Table of Contents

Advertisement

Quick Links

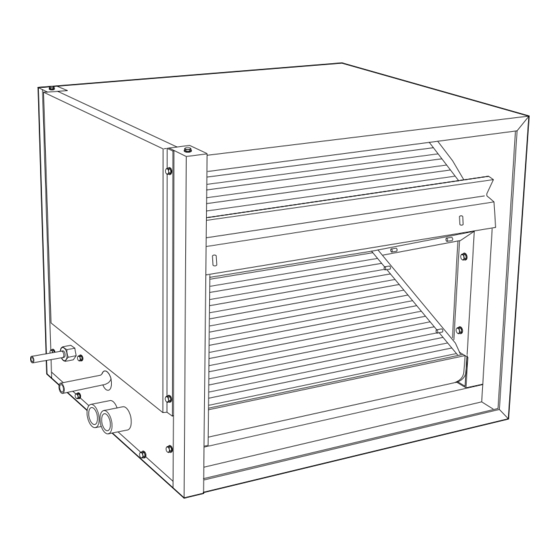

Cased Horizontal

Furnace Coil

This horizontal N-Coil is designed to provide the highest

standard of reliability and durability. The CK3B coil casing is

unpainted embossed galvanized steel. The cabinet is fully

insulated to minimize energy loss.

The CK3B is designed for application with horizontal furnaces.

The 2-directional airflow allows for either horizontal-right or

horizontal-left furnace fit-up. This coil is ideally suited for either

attic or crawl space installation.

Our advanced manufacturing methods give a better bond of the

fin and tube. Contaminants are not introduced into coil during

manufacturing. Galvanic action is minimized. The coils are

approved for air conditioning or heat pump application in the

horizontal configuration.

The CK3B coil includes a refrigerant control metering device for

improved serviceability over check valves and expansion

devices used in conventional coils. Sweat-type connections are

furnished for installation of the refrigerant tubes.

The coil is designed to provide improved condensate removal.

The robust condensate pan has brass inserts in the primary and

secondary drain connections and meets FHA requirements.

CK3B

Sizes A024 thru A060

Form No. PDS CK3B.24.2

Advertisement

Table of Contents

Summary of Contents for Bryant CK3B

- Page 1 Cased Horizontal Furnace Coil This horizontal N-Coil is designed to provide the highest standard of reliability and durability. The CK3B coil casing is unpainted embossed galvanized steel. The cabinet is fully insulated to minimize energy loss. The CK3B is designed for application with horizontal furnaces.

-

Page 2: Model Number Nomenclature

C—Coil K—Cased, N-Coil 3—Horizontal 5—Upflow/Downflow MODEL NUMBER NOMENCLATURE A—Painted B—Embossed ® CERTIFICATION APPLIES ONLY WHEN USED WITH PROPER COMPONENTS AS LISTED WITH ARI —2— 024—2 Ton 030—2-1/2 Ton 036—3 Ton 042—3-1/2 Ton 048—4 Ton 060—5 Ton A—Standard N—Narrow W—Wide X—Max. Cap. Position •... - Page 3 ⁄ LIQUID LINE ⁄ ⁄ SUCTION LINE FRONT UNIT CK3BXA024 17-9/16 CK3BXA030 17-9/16 CK3BXA036 17-9/16 CK3BXA042 21-1/16 CK3BXA048 21-1/16 CK3BXA060 24-9/16 ⁄ OPTIONAL DUCT FILLER PANEL ⁄ ⁄ ⁄ ⁄ ⁄ IN. NPT DRAIN DIMENSIONS (In.) 19-1/16 10-1/16 19-1/16 10-1/16 22-1/16 10-1/4 22-1/16...

-

Page 4: Indoor Coil

INDOOR COIL UNIT SIZE 38.7 32.6 27.0 44.0 A024 37.4 30.6 47.9 1000 40.7 33.7 54.4 45.1 36.0 64.1 A030 1000 53.6 43.4 72.1 1250 59.6 49.0 63.4 52.1 42.8 75.1 A036 1200 61.6 51.1 83.3 1500 69.4 56.6 75.4 1050 62.1 51.5... - Page 5 CFM — Cubic Ft per Minute EWB — Entering Wet Bulb ( F) LWB — Leaving Wet Bulb ( F) — Total Cooling Capacity 1000 Btuh SHC — Total Sensible Capacity 1000 Btuh — Bypass Factor MBH — 1000 Btuh NOTES: 1.

-

Page 6: Horizontal Left

TYPICAL N-COIL HORIZONTAL INSTALLATIONS N-COIL Horizontal Left FILLER PLATE AIRFLOW FURNACE Horizontal Right FILLER PLATE FURNACE DRAIN CONNECTION N-COIL —6— AIRFLOW A97203 DRAIN CONNECTION A97037... - Page 7 —7—...

-

Page 8: Service Training

Course descriptions and schedules are in our catalog. CALL FOR FREE CATALOG 1-800-962-9212 [ ] Packaged Service Training © 1997 Bryant Heating & Cooling Systems, 7310 W. Morris St., Indpls., IN 46231 SERVICE TRAINING • Maintenance • Operating Sequence [ ] Classroom Service Training —8—...