Table of Contents

Advertisement

For use with machine having Code Number:

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However,

your overall safety can be

increased by proper installation

... and thoughtful operation on

your part.

most importantly, think before

you act and be careful.

Equipped with VRD (VOLTAGE REDUCTION DEVICE)

See Installation and Operation sections for an explanation.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

11657

And,

OPERATORʼS MANUAL

• World's Leader in Welding and Cutting Products •

®

Copyright © Lincoln Global Inc.

IM10064

August, 2010

Advertisement

Table of Contents

Troubleshooting

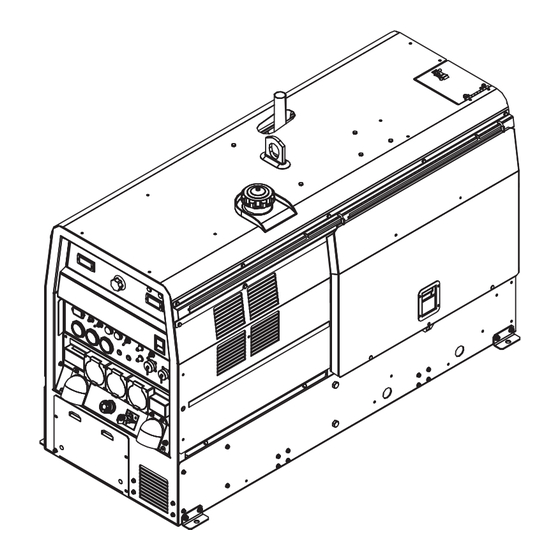

Summary of Contents for Lincoln Electric VANTAGE IM10064

- Page 1 For use with machine having Code Number: Lincoln arc welding and cutting equipment is designed and built with safety in mind. However, your overall safety can be increased by proper installation ... and thoughtful operation on your part. And, most importantly, think before you act and be careful.

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. - Page 4 WELDING and CUTTING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A LʼArc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 EN 60974-10 Electromagnetic Compatibility (EMC) Product Standard for Arc Welding Equipment. It is for use with other Lincoln Electric equipment. It is designed for industrial and professional use. All electrical equipment generates small amounts of electromagnetic emission. Electrical emission may be transmitted through power lines or radiated through space, similar to a radio transmitter.

- Page 7 SAFETY The size of the surrounding area to be considered will depend on the structure of the building and other activities that are taking place. The surrounding area may extend beyond the boundaries of the premises. Welding equipment should be connected to the mains supply according to the manufacturer’s recommenda- tions.

- Page 8 Electric for advice or information about their use of our products. We respond to our customers based on the best information in our posses- sion at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such infor- mation or advice.

-

Page 9: Table Of Contents

Machine Grounding ...A-5 Welding Terminals...A-5 Welding Output Cables ...A-5 Cable Installation...A-5 Auxiliary Power Receptacles and Plugs ...A-6 Standby Power Connections ...A-6 Connection of Lincoln Electric Wire Feeders...A-7, A-8 ________________________________________________________________________________ Operation...Section B Safety Precautions ...B-1 General Description...B-1 For Auxiliary Power ...B-1 Engine Operation...B-1... - Page 10 Fuel ...D-4 Bleeding the Fuel System ...D-4 Fuel Filter ...D-5 Engine Adjustment ...D-5 Battery Maintenance ...D-5 Servicing Optional Spark Arrestor ...D-5 Welder / Generator Maintenance ...D-6 Storage ...D-6 Cleaning...D-6 Brush Removal and Replacement ...D-6 ________________________________________________________________________ Troubleshooting ...Section E How to Use Troubleshooting Guide...E-1 Troubleshooting Guide...E-2 thru E-6...

-

Page 11: Installation

4 cylinder 43 HP PERKINS 1850 RPM 404D-22T Turbo Charged water cooled Diesel Engine RATED OUTPUT @ 104° F (40° C) - WELDER Welding Process Current/Voltage/Duty Cycle DC Constant Current DC Pipe Current Touch-Start™TIG DC Constant Voltage Arc Gouging RATED OUTPUT @ 40° C (104° F) -

Page 12: Installation

The welder should be located to provide an unrestrict- ed flow of clean, cool air to the cooling air inlets and to avoid restricting the cooling air outlets. Also, locate the welder so that the engine exhaust fumes are prop- erly vented to an outside area. STACKING VANTAGE®... -

Page 13: High Altitude Operation

HIGH TEMPERATURE OPERATION At temperatures above 104°F(40°C), Welder output derating is necessary. For maximum output ratings, derate the welder output 2 volts for every 18°F(10°C) above 104°F(40°C). Cold weather starting: With a fully charged battery and the proper oil, the engine should start satisfactorily down to -15°F(-... -

Page 14: Fuel

EXAMPLE: When the OUTPUT CONTROL on the welder is set to 200 amps the current range on the remote control will be MIN-200 amps, rather than the full MIN-MAX amps. Any current range that is less than the full range provides finer current resolution for more fine tuning of the output. -

Page 15: Electrical Connections

To prevent dangerous electric shock, other equipment to which this engine driven welder supplies power must: • Be grounded to the frame of the welder using a grounded type plug or be double insulated. WARNING • Do not ground the machine to a pipe that carries explosive or combustible material. -

Page 16: Auxiliary Power Receptacles

AUXILIARY POWER RECEPTACLES The auxiliary power capacity of the VANTAGE® 580 is 20kVA of 60Hz three phase power protected by an RCD (Residual Current Device) and a 3 phase 32 amp circuit breaker. The auxiliary power capacity in watts equivalent to volt-amperes at unity power factor. This model has: 1 x 3 phase and neutral Residual Current Device (RCD) protection (30mA) -

Page 17: Connection Of Lincoln Electric Wire Feeders

"+" terminal of the welder and work cable to the "-" terminal of the welder. For elec- trode Negative, connect the electrode cable to the "-" terminal of the welder and work cable to the "+" terminal of the welder. 3. Across The-Arc Model: •... - Page 18 2. For electrode Positive, connect the electrode cable from the LN-25 to the "+" terminal of the welder and work cable to the "-" terminal of the welder. For electrode Negative, connect the elec- trode cable from the LN-25 to the "-" terminal of the welder and work cable to the "+"...

-

Page 19: Operation

• Insulate yourself from work and ground • Always wear dry insulating gloves. • Always operate the welder with the hinged door closed and the side panels in place. • Read carefully the Safety Precautions page before operating this machine. Always follow... -

Page 20: Welding Controls

EXAMPLE: When the OUTPUT CONTROL on the welder is set to 200 amps the current range on the remote control will be MIN-200 amps, rather than the full MIN-MAX amps. Any current range that is less than the full range provides finer current resolution for more fine tuning of the output. - Page 21 4. ARC CONTROL - The ARC CONTROL dial is active in the CV-WIRE, CC-STICK and DOWNHILL PIPE modes, and has different functions in these modes. This control is not active in the TIG and ARC GOUGING mode. CC-STICK mode: In this mode, the ARC CONTROL dial sets the short circuit current (arc-force) during stick welding to adjust for a soft or crisp arc.

-

Page 22: Engine Controls

ENGINE CONTROLS: 13. RUN/STOP SWITCH -RUN position energizes the engine prior to starting. STOP posi- tion stops the engine. The oil pressure interlock switch prevents battery drain if the switch is left in the RUN position and the engine is not operating. 14. -

Page 23: Stopping The Engine

STOP the engine by placing the RUN-STOP switch in the STOP position. NOTE: A fuel shut off valve is located on the fuel pre-filter. WELDER OPERATION DUTY CYCLE Duty Cycle is the percentage of time the load is being applied in a 10 minute period. For example a 60% duty cycle, represents 6 minutes of load and 4 minutes of no load in a 10 minute period. -

Page 24: Tig Welding

The ARC CONTROL dial sets the short circuit current (arc-force) during stick welding to adjust for a soft or more forceful digging arc (crisp). Increasing the number from -10(soft) to +10(crisp) increases the short circuit current which results in a more forceful digging arc. Typically a forceful digging arc is preferred for root and hot passes. -

Page 25: Wire Welding-Cv

This will keep the "Solid State" contactor open and provide a "cold" electrode until the Amptrol or Arc Start Switch is pressed. When using the TIG Module, the OUTPUT CONTROL on the VANTAGE® 580 is used to set the maximum range of the CUR- RENT CONTROL on the TIG Module or an Amptrol if connect- ed to the TIG Module. -

Page 26: Field Installed Options / Accessories

Mounts on roof with K2663-1 Docking Kit. Order K2642-1 ACCESSORIES DOCKING KIT Secures the K2642-1 Polarity/Multi-Process Switch to the engine-driven welder roof. Release latch permits removal of K2642-1 Polarity/Multi-Process Switch. Made from stainless steel for rust-free operation. For all Lincoln Chopper Technology® engine-driven welders. -

Page 27: Wire Feeder Options

HAND AMPTROL® Provides 25 ft. (7.6 m) of remote current control for TIG welding. (6-pin plug connection). Velcro straps secure torch. Order K963-3 (one size fits all Pro-Torch® TIG Torches) WIRE FEEDER OPTIONS LN-25 PRO WIRE FEEDER Portable CC/CV unit for flux-cored and MIG welding with MAXTRAC®... -

Page 28: Maintenance

SAFETY PRECAUTIONS WARNING • Have qualified personnel do all maintenance and troubleshooting work. • Turn the engine off before working inside the machine or servicing the engine. • Remove guards only when necessary to perform maintenance and replace them when the maintenance requiring their removal is complete. -

Page 29: Engine Service Items

• Locate oil drain hose and valve in bottom of base and pull through the hole in the battery access panel on the welder. • Open oil drain valve by lifting up spring loaded lever and rotate 90 counterclockwise. - Page 30 Single- and Two-Stage Engine Air Cleaners Single- and Two-Stage Engine Air Cleaners Rotate the filter while pulling straight out. Wipe both sides of the outlet tube clean. Outer edge of the outlet tube If your air cleaner is equipped with a Vacuator Valve MAINTENANCE Inner edge of the outlet tube...

-

Page 31: Cooling System

COOLING SYSTEM WARNING HOT COOLANT • Do not remove cap if radiator is hot. ------------------------------------------------------------------------ Check the coolant level by observing the level in the radiator and recovery bottle. Add 50/50 antifreeze / water solution if the level is close to or below the "LOW"... -

Page 32: Fuel Filter

CONNECTING A BATTERY CHARGER — remove battery from welder by disconnecting negative cable first, then positive cable and battery clamp. When reinstalling, connect negative cable last. Keep well ventilated. -

Page 33: Storage

WARNING • Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equip- ment may result in danger to the technician and machine operator and will invalidate your factory warranty. -

Page 34: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 35: Troubleshooting

Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Major Physical or Electrical Damage is Evident. Engine will not "crank". Engine will "crank" but not start. Engine shuts down shortly after starting. If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. - Page 36 3. Faulty engine alternator or charg- er module. Consult authorized Engine Service Shop. 1. Idler switch in High idle position. Set switch to Auto. 2. External load on welder or auxil- iary power. Remove all external loads. 3. Faulty PC board or idler sole- noid.

-

Page 37: Auxiliary Power

Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Engine will not go to high idle when using auxiliary power. Engine will not go to high idle under weld or auxiliary loading. Engine does not develop full power. Engine runs rough. Engine will not go to high idle when attempting to weld or using auxil- iary power. - Page 38 2. "Weld Terminals" switch in wrong position. Place switch in "Weld Terminals On" position when welding without control cable. 3. Faulty PC board or welder alterna- tor. 1. Poor remote/control cable connec- tion to 6-pin or 14-pin connector. Check connections.

- Page 39 3. "Weld Terminals" switch in wrong position. Place switch in "Weld Terminals On" position when welding without control cable. 4. Faulty PC board or welder alterna- tor. 1. Ensure VRD ON/OFF switch is in the “ON” position. 2. If light is burned out, replace both VRD lights.

- Page 40 DIAGRAMS VANTAGE® 580...

- Page 41 DIAGRAMS VANTAGE® 580...

- Page 42 DIAGRAMS VANTAGE® 580...

- Page 43 DIAGRAMS VANTAGE® 580...

- Page 44 DIAGRAMS VANTAGE® 580...

- Page 45 DIAGRAMS VANTAGE® 580...

- Page 46 DIAGRAMS VANTAGE® 580...

- Page 47 DIAGRAMS VANTAGE® 580...

- Page 48 DIAGRAMS VANTAGE® 580...

-

Page 49: Wiring Diagram

F-10 F-10 WIRING DIAGRAM VANTAGE® 580... -

Page 50: Dimension Print

F-11 F-11 DIMENSION PRINT VANTAGE® 580... - Page 51 WARNING Spanish AVISO DE PRECAUCION French ATTENTION German WARNUNG Portuguese ATENÇÃO Japanese Chinese Korean Arabic READ AND UNDERSTAND THE MANUFACTURERʼS INSTRUCTION FOR THIS EQUIPMENT AND THE CONSUMABLES TO BE USED AND FOLLOW YOUR EMPLOYERʼS SAFETY PRACTICES. SE RECOMIENDA LEER Y ENTENDER LAS INSTRUCCIONES DEL FABRICANTE PARA EL USO DE ESTE EQUIPO Y LOS CONSUMIBLES QUE VA A UTILIZAR, SIGA LAS MEDIDAS DE SEGURIDAD DE SU SUPERVISOR.

- Page 52 Keep your head out of fumes. Use ventilation or exhaust to remove fumes from breathing zone. Los humos fuera de la zona de respiración. Mantenga la cabeza fuera de los humos. Utilice ventilación o aspiración para gases. Gardez la tête à lʼécart des fumées.

- Page 53 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the VANTAGE IM10064 and is the answer not in the manual?

Questions and answers