Summary of Contents for Eckold KF 170 PD

- Page 1 Operating Instructions ECKOLD KRAFTFORMER KF 170 PD Date of issue: 2018-05-09 English Illustrations and measurements unbinding. Subject to change without notice. Translation of the original instructions...

- Page 2 Distributed by: Trick-Tools 75 Truman Road Pella, IA 50219 Phone:1-877-VAN-SANT E-mail: sales@trick-tools.com Here at Trick Tools we believe that our customers deserve the best value in their tool and equipment purchases. We are constantly at work searching out a variety of high quality, high performance tools to offer at the best prices possible.

-

Page 3: General Information

General information Dear valued customer, You have purchased an ECKOLD product, which is characterised by its high quality and durability. We would like to congratulate on making this purchase. This product is sure to bring you plenty of joy and provide great service during your day-to-day work. Our customer services and sales staff are always happy to help if you have any technical questions. -

Page 4: Table Of Contents

Warranty ............................Technical data ........................Characteristic data........................Type plate ............................Short Description.......................... 2.3.1 Purpose of use ..........................2.3.2 Forming capacity of the Kraftformer KF 170 PD ..............Drive .............................. Mechanics............................2.5.1 Dimensions and weight ......................2.5.2 Ram postion ..........................2.5.3 Working stroke .......................... - Page 5 Check pneumatic switch- and control elements for visible damages........Maintenance..........................8.4.1 General information about maintenance .................. 8.4.2 Maintenance list..........................8.4.3 Mechanical components......................8.4.3.1 Maintenance of standard forming tools ..................8.4.3.2 Lubrication instruction........................ 8.4.3.3 Air servicing unit .......................... Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG...

- Page 6 Order form ............................ 10.3 Customer Service Adress ......................Machine Spare Parts List (MEL)..................MEL-1 11.1 Kraftformer KF 170 PD ......................MEL-1 11.2 Apparatus head KF 170 PD ....................MEL-2 11.3 Housing ............................ MEL-3 11.3.1 Housing ............................ MEL-4 11.3.2 ............................MEL-5 11.3.3...

-

Page 7: Application Of The Operating Instructions

We reserve the right to alterations without prior notice in the course of the technical developments. For all inquiries please state the ECKOLD contract No./Serial No. We wish you a lot of success with the ECKOLD Kraftformer type KF 170 PD. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 8: Technical Data

++41– 81 354 12 70 Telefax ++41– 81 354 12 01 e mail machines@eckold.ch www.eckold.com Customer data Company Street / No. ZIP code / City Country Phone e Mail Type plate Pic. 2.2 - Type plate Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 9: Short Description

2.0 mm thickness. The single stroke operati- on makes the KF 170 PD ideal for correcting and adjusting jobs – and it can be used for punching, notching and clinching (connecting of sheet metal and profile sections). -

Page 10: Mechanics

93 kg Weight (with stand) ca. 151 kg 560 mm (22.047 inch) (6.693 inch) 505 mm 790 mm 4 x d11 (31.10 inch) (19.882 inch) • without stand • with stand Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 11: Ram Postion

, RAL 5012 Apparatus head textured coating (without silicon) sapphire , RAL 5003 Pedestal textured coating (without silicon) Ambient temperature range Operating ambient temperature -20°C ..+55°C Storage and transport temperature -25°C ..+70°C Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 12: Fundamental Safety Instructions

• Protective measures: The lines that are marked with a dot contain mandatory instructions that must be strictly adhered to in order to prevent the above consequences. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 13: Basic Operation And Designated Use Of The Machine/Plant

Any functional disorders, especially those affecting the safety of the machine/plant, should therefore be recti- fied immediately! The ECKOLD-Kraftformer KF 170 PD has been designed exclusively for the driving of ECKOLD-tools for the non-cutting cold shaping of sheet metals and profiles. -

Page 14: Possible Misuse

Ensure that the operating manual is available to your personnel so that they can familiarize themselves with the content. • Personnel: Follow all instructions listed in the operating manual. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 15: Protective Measures

The following areas are danger zones of the product: In the working range of the ram, in particular between the tools On the component (metal sheet) which is to be processed In the whole access area around the product Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... - Page 16 — Personnel who have been assigned with maintenance (service, inspection, repair). — Personnel who have been assigned with transport. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG...

-

Page 17: Required Protective Equipment (Provided By The Customer)

Always wear protective gloves when processing components on the Kraftformer. Eye protection Always wear eye protection when processing components on the Kraftformer. Safety boots Always wear safety shoes when processing components or when changing tools. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 18: Transport / Set Up

Inspect the package for visible damage and journalize them at the acceptance oft the delivery by the carrier. • In sever damage inform immediately your transport insurance to secure your claim on compensation for damages. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 19: Transport

Adjust the forks of the forklift to the maximum possible width! The centre of gravity of this unit is quite high. Danger of tilting! Please handle with extreme care to avoid damages and/or injuries. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 20: Delivery Contents

SW 17 DIN 894 SW 24 DIN 894 (only for delivery KF 170 PD with stand) Degree of Disassembly The following work must be carried out in order to create operational conditions: 1. Set up of the machine (see page 22) 2. -

Page 21: Unpacking / Setup Of The Machine

Place the machine on a solid and flat underground. Fastening the machine to the floor is not necessary. Clean the Kraftformer from possible soiling such as packing residue, dust, and the similar. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 22: Unpacking / Setup Of The Machine (Apparatus Head)

• Apparatus heads securely on a stable workbench fix Apparatus heads have to be securely fastened to a sturdy workbench by means of screws. 140 mm 186 mm Pic. 4.8.1 - Fastening of Apparatus head Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 23: Swivelling Up Of Apparatus Head

• Two persons are required to swivel up the Apparatus head Remove transport security profiles. Pic. 4.8.3a - Remove transport security profiles. Have two persons swivel up the Apparatus head. Pic. 4.8.3b - Swivelling up of Apparatus head Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 24: Workplace Illumination

Ensure good illumination of the workplace of the press and the workplace environment. • The working area and environment of the Kraftformer must be illuminated sufficiently according to DIN 5035 (min. 300 Lux). Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 25: Internal Transport

— The centre of gravity of this unit is quite high. Danger of tilting! —> Damages on the product • Transport machine only with great caution. The two wheels on the stand make the KF 170 PD machines mobile so that they can be easily moved to another workplace. 4.11... -

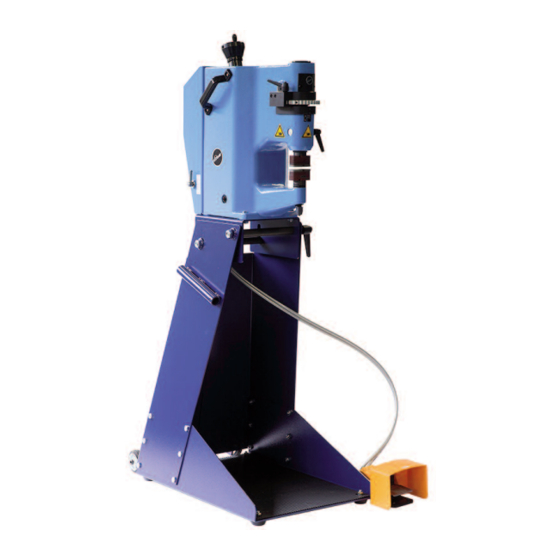

Page 26: Construction And Operation

Construction and Operation General Description The Eckold Kraftformer KF 170 PD is a product from the wide Eckold product range of machines and tools for chipless coldforming of sheet metal and profile sections. Materials in condition to be shaped, from 0,5 bis 2,0 mm thickness can be shrinked, stretched, domed, pla- nished, corrected, clinched, punched, notched or adjusted with the suitable original ECKOLD shaping tools. -

Page 27: Application Areas

Construction and Operation Application areas The Kraftformer KF 170 PD used for cold forming of sheet metal and profiles made of steel, light metal, nonferrous metal and stainless steel. Standard forming-tools are available for above operations. Please compare the respective tooling and tooling spare parts catalogue. -

Page 28: Indicators And Controls

Foot switch 5.5.1 Lever for single- or continuous stroke By turning the lever in the respective direc- tion the KF 170 PD machine can be swit- ched either to the single stroke or to the continuous stroke mode. Single stroke... -

Page 29: Foot Switch For Single- Or Continuous Stroke

IMPORTANT The tools ASW 42 K (Notching tool), LSW1K (Punching tool) and DFW 1 K (Clinching tool) must only operated in single stroke mode! Otherwise tools will be damaged or even destroyed! Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 30: Connection / Installation

Connect the air supply as shown under (c) and fasten it securely. ø 9 mm Pic. 6.2 - Connecting air supply Open the stop cock (1) and check that the required 6 bar of pneumatic pressure are indeed avai- lable (2). Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 31: Mounting / Dismantling Of The Forming Tools

Loosen the tool locking levers and pull the tool straight out or push it in all the way. Pic. 6.3 - Mounting / Dismantling of the forming tools IMPORTANT Do not forget to clamp the tools in securely! Tool shelf Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 32: Operation

The apparatus head (1) is slewable. The apparatus head can be swivelled by approx. 15 degrees after loose- ning the clamping levers (2) to set it to the most suitable working height. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 33: Standard Operation

Make sure that compatible forming tools are installed in the upper and lower tool holding fixtures (same type and size) 3. Now process your component according to the directives in the chapter “Processing of components”. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 34: Processing Of Components

Insert the material between the contacting surfaces of the tools and lower the ram until you feel the tools working on the material starting the forming. The working pressure can be adjusted by turning the adjusting knob. Slowly lead the component between the tool halves with your hands. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 35: Adjustable Ram Position

This adjustment does not change the stroke length. This scale shows the basic position. Fine adjustment in steps of 0.1 mm is shown on the handwheel. Handwheel = 6.0 ram position +/- 0,1 mm Pic. 7.5 - Adjusting ram postion Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 36: Adjustment Of Ram

The handwheel has to be turned anti-clockwise to lower the ram position (1). The handwheel has to be turned clockwise to lift the ram position (2). First loosen the clamping lever (A). After adjustment lock the clamping lever. Pic. 7.6 - Adjustment of ram Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 37: Ram Stroke Limitation

Pic. 7.7 - Ram stroke limitation IMPORTANT Turn the knob carefully when reaching the upper and the lower position! The knob can be jammed when it is turned too quick or too strong against the end position. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 38: Recommended Settings For Ram Position And Stroke Length

FWR 603 K HS 40 K Material: ........... Material: 1.0 mm aluminium not hardened, formable (R ~250 N/mm Tools Ram postion Stroke length setting Ram postion Stroke length setting HFL 70 K Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 39: Setting Of Best Ram Position For The Clinching

Pic. 7.8 a - Setting of ram position for the clinching - 1st step IMPORTANT We strongly recommend to preceed STEP by STEP, beginning from ZERO position. This way you avoid OVER-LOADING and DAMAGE to punch and die and to the tool. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... - Page 40 • Repeat this procedure until you reach the correct form of the joining point. • Control the joint as described in your pressjoining manual. Pic. 7.8 c - Setting of ram position for the clinching - Next steps Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG...

-

Page 41: Clinching Parameters

In all forming tools rubber-metal combinations are essential construction elements. These can be damaged by lubricants. IMPORTANT The ECKOLD Elastic-Forming Tools are designed and manufactured for use in Kraftformer Machine. They will be damaged or destroyed when used in other machines. -

Page 42: Maintenance

The machine should only be repaired by trained and qualified personnel. Improper repairs can cause acci- dents. Do not work with oily hands. Pay close attention to the highest standard of cleanliness during all maintenance operations. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 43: Inspection List

= yearly = Specialized personnel Example: 1 in column d means one week or weekly 2500 2500 - yearly monthly weekly 1.1, 1.2, 1.3, 2.1, 2.2 1.4 , 1.5 daily hourly Operation hours Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 44: Mechanical Components

• Machine/plant may not be cleaned with water or steam jet (high-pressure cleaner)! • Apply low inflammable cleaning liquid (if needed at all) with extreme care. • Inspect the product for damage after the cleaning! Let qualified personnel repair any detected faults! Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 45: Damage (Visual Check)

8.3.1.5 Check the tools for secure fit • Disconnect the air supply. • Check to see if the tools sit securely. If the tools are loose: • Install the loose tool properly. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 46: Type Plate And Information Sign Existant And Legible

Check that all labels are attached to the product, and legible If the signs become dirty: • Clean all dirty signs If signs are missing: • Place new signs on the product Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 47: Pneumatic Components

Ensure that operation with the product is not resumed (e.g. using warning signs). • Get the damage repaired immediately by the maintenance service of your company, or through the customer service department of the machine manufacturer. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 48: Maintenance

= weekly m = monthly a = yearly = Specialized personnel Example: 1 in column d means one week or weekly 2500 2500 - yearly monthly weekly daily hourly Operation hours Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 49: Mechanical Components

Do not try to force an achievement of the original forming power by using higher working pressure. This leads to an overload of the machine and tool. • For ordering spare parts, please use the tool catalogue. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 50: Lubrication Instruction

Use only the given lubricants or ones of the same quality. The grease gun delivered with the machine is filled with this grease. All lubrication points have been provided with sufficient lubricant by the manufacturer. Therfore, no lubri- cation is necessary when putting the machine into service. Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 51: Air Servicing Unit

- Stop-cock [1] ON/OFF (normally in ON position) - Pressure reducing valve [2] adjustable Condensed water has to be emptied periodically, 1 turn of the knurled screw [3] Pic. 8.4.3.2 - Air servicing unit Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 52: Appendix

Directory of changes The current date of issue and corresponding edition number are noted on the cover sheet of the operating instructions. Date of issue Version Note and change 2018-05-09 Document creation Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 53: Symbols And Pictograms

ATTENTION Indicates a potentially damaging situation. If it is not avoided, the machine or property close to it might be damaged. Indicates tips and other instructions that are particularly useful. IMPORTANT Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 54: Registration Sheet For The Operating Hours

Registration sheet for the operating hours Datum Stunden Gesamt Datum Stunden Gesamt Datum Stunden Gesamt Date Hours Total Date Hours Total Date Hours Total Übertrag Übertrag Carry-over Carry-over Gesamtstunden Gesamtstunden Gesamtstunden Total hours Total hours Total hours Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 56: Spare Parts Stock / Order Of Spare Parts

Unit/Machine and thereby adversely affect the active and/or the passive operating safety. ECKOLD declines to accept any guarantee or liability for damage which results through the use of parts and accessories which are not original. -

Page 57: Example Order

_____________ Country _____________________________ Factory-No. _____________ Phone _____________________________ Order-No. _____________ E-Mail _____________________________ Year of construction _____________ Item No. Description Qty. Type / Dimension 258.270.0026 Tension disc, light M 8 d 18/8.4 x 1 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 58: Order Form

_____________ Phone _____________________________ Order-No. _____________ E-Mail _____________________________ Year of construction _____________ Item No. Designation Type / Dimension Send copy of the order form: ECKOLD AG Rheinstrasse 8 CH-7203 Trimmis eMail : machines@eckold.ch Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 59: Customer Service Adress

Customer Service Adress ECKOLD AG Rheinstrasse 8 CH-7203 Trimmis Schweiz / Switzerland Telefon : ++41 (081) 354 12 70 Telefax : ++41 (081) 354 12 01 eMail : machines@eckold.ch Net : www.eckold.com Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG... -

Page 60: Machine Spare Parts List (Mel)

Kraftformer KF 170 PD 021.200.2502 Item No. Designation Type / Dimensions 021.200.2502 Kraftformer KF 170 PD 021.200.2500 Apparatus head KF 170 PD 023.127.0000 Pedestal 268.100.0080 Mandatory sign ”Read the instructions before” 268.130.0101 Warning sign ”Danger of Tilting” 023.122.0011 Accessory parts... -

Page 61: Apparatus Head Kf 170 Pd

Machine Spare Parts List (MEL) 11.2 Apparatus head KF 170 PD 021.200.2500 Item No. Designation Type / Dimensions 021.200.2500 Apparatus head KF 170 PD 021.300.1002 Housing 021.300.1000 Stroke adjustment 023.125.0001 Pneumatic cylinder 023.125.0017 Covering 023.125.0019 Pressure lever 271.450.0010 Covering PG 11 271.450.0020... -

Page 62: Housing

Eccentric lever 023.125.0029 Return motion device 023.125.0014 Covering 023.125.0015 Covering PG 11 021.300.1005 Tool holder PG 16 024.910.0017 Indicator 255.060.0201 Spherical head notched nail st DIN 1476 d 2 x 4 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-3... -

Page 63: Housing

Bush, maintenance-free 18 x 20 x 15 mm 261.003.1350 Plain bearing bush in bronze 30 x 34 x 30 mm 261.003.1900 Plain bearing bush in bronze 45 x 50 x 30 mm Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-4... -

Page 64: Ram

ISO 7379 6 / M 5 x 20 261.004.0024 Bush, maintenance-free d 10 x d 12 x 10 023.910.0314 Set collar 023.910.0226 Dinstance ring 256.021.1002 Setscrew black DIN 913 M 6 x 8 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-5... -

Page 65: Eccentric Lever

Clamping lever with threaded bolt MR. 63 p-M 8x16 258.270.0026 Tension disc, light M 8 d 18/8.4 x 1 258.340.0007 Safety-ring for shaft bl. st. DIN 471 d 10 023.910.0316 Tension piece 023.910.0275 Covering Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-6... -

Page 66: Return Motion Device

12.5 / d 25 / Lo 102 256.021.1315 Setscrew black DIN 913 M 12 X 80 253.002.0413 Hexagon screw DIN 933 M 8 x 45 257.002.0160 Hexagon nut DIN 439B M12x0.5d Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-7... -

Page 67: Covering

DIN 2098 0.63 x Dm5.0 x 38.5 260.009.0062 Clamping leves with threaded bolt MR.63 p-M 6 x 40 252.020.0106 Cap screw DIN 6912 M 5 x 20 252.020.0101 Cap screw DIN 7984 M 5 x 10 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-8... -

Page 68: Tool Holder

020.910.0011 Pulling rod 021.400.1009 Tool holder 020.910.0018 260.002.0103 Clamping lever J 2 M 8 252.140.0102 Cap screw M 5 x12 266.000.0320 Pressure spring DIN 2095 0.63 x Da 11.6 x 26 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-9... -

Page 69: Stroke Adjustment

DIN 2097 1.1 x Da 9.9 x Lk 22 023.910.0318 Disc 255.002.1015 Dowel pins DIN 6325 ø8m6 x 60 023.910.0282 Spindle housing 266.700.0050 Spring d 40 80 Shore A 258.321.0017 Snap ring DIN 7993 B d 40 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-10... -

Page 70: Adjusting Handle

023.125.0008 Adjusting handle 023.125.0007 Retention pin 023.910.0218 Adjusting handle 021.910.0059 Pressure spring 261.150.0060 Ball DIN 5401 ø6 258.320.0002 Retainer ring bl. DIN 7993A ø6 256.100.1215 Socket Set Screws DIN 916 M8x12 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-11... -

Page 71: Pneumatic Cylinder

Machine Spare Parts List (MEL) 11.5 Pneumatic cylinder 023.125.0001 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-12... - Page 72 NG 12-G1/2" 277.003.0410 Muffler G 3/8" 252.000.0407 Cap screw DIN 912 M 8x25 023.910.0317 Clamp 266.011.0895 Pressure spring Dm 8 x d 0.8 x Lo 68 277.000.4118 Sealing ring G 1/2" Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-13...

-

Page 73: Covering

258.021.0004 Washer with basil DIN 125 B M 10 253.021.0105 Self tapping hexagon screw DIN 7500 M 5 x 10 253.021.0040 Self tapping hexagon screw DIN 7500 M 4 x 25 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-14... -

Page 74: Pneumatic Control Set

NL2 1 821 336 006 023.910.0287 Hose pipe 277.003.0515 Pneumatic foot pedal AM-5000 3/2 NC G1/4" 277.003.0404 Muffler G1/4 1 827 000 001 277.000.0910 L - type plug connection QSLL - 1/4 - 10 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-15... -

Page 75: Pressure Lever

257.600.0020 Lubricating nipple D 6 K 1A 256.021.1103 Setscrew DIN 913 M 8 x 12 252.000.0203 Cap screw DIN 912 M 5 x 12 256.021.1202 Setscrew DIN 913 M10 x 12 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-16... -

Page 76: Repair Kit Pressure Link

Repair kit Pressure link 023.125.0037 Molykote TP 42 Item No. Designation Type / Dimensions 023.125.0037 Repair kit Pressure link 023.910.0311 Clamping piece 252.100.0000 Hexagon key DIN 911, SW 3 023.125.0031 Pressure Knuckle Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-17... -

Page 77: Continuous Stroke Modul

Machine Spare Parts List (MEL) 11.8 Continuous stroke modul 021.300.2029 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-18... - Page 78 FESTO PUN - 10x1,5 - 3 / 300 mm 277.002.0108 Plastic tubing FESTO PUN - 10x1,5 - 3 / 65 mm 277.002.0108 Plastic tubing FESTO PUN - 10x1,5 - 3 / 50 mm 021.400.2091 Pneumatic diagram Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-19...

-

Page 79: Pedestal

DIN 931 M 10 x 20 253.003.0609 Hexagon screw DIN 931 M 10 x 35 257.110.0180 Hexagon nut DIN 934 M 10 023.910.0306 Rubber mat 252.102.0065 Fork wrench SW 24 DIN 894 Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-20... -

Page 80: Accessory Parts

DIN 894 252.100.0002 Hexagon srew driver DIN 911, SW 5 252.100.0000 Hexagon srew driver DIN 911, SW 3 023.910.0311 Clamping piece 300.100.0660 Grease paste MOLYKOTE TP 42 100 gr. 023.125.0036 Grease gun Kraftformer KF 170 PD 2018-05-09 | ECKOLD AG MEL-21... - Page 81 ECKOLD AG Rheinstrasse 8 CH-7203 Trimmis Switzerland +41 81 354 12 00 www.eckold.com info@eckold.ch...