Sharp AR-M550N Service Manual

Hide thumbs

Also See for AR-M550N:

- Circuit diagram (198 pages) ,

- Operation manual (172 pages) ,

- Printer operation manual (57 pages)

Table of Contents

Advertisement

Quick Links

[1] OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . 5-1

[6] DETAILS OF EACH SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] SETTING AND ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SELF DIAG MESSAGE AND TROUBLESHOOTING . . . . . . . . . . 9-1

[10] ROM VERSION-UP METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] MAINTENANCE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] OTHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

[14] SIGNAL NAME LIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SERVICE MANUAL

DIGITAL LASER COPIER/PRINTER

DIGITAL MULTIFUNCTIONAL SYSTEM

AR-M550N/M550U

AR-M620N/M620U

AR-M700N/M700U

MODEL

CONTENTS

SHARP CORPORATION

CODE: 00ZAR700//F1E

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Advertisement

Table of Contents

Summary of Contents for Sharp AR-M550N

-

Page 1: Service Manual

SERVICE MANUAL CODE: 00ZAR700//F1E DIGITAL LASER COPIER/PRINTER DIGITAL MULTIFUNCTIONAL SYSTEM AR-M550N/M550U AR-M620N/M620U AR-M700N/M700U MODEL CONTENTS [1] OUTLINE ..........1-1 [2] CONFIGURATION . - Page 2 CAUTION This product is a class 1 laser product that complies with 21CFR 1040 of the CDRH standard and IEC825. This means that this machine does not produce hazardous laser radiation. The use of controls, adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

-

Page 3: Table Of Contents

CONTENTS [1] OUTLINE [5] EXTERNAL VIEW AND INTERNAL STRUCTURE 1. Main Features ........1-1 1. -

Page 4: Table Of Contents

9. Filters ........6-146 [10] ROM VERSION-UP METHOD 10. -

Page 5: Outline

[1] OUTLINE (2) Strengthened Frame Structure Highly Rigid Frame 1. Main Features Improved stability with less machine distortion, and both rigidity and lightweight been achieved. (1) Single Pass Duplex Scanner (3) Energy Saving with Unique External Heat Roller • Max. 76 cpm for duplex scanning Fusing System •... -

Page 6: C. 2-Way Security Solution

C. 2-Way Security Solution ONLY-ONE Way-in : Network Security Allow access of authorized network address only and prevent unauthorized access from outside. Print data (Filtering of network address) Copy data Print data Fax data Scan data Way-out : HDD Data Clear + Encryption Data clear by plural writing random number. -

Page 7: D. Document Filing

Internet-Fax Copy Scan Send E-mail Print Print data Send <List of data stored in Main folder> G3 Fax i-FAX Send E-mail AR-M550N/U AR-M550N/U Internet Fax AR-M620N/U AR-M620N/U Telephone line Network/LAN PC Fax PC i-Fax Fax data i-Fax data PC-Fax is like printing Word data etc. -

Page 8: Configuration

AR-NS3/Network scanner expansion kit AR-FX8/ Facsimile expansion kit*1 AR-MM9/FAX expansion memory(8MB)*1 AR-U11M/Sharpdesk 1 license kit AR-U15, AR-U15M / Sharp desk 5 license kit AR-U1AM/Sharpdesk 50 license kit AR-U1BM/Sharp desk 100 license kit *1: North America, Europe, Australia, New Zealand, Singapore, Taiwan... -

Page 9: Block Diagram

AR-P19, is required. Software Data security kit (Not acknowledged version) (AR-FR11) Network scanner expansion kit (AR-NS3) Sharp desk 1 license kit (AR-U11M) Sharp desk 5 license kit (AR-U15M) Sharpdesk 50 license kit (AR-U1AM) Sharpdesk 100 license kit (AR-U1BM) FAX system... -

Page 10: Specifications

1 slot (168pin SDRAM DIMM compatible) 64MB/ 40ppm 45ppm 48ppm Executive-R slot 128MB/256MB expandable B4/8.5×14 35ppm 39ppm 45ppm *: Standard for the AR-M550N/M620N/M700N. The Printer expansion A3/11×17 30ppm 34ppm 39ppm kit AR-P19 is required for the AR-M550U/M620U/M700U. Extra 30ppm 34ppm 39ppm (10) Hard disk... -

Page 11: Engine Specifications

: Feb. 9 2004 2. Engine specifications A. Paper feeding, paper conveyance, and discharge section (1) Paper feeding performance Type 4-stage paper feed tray (Parallel LCC + 2 tray + Multi manual paper feed) Paper feed method Paper is fed from the above by the front loading system. Dehumidification heater Japan Standard Except for Japan Option... -

Page 12: B. Scanner Section (Read)

: Feb. 9 2004 • Manual paper feed Paper type Allowable paper type and Paper capacity Paper empty Paper size Paper type Document detection setting weight for paper feed (Standard paper) detection A3, B4, A4, A4R, Thin paper: 52 – 59g/m Plain paper: 100 Normal paper, recycled Automatic... -

Page 13: C. Scanner Section (Write)

Scan system Laser scanning Capacity 725g x 2 (2 bags are used.) (2) Laser unit specifications Life 55ppm: 250K, 62/70ppm: 300K Rotation speed 34000 rpm (AR-M550N/U, AR-M620N/U) (5) Charging 40000 rpm (AR-M700N/U) Mirror surfaces 14 surfaces Type Corotron Laser power 0.385±0.04 mW (AR-M550N/U, AR-M620N/U) -

Page 14: Operating Specifications

Within approx. 30 sec (Condition: door open/ fusing unit pull-out, after leaving for 60sec, standard condition, polygon stop) Under 30 seconds (conditions: door open) c. Low power mode, sleep mode AR-M550N/U AR-M620N/U AR-M700N/U Low power consumption S/U model*1 216.75W 243.7W 274.5W... - Page 15 (3) Paper type summary Yes: This function is effective No: This function is invalid USER: by USER setting Paper Type Print job Copy job Fax job I-Fax job Filing job F-R attribute Duplex disable Staple disable Punch disable Standard paper USER USER USER...

-

Page 16: B. Copy Mode

Sub scanning direction Performed by changing image processing | D | 1mm and scanning speed 203mm (5) Job speed a. First copy time Print vertical line AR-M550N/ AR-620N/ AR-M700N/ M550U M620U M700U Document table Within 3.9sec Within 3.9sec Within 3.3sec... - Page 17 : Feb. 9 2004 b. Copy speed AR-M550N/M550U AR-620N/M620U AR-M700N/M700U Copy magnification Copy magnification Copy magnification Copy mode Paper size Reduction Normal copy Enlargement Reduction Normal copy Enlargement Reduction Normal copy Enlargement copy (25%) (100%) copy (400%) copy (25%) (100%)

-

Page 18: C. Image Send Function

C. Image send function items of direct address input * (1) Mode Broadcast send (Broadcast Scanner (Scan to E-mail, Scan to Sharp desk, Scan to FTP, Scan to send is disabled HDD ), FAX, Internet FAX for FTP/ (2) Support system Desktop) Sequential send –... - Page 19 : Feb. 9 2004 (7) Functions Mode Scanner Internet FAX Mode Scanner Internet FAX Receive Transfer – function function when Send Memory – output is function transmission disable Onhook – Automatic boot – Quick online – mode send Special Time Direct –...

-

Page 20: D. Printer Function

– USB 2.0: Windows 2000 / XP only D. Printer function For NetWare Used in NetWare environment. Standard for the AR-M550N/M620N/M700N. The Printer expansion kit environment Print channel in the PSERVER/PRINT mode. AR-P19 is required for the AR-M550U/M620U/M700U. PSERVER/RPRINT UNIX LPR/LPD command compatible print... - Page 21 Reverse N selection N-up frame (Always ) (*2) Smoothing (AR-M550N/U, AR-M620N/U) line – (AR-M700U/N) (AR-M550N/U, *1: For printing, the PS driver bundled in Windows is required. AR-M620N/U) *2: The PS driver bundled in Windows may differ in specifications –...

- Page 22 Half tone – magnification ratio Graphic mode selection – Cover insertion +center – Smoothing / (AR-M550N/U, AR-M620N/U) binding – (AR-M700N/U) Document filing – Toner save *1: For printing, the PS driver bundled in Windows is required. Ultra fine photo / (AR-M550N/U, AR-M620N/U) (11) Macintosh driver functions –...

-

Page 23: E. Document Filing Function

EXCL.xls 3 J11.ppt 12 Model PDL type Each folder in the (jpn) 9 pages pages in pages in standard folder/user Temporary folder in total total total folder AR-M550N/ PCL5 14sec 9sec 28sec Common Confidential Common Confidential M550U (SPDL2) data data data... -

Page 24: Safety And Environmental Protection Standards

International energy program complex machine (EPS) Environmental Choice Program (ECP) –10˚C 50˚C Conforms to New Blue Angel. Temperature Nordic swan (Sharp: Follows the Green Product Declaration.) Consumable items (unopened) (2) Ozone level Humidity Max. 0.02mg/m³ 40˚C, 90% (3) Noise level... -

Page 25: D. Ambient Conditions For Transporting

Telephone line RIC terminal available E-mail RIC available (Conforming to soft key.) Coin vendor terminal Card counter Angle/Harness parts supply Key counter Only the harness is left. (SF-71A/B) Mechanical counter Conforming to 7-digit OEM For SHARP (Parts support) AR-M550/M620/M700 SPECIFICATIONS 3 - 16... -

Page 26: Consumable Parts

: Feb. 9 2004 [4] CONSUMABLE PARTS 1. Supply system table A. USA, Canada, South and Central America Part name Content Life Model name Packing Remark Toner cartridge (Black) Toner cartridge (Black) x 10 720k (72k x 10) AR-620MT * Life setting by A4/LT (Toner;... -

Page 27: F. Middle East/Philippine

: Feb. 9 2004 F. Middle East/Philippine Part name Content Life Model name Packing Remark Toner cartridge (Black) Toner cartridge (Black) x 10 720k (72k x 10) AR-620ET * Life setting by A4/LT (Toner; Net weight 1430g) 6% document With IC chip ET=FT x 10 Toner cartridge (Black) x 10... -

Page 28: Australia/New Zealand/Uk

: Feb. 9 2004 Life Name Content Model name Packing Remark 55cpm 62cpm 70cpm 11 Staple cartridge Finisher staple 5,000 5,000 5,000 SF-SC11 Cartridge for AR-F15 times x 3 times x 3 times x 3 (Common with the cartridge for AR-F11/ F12) 12 Staple cartridge Saddle finisher staple... -

Page 29: C. Middle East/Asia/South And Central America

: Feb. 9 2004 C. Middle East/Asia/South and Central America Life Part name Content Model name Packing Remark 55cpm 62cpm 70cpm Maintenance kit 1 Side seal F 250K 300K 300K AR-620KA Side seal R MC cleaning unit Cleaner blade Drum separation pawl Screen grid Toner reception seal Charging plate... -

Page 30: D. China

: Feb. 9 2004 D. China Life Part name Content Model name Packing Packing 62cpm 70cpm Maintenance kit 1 Side seal F 300K 300K AR-620KA Side seal R MC cleaning unit Cleaner blade Drum separation pawl Screen grid Toner reception seal Charging plate Paper dust removal unit DV seal... -

Page 31: E. Taiwan

: Feb. 9 2004 E. Taiwan Life Part name Content Model name Packing Packing 55cpm 62cpm 70cpm Maintenance kit 1 Side seal F 250K 300K 300K AR-620KA Side seal R MC cleaning unit Cleaner blade Drum separation pawl Screen grid Toner reception seal Charging plate Paper dust removal unit... -

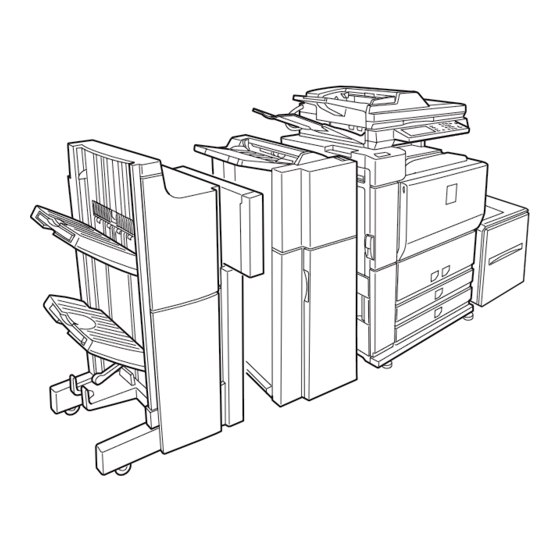

Page 32: External View And Internal Structure

Paper feed tray 5 (Large capasity tray The large capacity tray can hold up to 3,500 sheets of commonly (AR-LC6)) * used (8-1/2" x 11", B5, A4) SHARP standard paper (20 lbs. (80 g/m²)). Paper feed trays 1, 2 The trays hold paper. Approximately 800 sheets of standard 8-1/2" x 11"... -

Page 33: B. Internal Operation Parts

B. Internal operation parts Parts Note Name Function/Operation Duplex unit Open this cover to remove a misfeed from the fusing unit area. Fusing unit Toner images are fused here. The fusing unit is hot. Take care in removing misfed paper. Cover of the duplex unit Open when a misfeed has occurred in duplex unit. -

Page 34: C. Operation, Display Parts

C. Operation, display parts Parts Note Name Function/Operation Touch panel The machine status, messages and touch keys are displayed on the panel. The document filing, copy, network scanner*1 , and fax*2 functions are used by switching to the screen for the desired function. Mode select keys and indicators Use to change modes and the corresponding display on the touch panel. - Page 35 D. Job status screen (common to print, copy, network scan and internet fax) This screen is displayed when the [JOB STATUS] key on the operation panel is pressed. A job list showing the current job at the top of the job queue or a list showing completed jobs can be displayed. The contents of jobs can be viewed or jobs can be deleted from the queue.

- Page 36 (Displayed in the touch panel) Note Name Function/Operation [E-MAIL/FTP] key This displays the transmission status and finished jobs of scan mode (Scan to e-mail, Scan to FTP, and Scan to SharpDesk) when the network scanner option is installed. [FAX JOB] key This displays the transmission/reception status and finished jobs of fax mode (fax and PC-Fax) when the fax option is installed.

-

Page 37: Function Parts

: Feb. 9 2004 2. Function parts A. Sensor/detector SPED1 SPED1 SPED1 STUD STUD STUD SPLS2 SPLS2 SPLS2 SPPD1 SPPD1 SPPD1 SPLS1 SPLS1 SPLS1 SPWS SPWS SPWS STLD STLD STLD SPPD3 SPPD3 SPPD3 SPPD2 SPPD2 SPPD2 SPPD4 SPPD4 SPPD4 SPED2 SPED2 SPED2 SPOD... - Page 38 : Feb. 9 2004 Connector level Signal Code Name Function/Operation Type Note name name "L" "H" M2PFD M2PFD Paper pass detector (Paper Paper feed tray 4 paper pass Transmission type Paper pass Paper transport feed tray 4) detection system sensor MPED MPED Manual feed paper empty...

- Page 39 : Feb. 9 2004 SCOV SCOV SCOV SOCD SOCD SOCD LEDX LEDX LEDX MHPS MHPS MHPS OCSW PDSELX PDSELX PDSELX TH-EX TH-EX TH-EX RTH1 RTH1 RTH1 RTH2 RTH2 RTH2 TH-CL TH-CL TH-CL RTH3 RTH3 RTH3 TH-RA HUS-TC HUS-TC HUS-TC DSW-ADU DSW-ADU DSW-ADU DSW-L...

-

Page 40: Signal Name List

: Feb. 9 2004 Signal Connector level Code Name Function/Operation Type PWB name Note name "L" "H" M1SPD M1SPD Paper remaining quantity Paper remaining quantity Transmission Remaining PCU PWB Paper feed tray detector (Paper feed tray 3) detection (Paper feed tray 3) type paper quantity remaining quantity... -

Page 41: B. Switch

: Feb. 9 2004 Signal Connector level Code Name Function/Operation Type PWB name Note name "L" "H" SOCD SOCD SPF open/close detector SPF unit open/close detection Transmission Close SCN PWB Sensor type T1SPD T1SPD Paper remaining quantity Paper remaining quantity Transmission Remaining PCU PWB Paper feed tray... -

Page 42: C. Clutch/Solenoid

: Feb. 9 2004 C. Clutch/solenoid SPFC STRRC SRRC SRRBC STRRBC STRC STRBC PSPS DSKLS MFPUS PSBC MPFGS T1PFC DSKPFC2 T1PUS MPFC M1PUS HPFC T2PFC M1PFC T2PUS DSKPFC1 M2PFC M2PUS Signal Code Name Function/Operation Type MODEL NOTE name Paper exit gate solenoid Paper exit gate drive Electromagnetic solenoid... -

Page 43: D. Motor

: Feb. 9 2004 Signal Code Name Function/Operation Type MODEL NOTE name SPFC SPFC SPF paper feed clutch SPF paper feed section roller ON/ Electromagnetic OFF control clutch SRRBC SRRBC SPF resist roller brake clutch SPF resist roller braking Electromagnetic clutch SRRC SRRC... - Page 44 : Feb. 9 2004 Signal Active Code Name Type Function/Operation MODEL NOTE name condition M1LUM M1LUM Paper feed tray lift-up DC brush motor Drives the lift plate of the Selection of motor (Paper feed tray 3) paper feed tray. Rotation mode/ Brake mode M2LUM M2LUM...

- Page 45 E. Lamp LEDCL CCFT Active Code Signal name Name Type Function/Operation MODEL NOTE condition Scanner lamp Xenon lamp Radiates lights onto a document for the CCD to scan the document image. CCFT CCFT LCD backlight CCFT cool CRT LCD backlight Discharge lamp Lamp Discharges electric charges on the OPC...

-

Page 46: F. Fan Motor

: Feb. 9 2004 F. Fan motor CFM-U1 CFM-U3 SPFFAN VFM-EX1 CFM-U4 VFM-EX2 CFM-U2 VFM-EX3 VFM-BKU VFM-BKR CFM-R1 VFM-BKL CFM-R2 CFM-HDD CFM-R3 CFM-DV CFM-ICU CFM-DC1 CFM-DC2 Signal Active Code Name Type Function/Operation MODEL NOTE name condition CFM-DC1 CFM-DC1 Power cooling fan motor DC brushless Cools the DC power unit. -

Page 47: G. Pwb (Main Unit Section)

: Feb. 9 2004 Signal Active Code Name Type Function/Operation MODEL NOTE name condition VFM-BKL VFM-BKL Process exhaust fan motor 4 DC brushless Exhaust ozone and heat PWM control motor from the process section. VFM-BKR VFM-BKR Fusing exhaust fan motor DC brushless Exhaust heat from the PWM control... -

Page 48: H. Fax Section

: Feb. 9 2004 Name Function/Operation MODEL NOTE Document size detection light Generates lights to detect the document size. emitting PWB High voltage PWB (MC/DV/TC) Generates the main charger voltage, the developing bias voltage, the transfer voltage and the transfer belt cleaning voltage. Transfer bias high voltage PWB Provides the bias voltage for the transfer cleaning roller and the print (TD CL) -

Page 49: I. Fuse/Thermostat

: Feb. 9 2004 I. Fuse/thermostat 28,31 27,30 26,29 18,21,24 17,20,23 19,22,25 9,12 Code Name Type Specificaiton Funciton/Operation Section NOTE F201 Fuse Time lag 250V 6.3A PCU PWB protection (24V1) DC main 100V system/ power PWB 200V system F202 Fuse Time lag 250V 6.3A Driver PWB protection (24V2) -

Page 50: J. Adjustment Volume

: Feb. 9 2004 Code Name Type Specificaiton Funciton/Operation Section NOTE F1,F2 Fuse Time lag 240V 10A AC power source overcurrent protection (Main AC power EX Japan source) PWB EX200 200V system F3,F4 Fuse Time lag 250V 2.0A Thermal heater overcurrent protection AC power EX Japan PWB EX200... -

Page 51: L. Heater

K. Gate Name Function/Operation MODEL NOTE Switchback gate Selects the paper route when discharging paper to the inner tray and Switched not by the solenoid drive when switching back. but by the automatic procedure. Paper exit gate Selects the paper route to transport paper to the duplex (ADU) Driven by the solenoid (DGS). -

Page 52: M. Lock Position

Code Name Type Function/Operation MODEL NOTE WH1 DESK Dry heater (Paper Nichrome wire Dehumidifies paper on the paper Standard for Japan model, option feed tray 1, 2) (18W) fee4d tray 1 and 2. for the other destinations. WH1 SCN Scanner dry heater Nichrome wire (7W) Dehumidifies the scanner section. -

Page 53: N. Roller

: Feb. 9 2004 N. Roller 76 75 74 73 71 72 79 84 80 81 34 35 33 31 32 Name Function/Operation NOTE Paper feed roller (Manual paper feed tray) Feeds paper to the paper transport section. Separation roller (Manual paper feed tray) Separates paper to prevent against double-feed. - Page 54 : Feb. 9 2004 Name Function/Operation NOTE Transport roller 1 (Drive) Transports paper fed from the large capacity tray (LCC) to the transport roller 2. Transport roller 1 (Idle) Applies a pressure to paper and the transport roller to provide a transport power of the transport roller to paper.

-

Page 55: O. Filter

: Feb. 9 2004 Name Function/Operation NOTE Paper exit roller 1 (Idle) Applies a pressure to paper and the paper exit roller to provide a transport power of the paper exit roller to paper. Paper exit roller 2 (Drive) Discharges paper. / Transports paper to the duplex (ADU) section. Paper exit roller 2 (Idle) Applies a pressure to paper and the transport roller to provide a transport power of the paper exit roller to paper. -

Page 56: Details Of Each Section

[6] DETAILS OF EACH SECTION 1. Operation panel section 2. Paper feed, paper transport, duplex, and 3. Laser scan unit (LSU) paper exit reverse sections 4. Image process section 5. Scanner section 6. Fusing section 7. SPF section 8. Drive section 9. -

Page 57: Operation Panel Section

: Feb. 6 2004 1. Operation panel section A. General This section describes various types of settings, display and operation. The LCD display section is controlled by the MFP CONTROL PWB. The touch panel, operation keys and LED display are controlled by the SCANNER CONTROL PWB. -

Page 58: C. Maintenance And Parts Replacement

: Feb. 6 2004 Signal Code Name Function/Operation Type Model Note name LCD unit Display the each memu and the information. TOUCH Touch panel Various adjustments and setting operation are performed. ORSLED Document size detection light Generates the document size detection signal. emitting PWB ORSPD Document size detection light... - Page 59 : Feb. 6 2004 a-1. Operation control PWB 4) Remove the LCD unit. 1) Remove the operation panel unit. (See “a. Operation panel unit”) 2) Remove the ground lead. b-1. Touch panel 1) Remove the operation panel unit. (See “a. Operation panel unit”) 2) Remove the LCD unit.

-

Page 60: And Paper Exit Reverse Sections

2. Paper feed, paper transport, duplex, and paper exit reverse sections [Paper feed section] General The paper feed tray 1 holds 900 sheets, the paper feed tray 2 holds 1,300 sheets, the multi-purpose paper feed tray 3 holds 500 sheets, the paper feed tray 4 holds 500 sheets, and the manual paper feed tray holds 100 sheets. - Page 61 (Manual paper feed section) A. Major parts and signal functions MPFC MFPUS MPFD1 MTOP2 MTOP1 MPED MPFPWS DSW-R MPLD2 MPLD1 MPFGS 1 2 3 PHNR-09-H+BU09P-TR-P-H DF3-3S-2C GND2 GND2 MPLD1 MPLD1 DRAWER PCU PWB +5V2 +5V2 QR/P4-24S-C(01)/QR/P4-24P-C(01) MPLD2 DSW-F(R) DF3-3S-2C MTOP1 GND2 MTOP2 GND2...

- Page 62 Signal Code Name Function/Operation Type Model Note name MPED MPED Manual feed paper empty Manual paper feed tray paper empty Transmission type Manual paper feed unit detector detection MPFD1 MPFD1 Manual feed paper pass Manual tray paper pass detection Transmission type Paper transport system detector 1 sensor...

- Page 63 : Feb. 6 2004 B. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 64 a. Multi manual paper feed tray unit 4) Remove the manual paper feed unit open/close switch. 1) Pull out the multi manual paper feed tray unit. 2) Remove the multi manual paper feed tray unit from the right and left accurides. a-2.

- Page 65 a-3. Pickup roller a-6. Torque limiter 1) Pull out the multi paper feed tray unit. (See “a. Multi manual paper a-4. Paper feed roller feed tray unit”) a-5. Separation roller 2) Remove the bottom cover. 1) Pull out the multi manual paper feed tray unit. (See “a. Multi man- ual paper feed tray unit”) 2) Remove the actuator unit.

- Page 66 : Feb. 6 2004 4) Remove the manual feed gate solenoid. 5) Remove the connector and the E-ring, and remove the paper feed clutch. ∗ When assembling, tighten the screw so that the lever tip is at 13±0.5mm from the frame edge with the solenoid plunger pulled. 13 5mm a-8.

- Page 67 : Feb. 6 2004 a-11. Manual feed paper width size detection PWB 5) Disconnect the connector, and remove the manual paper feed tray pull-out position detector 1(A) and the manual paper feed tray pull- 1) Remove the multi manual paper feed tray unit. (See “a. Multi man- out position detector 2 (B).

- Page 68 (Paper feed tray sections 1 and 2) A. Major parts and signal functions PHR-2 T1LUM GND2 PCU PWB SMR-02V-N/SMP-02V-NC +24V1 /T1PUS CN-14 B24B-PHDSS-B PHR-2 T1LUM T2LUM T2LUM GND2 GND2 GND2 SMR-02V-N/SMP-02V-NC +24V1 +24V1 +24V1 /T1PUS /T2PUS /T2PUS +5V2 +24V1 GND2 /DSKLS T1LUD GND2...

- Page 69 Signal Code Name Function/Operation Type Model Note name T1SPD T1SPD Paper remaining quantity Paper remaining quantity detection Transmission Paper feed tray remaining detector (Paper feed tray 1) (Paper feed tray 1) type quantity sensor T2SPD T2SPD Paper remaining quantity Paper remaining quantity detection Transmission Paper feed tray remaining detector (Paper feed tray 2)

- Page 70 : Feb. 6 2004 C. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 71 a. Paper feed tray units 1 and 2 a-2. Paper feed roller 1) Pull out the paper feed tray units 1 and 2. 1) Pull out the paper feed tray units 1 and 2. (See “a. Paper feed tray units 1 and 2”) 2) Unhook the claws to remove the paper guide.

- Page 72 4) Remove the torque limiter. 5) Remove the wire. a-5. Lift wire (Rear) 1) Remove the paper feed tray units 1 and 2. (See “a. Paper feed tray units 1 and 2” in “(Paper feed tray sections 1 and 2)” 2) Remove the E-ring, slide the winding pulley, and loosen the wire.

- Page 73 ∗ Turn it counterclockwise and fit with the T-shape pin position and 3) Remove the E-ring, slide the winding pulley, and loosen the wire. insert. 4) Release the pawl, and remove the wire. b-1. Paper remaining quantity sensor PWB 1) Remove the paper feed tray units 1 and 2. (See “a. Paper feed tray units 1 and 2”...

- Page 74 : Feb. 6 2004 b-3. Paper feed trays 1 and 2 sensor 4) Remove the dry heater. 1) Remove the rear cabinet. 2) Disconnect the connector, and remove the paper feed trays 1 and 2 sensor. b-4. Dry heater 1) Remove the rear cabinet. (See “b-3. Paper feed trays 1 and 2 sen- sor”...

- Page 75 (Paper feed trays 3 and 4) A. Major parts and signal functions CN-17 B30B-PHDSS-B M2LUM +24V1 GND2 /T1PFC +24V1 +24V1 /M2PFC PHR-2 /DSKPFC2 GND2 M2LUM GND2 GND2 M2LUM TXD-FIN PHNR-02-H+BU02P-TR-P-H GND2 +5V2 +24V1 +24V1 RXD-FIN /M2PFC /M2PFC GND2 /DTR-FIN TXD-FIN MMCLK RXD-FIN /DSR-FIN...

- Page 76 Signal Code Name Function/Operation Type Model Note name M1LUD M1LUD Paper tray upper limit detector Paper tray upper limit detection Transmission Paper feed tray system (Paper feed tray 3) (Paper feed tray 3) type sensor M1PED M1PED Paper empty detector (Paper Paper empty detection (Paper Transmission Paper feed tray system...

- Page 77 B. Operational descriptions 2) Paper size detection The paper size detection is made by the combination of the cas- (1) Each paper feed tray paper size detection method sette paper size detector 1 to 4. a. Multi-purpose paper feed tray (Tray 3), paper feed tray (Paper feed tray 4) CSS1 1) Paper width detection...

- Page 78 (2) Remaining paper detection a. Remaining paper detection b. Detection method Remaining paper detection is performed according to four stages, i.e. The number of remaining sheets is determined according to the num- three stages with paper and one stage with no paper, and the result is ber of times the remaining paper sensor changes from the time the displayed.

- Page 79 : Feb. 6 2004 C. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 80 : Feb. 6 2004 a. Paper feed tray units 3 and 4 5) Disconnect the connectors. 1) Gently pull out the paper feed tray until it stops. 6) Remove the paper feed tray paper feed units 3 and 4 from the lower shelf.

- Page 81 a-2. Paper feed roller 5) Remove the E-ring, and one-way clutch. 1) Remove the paper feed tray units 3 and 4. (See “”) 6) Remove the E-ring and shift the separation roller shaft. 2) Remove the paper guide. (See “a-1. Pickup roller”) 3) Release the pawl, and remove the paper feed roller.

- Page 82 3) Remove the solenoid unit. a-8. Transport roller 8, 10 1) Remove the paper feed tray 3/4. (See “”) 2) Remove the cover.(See “a-5. Paper pickup solenoid”) 3) Remove the E-ring and remove the pulley bearing. 4) Remove the paper pickup solenoid. 4) Remove the transport roller 8, 11.

- Page 83 : Feb. 6 2004 a-10. Paper pass detector 3) Remove the paper remaining quantity detector cover. Remove the paper remaining quantity detector. 1) Remove the paper feed tray 3/4. 2) Remove the cover. (See “a-5. Paper pickup solenoid”) 3) Remove the paper pass detector unit. b-3.

- Page 84 : Feb. 6 2004 4) Remove the rear cabinet. 5) Disconnect the connector from the dehumidifying heater relay PWB, and remove the band. 6) Remove the dry heater unit. 7) Remove the dry heater. AR-M550/M620/M700 DETAILS OF EACH SECTION 6 - 29...

-

Page 85: Paper Transport Section]

[Paper Transport Section] Outline The paper transport section serves the function of transferring paper from each paper feed port to the registration roller section. Paper from manual feed, paper feed tray units 1 and 2 (optional), and the right paper feed tray of the paper feed tray units 1 and 2 is trans- ported horizontally, whereas paper from the left paper feed tray of the paper feed tray units 1 and 2, paper feed tray 3 and paper feed tray 4 is transported vertically to the registration roller section. - Page 86 : Feb. 6 2004 Signal Code Name Function/Operation Type Model Note name DSKPFC2 DSKPFC2 Paper feed tray 3/4 paper Paper transport roller 11 ON/OFF control Electromagnetic transport clutch 2 clutch Vertical paper transport Drives the paper transport rollers 4 and 13. Stepping motor Normal speed mode motor Main motor...

- Page 87 a. Left lower cabinet unit c. Paper feed tray 1 and 2 left PG unit 1) Open the left lower cabinet. 1) Remove the left lower cabinet. (See “a. Left lower cabinet unit”) 2) Remove the resin E-ring, and remove the pressure fulcrum shaft. 2) Remove the left vertical transport unit.

- Page 88 d. Vertical transport upper unit 3) Remove the upper PG holding plate. 1) Open the left door. 2) Remove the resist roller unit. 3) Disconnect the connector, and remove the vertical transport upper unit. 4) Remove the vertical transport upper PG. d-1.

- Page 89 (Vertical paper transport section 2) A. Major parts and signal functions PSBC MPRD2 MPRD1 CN-17 PCU PWB B30B-PHDSS-B M2LUM +24V1 GND2 CN-12 B30B-PHDSS-B /T1PFC +24V1 +24V1 +24V1 +24V1 /T2PFC /M2PFC /HPLS /DSKPFC2 PHNR-06-H+BU06P-TR-P-H PHNR-02-H+BU02P-TR-P-H +24V1 GND2 DVCH1 +24V1 +24V1 +24V1 GND2 /HPFC /PSBC...

- Page 90 : Feb. 6 2004 Signal Code Name Function/Operation Type Note name MPRD1 MPRD1 Paper feed tray 2 paper pass Manual feed/paper feed tray 2/LCC paper Transmission Paper transport system sensor detector 1 pass detection type MPRD2 MPRD2 Paper feed tray 2 paper pass Manual feed/paper feed tray 2/LCC paper Transmission Paper transport system sensor...

- Page 91 : Feb. 6 2004 (2) Maintenance and parts replacement 2) Remove the paper dust removing unit. (List of Replacement Parts) Unit Parts Resist roller unit Resist roller (Idle) Resis roller break clutch Transport roller 15 Resist roller (Drive) Resist roller front paper pass detector Paper dust cleaner 3) Remove the rear frame side cover, and disconnect the connector.

- Page 92 a-1. Resist roller (Idle) a-2. Resist roller break clutch 1) Remove the resist roller unit. (See “a. Resist roller unit” in this sec- 1) Remove the resist roller unit. (See “a. Resist roller unit” in this sec- tion) tion) 2) Remove the cover. 2) Remove the cover.

- Page 93 a-4. Resist roller (Drive) a-5. Resist roller front paper pass detector 1) Remove the resist roller unit. (See “a. Resist roller unit” in this sec- 1) Remove the resist roller unit. (See “a. Resist roller unit” in this sec- tion) tion) 2) Remove the follower roller and the tension spring.

- Page 94 : Feb. 6 2004 (Horizontal transport section) A. Major parts and signal functions HPFC T1PPD MPRD2 MPRD1 MPFD2 LPPD CN-17 CN-12 B30B-PHDSS-B B30B-PHDSS-B +24V1 M2LUM +24V1 +24V1 /T2PFC GND2 /HPLS /T1PFC +24V1 +24V1 DVCH1 +24V1 /HPFC /M2PFC DVCH2 /DSKPFC2 +24V1 GND2 DVCH3 GND2...

- Page 95 : Feb. 6 2004 Signal Code Name Function/Operation Type Note name MPFD2 MPFD2 Manual feed paper pass detector 2 Manual tray and LCC unit paper pass Transmission Paper transport system detection type sensor Main motor Drives the paper feed trays 1, 2, 3, and 4, DC brushless Paper pass and the manual paper feed section.

- Page 96 a. Relay pass unit a-1. Paper guide lock solenoid 1) Pull out the multi manual paper feed tray unit. 1) Remove the relay pass unit. (See “a. Relay pass unit” in this sec- tion) 2) Disconnect the connector, and remove the paper guide lock sole- noid unit.

- Page 97 a-3. Paper guides 6) Remove the E-ring from transport roller 3 and 4 (Drive), and remove the belt pulley. 1) Remove the relay pass unit. (See “a. Relay pass unit” in this sec- tion) 2) Remove the lower paper guide unit. (See “a-2. Lower paper guide unit”...

- Page 98 : Feb. 6 2004 a-7. Paper feed tray 2 paper pass detector 1 b-1. Manual paper pass detector 2 a-8. Paper feed tray 2 paper pass detector 2 b-2. No. 5 paper feed paper pass detector 1) Remove the relay pass unit. 1) Remove the multi manual paper feed unit.

-

Page 99: Paper Exit And Turning Section]

: Feb. 6 2004 [Paper exit and turning section] A. Outline The paper exit and turning section discharges paper which is trans- ported from the fusing section, and detects paper full. It also turns paper to transport it to the duplex or the finisher. B. - Page 100 : Feb. 6 2004 Signal Code Name Function/Operation Type Note name POD1 POD1 Paper exit detector 1 Paper exit detection from fusing Transmission Paper transport system sensor type POD2 POD2 Paper exit detector 2 Paper pass detection from paper exit Transmission Paper transport system sensor type...

- Page 101 : Feb. 6 2004 (2) Maintenance and parts replacement 5) Disconnect the connectors. 6) Remove the front fixing bracket. (List of Replacement Parts) 7) Remove the paper exit unit in the arrowed direction. Unit Parts Paper exit unit Transport roller 16 Paper exit roller 1 Fusing cooling fan motor 1 Fusing cooling fan motor 3...

- Page 102 4) Remove the E-ring to remove the gear. 4) Remove the E-ring to remove the gear. 5) Remove the transport roller in the arrowed direction. 5) Remove the paper exit roller 1 in the arrowed direction. a-3. Fusing cooling fan motor 1 a-2.

- Page 103 : Feb. 6 2004 3) Remove the fusing cooling fan motor 1 (A), 3 (B), and 4 (C). 3) Remove the paper exit detection 1 detector. REVERSE a-8. Paper exit detector 2 a-9. Paper exit detector 3 1) Remove the paper exit unit. (See “a. Paper exit unit” in this section) Fan blowing direction 2) Remove the upper cover.

- Page 104 : Feb. 6 2004 (Duplex section) A. General When duplex print is selected, paper one surface of which was printed is switched back to feed to the duplex section to make duplex print. B. Major parts and signal functions ADM1 DSW-ADU AINPD DSW-L...

- Page 105 : Feb. 6 2004 Signal Code Name Function/Operation Type Model Note name AINPD AINPD Duplex (ADU) paper entry Duplex (ADU) paper entry Transmission Paper transport system detector detection, detection of paper exit type sensor to finisher APPD1 APPD1 Duplex (ADU) paper pass Duplex (ADU) upstream paper Transmission Paper transport system...

- Page 106 C. Operational descriptions 4) When the specified time has passed from reverse rotation of POM2, DGS (paper exit guide) turns on for a certain time and (1) Paper transport operation in duplex print paper is sent to the reverse section. a.

- Page 107 : Feb. 6 2004 D. Maintenance and parts replacement AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K When AR-M620U/N, AR-M700U/N (PM: 300k) 300K 600K 900K 1200K 1500K 1800K 2100K 2400K Remark calling Unit name Part name Duplex Transport rollers Transport paper guides (1) Maintenance and parts replacement...

- Page 108 a. Left door unit a-1. ADU opening/closing door 1) Pull out the left door. 1) Pull out the left door. 2) Remove the stopper section plastic E-ring. 2) Remove the front cabinet. 3) Remove the stopper from the fulcrum shaft to remove the opening/ closing door in the arrowed direction.

- Page 109 a-3. Transport roller 19 9) Remove the ground plate. a-4. Transport roller 20 a-5. Transport roller 21 1) Pull out the left door. 2) Remove the ADU opening/closing door. 3) Remove the left door cabinet F. 4) Remove the left door cabinet R. 10) Remove the belt.

- Page 110 : Feb. 6 2004 15) Remove the bearing, pulley, gear and pin from the transport roller a-8. Paper exit gate solenoid 1) Pull out the left door. 2) Remove the cover. a-6. Duplex motor 1 1) Pull out the left door. 2) Remove the cover.

- Page 111 : Feb. 6 2004 4) Remove the duplex paper entry detector. a-11. Left door transport paper guide R unit. 1) Pull out the left door. 2) Remove the transfer unit. a-10. Duplex paper pass detector 1 3) Remove the cover, and remove the connector, the snap band, and 1) Pull out the left door.

- Page 112 a-13. Paper pass detector 2 4) Remove the PWB holder. 1) Pull out the left door. 2) Remove the left door transport paper guide R unit. 3) Remove the paper pass detector 2. 5) Remove the transfer separation unit. a-14. Transfer high voltage transformer 1) Pull out the left door.

- Page 113 : Feb. 6 2004 a-17. Paper exit gate 3) Remove the switchback gate. 1) Pull out the left door. 2) Remove the paper guide. Open the door, and remove the cabinets. 3) Remove the paper exit gate. a-19. Left door open/close detector 1) Pull out the left door.

- Page 114 : Feb. 6 2004 a-20. Duplex cover open/close detector a-22. Reversing discharge brush 1) Pull out the left door. 1) Pull out the left door. 2) Open the door, and remove the cover. 2) Remove the switchback gate. 3) Remove the reversing discharge bursh. 3) Remove the duplex cover open/close detector.

-

Page 115: Laser Scan Unit (Lsu)

3. Laser scan unit (LSU) A. General This section performs the following operations. Image data sent from the MFP (image process circuit) through the mother board and PCU are converted into laser beams to radiate onto the drum surface. B. Major parts and signal functions CN-8 CN-8 CN-6... - Page 116 600dpi Main scan = 60 - 85 µm Beam diameter: Sub scan = 75 - 110 µm Laser power: 0.385±0.04mW (AR-M550N/U, AR-M620N/U) 0.480±0.04mW (AR-M700N/U) LD wave length: 770 - 795nm ∗ This unit must not be disassembled in the market.

- Page 117 : Feb. 6 2004 D. Maintenance and parts replacement 4) Disconnect the connectors to remove the LSU unit. (1) Maintenance and parts replacement (List of Replacement Parts) Unit Parts a. LSU 1) Pull out the multi paper feed tray, and remove the manual paper feed cover F.

-

Page 118: Image Process Section

Cleaning mode Transfer mode AC4.5kv Cleaning Developing 1.0 - 1.5kv (35µA) mode mode -100v Ω AR-M550N/U, +150v -500v AR-M620N/U 2.0 - 2.5kv (40µA) AR-M700N/U Name Functions Laser beams Forms electrostatic latent images on the OPC drum. (Writing resolution: 600dpi) Radiated from the LSU. The output can be set with the simulation. (Basically not changed from the default.) OPC drum Electrostatic latent images are formed by laser beams. -

Page 119: Toner Hopper And Toner Bottle Section]

: Feb. 6 2004 Name Functions Transfer roller Applies a voltage to transfer toner from the OPC drum to paper. Drum separation pawl Separates paper from the OPC drum mechanically. Cleaning blade Cleans and scrapes toner from the OPC drum. Resist roller Deflects paper to adjust the paper feed timing to the process section. -

Page 120: Toner Hopper

B. Major parts and signal functions TM1X TM2X TFSD CRUM TONER HOPPER PHR-4 TSDP-12V-K/TSDR-12V-K +24V1 +24V1 TFSD TFSD (NC) GND2 GND2 (NC) CN-11 B12B-PHDSS-B TM1a TM1b TM1a (NC) GND2 GND2 TM1b +5V2 +5V2 SMR-02V-N/SMP-02V-NC CRUCLK TM2a PCU PWB TM1a CRUSDA CRUCLK TM1b GND2... - Page 121 C. Operational descriptions (1) Composition Shutter lock pawl TB holder upper Toner bottle TB shutter TB holder lower CRUM TH shutter TB holder upper Heat seal Toner bottle TB holder lower CRUM The toner cartridge is composed of the toner bottle with toner filled in it, the TB holder lower which holds the toner bottle and to which the CRUM and the waste toner box assembly are attached, and the TG holder upper.

- Page 122 : Feb. 6 2004 D. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 123 b-1. Toner sensor 4) Disconnect the connector, and remove the toner motor unit. 1) Remove the toner hopper unit. (See “b. Toner hopper unit” in this section) 2) Remove the cover. 5) Remov the toner motor 2. 3) Remove the toner sensor. b-2.

-

Page 124: Developer Tank Section]

: Feb. 6 2004 [Developer tank section] A. General In this section, toner is attached to electrostatic latent images formed by laser beams on the OPC drum, making visible images. B. Major parts and signal functions CN-5 B16B-PADSS-1 +38V +38V AC PWB +38V GND1... - Page 125 : Feb. 6 2004 C. Operational descriptions Electrostatic latent images formed on the OPC drum by the LED (writ- ing) unit (LED image light) are converted into visible images by toner. layer Aluminum Drum Cleaning Developing mode mode +150v -500v Toner in the developing unit is stirred by the mixing roller.

- Page 126 : Feb. 6 2004 D. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 127 3) Turning the MG roller, take out the old developer. a-3. MG holders F and R 1) Take out the developing tank. (See “a. Developing unit” in this sec- tion) 2) Remove the DV cover. (See “a-1. Developer” in this section) 3) Remove the doctor cover.

- Page 128 8) Remove the MG roller unit. a-5. Toner concentration sensor 1) Remove the developing tank. (See “a. Developing unit” in this sec- tion) 2) Remove the DV cover. (See “a-1. Developer” in this section) 3) Remove the toner concentration sensor. 9) Remove the doctor attaching plate.

-

Page 129: Opc Drum Section]

[OPC drum section] A. General In this section, laser beams are radiated to the OPC drum surface which was negatively charged, making electrostatic latent images. B. Major parts and signal functions CN-5 B2PS-VH B16B-PADSS-1 +38V 1 +38V GND1 +38V AC PWB +38V S5B-PH-K-S GND1... - Page 130 C. Operational descriptions 3) After transfer operation, remaining toner is removed by the clean- ing blade. The OPC drum surface is negatively charged by the main charger. The laser beam images are radiated to the OPC drum surface by the laser unit to form latent electrostatic images.

- Page 131 : Feb. 6 2004 D. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 132 : Feb. 6 2004 AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K Remark (PM: 300k) calling Unit name Part name Drum Sawtooth peripheral 10 Screen grid section 11 MC cleaner (2) Maintenance and parts replacement...

- Page 133 : Feb. 6 2004 a. Process unit a-1. OPC drum 1) Open the front door. 1) Disconnect the connectors. 2) Open the process cover. 3) Open the left door. 4) Remove the MC charger unit. 5) Remove the blue screw. 6) Unfix the drum to remove the bearing.

- Page 134 : Feb. 6 2004 a-2. Separation pawl a-5. Side seal F/R 1) Remove the OPC drum. (See “a-1. OPC drum” in this section) a-6. Side seal R base sheet 2) Remove the plastic E-ring. 1) Remove the OPC drum unit. (See “a-1. OPC drum” in this section) 3) Remove the separation pawl.

- Page 135 : Feb. 6 2004 4) Remove the brush roller. a-9. OPC drum cleaner temperature sensor 1) Remove the upper cover. a-7. Process adsorption plate 1) Remove the drum unit. 2) Remove the cover to remove the adsorption plate. a-8. Drum separation pawl solenoid 2) Remove the OPC drum cleaner temperature sensor.

- Page 136 : Feb. 6 2004 a-11. Image density sensor 1) Remove the upper cover. (See “a-9. OPC drum cleaner tempera- ture sensor” in this section) 2) Disconnect the connector. 3) Remove the OPC drum unit. (See “a-1. OPC drum” in this section) 4) Remove the image density sensor.

-

Page 137: Transfer Section]

: Feb. 6 2004 [Transfer section] A. General In this section, toner images on the OPC drum are transferred to paper. B. Major parts and signal functions TURM DRAWER CN-7 CN-15 DSW-L B32B-PHDSS-B LEFT DOOR UNIT B34B-PHDSS-B /ADUM2/A +24V1 7 MHV-T /ADUM2A /THV+PWM +24V1... - Page 138 Cleaning roller Transfer belt cleaning mode cleaning mode -2.0kv 2.0kv AC4.5kv 1.0 - 1.5kv (35µA) -100v 10 Ω (AR-M550N/U, AR-M620N/U) Cleaning roller Transfer mode cleaning mode 2.0 - 2.5kv (40µA) (AR-M700N/U) AC4.5kv 1.0 - 1.5kv (35µA) -100v (AR-M550N/U, AR-M620N/U) Cleaning timing: 10 Ω...

- Page 139 : Feb. 6 2004 D. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 140 : Feb. 6 2004 a. Transfer unit 5) Remove the transfer belt unit. (See “a-1. Transfer drive gear” in this section) 1) Open the left door unit. 6) Remove the ground members. 2) Loosen the blue screw and open the holder to remove the transfer unit.

- Page 141 : Feb. 6 2004 a-2. Transfer belt a-6. Transfer cleaning roller 1) Remove the transfer unit. (See “a. Transfer unit” in this section) 1) Remove the transfer unit. (See “a. Transfer unit” in this section) 2) Remove the transfer belt unit. (See “a-1. Transfer drive gear” in 2) Remove the transfer belt unit.

-

Page 142: Main Charger Section]

: Feb. 6 2004 [Main charger section] A. General The OPC drum surface is negatively charged in this section. B. Major parts and signal functions PCU PWB CN-1 CN-15 B16B-PH-K-S B34B-PHDSS-B PS-187(RD) DSW-F DSW-F GND2 (NC) GND2 GND2 PS-187(YL) /GBPWM GND2 /GBPWM /MHVREM... - Page 143 : Feb. 6 2004 4) Remove the main charger unit. 2) Lifting one end up, slide off the saw blade holder. a-1. Screen grid 1) Loosen the screw. a-3. MC cleaner 1) Remove the screen grid. (See “a-1. Screen grid” in this section) 2) Remove the saw teeth plate.(See “a-2.

-

Page 144: Scanner Section

5. Scanner section A. General There are following three methods of scanning documents in this machine. a. Place a document on the table glass. The copy lamp unit is oper- ated to radiate copy lamp light onto the document, scanning the document with the CCD. - Page 145 B. Major parts and signal functions CIS unit MHPS Copy lamp unit Scanner motor CCD PWB CCD lens unit MHPS CIS unit Copy lamp unit MIMDA CCD PWB TX25-100P-LT-H1 TX24-100R-LT-H1 /1_DBL- /1_DBL- /1_DBL+ /1_DBL+ 1_CLK- 1_CLK- CIScnt 1_CLK+ 1_CLK+ 1_DATA0- 1_DATA0- 1_DATA0+ 1_DATA0+...

- Page 146 : Feb. 6 2004 Code Signal name Name Function/Operation Type Model Note Scanner (reading) motor Drives the scanner (reading) section. Stepping motor MHPS MHPS Scanner home position Scanner home position detection Transmission type Sensor sensor detector CIS unit CIS unit Contact-type image scan sensor unit Back document image scan CCD PWB...

- Page 147 Copy lamp unit CCD UN MOTHER PWB PCU PWB MFP CONTROL PWB DRUM (4) Carriage (lamp unit) shift (scan) speed The carriage scan speed depends on the copy magnification ratio. Speed up to 171% = 220mm/s Speed of 172% - 400% = 110mm/s (5) Timing chart Platen timing chart Feed...

- Page 148 : Feb. 6 2004 D. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K Remark When AR-M620U/N, AR-M700U/N (PM: 300k)

- Page 149 (2) Maintenance and parts replacement a. Scanner unit 1) Remove the SPF unit. (See “a. SPF unit” in the “SPF section”) (Replacement parts) 2) Remove the table glass. (See “a-1. Table glass” in this section) Unit Parts Scanner Table glass 3) Remove the panel lock connector.

- Page 150 : Feb. 6 2004 7) Remove the tray. a-1. Table glass a-2. Slit glass (SPF scan mode) (When executing internal maintenance of the scanner) 1) Loosen the screws in the hinge section, and lower the two metal fixtures. 8) Remove the left side cabinets front and rear. 2) Open the SPF, and slide the SPF drop-preventing stopper pin of the Hinge L to the drop preventing position.

- Page 151 : Feb. 6 2004 a-3. Mirror 5) Remove the lens cover. a-4. Lens a-5. Reflector 1) Remove the table glass. (See “a-1. Table glass” in this section) 2) Move the lamp unit. 6) Cary out cleaning of the lens and CCD. 3) Clean mirrors 2 and 3.

- Page 152 a-7. Rails 3) Remove the front side connector. 1) Remove the table glass. (See “a-1. Table glass” in this section) 2) Grease up the rails. a-8. Drive belt a-9. Drive wire a-10. Pulley 4) Turn up the cutout mylar and remove the screw; then shift the lamp 1) Remove the table glass.

- Page 153 : Feb. 6 2004 a-13. CCD lens unit a-14. Scanner relay PWB 1) Remove the table glass. (See “a-1. Table glass” in this section) 1) Remove the table glass. (See “a-1. Table glass” in this section) 2) Remove the harness cover B. 2) Remove the harness clamp and the dark box.

- Page 154 : Feb. 6 2004 3) Remove the scanner motor unit. 4) Remove the scanner control PWB unit. 5) Remove the scanner control PWB. 4) Remove the scanner motor. a-18. SPF open/close detector 1) Remove the rear cabinet. (See “a-15. Scanner motor” in this sec- tion) 2) Disconnect the connector, and remove the SPF open/close detec- tor.

- Page 155 : Feb. 6 2004 3) Disconnect the connector, and remove the scanner home position 4) Remove the document detection arm lower, and remove the docu- sensor. ment detection light emitting unit. a-20. Document size detection light emitting PWB 1) Remove the SPF unit. (See “a. SPF unit” in the “7. SPF section”) 2) Disconnect the connector and the earth terminal, and remove the a-21.

-

Page 156: Fusing Section

(2 pcs.) heat roller Heat lamp Sub power PWB (1 pc) B. Major parts and signal functions AR-M550N/U, AR-M620N/U +12VS GND2 AC-MON FW-SUB HLCNT3 GND2 +24VPR HLPR12 GND2 HLCNT2 HLCNT1 GND2 CN-4 CN-3 Sub power PWB CN-1 CN-2... - Page 157 : Feb. 6 2004 AR-M700N/U Sub power PWB Drawer connector HLTS2 HLTS1 RT H1 RTH2 Cross- sectional view of connector HLTS3 RTH 3 Signal Code Name Type Function/Operation Active condition Note name RTH1 RTH1 Fusing temperature Thermistor Detects the surface temperature of the fusing roller Analog input sensor (1) (heating).

- Page 158 Name Cleaning sheet Auxiliary heat roller Fusing roller (Pressing) Cleaning scraper (AR-M550N/U, AR-M620N/U) Discharge brush Two heater lamps are provided for the fusing heat roller (heating) and Fusing roller (Heating) one heater lamp is provided for the auxiliary heat roller for the fusing roller (pressing) to heat paper from above and below.

- Page 159 : Feb. 6 2004 D. Maintenance and parts replacement (1) Maintenance list (AR-M550N/U, AR-M620N/U) : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K...

- Page 160 : Feb. 6 2004 (2) Maintenance list (AR-M700N/U) : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M700U/N (PM: 300K) 300K 600K 900K 1200K 1500K 1800K 2100K 2400K When Remark calling Unit name No.

- Page 161 Heater lamp 2 a-10 Heat roller gear a-11 Thermistor (upper) Pressure roller a-19 Cleaning scraper a-18 (AR-M550N/U, AR-M620N/U) Oil roller (AR-M700N/U) a-16 CL roller bearing (AR-M700N/U) Paper guide Cleaning plate (AR-M700N/U) a-15 Sub heat roller Sub heat roller bearing Thermistor (lower)

- Page 162 : Feb. 6 2004 3) Release the fixing members on the rear frame side. 3) Remove the heat roller separation pawl. a-2. Pressure roller separation pawl 4) Release the right and left lock levers of the fusing unit to remove the fusing unit.

- Page 163 : Feb. 6 2004 7) Clean the upper thermistor. 3) Remove the screws to open the fusing unit. NOTE: Be careful of deformation of the plate spring of the ther- mistor. 4) Remove the lamp fixing screw. NOTE: The thermistor position can be changed by shifting the thermistor mounting plate.

- Page 164 • When installing the pressure roller to the fusing unit, be careful not to damage the cleaning blade. If the cleaning plate would be deformed, copy dirt would be resulted. [Note for assembly (AR-M550N/U, AR-M620N/U)] a-9. Cleaning scraper (AR-M550N/U, AR-M620N/U) • Wind paper with the scraper tip without scratching the pressure 1) Remove the fusing unit.

- Page 165 : Feb. 6 2004 [Cleaning] a-12. Paper guide • Clean and remove paper dust and toner remained in the concave of 1) Remove the fusing unit. (See “a. Fusing unit” in this section) the scraper holder. 2) Release the pressure. (See “a-4. Heater lamp 1” in this section) 3) Remove the screw to open the fusing unit.

- Page 166 : Feb. 6 2004 a-14. Sub heat roller 7) Remove the thermistor. a-15. Sub heat roller bearing a-16. Thermistor (lower) a-17. Sub heater lamp Marks 1) Remove the fusing unit. (See “a. Fusing unit” in this section) 2) Release the pressure. (See “a-4. Heater lamp 1” in this section) 3) Lay the unit on its side to prevent paper dust from dispersing, and remove the lower cover.

- Page 167 : Feb. 6 2004 a-18. Thermostat 1 5) Do not lay the unit with the discharge brush on the lower side. a-19. Thermostat 2 Cleaning 1) Remove the fusing unit. (See “a. Fusing unit” in this section) 2) Remove the thermostat 1 (A) and the thermostat 2 (B). NOTE: Clean and remove paper dust.

-

Page 168: Spf Section

7. SPF section A. General Sheet documents are automatically fed and transported for continuous scanning. The front and the back surfaces of duplex sheet documents can be scanned at a time. Name Function Document tray Paper feed tray for documents. Max. loading capacity of documents: 150 sheets (80g/m²) or 19.5mm or less Pickup roller Picks up a document and transports it to the document feed roller. -

Page 169: External Outfit Section]

: Feb. 6 2004 [External outfit section] 3) Remove the harness. A. Maintenance and parts replacement (1) Maintenance and parts replacement (Replacement parts) Unit Parts SPF unit Cabinet Document mat [Note for assembly] Install the earth terminal in the direction shown in the figure below. a. - Page 170 : Feb. 6 2004 a-1. Cabinet a-2. Document mat 1) Open the cover and remove the screws. 1) Open the SPF. 2) Remove the mat. 2) Open the SPF and remove the screws. Caution when attaching • Place the mat on the document base glass surface; close the SPF to 3) Unhook the claws on the tray side to remove the front cover.

-

Page 171: Paper Feed Tray Section]

[Paper feed tray section] A. Major parts and signal functions SPLS2 SPLS1 /SLUMB SPWS TX24-100R-LT-H1 TX25-100P-LT-H1 SPED2 /1_DBL- /1_DBL- /1_DBL+ /1_DBL+ 1_CLK- 1_CLK- STLD SCNcnt SPWS 1_CLK+ 1_CLK+ 1_DATA0- 1_DATA0- 1_DATA0+ 1_DATA0+ 1_DATA1- 1_DATA1- 1_DATA1+ 1_DATA1+ 1_DATA2- 1_DATA2- 1_DATA2+ 1_DATA2+ 1_DATA3- 1_DATA3- 1_DATA3+... - Page 172 B. Operational descriptions C. Maintenance and parts replacement (1) Document tray lift operation (1) Maintenance and parts replacement When a job is started, the document tray is lifted until a document at (Replacement parts) the top in the document tray turns on the document upper limit sensor Unit Parts (STUD).

- Page 173 4) Disconnect the connector, and remove the SPF document length b-2. SPF paper tray lower limit detector detector 1 (A) and the SPF document length detector 2 (B). b-3. SPF document empty detector 1) Remove the cabinet. (See “a-1. Cabinet” in the previous section, “[External outfit section]”) 2) Remove the document tray unit.

-

Page 174: Paper Feed/Transport Section]

: Feb. 6 2004 [Paper feed/transport section] A. Major parts and signal functions SPFM SCOV SPFC SPED1 STUD SPPD1 STRRBC STRRC STRBC STRC PHNR-2-H PHNR-2-H +BU2P-TR-P-H /SPFC 24V3 B3B-PH-K-S SCOV B3B-PH-K-S SPPD2 B14B-PH-K-S SPPD1 /SPFC SPF PWB 24V3 SCOV SPPD1 B3B-PH-K-S SPED1 SPED1... - Page 175 : Feb. 6 2004 B. Operational descriptions (1) Document feed, transport, scan, paper exit, and operating speed The document fed by the take-up roller is sent through the paper feed roller and the transport roller to the resist roller section. In the resist roller section, the document lead edge and the scan start position are synchronized.

- Page 176 : Feb. 6 2004 (2) Maintenance and parts replacement a-1. Paper feed roller (Replacement parts) a-2. Pickup roller Unit Parts 1) Pull up the lever and open the upper cover. Paper feed Document feed roller unit Pickup roller SPF paper feed clutch SPF document tray upper limit detector SPF document upper limit...

- Page 177 : Feb. 6 2004 4) Remove the E-ring, and remove the SPF paper feed clutch. b-2. SPF paper feed/paper transport motor 1) Remove the rear cover. (See “a-1. Cabinet” in the previous sec- tion, “[External outfit section]”) 2) Remove the SPF paper feed/paper transport motor. 5) Disconnect the connector, and remove the SPF document tray upper limit detector (A), the SPF document upper limit detector (B), the SPF cover switch (C), and the SPF document paper pass...

- Page 178 4) Remove the separation roller. (Refer to "b-1. Separation roller" in 10) Remove the No. 1 resist roller drive in the arrow direction. this section.) 5) Remove the paper feed paper guide lower unit in the arrow direc- tion. b-7. SPF paper transport roller 2 brake clutch b-8.

- Page 179 3) Remove the plastic E-ring to remove the bearing. 10) Remove the lever and shaft. 6) Remove the belt, and remove the transport roller 1 in the arrowed 11) Remove the transport roller 2 in the arrowed direction. direction. b-11. SPF document paper pass detector 2 7) Remove the plastic E-ring to remove the bearing.

-

Page 180: Cis Section]

: Feb. 6 2004 [CIS section] A. Major parts and signal functions CIScnt B12B-PHDSS-B 9604S-35F SCN cnt PWB /LST SCLK CN10 S26B-PHDSS-B B26B-PHDSS 2_DATA1- 2_DATA1- 2_DATA1+ 2_DATA1+ 2_DATA0- 2_DATA0- CIS unit 2_DATA0+ 2_DATA0+ 2_CLK- 2_CLK- FFC-35Pin 2_CLK+ 2_CLK+ /LST /2_DBL- /2_DBL- /2_DBL+ /2_DBL+... - Page 181 : Feb. 6 2004 (2) Maintenance and parts replacement 6) Open the SPF, attach the SPF drop preventing stopper, and (Replacement parts) remove the paper guide. Unit Parts CIS control PWB/CIS unit a-1. CIS control PWB/CIS unit 1) Remove the cabinet. (See “a-1. Cabinet” in the previous section, “[External outfit section]”) 7) Remove the ground lead and CIS.

-

Page 182: Paper Exit Section]

: Feb. 6 2004 [Paper exit section] A. Major parts and signal functions SPSM SRRBC SRRC SPOD SPPD4 SOCD SPPD3 B12B-PH-K-S SPFMB1 /SPFMB1 /SPFMA1 SPF PWB SMR-06V-B SMP-06V-BC SPFMA1 24V3 /SPFMB2 24V3 24V3 24V3 SPFMB2 24V3 SPFMA2 SPFMA2 24V3 /SPFMA2 /SPFMA2 B34B-PHDSS-B /SPFMB2... - Page 183 : Feb. 6 2004 C. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K When AR-M620U/N, AR-M700U/N (PM: 300k) 300K 600K 900K 1200K 1500K 1800K 2100K 2400K...

- Page 184 : Feb. 6 2004 a-2. SPF paper transport roller 3 brake clutch a-4. No. 2 resist roller (Drive) 1) Remove the cabinet. (See “a-1. Cabinet” in the previous section, a-3. SPF paper transport roller 3 clutch “[External outfit section]”) 1) Remove the rear cover. (See “a-1. Cabinet” in the previous sec- 2) Remove the document tray unit.

- Page 185 : Feb. 6 2004 a-5. Paper exit roller (Drive) a-6. SPF document paper pass detector 3 1) Remove the cabinet. (See “a-1. Cabinet” in the previous section, a-7. SPF document paper pass detector 4 “[External outfit section]”) a-8. SPF paper exit detector 2) Remove the document tray unit.

-

Page 186: Other]

: Feb. 6 2004 [Other] A. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K... - Page 187 : Feb. 6 2004 b. Drive unit 1) Remove the rear cover. (See “a-1. Cabinet” in the previous sec- tion, “[External outfit section]”) 2) Remove the electromagnetic clutch. 3) Loosen the screw to raise up the belt tension roller; then fix it by tightening the screw again.

-

Page 188: Drive Section

: Feb. 6 2004 8. Drive section A. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K AR-M620U/N, AR-M700U/N When 300K 600K 900K 1200K 1500K 1800K 2100K 2400K... - Page 189 : Feb. 6 2004 (2) Maintenance and parts replacement a-1. Paper exit motor 1 a-2. Paper exit motor 2 [Fusing drive section] 1) Remove the fusing unit. (See “a. Fusing unit” in the “6. Fusing sec- (Replacement parts) tion”) Unit Parts 2) Remove the fusing drive unit.

- Page 190 : Feb. 6 2004 2) Remove the tray. [Drum drive section] (Replacement parts) Unit Parts Drum drive unit Waste toner pipe lock detector Process humidity sensor Other OPC drum motor Developing motor 3) Remove the left cover cabinet. 4) Disconnect the connector and remove the harness clamp, and remove the paper exit tray duct R unit.

- Page 191 : Feb. 6 2004 a-1. Waste toner pipe lock detector 7) Remove the parts. 1) Remove the developing unit and the process unit. 2) Remove the OPC drum motor and the developing motor. (See “b- 1. OPC drum motor” and “b-2. Developing motor” in this section) 3) Remove the drum drive unit.

- Page 192 2) Remove the flywheel. a. Main drive unit 1) Remove the resist roller unit. (See “2. Paper feed, paper transport, duplex, and paper exit reverse sections” “(Vertical paper transport section 2)”, “a. Resist roller unit”) 2) Remove the flywheel. (See “b-1. OPC drum motor” in this section (a.

- Page 193 : Feb. 6 2004 a-1. Resist roller front drive motor 7) Remove the bearing, the E-ring, and the set screw, and remove the resist roller clutch. 1) Remove the resist roller unit. (See “2. Paper feed, paper transport, duplex, and paper exit reverse sections” “(Vertical paper transport section 2)”, “a.

- Page 194 : Feb. 6 2004 [Manual paper feed drive section] 3) Remove the plastic E-ring, the belt holding sheet, the belt, and the pulley. (Replacement parts) Unit Parts Manual paper feed drive unit ∗ When installing, be careful of the direction of the belt holding sheet. 4) Remove the harness from the clamp, and remove the manual paper feed unit.

- Page 195 : Feb. 6 2004 a. 1/2 paper feed drive unit 7) Remove the harness, and remove the drive joint plate. 1) Remove the main motor. (See “a-1. Main motor” in the “[Paper feed/paper transport drive section]”) 2) Remove the high voltage PWB unit. (See “a. Manual paper feed drive unit”...

- Page 196 : Feb. 6 2004 4) Remove the 1/2 paper feed drive frame lower. Remove the har- a-3. Paper feed clutch (Paper feed tray 1) ness clamp. 1) Remove the 1/2 paper feed drive unit. (See “a. 1/2 paper feed drive unit” in this section) 2) Remove the 1/2 paper feed drive frame lower.

- Page 197 b-1. Remove the paper tray lift-up motor (paper feed tray 1) a-5. Paper feed clutch (Paper feed tray 2) 1) Remove the rear cabinet. 1) Remove the 1/2 paper feed drive unit. (See “a. 1/2 paper feed drive unit” in this section) 2) Remove the 1/2 paper feed drive frame lower.

- Page 198 b-2. Paper tray lift-up motor (Paper feed tray 2) [3/4 paper feed drive section] 1) Remove the high voltage PWB unit. (See “a. Manual paper feed (Replacement parts) drive unit” in the “[Manual paper feed drive section]”) Unit Parts 2) Disconnect the connector, and remove the lift-up motor unit. 3/4 paper feed drive unit Paper feed clutch (Paper feed tray 3)

- Page 199 4) Disconnect the connector and remove the harness clamp. Remove 4) Disconnect the connector, and remove the paper feed clutch unit. the 3/4 paper feed drive unit. 5) Remove the E-ring, and remove the paper feed clutch. ∗ Remove the screw which was indicated with the arrow mark. a-1.

- Page 200 : Feb. 6 2004 a-3. Paper feed tray 3/4 paper transport clutch 1 b-1. Paper tray lift-up motor (Paper feed tray 3) 1) Remove the 3/4 paper feed drive unit. (See “a. 3/4 paper feed drive b-2. Paper tray lift-up motor (Paper feed tray 4) unit”...

-

Page 201: Filters

: Feb. 6 2004 9. Filters A. Maintenance and parts replacement (1) Maintenance list : Replace ∆: Adjust : Check (Clean, replace, or adjust as necessary.) : Clean : Lubricate : Shift position AR-M550U/N (PM: 250K) 250K 500K 750K 1000K 1250K 1500K 1750K 2000K When AR-M620U/N, AR-M700U/N (PM: 300k) 300K 600K 900K 1200K 1500K 1800K 2100K 2400K... -

Page 202: Pwb Section

: Feb. 6 2004 10. PWB section a-2. DV ozone filter a-3. Toner filter A. Maintenance and parts replacement 1) Remove the rear cabinet. (See “a-1. Ozone filter” in this section) (2) Maintenance and parts replacement 2) Remove the DV filter box. (Replacement parts) Parts PCU FLASH PWB... - Page 203 : Feb. 6 2004 2) Disconnect the connector, and remove the PCU PWB. 4) Remove the driver PWB. a-3. Driver PWB a-4. Mother PWB 1) Remove the rear cabinet and the rear cabinet upper. 1) Remove the driver PWB unit. (See “a-3. Driver PWB” in this sec- tion) 2) Remove the harness, and remove the mother PWB stay.

- Page 204 : Feb. 6 2004 a-5. Controller cooling fan motor a-7. HDD 1) Remove the driver PWB unit. (See “a-3. Driver PWB” in this sec- 1) Remove the cooling fan motor unit. (See “a-5. Controller cooling tion) fan motor” in this section) 2) Disconnect the connector and remove the harness clamp.

- Page 205 : Feb. 6 2004 3) Remove the soft NIC PWB unit. a-9. MFP FLASH ROM PWB 1) Pull out the NIC control unit. (See “a-8. Soft NIC PWB” in this sec- tion) 2) Release the lock, and remove the MFP Flash PWB. 4) Remove the soft NIC PWB angle from the soft NIC PWB.

-

Page 206: Power Section

: Feb. 6 2004 11. Power section a-2. DC main power PWB (Method 1) A. Maintenance and parts replacement 1) Remove the rear cabinet. (See “a-1. AC power PWB” in this sec- (1) Maintenance and parts replacement tion) (Replacement parts) 2) Disconnect the connector and remove the harness clamp. - Page 207 : Feb. 6 2004 a-3. Power cooling fan motor 1 3) Remove the AC/DC power unit. a-4. Power cooling fan motor 2 1) Remove the rear cabinet. (See “a-1. AC power PWB” in this sec- tion) 2) Disconnect the connector, and remove the AC power PWB unit.(See “a-1.

-

Page 208: Fan Motors

: Feb. 6 2004 a-6. DC sub power PWB 12. Fan motors 1) Remove the paper exit tray cabinet. A. Maintenance and parts replacement (1) Maintenance and parts replacement (Replacement parts) Unit Parts Developing cooling fan motor Paper cooling fan motor 2 Fusing cooling fan motor 2 Process exhaust fan motor 5 Process exhaust fan motor 4... - Page 209 : Feb. 6 2004 3) Disconnect the connector, and remove the DV fan. 3) Remove the left cover cabinet. Fan blowing direction a-2. Paper cooling fan motor 2 1) Remove the rear cabinet and the rear cabinet upper. 4) Open the left door. 5) Remove the left cabinet upper.

- Page 210 : Feb. 6 2004 7) Disconnect the connector, and remove the fusing cooling fan a-6. Process exhaust fan motor 1 motor. a-7. Process exhaust fan motor 2 a-8. Process exhaust fan motor 3 1) Remove the SPF unit. (See “6. Fusing section” in the “a. SPF unit”) 2) Remove the scanner unit.

- Page 211 : Feb. 6 2004 7) Remove the toner bottle. (See “a. Toner bottle unit” in “[Toner 15) Disconnect the connector and remove the harness clamp. Remove hopper and toner bottle section]”) the main duct unit. 8) Remove the toner hopper unit. (See “b. Toner hopper unit” in “[Toner hopper and toner bottle section]”) 9) Remove the developing unit.

- Page 212 : Feb. 6 2004 a-9. Process cooling fan motor 1 (LSU, process section) 4) Disconnect the connector, and remove the process cooling fan motors 1 (A), 2 (B), and 3 (C). a-10. Process cooling fan motor 2 (LSU, process section) a-11.

-

Page 213: Sensors And Switches

: Feb. 6 2004 13. Sensors and switches 7) Disconnect the connector, and remove the power switch. A. Parts replacement (1) Parts replacement (Replacement parts) Unit Parts Power switch Main power switch Front door open/close detector Left door open/close detector Dry heater switch Machine temperature sensor NOTE: When installing, be careful of the connector connecting... - Page 214 9) Remove the main power switch. 3) Disconnect the connector, and remove the left door open/close detector unit. Remove the left door open/close detector. 10) Remove the counter mounting plate. a-5. Dry heater switch 1) Remove the rear cabinet. 11) Disconnect the connector and remove the front door open/close switch unit.

- Page 215 : Feb. 6 2004 a-6. Machine temperature sensor 1) Pull out the multi paper feed tray, and remove the manual paper feed cover F. 2) Pushing the lower part, remove the right cabinet center. 3) Disconnect the connector, release the pawl, and remove the machine temperature sensor.

-

Page 216: Setting And Adjustments

: Feb. 9 2004 [7] SETTING AND ADJUSTMENTS Each adjustment item in the adjustment item list is associated with a specific JOB number. Perform the adjustment procedures in the sequence of Job numbers from the smallest to the greatest. However, there is no need to perform all the adjustment items. Perform only the necessary adjustments according to the need. Unnecessary adjustments can be omitted. -

Page 217: Adj 1] Adjusting High Voltage Values

: Feb. 9 2004 Job No Adjustment item list Simulation ADJ11 Adjusting the image quality in scan mode ADJ 11A Adjust the scan mode image density for all modes at once 46-21 ADJ 11B Scan mode image density adjustment/individual setup 46-21, 46-22, (standard mode) 46-23, 46-24,... - Page 218 : Feb. 9 2004 3) Go through the modes specified in Simulation 8-2. 4) Select the number that corresponds to the adjustment item using the numeric keypad. 5) Press the Start key. SIMULATION 8-2 MAIN GRID SETTING. SELECT 1-6, AND PRESS START. 6) Press the start key to have the voltage output for 30 seconds.

- Page 219 : Feb. 9 2004 4) Select the number that corresponds to the adjustment item using the numeric keypad. 5) Press the Start key. 6) Press the start key to have the voltage output for 30 seconds. The operation can be stopped with the CUSTOM SETTINGS key. If the output voltage is not within the requirement, do the following steps.

- Page 220 3) Go through the modes specified in Simulation 8-17. Transfer voltage adjustment (transfer roller cleaning/ transfer roller print modes) SIMULATION 8-17 This adjustment is needed in the following situations: TRANSFER ROLLER SETTING. SELECT 1-3, AND PRESS START. • The high voltage power PWB (TC cleaning) has been replaced. 1.SHV FRONT •...

-

Page 221: Adj 2] Adjusting The Developing Unit

4) Go through the modes specified in Simulation 8-18. 3) Loosen the DV doctor fixing screws. SIMULATION 8-18 TRANSFER CLEANING ROLLER SETTING. SELECT 1-2, AND PRESS START. 1.CRHV PLUS 2.CRHV MINUS Press [START] key. Press [CUSTOM SETTINGS] key. SIMULATION 8-18 TRANSFER CLEANING ROLLER SETTING. -

Page 222: Adj 3] Adjusting Image Distortions

: Feb. 9 2004 7) On both sides of the DV doctor and at its center, make sure that 5) Keeping the needle 2 to 3 mm off the DV roller surface, mark the the DV doctor gap is 0.525 ±0.03. DV roller surface at an extension of the needle tip. - Page 223 : Feb. 9 2004 No adjustment is needed if the difference between these dimen- sions is within 0.5 mm. SIMULATION 64-1 SELF PRINT MODE. SELECT 0-7, AND PRESS START. 0. TRAY SELECT 1. PRINT START 2. PRINT PATTERN:87 3. DENSITY 4.

- Page 224 : Feb. 9 2004 2) Manually turn the scanner drive pulley, and move Scanner Unit B until contact with the two stoppers on the CCD mounting plate. If Scanner Unit B makes contact with the two stoppers on the CCD mounting plate simultaneously, the parallelism of Scanner Unit B is proper.

- Page 225 8) Without moving the scanner unit drive shaft, manually turn the ADJ 3C Adjust scanned image distortions in the scanner unit drive pulley so that Scanner Unit B makes contact sub-scanning direction with both of the two stoppers on the CCD mounting plate at the same time.

- Page 226 If there is some distortion in the sub scanning direction, do the follow- 3) Check for distortions in the main scanning direction. ing steps. If the four angles of the rectangle on the copy are right angles, 4) Loosen either of two fixing screws of the scanner unit drive pulley. there is no distortion and therefore no further steps are needed.

-

Page 227: Adj 4] Adjusting The Spf Parallelism

4) Remove the document table glass, and make adjustments by turn- ADJ 3E Adjust scanned image distortions in the ing the main scanning direction image distortion adjusting screw. main scanning direction - 2 This adjustment is needed in the following situations: •... - Page 228 : Feb. 9 2004 3) Gently pulling out each check sheet for SPF levelness adjustment, 2) Copy the adjustment chart (created in step 1) to A3 (11" x 17") make sure that no gap is felt between the CIS guide boss and the paper in duplex mode, and then check the image for skews (Set in glass for SPF mode for each of the front and rear frame sides.

-

Page 229: Adj 5] Adjusting The Image Focus

: Feb. 9 2004 4) Open the SPF and loosen the screw. ADJ 5 Adjusting the image focus The result of this adjustment will affect all image scan modes (copy, scan, and fax). ADJ 5A Adjust the image focus in original table mode and SPF front-face mode (CCD) This adjustment is needed in the following situations: •... - Page 230 : Feb. 9 2004 4) Make a normal copy on A4 paper. 9) Slide the CCD unit in the arrow direction (CCD sub-scanning direc- tion) to change its mounted position. 5) Compare the copied image of the scale and the actual scale length in terms of length.

-

Page 231: Adj 6] Adjusting The Image Magnification

: Feb. 9 2004 4) Determine the image magnification factor using the following for- mula: Image magnification factor (%) = Copy dimension/original dimen- sion x 100 Example: Compare the copy and original dimensions by aligning the scale’s 10 mm position with the copied image’s 10 mm posi- tion. - Page 232 : Feb. 9 2004 5) Go through the modes specified in Simulation 48-1. ADJ 6B Adjust the image magnification in the sub-scanning direction in original table SIMULATION 48-1 mode (CCD) MAGNIFICATION ADJUSTMENT. SELECT 0-7, AND PRESS START. 0.TRAY SELECT 1.PRINT START This adjustment is needed in the following situations: 2.MAGNIFICATION •...

- Page 233 : Feb. 9 2004 ADJ 6C Adjust the image magnification in the SIMULATION 48-1 main scanning direction in SPF front- MAGNIFICATION ADJUSTMENT. SELECT 0-7, AND PRESS START. face mode (CCD) 0.TRAY SELECT 1.PRINT START 2.MAGNIFICATION This adjustment is needed in the following situations: 3.CCD(MAIN) 4.CCD(SUB) 5.SPF(SUB)

- Page 234 : Feb. 9 2004 1) On the SPF original tray, place such a duplex original as illustrated 5) Go through the modes specified in Simulation 48-1. below. SIMULATION 48-1 MAGNIFICATION ADJUSTMENT. SELECT 0-7, AND PRESS START. A4 size 0.TRAY SELECT 1.PRINT START 2.MAGNIFICATION 3.CCD(MAIN)

- Page 235 : Feb. 9 2004 ADJ 6E Adjust the image magnification in the SIMULATION 48-1 sub-scanning direction in SPF mode MAGNIFICATION ADJUSTMENT. SELECT 0-7, AND PRESS START. 0.TRAY SELECT 1.PRINT START This adjustment is needed in the following situations: 2.MAGNIFICATION • Images are not correctly magnified in the sub-scanning direction. 3.CCD(MAIN) 4.CCD(SUB) 5.SPF(SUB)

-

Page 236: Adj 7] Adjusting The Image Off-Center

: Feb. 9 2004 1) Go through the modes specified in Simulation 48-5. SIMULATION 50-5 SIMULATION 48-5 LEAD EDGE ADJUSTMENT. SELECT 0-20, AND PRESS START. MOTOR SPEED ADJUSTMENT. SELECT 0-4, AND PRESS START. 0.TRAY SELECT 1.PRINT START (ADJUSTMENT DATA) 0.MIR(220) 1.MIR(110) LEAD EDGE: 2.RRCB 20.SIDE2 ADJ. - Page 237 : Feb. 9 2004 2) Enter the number that corresponds to the paper feed tray that ADJ 7B Adjust the scanned image off-center in needs adjustments. (Choose from numbers 10 to 16.) original table mode (scan section) 3) Press the Start key This adjustment is needed in the following situations: 4) Press the Start key •...

- Page 238 (Scan off-center adjustment) (Adjustment mode selection) 1) Place an original on the original table. 1) Go through the modes specified in Simulation 50-12. 2) Press the Start key Check the off-center of the printed image. SIMULATION 50-12 ORIGINAL OFF-CENTER ADJUSTMENT. SELECT 0-9, AND PRESS If the off-center is 0±4.0 mm, no adjustment is required.

- Page 239 : Feb. 9 2004 (Scan off-center adjustment) (Adjustment mode selection) 1) Place an original on the SPF original tray. 1) Go through the modes specified in Simulation 50-12. 2) Press the Start key Check the off-center of the printed image. SIMULATION 50-12 ORIGINAL OFF-CENTER ADJUSTMENT.

-

Page 240: And Void Area