Greenheck Vektor-H Installation, Operation And Maintenance Manual

Laboratory exhaust system

Hide thumbs

Also See for Vektor-H:

Table of Contents

Advertisement

Quick Links

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

®

Vektor

-H

Belt Drive

General Safety Information

Only qualified personnel should install this fan system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan RPM. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

®

®

Vektor

-H

Direct Drive

5. Do not allow the power cable to kink or come in

6. Verify that the power source is compatible with the

7. Never open access doors to a duct while the fan is

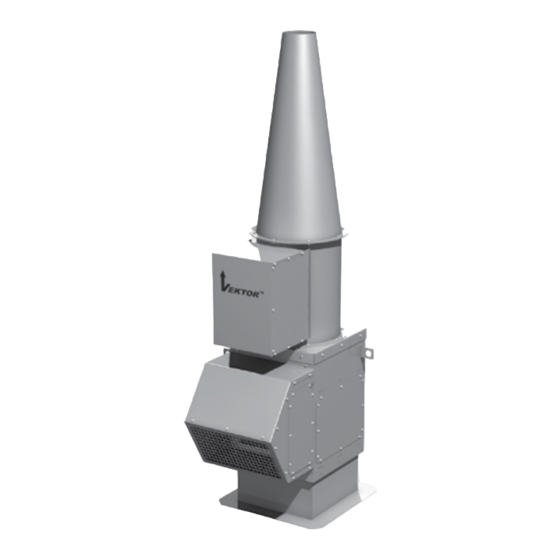

Model Vektor

Laboratory Exhaust System

®

Vektor

-HS

Belt Drive

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

equipment.

running.

DANGER

Always disconnect, lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

Document 469003

®

-H and Vektor

®

-HS

Laboratory Exhaust System

1

Advertisement

Table of Contents

Summary of Contents for Greenheck Vektor-H

- Page 1 Document 469003 Model Vektor ® -H and Vektor ® Laboratory Exhaust System ® Installation, Operation and Maintenance Manual Please read and save these instructions for future reference. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with these instructions will result in voiding of the product warranty and may result in personal injury and/or property damage.

- Page 2 Receiving Greenheck models Vektor-H and Vektor-HS fans are thoroughly inspected, test run at the factory, and shipped on a skid or packaged to minimize damage during shipment. The transportation carrier has the responsibility of delivering all items in their original condition as received from the manufacturer. The individual receiving the equipment is responsible for inspecting the unit for obvious or hidden damage and recording any damage on the bill of lading before acceptance of the equipment.

-

Page 3: General Information

Assembling systems with different identification tags can cause reductions in the fan(s) performance. Prior to fully assembling and installing the Vektor-H or Vektor-HS fans, inspect bypass air plenums and the fan assembly to make sure they are in working order. -

Page 4: Rigging And Lifting

7. Never lift unit in windy conditions. 8. Preparation of roof opening should be completed prior to lifting the unit onto the roof. 9. Use well-padded chains to protect the unit from damage. Vektor-H Unit Assembly Lifting Lugs Nozzle Lifting Points... - Page 5 Bypass Air Plenum (BAP) Size Quantity Placement Steel 1x1 – 9-22 Opposite sides of plenum Greenheck Roof Curb GPFHL/GPFHD 1x1 – 24-36 Two on each end of plenum Continuous weld or stitch weld. Install 3 2x1 – 9-16 Opposite sides of plenum Minimum 6 inch (152.4 mm) stitch weld by...

-

Page 6: Duct Installation

The end of the duct (customer-supplied) is secured between the roof curb’s top edge and the curb cap of either the Vektor-H or bypass air plenum. If an isolation damper is present in the roof curb, the duct is located between the roof curb and the damper adapter tray. -

Page 7: System Assembly

Stack Extensions Systems with multiple stack extensions require all sections assembled and installed on site between the main fan body and the discharge cone. Each section has guy wire attachment brackets located on the upper end of each section. The order sections are installed in are universal. Gasketing (3/16 x 1/2 inch with sticky back) is provided and is to be installed between each joining section. - Page 8 Kitchen Roof Mounting Installation UL/cUL 762 installation for restaurant applications 1. The size of the duct must be equal to the inlet opening. 2. Secure the fan to curb at all four corners using a minimum eight anchor bolts, lag screws or other suitable fasteners.

- Page 9 Fan and Plenum Drainage Piping / Trap Detail (By Others) There is a location for a pipe connection on each tubular fan housing and bypass air plenum. Each drain may need to be connected to a drainage system to ensure proper disposal of any water or condensate that may occur.

-

Page 10: Electrical Connections

Optional transformer and isolation damper, refer to CAPS file selection 208/230/460/575 volt, single phase TRANSFORMER 208/230/460/575 volt, single phase Transformers must be wired independent PHASE from VFD control. Vektor-H Motor Disconnect and Isolation Damper Transformers must be wired independent from VFD control. LAYOUT MOTOR 24/115 volt, single phase TRANSFORMER... -

Page 11: Pre-Start-Up Checks

Vektor-H Applications with Variable Frequency Drive (VFD) For Vektor systems with single-point, three-phase wiring per blower, the isolation damper actuator will be powered via a step-down transformer, which is wired to the fan disconnect, as shown in the wiring diagrams on page 10. -

Page 12: Maintenance

Locking collars and set screws, in addition to fasteners attaching the bearing to the bearing plate must be checked for tightness. Greenheck Fan Corporation recommends bearings to be relubricated quarterly at a minimum. All Vektor-H and Vektor-HS fans use Mobil Mobilith SHC 100 synthetic grease conforming to NCGI Grade 2. - Page 13 Then remove the panel opposite the weatherhood on the bypass air 1000 plenum section and slide the isolation damper out. 1250 Damper actuators, when supplied by Greenheck, are 1500 designed to be maintenance free. No lubrication is 2000 required.

- Page 14 Field Coating Touch-Up for Scratched Areas Standard coating and color is LabCoat™ RAL 7023 Concrete Grey. Failure to perform touch-ups may result in rust or corrosion which can accelerate color fade. This not covered under warranty. TOUCH-UP PAINT REPAIR KIT CONTENTS •...

- Page 15 Vektor-H and Vektor-HS Exhaust Fan Parts List and Assembly Each fan bears a manufacturer’s nameplate with model number and serial number embossed. This information in addition to the parts list shown, will assist the local sales representative and the factory in providing service and replacement parts.

-

Page 16: Maintenance Log

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice. Product warranties can be found online at Greenheck.com, either on the specific product page or in the literature section of the website at Greenheck.com/Resources/Library/Literature.