Summary of Contents for Viessmann Dekamatik-M1

-

Page 1: Operating Instructions

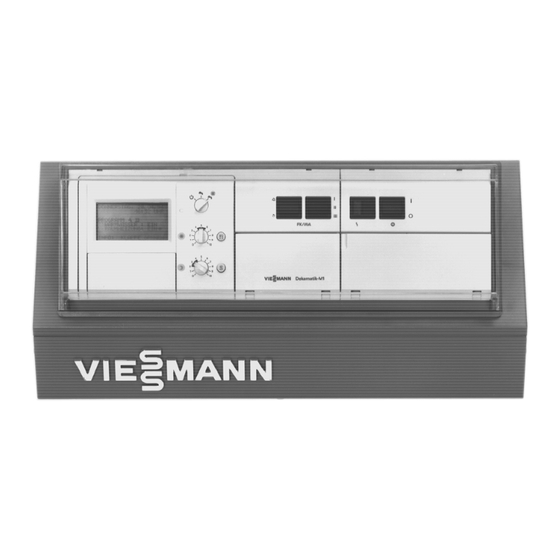

Operating Instructions Dekamatik-M1 Digital indoor/outdoor boiler and heating system control Dekamatik-M1... -

Page 2: Table Of Contents

1.0 Contents 1.1 Safety 1.0 Contents Page Important Precautions 1.1 Safety ............................Operating Instructions (overview) 2.1 Operating Controls / Display Elements . -

Page 3: Safety

Canada use latest edition of CSA C22.1 necessary licenses. Ensure main power Viessmann boilers, burners and controls Part 1 and/or local codes. supply to equipment, heating system, and are approved for sale in North America by... -

Page 4: Method Of Operation Of The Heating System

To control this indicate any malfunctions. system, your Viessmann boiler is equipped with the Dekamatik digital indoor/outdoor boiler and heating system control. 2.3 Control Activation The initial start-up must be conducted by the heating contractor. -

Page 5: H Symbols In The Display

2.4 Settings and Adjustments Symbols in the display The symbols “ ” , “ ” or “ ” appear the system, i.e. depending on the program individually or in combination or activation periods. according to the current operating status of Heating program “... -

Page 6: H Altering Room Temperatures

2.4 Settings and Adjustments Altering room temperatures Normal operation (i.e. during daytime) H Set selector knob to required SELECTED ROOM TEMP. temperature. 20 ºC PREVIOUS: . . ºC CURRENT: H The previous and current room colder warmer temperatures appear immediately in the display. -

Page 7: H Setting Party Mode

2.4 Settings and Adjustments Setting party mode Note: H Press “ ” button. TUESDAY, 04.02.96 Set the party mode when you require room 18:30 HRS heating outside the preset heating program To change the party temperature PARTY MODE and the preset switching times. Domestic H Follow the instructions in the display. -

Page 8: Menu Structure

2.4 Settings and Adjustments Menu Structure The following descriptions provide you with H Pinpoint the information you wish to query H Follow the appropriate sequence on the an overview of the menu structure within the on the 2nd, 3rd, or 4th level (see control unit as described in the diagram menu-driven Comfortrol control unit. - Page 9 2.4 Settings and Adjustments ”System” menu structure (Overview 3) 1st level 2nd level 3rd level 4th level >BC CIRCUIT A: ..CHANGE CLOCK FACTORY DATE SETTING >DHW: ... . . >SYSTEM: .

-

Page 10: H Time Program - Explanatory Remarks

2.4 Settings and Adjustments Time program - Explanatory remarks General information A time program consists of switch-on and - normal operation Example: switch-off times which are set on the (room heating ON Heating program “ ” Comfortrol control unit. Depending on the - reduced operation (Domestic hot water ON/room heating ON) heating program you have selected, these... -

Page 11: Altering The Switching Times

2.4 Settings and Adjustments Altering the switching times Set the switching times precisely for those You can enter the same time program for When setting the activation periods, please periods in which you require space heating every day of the week or a different time take into account the reaction time of your or DHW production. -

Page 12: Deleting Activation Periods

2.4 Settings and Adjustments Deleting activation periods H Open cover. H Select BOILER CIRCUIT or DHW. H Call up the entered times via TIMES or SWITCHING TIMES and change. H Turn the “ ” adjustment knob counter-clockwise until “--: --” appears; the corresponding time is now deleted. - Page 13 2.4 Settings and Adjustments Holiday program You may enter a duration from 1 to 99 days The heating system resumes operation in Note: and maintain a constant room temperature accordance with the switching times at the When selecting the end of the holiday between 41 and 95 ºF / 5 and 35 ºC during selected switch-off time (end of program program, please bear in mind that a building...

-

Page 14: H Installer Set-Up

2.4 Settings and Adjustments Installer set-up Electronic programming entails making specific adjustments which apply to your heating system and should be undertaken by a qualified heating contractor only. Service work is thereby simplified as the heating contractor can perform diagnostic and service activities by taking sensor readings and making status inquiries. -

Page 15: H Maximum Temperature Limit

2.4 Settings and Adjustments Maximum temperature limit Maximum boiler water temperature limit The adjustable high limit “ ” takes precedence over the electronic The Dekamatik incorporates two devices for temperature high limit limiting the maximum boiler water i.e. you can only effectively influence the temperature: maximum supply temperature below the - electronic temperature high limit... -

Page 16: H Heating Curves

2.4 Settings and Adjustments Heating curves Function In order to ensure that sufficient heat energy The heating curves determine the There are various heating curves: is provided with the minimum consumption relationship between outdoor temperature Flat heating curves set lower boiler water of fuel for all outdoor temperatures, the and boiler water temperature or supply temperatures (=supply temperatures), steep... - Page 17 2.4 Settings and Adjustments Changing the heating curve Changing the slope and parallel shift of the It is possible that the factory setting of the heating curve: heating curve may not give the required room temperature at different outdoor In this way you can raise or lower the boiler temperatures.

- Page 18 2.4 Settings and Adjustments Helpful hints Alter your heating curve, if ... Type of alteration ... heat output is insufficient when Increase the value of the “slope” to the next level. outdoor temperatures are cold, but adequate during spring and fall Decrease the value of the “slope”...

-

Page 19: H Lead Boiler Selection Control

2.4 Settings and Adjustments Lead boiler selection control On/off sequence of boilers in multi-boiler systems The sequence in which the boilers in a multi-boiler system are activated and deactivated is automatically determined by the control unit (factory default). However, the user has the ability to select a particular sequence manually. -

Page 20: H Default Factory Settings " " Button

H Deactivate Dekamatik-M1 by switching next time the system is switched on. the on/off switch “ ” to “O”. -

Page 21: Override Switch

3 Override Switch 3 Override Switch For provisional operation with fixed boiler water temperatures: H Open middle flip-down cover. H Switch override “ ” from “ ” to “ ”. = Provisional The following functions are activated: operation - control of boiler water temperature via the = Automatic adjustable high limit “... -

Page 22: Scanning Temperatures (Desired/Actual Values) And Operating Status Information

4.1 Scanning Temperatures (Desired/Actual Values) and Operating Status Information 4.1 Scanning Temperatures (Desired/Actual Values) and Operating Status Information Scanning system data H Follow the appropriate menu structure (Overview 1, 2 or 3 on page 8 and 9) and press the specified button. Scan Desired/actual value Switch conditions... -

Page 23: Fault Indication

4.2 Fault Indication 4.2 Fault Indication If a fault occurs during operation of the Heating systems with a central fault Not every “irregularity” in the system is a heating system, it will be displayed by the indicator defect in the Dekamatik; these are control unit. -

Page 24: Troubleshooting Guide

Heating system does not Dekamatik-M1 has been set to activate “O” Main power is deactivated. Activate power supply to Dekamatik-M1 and burner Fuse in distribution circuit is Advise heating contractor blown and deactivation has consequently occurred Burner activation does not occur... -

Page 25: Operating The Comfortrol Control Unit

4.4 Operating the Comfortrol Control Unit 4.4 Operating the Comfortrol Control Unit Operational information Operating the Comfortrol control unit The following can be programmed: Programming necessitates opening of the when detached from boiler control - time flip-down cover; the display then The Comfortrol can be programmed while - date automatically appears. -

Page 26: H Language Selection

4.4 Operating the Comfortrol Control Unit Language selection If you wish to adjust the language, open the ANGUAGE/LANGUE flip-down cover and follow this path through the menu: H SYSTEM “D” button ........H FACTORY SETTING “A”... -

Page 27: Settings Checklist

4.5 Settings Checklist 4.5 Settings Checklist Tables for entering System Settings / Equipment All functions, their default factory settings, as well as their alternatively possible settings are outlined in this table, Ensure functions which have been altered are checked off accordingly. Default factory setting Alternative possibilities Safety temperature high limit ”... - Page 28 4.5 Settings Checklist Default factory setting Alternative possibilities H If boiler (shunt) pump is utilized: 20 B The boiler (shunt) pump switches on when the boiler water tem- j The boiler (shunt) pump switches on when the boiler is released perature falls below the minimum value Boiler isolation valve j Off delay for boiler (shunt) pump and for boiler isolation valve:...

- Page 32 Viessmann Manufacturing Company (U.S.) Inc. Viessmann Manufacturing Company Inc. 45 Access Road 750 McMurray Road Warwick, Rhode Island • 02886 • USA Waterloo, Ontario • N2V 2G5 • Canada Tel. (401) 732-0667 • Fax (401) 732-0590 Tel. (519) 885-6300 • Fax (519) 885-0887 www.viessmann-us.com •...