Summary of Contents for TFC Tower APUMP-HE Series

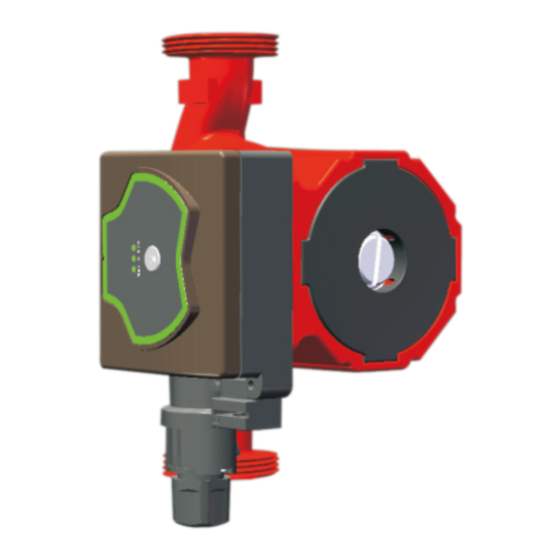

- Page 1 APUMP-HE Series Energy-saving Pipeline Canned Motor Pump Installation and Operation Manual EEI≤0.20 TFC Group LLP...

- Page 2 APUMP-HE Notes: 01. Read the installation manual 11. Some models are not suitable for carefully before installation and drinking water. use. 12. The liquid may be high-temperature 02. The manufacturer will not be liable and high-pressure; therefore, the for any personal injury, pump liquid in the system must be damage and other property...

- Page 3 APUMP-HE or abnormality of motor is detected, and contact your vendor or service center immediately. 19. If problem cannot be addressed according to the manual, please close the valves on the inlet and outlet of the pump immediately, cut off power supply and contact your vendor or service center immediately.

- Page 4 APUMP-HE 2. General 2.1. The APUMP-HE circulation 2.2. Advantages pump is designed for use Easy installation and start-up in domestic heating and hot · Provided with self adaptivc mode water systems. AUTO Initial setting). In most cases, the The product is most applicable to the motor pump needs no adjustment following systems: and can be readily started and...

-

Page 5: Operating Conditions

APUMP-HE 3. Operating Conditions 3.1 Ambient Temperature ℃~+ ℃ Ambient temperature: 0 3.2. Relative humidity(RH): Max. humidity: 95% 3.3. Medium (liquid delivery) temperature ℃ ℃ Liquid delivery temperature: +2 To avoid condensation in control box and the stator, the temperature of liquid pumped by the motor pump must be always higher than ambient temperature. -

Page 6: Installation

APUMP-HE 4. Installation 4.1. Installation · When installing APUMP-HE series circulation pump, the arrow on the motor pump case indicates the flow direction of liquid through the pump. · When installing the motor pump in the pipeline, the two gaskets supplied must be installed at the inlet and outlet. - Page 7 APUMP-HE 4.2. Position of Junction Box 4.3. Changing Position of Junction Box The junction box can be rotated in a step of 90°. The procedures for changing the position of junction box are as follows: 1. Close the valves at the inlet and outlet and release the pressure; 2.

- Page 8 APUMP-HE Warning Pumping liquid may be high-temperature and high-pressure; therefore, the liquid in the system must be completely drained or the valves on both sides of motor pump must be closed before removing the socket head screws. 4.4. Thermal Insulation of Motor Pump Body Limiting the heat loss of motor pump body and pipeline.

-

Page 9: Electrical Connection

APUMP-HE 5. Electrical Connection... - Page 10 APUMP-HE Electrical connection and protection shall comply with local codes and norms. Warning The motor pump must be earthed The motor pump must be connected to an external power switch, with 3mm minimum contact gap in both poles. · APUMP-HE series circulation motor pump needs no protection from external motor. ·...

-

Page 11: Control Panel

APUMP-HE 6. Control Panel 6.1. Controls on Control Panel Position Descriptions Indication lamp area of three operation modes set by motor pump. Button for setting operation modes of the motor pump. 6.2. Indication Lamp Area of Motor Pump Setting APUMP-HE series circulation motor pump has three settings which can be chosen with the button. - Page 12 APUMP-HE 7. Motor Pump Setting 7.1. Motor Pump Setting Based on System Type Initial setting AUTO Self-adaptive mode Recommended and available pump setting · AUTO (Self Adaptive Mode) mode can adjust the performance of motor pump based on the actual heat demand of the system. Self adaptive mode adjusts over time to find the most effective setting, so before changing the motor pump setting, maintain AUTO (Self Adaptive Mode) mode setting for at least one week.

-

Page 13: Performance Curve

APUMP-HE Pump Setting Characteristics Functions Curve AUTO function will automatically control the pump performance within the specified scope. Highest to adjust pump performance based on system scale; AUTO Lowest adjust pump performance based on load variance (Initial Proportional within a period of time; Setting) Pressure Curve Under the AUTO mode, the pump will be set to... - Page 14 APUMP-HE . Curve conditions The followings are applicable to the performance curve specified in the APUMP-HE series manual: · Test liquid: air-free water. · ℃. Applicable density of curve ρ=983.2 kg/m³, and liquid temperature +60 · All curves represent averaged value, and shall not be used as guarantee curve. If a specific performance is needed, then separate measuring shall be conducted.

- Page 15 APUMP-HE 10. Features APUMP-HE 21030001 Descriptions Company name ( brand ) Pump Type Date of manufacture : the first six numbers Number Serial number: the rest four numbers Minimum power input in minimum pattern Power (Watt) Minimum power input in maximum pattern Minimum flow in minimum pattern Electricity (ampere)

- Page 16 APUMP-HE 11. Technical Parameters and Installation Dimensions 11.1. Technical Parameters Power Supply Voltage 220V-240V,50/60Hz,PE Motor Protection The pump needs no external protection Degree of Protection IP 44 Insulation Class Max. 95% Relative Humidity(RH) System Load Bearing 1.0 MPa Minimum Inlet Pressure Liquid Temperature ≤+ ℃...

- Page 17 APUMP-HE 11.2. Installation Dimensions Material of Dimension (mm) Pump Body Power Product Model Cast Plastic Copper SS B1 B2 H1 H2 G Iron APUMP-HE ● ● ● 82 1301031301½"...

-

Page 18: Troubleshooting Schedule

APUMP-HE 12. Trouble-Shooting Schedule Warning Before conducting any maintenance and repair of the motor pump, ensure that power supply has been cut off and will not be connected accidentally. Symptom Control Panel Cause Corrective Action Replace the fuse Equipment fuse burned Indication The circuit breaker of Connect the circuit...