Table of Contents

Advertisement

Quick Links

H-IM-79G

Replaces H-IM-79F (08/17)

Installation and

Operation Manual

Refrigeration Systems

April 2018

Beacon II™ Board Layout .......................................................................... 2

Installation Tips .......................................................................................... 3

Refrigerant Line Brazing ............................................................................ 4

Power Supply............................................................................................. 4

Wiring ........................................................................................................ 4

Multiple Evaporator Configuration .............................................................. 5

Box Temperature Control Settings .............................................................. 6

Leak Testing .............................................................................................. 6

Refrigerant Charging ................................................................................. 6

Start-Up Operation ................................................................................ 7-10

Operating Mode Display ........................................................................... 10

Programming and Reviewing Settings and Changes ........................... 11-14

Monitoring Items ...................................................................................... 13

Monitor Button

Clear/Test Button

Locking The Beacon II Board .................................................................... 14

Status Indicator LED ................................................................................ 15

Low Ambient Operation ............................................................................ 15

Pumpdown .............................................................................................. 15

Defrost ............................................................................................... 16-17

Alarms .................................................................................................... 17

Error Indicator .......................................................................................... 18

Checking Operation of Expansion Valve ............................................... 19-20

Power Failures ......................................................................................... 20

Spare Sensor Terminals ........................................................................... 20

Checking Sensors .................................................................................... 20

Sensor Resistance/Temperature Table ...................................................... 21

System Defaults ...................................................................................... 21

Back Compatibility ................................................................................... 22

InterLink Replacement Parts List .............................................................. 23

™

Operational Limits .................................................................................... 23

Expansion Valve Capacity ......................................................................... 24

Diagnostics ......................................................................................... 24-27

Wiring Diagrams ................................................................................. 28-33

Preventive Maintenance ........................................................................... 34

Service Record ................................................................................... 35-36

Beacon II ™

Part No. 25001401

Table of Contents

Advertisement

Table of Contents

Summary of Contents for Heatcraft Refrigeration Products Beacon II H-IM-79G

-

Page 1: Table Of Contents

Beacon II ™ Refrigeration Systems H-IM-79G April 2018 Part No. 25001401 Replaces H-IM-79F (08/17) Installation and Table of Contents Operation Manual Beacon II™ Board Layout ................2 Installation Tips ..................3 Refrigerant Line Brazing ................4 Power Supply..................... 4 Wiring ......................4 Multiple Evaporator Configuration .............. -

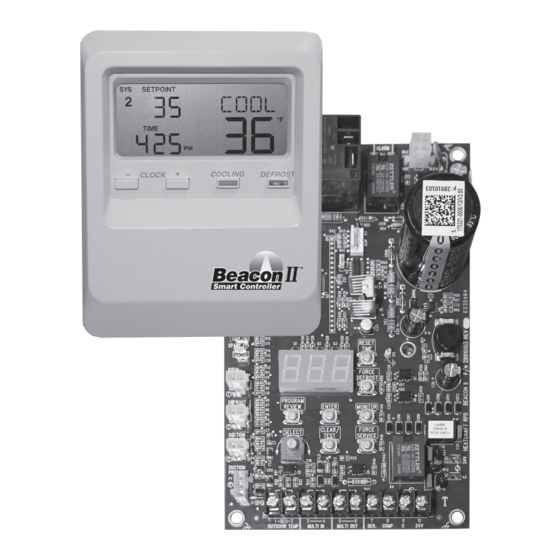

Page 2: Beacon Ii™ Board Layout

Beacon II Board Layout ™ Beacon II Board ™ Alarm Defrost Contacts Heater Relay Evaporator Expansion Valve Relay Connection Test Pins Display Selection Buttons Spare Temperature Room Temperature Defrost Temperature Suction Temperature Suction Pressure Terminal Block ©2017 Heatcraft Worldwide Refrigeration... -

Page 3: Installation Tips

Installation Installation Tips • Some systems may require the crankcase heater • Use a minimum 18 gauge wire for all low voltage be energized 24 hours prior to start-up. The Beacon connections. should be de-energized for this period by placing it in the SERVICE MODE. -

Page 4: Refrigerant Line Brazing

Installation Refrigerant Line Brazing (Caution) Wiring The electric expansion valve and the suction temperature sensor Wiring at the unit cooler(s) will be as follows (see wiring diagrams): on the suction line are factory installed.Care must be taken when brazing these lines at the evaporator. •... -

Page 5: Multiple Evaporator Configuration

Installation Multiple Evaporator Configuration (Master/slave) If there are multiple evaporators on a system, the program for each while you program the setpoints to avoid errors and alarms which SLAVE evaporator must be changed to identify it as a SLAVE. To do may cause troubles at startup. -

Page 6: Box Temperature Control Settings

Installation Leak Testing Box Temperature Control Settings • There is an on board room thermostat on the Beacon After all lines are connected, the entire system must be leak II board which can be adjusted to the desired room tested. The complete system should be pressurized to not more than 150 psig with refrigerant and dry nitrogen. -

Page 7: Start-Up Operation

Start-Up Operation Start-Up Operation Single System With 1 Evaporator • On the evaporator • Check all wiring connections to be sure they are correct and tight. Use the “PROGRAM REVIEW” button to scroll through settings. • On the condensing unit Check “rEF”... - Page 8 Single System With Multiple Evaporators • On the SLAVE evaporators. • Check all wiring connections to be sure they are correct All Beacon II boards are shipped with the factory default as and tight. a "MASTER" evaporator. • On the condensing unit DO NOT NEED TO REMOVE the Room Check the low pressure switch setting on freezer Sensor on any evaporator.

- Page 9 Multiple Systems With Multiple Evaporators (Requires A Smart Controller) • Check all wiring connections to be sure they are • Each SLAVE evaporator must be changed to correct and tight. identify it as a SLAVE. Use the "PROGRAM REVIEW" button to scroll until "SLA" appears, •...

-

Page 10: Operating Mode Display

Start-Up Operation Initial Power On At the initial application of power to the system, the compressor and When the room sensor detects a rise in temperature of the evaporator fans will be in a 4 minute hold-off cycle and will not approximately 2°F, and the compressor has been off for at least 4 start immediately. -

Page 11: Programming And Reviewing Settings And Changes

Programming & Reviewing Programming And Reviewing Settings/Changes “PROGRAM REVIEW” ITEMS The PROGRAM REVIEW button is used to program, review and change all program settings for the system. A-E - Set Defrost type (Air or ELE) Press “PROGRAM REVIEW” button. The setpoint item will appear on the LED. - Page 12 Programming & Reviewing Programming And Reviewing Settings/Changes (cont’d.) Use the “PROGRAM REVIEW” button to select these items: • Defrost Type – “A-E” - Selection is made for air • Defrost fail-safe - “dFF” - This is the maximum time allowed defrost or electric defrost coil.

-

Page 13: Program Review Button Select Button Enter Button Monitoring Items

Programming & Reviewing Use this button to “FORCE DEFROST”. To force a defrost, press the “FORCE DEFROST” button. The system will pumpdown. The heaters MONITOR are then turned on. The display will show “dEF” and room temp. FORCE DEFROST Use the “MONITOR” button to review these items: - Superheat (°F/°C) - Expansion valve steps... -

Page 14: Locking The Beacon Ii Board

Programming & Reviewing Programming And Reviewing Settings/ Controller Board Changes (Cont’d.) The Heatcraft Quick Response Controller board is lockable to prevent Use this button to “CLEAR/TEST”. Pressing this button ONCE will programmed setting changes by unauthorized personnel. When return the LED display to the default display. With the system in the locked, the program setpoints cannot be changed. -

Page 15: Status Indicator Led

Status Indicator LED STATUS INDICATOR LED • ERRORS E 1 - Room temperature sensor shorted, open or not installed E 2 - Defrost temperature sensor shorted, open or not installed E 3 - Suction temperature sensor shorted, open or not installed E 4 - Suction pressure transducer shorted, open or not installed E 5 -... -

Page 16: Defrost

Service Defrost Service Mode Defrost Delay Start Time Example: The system is first powered up at 8:00 AM and is A single pole, single throw switch (SPST) is supplied in each programmed for 4 defrost per day. The user would like the first condensing unit for shutting off the system. -

Page 17: Alarms

Defrost / Alarms Electric Defrost Mode • System Start-up failure - LED Display: A 3 - Compressor When a defrost is initiated, the EEV closes, the system is allowed to pumps down and tries to restart after 4 minutes. After 4 pumpdown and shut off. -

Page 18: Error Indicator

Error Indicator Error Indicator LED ERROR CODES E1 - Room temperature sensor shorted, open or not installed E2 - Defrost temperature sensor shorted, open or not installed At initial power up, each Heatcraft Quick Response Controller board E3 - Suction temperature sensor shorted, checks for system errors. -

Page 19: Checking Operation Of Expansion Valve

Checking Operation of Expansion Valve Checking Operation Of Expansion Valve (EEV) To check if the expansion valve is closing properly: This can also be checked by using the EXV test pins on the board. Install a pressure gauge-set to suction line at the condensing This is indicated by a 0 to 5 volts DC signal. -

Page 20: Power Failures

Power Failures Power Failures Checking Sensors In the event of a power failure, Beacon II will automatically close the DO NOT REMOVE SENSORS FROM EVAPORATORS FOR CHECKING. expansion valve to prevent refrigerant from migrating throughout the system. After power returns, with 24 VAC at the board, the system Use the monitor button to display the value the sensors are reading will restart in the cooling mode after the four-minute hold off period. -

Page 21: Sensor Resistance/Temperature Table

System Defaults Table 1. Resistance/Temperature Specification Temperature °F Ohms Temperature °F Ohms 5,320 32,650 8,060 42,330 10,000 55,330 12,490 72,950 15,710 97,070 19,900 130,410 25,400 176,960 Table 2. System Defaults 29310103 (Blue) 29310101 (Green) PARAMETERS CODE ELECTRIC ELECTRIC Refrigerant R-404A R-404A R-22 R-404A... -

Page 22: Back Compatibility

Back Compatibility In order to accommodate updates in technology and in industry, new Beacon II part numbers were created to handle a number of enhancements. For Beacon II, the updated boards are Blue to conveniently identify the new part. The “NEW” part numbers listed below will serve as service parts for any “OLD” part numbers in the event a replacement part is needed. The Table and notes below highlight key differences between the OLD and NEW parts. -

Page 23: Interlink Replacement Parts List

InterLink is your link to a complete line of dependable and certified commercial refrigeration parts, accessories and innovative electronic controls for all Heatcraft Refrigeration Products (HRP) brands - including Bohn, Larkin, Climate Control and Chandler. At InterLink, we provide our wholesalers with a comprehensive selection of product solutions and innovative technologies for the installed customer base. -

Page 24: Expansion Valve Capacity

Expansion Valve Capacity Table 5. Evaporator Temperatures R-22 R-404A/R-507 Evaporator Temperature (°F) Evaporator Temperature (°F) 100 psi Pressure Drop 100 psi Pressure Drop 50839.25 PART NUMBER TONS BTUH TONS BTUH TONS BTUH TONS BTUH 29326101 0.44 5220 0.41 4920 0.73 8706 0.64 7692... -

Page 25: Diagnostics

Diagnostics Beacon II Troubleshooting Guide PROBLEM Step ACTION ITEM IF OK IF NOT OK Check Primary Power Supply Disconnect 1. Check fuses and circuit breakers Check Voltage to Evaporator Transformer Go to 2. Check field wiring for breaks LED is not lit. Check Transformer Secondary Output Volts next step 3. - Page 26 Diagnostics Beacon II Troubleshooting Guide (continued) PROBLEM Step ACTION ITEM IF OK IF NOT OK Check wiring connection to the board • Correct field wiring to the board Low Pressure Safety (LPS) Tripped: • Check for correct refrigerant type • Change setpoint to match refrigerant •...

-

Page 27: Wiring Diagrams

Diagnostics Beacon II Troubleshooting Guide (continued) PROBLEM Step ACTION ITEM IF OK IF NOT OK Multi-out to Multi-in Check for 24 volts power to the board 1. If no voltage, see “LED is not lit” above Communication Wiring for low voltage, see “88888 LED display” (only shows after initial Check for crossed communication wiring Go to... - Page 28 Diagnostics Beacon II Troubleshooting Guide (continued) PROBLEM Step ACTION ITEM IF OK IF NOT OK Check system operation: Is it running? 1. Check power to condensing unit Check position of Service Mode switches Check compressor overloads and contactor Check system charge 2.

- Page 29 Wiring...

- Page 30 Wiring...

- Page 31 Wiring...

- Page 32 Wiring...

-

Page 33: Preventive Maintenance

Preventive Maintenance EVAPORATORS 4. Check all fan motors. Tighten motor mount bolts All evaporator units should be checked once a month or more often and nuts and tighten fan set screws for proper defrosting because the amount and pattern of frosting can vary greatly. -

Page 34: Service Record

Service Record Date of Start-up CONDENSING UNIT Location Address MODEL # SERIAL # ELECTRICAL COOLER UNIT • Check Primary Supply voltage at Evaporator If 208 V, change MODEL # transformer wiring in the Cooler and Freezer to the 208 V tap SERIAL # FREEZER UNIT •... - Page 35 Service Record RECORD OUTDOOR TEMPERATURE ______°F SYSTEM VOLTAGE ______Volts ______PH ______Hz Cooler compressor amps ______L1 ______L2 ______L3 Freezer compressor amps ______L1 ______L2 ______L3 Cooler discharge pressure ______PSIG Freezer discharge pressure ______PSIG Cooler suction pressure ______PSIG Freezer suction pressure ______PSIG Cooler suction temp. ______°F Freezer suction temp.

- Page 36 Heatcraft Refrigeration Products, LLC 2175 West Park Place Blvd., Stone Mountain, GA 30087 www.heatcraftrpd.com Customer Service and Technical Support Normal Business Hours – 8:00 AM – 8:00 PM EDT (800) 321-1881 After Hours (after 5:00 PM EDT, weekends and holidays)