Summary of Contents for Nassenheider Fill Up 2 visco

- Page 1 Bottling machine Fill up 2 visco basic configuration for honey Manual...

-

Page 3: Table Of Contents

Manual Fill Up 2 fill up Contents Foreword Manufacturer Reading and application of the manual Security instructions Technical details Intended use Technical data Safeguards Connections on the drive module Preparations for use General instructions Components included in delivery (basic configuration for honey, Art.No. 301001) - Page 4 Manual Fill Up 2 fill up 10.4 SETUP menu 10.5 External switches 11 Maintenance, troubleshooting and reparation 11.1 Maintenance 11.2 Update of the software 11.3 Troubleshooting 11.4 Support and reparation 11.5 Disposal of your old machine 12 Warranty 13 CE - DECLARATION OF CONFORMITY ©...

-

Page 5: Foreword

Foreword Dear Customer, Thank you for purchasing our filling machine "Nassenheider fill up 2 visco" Your new appliance is specially designed and aimed to serve the requirements of small to medium size apiaries and consumer goods manufacturers. It will save you valuable time and work as well as having cost benefits. -

Page 6: Reading And Application Of The Manual

This will allow the optimum and safe use if the machine. You can use the „quickstart-manual“ for your everyday filling work. In the service section of our website www.nassenheider.com you are provided with manuals in different languages. -

Page 7: Technical Details

Manual Fill Up 2 fill up Technical details © Stefan Weiland 15.11.2012 Page 5... -

Page 8: Intended Use

Manual Fill Up 2 fill up Intended use The bottling-machine ʺNASSENHEIDER fill up 2 viscoʺ is desgned for the dosing and pumping of the following liquids and creams: Dynamic viscosity: (depending on the pumphead and equipment) 10³ bis 10 mPa*s (thick oils, sirup, mayon- naise, honey, shampoo, yoghurt, fresh cheese, quark, handcreme etc.) -

Page 9: Connections On The Drive Module

Manual Fill Up 2 fill up Connections on the drive module fig. 2.4 Right side: right side left side A - Control knob for speed regulation B - On/ Off toggle switch/ main switch (no lighting) C - Connection socket for 24V power supply (24 V DC by power supply Art.No. -

Page 10: Preparations For Use

Manual Fill Up 2 fill up Preparations for use © Stefan Weiland 15.11.2012 Page 8... -

Page 11: General Instructions

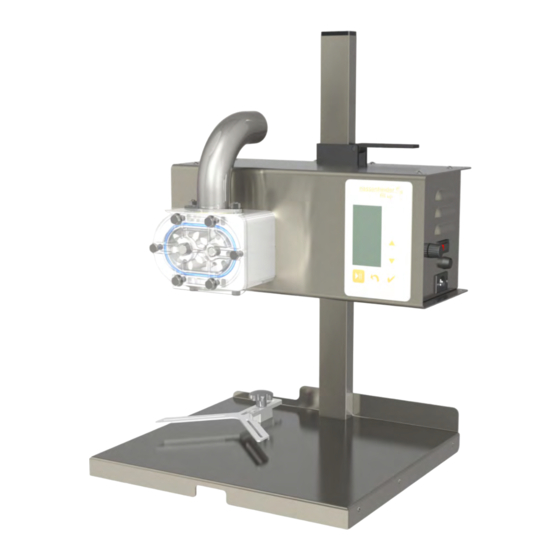

Manual Fill Up 2 fill up General instructions When unpacking, please make sure that the machine: - has not been damaged - is complete according to the following depiction If this is not the case, please get in contact with your local reseller or the manufacturer: STEFAN WEILAND PRODUKT SERVICE within two weeks, either verbally or in writing. -

Page 12: Unpacking And Set Up

Manual Fill Up 2 fill up Unpacking and set up fig. 3.3 - set up in a closed, dry area - room temperature : 15 - 35°C/ 59 - 95°F - before use, please allow allow about an hour for the the appliance to become acclimatized to the room;... -

Page 13: Processing Of Honey

Manual Fill Up 2 fill up Processing of honey © Stefan Weiland 15.11.2012 Page 11... -

Page 14: Suction Out Of A Container

Manual Fill Up 2 fill up Suction out of a container fig. 4.1 Assembly of the hose using a bent pipe - dip the hose and the bent pipeto hot water (approx. 95°C / 203°F) (fig. 4.1) - after assembly immediatly pull the hose clamp tight, making sure that the hose does not get damaged Attach check valve to the other end (fig. -

Page 15: Connection To A Container With Valves

Manual Fill Up 2 fill up Connection to a container with valves Direct connection by means of a connection pipe (Art.No. 304013 - 304015) and disk valve (Art.No. 304010 or 304012). The container should then be raised accordingly. Connection by hose with hose nozzle and swivel nut (Art.No. 304011) and disk valve (Art.No. -

Page 16: Processing Of Other Liquids (Apart From Honey)

Manual Fill Up 2 fill up Processing of other liquids (apart from honey) Each medium that is put through the machine requires a special selection of our components according to the unit assembly system. You can choose from diffe- rent gear wheels, pump heads like the impeller module and peristaltic modules as well as from different filling nozzles. -

Page 17: Assembly, Dismantling And Cleaning

Manual Fill Up 2 fill up Assembly, dismantling and cleaning © Stefan Weiland 15.11.2012 Page 15... -

Page 18: Filling Nozzles

Manual Fill Up 2 fill up filling nozzles fig. 6.9 a Wedge nozzle 22 mm Depending on the medium used, we provide suitable filling nozzles. The cor- rect assembly of the nozzles is described below. Wedge nozzle 22 mm soft (Art.No. 306014), hard (Art.No. 306015) (fig. -

Page 19: Operation

Manual Fill Up 2 fill up 10 Operation 10.1 Membrane keyboard and display Do not use the keys with you fingernails! Do not use aggressive detergents! 10.2 General use of the keyboard 10.3 Modes of operation The operation modes are chosen in the main menu. - Page 20 Manual Fill Up 2 fill up You can select the pumping direction by marking the arrow with the key and adjusting it by means of the keys. Confirm again with the key. Here you can select the following options:...

- Page 21 Manual Fill Up 2 fill up Choice of the nominal quantity/ jar size Most nominal quantities (jar sizes) are pre-programmed by the manufac- turer. They appear in the first line of the AUTO-menu and can be selected as follows:...

- Page 22 Manual Fill Up 2 fill up Filling Pushing the - key (or microswitch/ foot switch) once and a jar will be filled. After replacement of the jar press again to fill it. Selecting the density of the medium The machine has no in-built scale; it measures the volume of the medi- um to be filled by way of counting the revolutions of the gear wheels.

- Page 23 Manual Fill Up 2 fill up Drawback The motor moves a little backwards immediately after stopping. This happens in order to ensure a drip-free filling process. This motion draws the last drop of liquid back from the nozzle and at the same time, closes the filling nozzle.

- Page 24 Manual Fill Up 2 fill up 10.3.3 Time switch/ making creamed honey Another possible application of the filling machine is to stir honey in or- der to make creamed honey. For this, the use of the built in time switch is recommended.

-

Page 25: Setup Menu

Manual Fill Up 2 fill up 10.4 SETUP menu ABC: Select language FILLING: List of the pre-programmed filling amounts, different quantities can be added or existing ones changed: select an empty storage location with the -keys, mark with -key... -

Page 26: External Switches

Manual Fill Up 2 fill up 10.5 External switches All external switches are inserted into the 5-pin socket on the left side of the driving module. The microswitch (Art.No. 307006, fig. 7.2 a) is adjusted in such a way that fig. -

Page 27: Maintenance, Troubleshooting And Reparation

The filling machine is equipped with a USB interface. This allows the updat- ing of the software by means of a PC. Please inquire, on our homepage www.nassenheider.com or by phoning us directly, about the availability of a new software-version. This will be provided for downloading and includes an installation guide. -

Page 28: Troubleshooting

More tips and tricks: see our homepage www.nassenheider.com at Service → FAQ. At the service page you can also find other technical documents and manuals in serveral languages ©... -

Page 29: Support And Reparation

The filling machine is designed for a long-term and sustainable use. All components can be replaced individually, even after many years. Therefore you will be able to rely on your NASSENHEIDER filling machine for many years. When the time has finally come for your machine, we will take it back for disposal, free of charge. -

Page 30: Ce - Declaration Of Conformity

Leipziger Str. 33 01097 Dresden Deutschland hereby declare in our own responsibility, that our bottling machine NASSENHEIDER fill up 2 is designed and assembled in conformity with the following harmonized standards: EN 262-1 und 292-2 EN 50081-1/1992; EN 55014; EN 61000-3-2/3 EN 50082-1/1997;... - Page 32 Produktservice Stefan Weiland Leipziger Str. 33 01097 Dresden Germany Sales: +49(0)351-89 66 91-01 E-Mail: info@nassenheider.com Support: +49(0)351-89 66 91-05 Website: www.nassenheider.com Fax: +49(0)351-89 66 91-99...