和出料。 AODD pump is structured by suction port,discharge port, medium chamber and air chamber, air chamber is structured by main air valve,pilot valve, thimble on left diaphragm chamber and right diaphragm chamber,medium...

- Page 4 SECTION 3 3.1 Defination of Pump Nomenclature命名说明 SK80 Air Operated Diaphragm pump气动隔膜泵 Housing Intermediate Air Valve Diaphragm Valve Seat Valve Ball Other Model Size Air Valve Material Material Material Material Material Material 型号 尺寸 气阀 其它 外壳材质 中间体材质 气阀材质 膜片材质...

- Page 5 Equal to exceeding ASTM specification A743CF-BW forcorrosion resistant iron chromium,iron chromium nickel,and nickel based alloy castings for general Stainless steel applications. Commonly referred to as 316 Stainless Steel in the pump industry. 不锈钢 相当于或超过ASTM规范A743CF-BW,适用于一般用途的耐腐蚀的铬铁、铁铬镍和镍基 合金铸件。泵行业通常称为316不锈钢。 For specific applications,you can contact us其他特殊应用请联系我司。 SKY-SK-E-03 Skylink Fluid Technology...

- Page 6 -40℃ PVDF 250 ℉ 0 ℉ 聚偏二氟乙烯 121℃ -18℃ Polypropylene 32 ℉ 150℉ 0℃ 聚丙烯 66℃ EPDM 280 ℉ -40 ℉ 三元乙丙橡胶 138℃ -40℃ Alloy C 合金C Stainless steel 不锈钢 For specific applications,you can contact us其他特殊应用请联系我司。 Skylink Fluid Technology SKY-SK-E-03...

- Page 7 12.5 流量-升/分钟 Performance is based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. 以上性能是基于以下:氯丁橡胶膜片泵,泵入口没有吸程,出口没有扬程,输送介质为水。使用其他材料和不同 的液压条件可能导致偏差超过5%。 SKY-SK-E-03 Skylink Fluid Technology...

- Page 8 SECTION 3 3.6 SK80 dimensional drawing (Thread) 尺 寸 图 ( 螺 纹 ) mm(inch) 毫米(英寸) SIDE VIEW FRONT VIEW 侧视图 前视图 Thread B(Air Inlet) C(Discharge) A(Suction) 螺纹 (进气口) (出口) (进口) mm(inch) 3/4-14BSPT 3"-11BSPT 3"-11BSPT GB国标 ANSI美标 3/4"-14NPT 3"-11.5NPT 3"-11.5NPT...

- Page 9 SECTION 3 3.7 SK80 Dimensional drawing(flange) 尺 寸 图 ( 法 兰 ) mm(inch) 毫米(英寸) SIDE VIEW FRONT VIEW 侧视图 前视图 Flange Blot type A i r i n l e t 法兰 (D)进气口 螺栓类型 GB国标 195(7.68) 160(6.3) 8-18 3/4"-14BSPT...

- Page 10 SECTION 4 4.1 Housing drawing外壳图 Figure 1 SK80 Diaphragm Pump Exploded View 图1 SK80隔膜泵分解图 纸版本更新记录 日 期 线性尺寸公差极限数值表(mm)-G 公差等 尺寸分段 精密级 中等级 0.5~3 0.05 >3~6 0.05 >6~30 >30~120 0.15 >120~400 >400~1000 >1000~2000 所有机加工表面未标注粗糙度 图 号: 绘 制 审 核 批...

- Page 11 Flange Tee ANSI (316L) 3寸三通,美标法兰接口(316L不锈钢) 1080.0X93 Flange Tee JIS (316L) 3寸三通,日标法兰接口(316L不锈钢) 1080.1595 Tee BSPT (CI) 3寸三通,BSPT内螺纹接口(铸铁) Tee NPT (CI) 3寸三通,NPT内螺纹接口(铸铁) 1080.0Z95 Flange Tee DIN (CI) 3寸三通,国标法兰接口(铸铁) 1080.0W95 1080.0V95 Flange Tee ANSI (CI) 3寸三通,美标法兰接口(铸铁) Flange Tee JIS (CI) 3寸三通,日标法兰接口(铸铁) 1080.0X95 SKY-SK-E-03 Skylink Fluid Technology...

- Page 12 Center intermediate Parts List中间体零件图 Number图号 Part Number零件编号 Description描述 Quantity数量 Center intermediate Assembly中间体组件 1080.3701 Gracket,Intermediate assembly 3寸中间体组件(含内腔体) 1458.1390 Screw 1.5-3寸中间体螺丝 4050.1490B Flat Pad 平垫 4050.1490C Spring Washer 弹垫 1080.2691 Chamber,Inner 3寸内腔体 “O”ring 1.5-3寸中间体O型圈 1458.7251 1458.7551 “O”ring 1.5-3寸中间体螺丝O型圈 Bracket,Intermediate Assembly 3寸中间体组件(不含内腔体) Skylink Fluid Technology SKY-SK-E-03...

- Page 13 Gasket.Cap 1.5-3寸导向阀密封垫片 1458.6639 1080.3700 Bracket,Intermediate 3寸中间体组件(不含内腔体气阀导向阀) 1080.3791G Bracket,Intermediate 3寸中间体 Snap rings 3寸中间轴套筒卡簧 1080.9789 O-ring 3寸中间轴套筒O型圈 1080.9651 1458.8092 Bumper,plung 1.5-3寸顶针座 1458.5651 O-Ring 1.5-3寸顶针垫圈 1458.3593 Pin,Actuator 1.5-3寸阀套式顶针 1458.8000 Bumper,plung 1.5-3寸顶针座组件 1458.7351 Oring 1.5-3寸顶针O型圈 Bush 1.5-3寸顶针袖套 1458.3642 Bush 3寸中间轴套筒 1080.9540 SKY-SK-E-03 Skylink Fluid Technology...

- Page 14 Quantity数量 Sliding Style Main Valve滑阀式主气阀 1458.4600 Sliding Style Main Valve 1.5-3寸主气阀组件 1458.0891 Screw 1.5-3寸主气阀端部螺钉 1148.4899 Cap,End 1.5-3寸主气阀端部挡板 1458.7151 Gasket,Cap 1.5-3寸主气阀端部垫片 1458.6751 O-Ring outside 1.5-3寸主气阀外层O型圈 1458. 4791 Air valve 1.5-3寸主气阀外壳 1458.9000 Piston 1.5-3寸活塞组件 1458.5291 Spool Assembly 1.5-3寸主气阀滑阀芯阀套 Skylink Fluid Technology SKY-SK-E-03...

- Page 15 Pilot Valve List 导向阀零件目录 Part Number零件编号 Description描述 Number图号 Quantity数量 Pilot Valve导向阀 Pilot Valve 1.5-3寸导向阀组件 1458.4100 1258.6851 O-Ring 1-3寸阀套式导向阀阀套O型圈 1458.4291 Spool Bush 1.5-3寸阀套式导向阀阀套 1458.4391 Pilot Valve 1.5-3寸导向阀阀壳 1458.4400 Spool 1.5-3寸阀套式导向阀阀芯组件 1258.8451 O-Ring 1-3寸阀套式导向阀阀芯减震圈 1258.4589 Snap rings 1-3寸阀套式导向阀卡簧 SKY-SK-E-03 Skylink Fluid Technology...

- Page 16 SECTION 4 4.7 Common Parts通用备件 Part Package备件包 Part Number零件编号 Description描述 Quantity数量 SK80 Fluid Space Part Package 流体备件包 3" Neoprene Valve Ball 3寸氯丁橡胶阀球 3"Neoprene fluid spare part package 3" Neoprene Diaphragm 3寸氯丁橡胶膜片 1080.0152 3寸氯丁橡胶流体备件包 3" Neoprene Valve Seat 3寸氯丁橡胶球座 3" PTFE Valve Ball 3寸特氟龙阀球...

- Page 17 In addition, proper air filter and regulator are also important for requirements. pump to its p erformance, so SKYLINK recommends that a 斯凯力气动隔膜泵高超的设计和制造品质,能够满足客户不同需求 5μ(micron)air filter shall be applied before pump’s air inlet.

- Page 18 Before operating the pump, a visual inspection shall be taken, check all fasteners, tighten if they are loose. 不同的工作条件(使用频率,气压,流体粘度和流体磨损性)会影 响泵部件的寿命,所以每台泵都必须有自己的维护计划。在操作泵 之前,应进行目视检查,检查所有紧固件,有松的必须拧紧。 Skylink Fluid Technology SKY-SK-E-03...

- Page 19 请严格按照顺序拧紧螺栓。 Figure 6.1 Disassembly of Inlet/Outlet进出口拆卸 零 件 代 号 Figure 6.2-2 Disassembly Sequence of Bolts on 借(通)用件登记 Outer Chamber 外腔体螺栓的拆卸顺序 描图 描校 旧底图总号 底图总号 标记 处 设计 签字 校核 主管设计 日期 SKY-SK-E-03 Skylink Fluid Technology...

-

Page 20: Pump Disassembly

(including outer washer (22),diaphragm(19)) out of mid shaft (23) in CCW. 用活动扳手将隔膜部件(包括外压板(22)、隔膜 (19) 从中间轴(23)中取出。 4.Screwing off 5 bolts (20) on inner washer (18) by 3/16 allen wrench, separate outer washer (22),diaphragm (19) and inner washer(18). 用3/16内六角扳手拧紧内垫圈(20)上的5个螺(18), 分离外压板(22)、隔膜(19)和内压板(18)。 Skylink Fluid Technology SKY-SK-E-03... - Page 21 Check the brush (59) ,replace if brush is abrade. 将主气阀(32)、导向阀(34)从中间体取出,检查磨损情 拆开中间体上的顶针座组件(40),再取出O型圈(39), 况,必要时更换。取下主气阀组件和主气阀密封垫片。检查 检查,如有损坏则更换。检查轴套筒(59),如有磨损则更 垫片,在必要时进行更换。 换。 Figure 6.5 Disassembly of center block assembly Figure 6.6 Disassembly of O ring & Bumper plung O型圈和顶针座拆卸 中间体组件拆卸 SKY-SK-E-03 Skylink Fluid Technology...

- Page 22 Figure 6.7 Disassembly of main Valve主气阀拆卸 Caution: before disassembling main valve, air supply must be cut and disconnect from air source. It may cause injury, damage of pump or loss of property if disassembly with pressure. 注意:在拆卸主阀之前,必须先关供气并断开气源。如果带 压拆卸,可能会造成伤害、泵损坏或财产损失。 Skylink Fluid Technology SKY-SK-E-03...

- Page 23 材 料: 日 期: 滑阀式主气阀剖视图 *Spool valve and valve bush share one part(52), if one of those is damaged, the other one must be change as well. 滑阀芯和阀套是一套的,共用一个零件编号(52),如果其中 一个损坏,另一个也必须更换。 Figure 6.9-2 Sliding Style Main Valve 滑阀式主气阀 SKY-SK-E-03 Skylink Fluid Technology...

- Page 24 • While disassembling check valve, please also check if there is any damage on upper and lower “O” rings (8) 注意:在更换阀球(11)和球座(10)之前,必须先关供 which are combined with balls (11). 气并切断气源。如果带压拆卸,可能会造成人员伤害、泵损 坏或财产损失。最后,排出腔体内的所有物料,确保腔体内 在拆卸止回阀的同时,请检查上下球座密封圈(8)与阀 没有物料。 球(11)结合是否有任何损坏。 Skylink Fluid Technology SKY-SK-E-03...

- Page 25 零 件 代 号 双隔膜的安装 借(通)用件登记 描图 描校 旧底图总号 底图总号 阶 段 标 记 重量 比例 标记 处数 分区更改文件号 签名 年月日 “图样名称” 设计 标准化 0.590 签字 校核 工艺 “图样代号” 主管设计 审核 日期 批准 共 张 第 张 版本 替代 SKY-SK-E-03 Skylink Fluid Technology...

- Page 26 Liquid Chamber /Air Chamber, Aluminum Bolted Only 27.1 N m(20 ft-lb) 外腔体/内腔体,铝合金螺栓 Outer Pistons,Rubber & PTTE, Inner Pistons 22 N m(16 ft-lb) 外压板,橡胶和聚四氟乙烯隔膜,内压板 109 N m(16 ft-lb) Center Shaft & Inner Pistons中间轴与内压板 · 5 N m(45 in-lb) Bumper Plung & Center Block顶针座与中间体 Skylink Fluid Technology SKY-SK-E-03...

- Page 27 Thimble falls into mid chamber Change mid chamber 顶针掉入中间体 更换中间体组件 Excessive lubrication Decrease lubricating oil volume in oil-water separator 降低油水分离器润滑油流量 过度润滑 Air leakage due to glyd ring of shaft damages Change glyd ring seriously 更换格莱圈 中间轴格莱圈严重损坏导致漏气 SKY-SK-E-03 Skylink Fluid Technology...

- Page 28 Air leakage due to damage of diaphragm or Change diaphragm, tightening washer 出口出现气泡 looseness of washer 更换隔膜,紧固压板 隔膜损坏或压板松动引起的空气泄漏 Leakage occurs around bolt Retightening bolt Fluid leaks from 螺栓周围发生泄漏 再拧紧螺栓 chamber Leakage occurs around muffler Check diaphragm and washer 流体从消音器泄露出来 消音器周围发生泄漏 检查隔膜和压板 Skylink Fluid Technology SKY-SK-E-03...