Summary of Contents for Neles XG Series

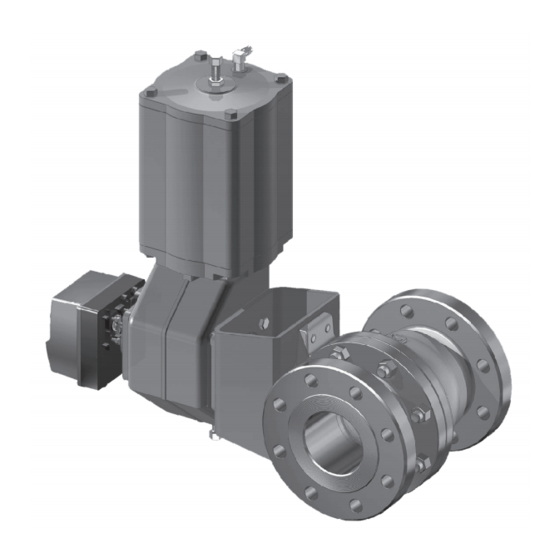

- Page 1 Trunnion mounted full bore MBV Ball valve Series XG, XM Installation, Maintenance and Operating Instructions 1X72EN 9/2020...

-

Page 2: Table Of Contents

TABLE OF CONTENTS TESTING THE VALVE GENERAL Scope of the manual INSTALLING Valve description THE ACTUATOR Markings Specifications General Valve approvals Installing the M-handwheel operator CE marking Installing the B1C-series actuator Recycling and disposal Installing the B1J-series actuator Safety precautions Installing other makes of actuators TRANSPORTATION, TROUBLE SHOOTING... -

Page 3: General

ID plate If you are uncertain about use of the valve or its suitability for your intended purpose, please contact Neles for more information. Fig. 2 Valve markings For valves in oxygen service, please see also the separate The identification plate (Fig. -

Page 4: Specifications

Beware of noise emission! ASME Class 300 The valve may produce noise in the pipeline. The noise level depends on the application. It can be measured or calculated using the Neles Nelprof computer program. Observe the relevant work environment regulations on noise emission. -

Page 5: Transportation, Reception And Storage

2 TRANSPORTATION, RECEPTION AND STORAGE NOTE: Use screws, nuts, bolts and gaskets equivalent to the Check the valve and the accompanying device for any damage that fasteningsused elsewhere in the pipeline. Center the flange may have occurred during transport. gaskets carefully when fitting the valve between flanges. Store the valve carefully. -

Page 6: Actuator

4.1 Maintenance general Although Neles valves are designed to work under severe conditions, proper preventative maintenance can significantly help to prevent unplanned downtime and in real terms reduce the total cost of ownership. - Page 7 must be tightened with care because excess force may damage the • If the leakage still occurs when the valve is pressurized, re- V-rings. tighten the nuts but don't exceed the value in the Table 1 by 50 % or do not fully compress the disc springs. •...

-

Page 8: Repair Of A Jammed Or Stuck Valve While It Is In The Pipeline

4.3 Repair of a jammed or stuck 4.5 Removing the valve from the valve while it is in the pipeline pipeline Jamming may be due to the ball (3) and seats (7) becoming clogged with flow medium. They may be cleaned by turning the ball to the CAUTION: partly open position and flushing the pipeline. -

Page 9: Re-Assembly Of The Valve

4.9 Re-assembly of the valve K and G seats: • Place the valve body (1) and the body cap (2) on the pipe flange end. Use a level surface that will not scratch the flanges. Pre assembly of the seats S and T seats: Fig. -

Page 10: Testing The Valve

Tightening torques of the body joint bolting • Place the pre-compressed graphite rings (back seals)(195) onto the seat. ASTM A320 gr. ASTM A193 gr. ASTM A193 gr. • Place seal ring (braided graphite) (129) into the groove of the ball Material B8M cl. -

Page 11: Installing The Actuator

CLOSED position 6.1 General CAUTION: Beware of ball cutting movement! Different Neles actuators can be mounted using suitable brackets and couplings. The valve can be actuated by an M-handwheel operator or B1-series actuators. 6.2 Installing the M-handwheel stop-screw for OPEN position operator Fig. -

Page 12: Installing Other Makes Of Actuators

6.5 Installing other makes of actuators NOTE: Neles accepts no responsibility for compatibility of actuators not installed by Neles. Other actuators can be installed only if they have an ISO 5211 actuator connection. 7 Trouble shooting table The following Table 4 lists malfunctions that might occur after prolonged use. -

Page 13: Exploded View And Parts List

10 EXPLODED VIEW AND PARTS LIST Sizes 2”-16”. Item Description Spare part category Body Body cap Ball Shaft 1 or 2 Seat (S, T) 1 or 2 Seat (H) Bonnet Gland Stud Stud Stud Hexagon nut Hexagon nut Hexagon nut Spring O-ring (S, T) Back seal (H) - Page 14 Sizes 18”-24”. S-Seat T-Seat G and K-seat D-seat 75 62 B-seat 130 129 63 63 129 Item Description Spare part category BODY BODY CAP BALL SHAFT 1 or 2 SEAT (G, K, D) 1 or 2 SEAT (S, T) 1 or 2 SEAT (B) BONNET GLAND...

-

Page 15: Dimensions

11 DIMENSIONS DN 250 - 400 DN 450 - 600 ASME 150 DIMENSIONS, mm WEIGHT ISO FLANGE □ ØB ØB1 ØD ØO F07, F10 50.8 4.76 22.16 F07, F10, F12, F14 96.5 76.2 4.76 22.16 F10, F12, F14 101.6 6.35 27.75 F14, F16 152.4... - Page 16 ASME 150 DIMENSIONS, inch WEIGHT Size ISO FLANGE □ ØB ØB1 ØD ØO F07, F10 7.01 3.11 5.91 5.75 2.00 7.99 6.61 0.19 0.79 0.87 F07, F10, F12, F14 7.99 3.80 7.48 7.48 3.00 8.86 7.48 0.19 0.79 0.87 48.4 F10, F12, F14 9.02 4.41...

-

Page 17: Valve With Manual Gear Operator Series M

12 Valve with manual gear operator series M ø Z *) See K dimensions from tables on page 13 Dimensions, mm Type øZ Dimensions, in Type øZ 7.72 5.98 2.28 1.52 4.92 11.69 9.41 2.64 2.05 7.87 14.06 11.10 3.19 2.63 9.84 17.13... -

Page 18: Valve With Pneumatic Cylinder Actuator Series B1C/B1J

12.1 Valve with pneumatic cylinder actuator series B1C/B1J ØB1* *) See K and ØB1 dimension from tables on page 13. B1C actuator Dimensions, mm Actuator B1C6 B1C9 B1C11 B1C13 B1C17 B1C20 B1C25 1040 B1C32 1330 B1C40 1660 1150 B1C50 1970 1350 Dimensions, in Actuator... -

Page 19: Type Code

Graphite Viton GF Metal Temperature range -50...+200C. Max pressure based on body rating. Stellite V-rings PTFE PTFE Viton GF Metal Oxygen cleaning acc. to Neles internal procedure FC-QC-0001included. Stellite Graphite Graphite Viton GF Metal Reinforced PTFE V-rings PTFE PTFE EPDM... - Page 20 Tel. +358 10 417 5000. neles.com Subject to change without prior notice. Neles, Jamesbury and Easyflow by Neles, and certain other trademarks, are either registered trademarks or trademarks of Neles Corporation or its subsidiaries or affiliates in the United States and/or in other countries. For more information www.neles.com/trademarks...