Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Dynajet 350 mg Plus

-

Page 1: Operating Instructions

Operating Instructions for machine operator and maintenance staff always keep by the machine High-Pressure Cleaner Dynajet 350 mg Plus Art. no. 111486047 Machine no. Rev. 00−0404 365051013 The paper on which this document is printed is 100% chlorine free... - Page 2 Putzmeister Postfach 2152 07127 / 599–0 07127 / 599 743 Internet: Mörtelmaschinen D–72629 Aichtal www.putzmeister.de GmbH Hotline: Max–Eyth–Str. 10 (07127) 599-699 e-mail: D–72631 Aichtal pmm@pmw.de...

-

Page 3: Table Of Contents

Contents About these Operating Instructions Foreword ..........Signs and symbols . - Page 4 ..........Dynajet 350mg Plus .

- Page 5 Contents Transport, Set-up and Connection Unpacking the machine ....... Disposing of packaging material .

- Page 6 Contents Fauls, Cause and Remedy High−pressure cleaner with operating module ... . High−pressure cleaner, general ......Maintenance Maintenance intervals .

-

Page 7: About These Operating Instructions

In the event of any queries, please consult: Putzmeister Aqua Pressure System Max−Eyth−Str .10 D−72629 Aichtal, Germany Tel.: +49 (0)7127 599−0 Fax: +49 (0)7127 599−743 Internet: http://www.Dynajet.de E−mail: @pmw.de or the branch or services agent responsible for you. Address: Telephone: Fax: E−mail:... -

Page 8: Foreword

About these Operating Instructions 1.1 Foreword This operating instructions should help you to get to know the machine and its range of intended uses. The operating instructions contain important information for operating the machine safely, correctly and economically. Observing these instructions helps to avoid hazards, reduce repair costs and downtimes and increase the reliability and the service life of the machine. - Page 9 About these Operating Instructions If after reading these operating instructions you have any questions, please contact your local branch, dealer or the Aichtal Works. You will make it much easier for us to answer any questions if you can give us the details of the machine model and the machine number.

-

Page 10: Signs And Symbols

About these Operating Instructions 1.2 Signs and symbols The following signs and symbols are used in these operating instructions: " Action symbol The text following this symbol describes tasks that usually have to be carried out in the sequence shown. å... -

Page 11: Safety Regulations

Safety Regulations 2 Safety Regulations This chapter summarises the most important safety regulations. This chapter is, therefore, particularly suitable for an initial basic instruction for new operators. Naturally, the various regulations are also repeated once more at the appropriate points in the operating instructions. -

Page 12: Principle

Safety Regulations 2.1 Principle Use high−pressure cleaners only as specified and in a technically perfect condition. Avoid danger by observing safety factors and the specifications in the operating instructions. Any faults, especially those affecting safety must therefore be rectified immediately. Make sure that: −... -

Page 13: Designated Use

Putzmeister concrete pumps for boom and support operation. The DYNAJET mg supplies cold pressurised water at a maximum of 350 bar, depending on the model. Cold, clean mains water should be supplied to the machine via the low−pr essure hose. -

Page 14: Use Contrary To The Designated Use

Safety Regulations 2.3 Use contrary to the Use of the machine other than that described above, or which goes beyond such use, is considered contrary to the designated use. designated use Putzmeister Mörtelmaschinen GmbH accepts no liability for damage resulting from such use. The machine operator bears full responsibility for risks caused by misuse of this kind. -

Page 15: Sources Of Danger

Safety Regulations 2.4 Sources of danger Never reach into the moving parts of the machine, whether the machine is running or switched off. Always switch off the main switch first. Take note of the warning plate. In the event of malfunctions, stop the machine immediately and secure it. -

Page 16: Handling High−Pressure Hoses

Safety Regulations 2.5 Handling high-pres- It is essential that correct high−pressure hoses be carefully selected and handled correctly to maintain the operational safety of the sure hoses high−pr essure cleaner. Observe the following rules when handling high−pressure hoses: − High−pr essure hoses that are marked with a permissible operating overpressure lower than the one specified in the technical specifications or hoses that have no markings at all, should not be used. -

Page 17: Unauthorised Use

Safety Regulations 2.6 Injuries from Work with high−pressure water jets produces very high pressure that acts over a relatively small surface area. This concentration of high-pressure water energy is the reason why a high−pressure water jet may cause jets serious injury. If a high−pressure water jet makes contact with the skin, it can penetrate the surface of the skin and damage the tissue underneath. - Page 18 Safety Regulations Protective helmet Ear defenders Protective goggles Face protection visor Protective suit Protective gloves Protective boots Operating personnel must be informed that waterproof protective clothing only provides protection from spray water and splash particles. In the case of direct contact with the high−pressure water jet, protective equipment does not guarantee protection against injuries caused by the high−pressure water jet.

-

Page 19: Selecting Qualified Personnel

Safety Regulations 2.9 Selecting qualified The machine may only be operated, maintained or serviced independently by persons (machine operators) who: personnel − have reached the legally required age; − are physically capable (rested and not under the influence of alcohol, drugs or medication); −... -

Page 20: Inspection

Safety Regulations Inspection Check all lines, hoses and threaded unions regularly for leaks and external damage! Have any damage repaired immediately! Discharged oil can cause injuries and burns. 10400800 Checking hydraulic hoses Regular checks are required as part of the overall machine safety inspection routine. -

Page 21: Lines

Safety Regulations There is a risk of eye and skin injuries caused by hydraulic oil discharging when screw connections are opened without the complete system having been previously depressurised. Lines Lay and fit hydraulic lines professionally! Make sure the connections are correct! Connectors and the length/quality of the hoses must meet requirements. -

Page 22: Noise

Safety Regulations 2.14 Noise Extreme noise levels can cause permanent hearing damage. Ear defenders Depending on the operation involved, sound levels of 85 dbA may be exceeded within close−range of the machine. Close−range means at a distance of less than 5m from the machine. Wear the specified ear defenders! Instruct your personnel to always wear their personal ear defenders. -

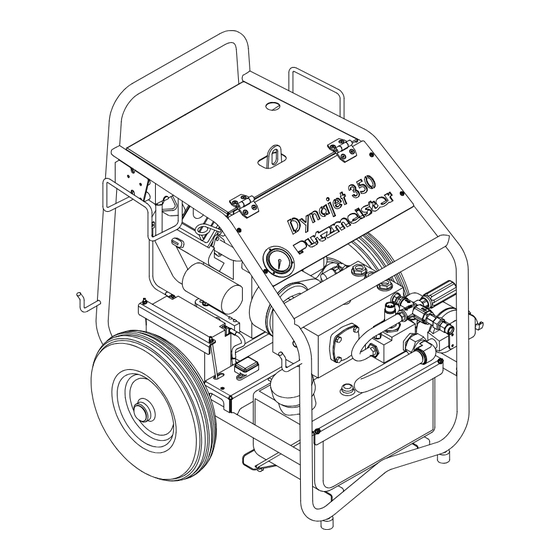

Page 23: General Technical Description

Please see the machine card to find out whether a particular option is fitted. 3.1 Designation of the Your high−pressure cleaner is a Dynajet mg from Putzmeister Mörtelmaschinen GmbH. high-pressure cleaner You will make it much easier for us to answer any questions or respond to orders if you can give us the details of the machine model and the machine number. -

Page 24: Scope Of Delivery

General Technical Description 3.2 Scope of delivery The scope of delivery includes: − the Dynajet mg, − a 10 m high−pressure hose, − a spray gun with nozzle pipe and a fan jet nozzle, − a 10 m oil−pressure hose −... - Page 25 General Technical Description 3.4 Technical data The technical data and features listed below relate to the Dynajet Dimensions Dynajet 350mg Plus Length: 750 mm Width: 790 mm Height: 945 mm Weights Weight: (empty) 105 kg Power output Petrol motor 14.5 kW Drive motor: 3250 rpm.

-

Page 26: Rating Plate

General Technical Description The most important data is shown in brief on the rating plate mounted on the machine. Rating plate 24000201 Model (machine model) Machine no. (machine number) Year of manufacture Max. delivery pressure [bar] Hydr. pressure max. [bar] (maximum fluid pressure in the hydraulic system) Voltage [V] Frequency [Hz] Power [kW]... -

Page 27: Safety Equipment

− 150 bar, for the Dynajet 150 mg, − 280 bar, for the Dynajet 280 mg, − 350 bar, for the Dynajet 350 mg and 350 mg Plus. the unloader depressurises the water and returns it to the water inlet. -

Page 28: Water System

Drive motor Drive motor Manual starting device The Dynajet mg is driven by a petrol motor. The motor powers the high−pressure water pump. The motor has a manual starting device that can be used to start the motor if the battery voltage is insufficient. -

Page 29: High−Pressure Water Pump

General Technical Description High-pressure water pump High−pr essure water pump Drive motor The high−pressure water pump sucks" the water through the water inlet and pressurises it at a maximum of 350 bar. The high−pressure water pump is driven by the petrol motor. The valve seats are suitable for hydraulic fluid up to 80°... -

Page 30: Fan Jet Nozzle

General Technical Description Fan jet nozzle A fan jet nozzle (1505) is included in the scope of delivery. It has a spray angle of 15° and a nozzle size of 34. Fan jet nozzles are characterised by a uniform fluid and pressure distribution. -

Page 31: Operating Module

General Technical Description Operating module The operating module checks and displays the different machine parameters. The ignition lock is also located in the operating module The LEDs indicate the status of the switch before the machine is started. If a switch changes status during operation, the motor is stopped after 3 seconds. -

Page 32: Socket (12 V)

General Technical Description Socket (12 V) Socket (12 V) The Dynajet mg is fitted with a 12V DC socket as standard. Additional equipment that requires a maximum of 16 amps 12V DC can be connected to the socket. The socket gives the option of connecting die Putzmeister Dynabox 350 12V, for example. -

Page 33: Components On The Control And Monitoring Units

General Technical Description 3.8 Components on the This section gives you a summary of the various control devices on the machine and the symbols used for control actions. control and monito- ring units The functions of the machine are assigned to the following control devices: −... -

Page 34: Operating Module

General Technical Description Operating module Operating hour counter Ignition lock Water−oil temperature above 80° Water−oil deficiency Oil pressure Charge monitor Ready The operating module monitors and displays: From the motor − Motor oil pressure − Dynamo From the pump − Oil temperature / Water temperature −... -

Page 35: Transport, Set-Up And Connection

Transport, Set−up and Connection 4 Transport, Set-up and Connection This chapter contains information concerning safe transport of the machine. In addition, this chapter describes operations that are required for assembling and connecting the machine. Starting up the machine will not be described until the chapter "Commissioning". 4.1 Unpacking the ma- Before shipment, the machine is packaged for transportation. -

Page 36: Set−Up Site

Transport, Set−up and Connection 4.2 Loading Use the slinging points provided on the machine when loading it by crane. Only in this way can you be sure that the machine is suspended horizontally and securely in the hook and will not be able to tip over. -

Page 37: Connecting

Transport, Set−up and Connection 4.4 Connecting The following section describes how to connect the high−pressure cleaner to the water supply. Water connection The connection to the drinking water supply may only be made in compliance with DIN 1988 − Technical Rules for Drinking Water Installations, i.e. -

Page 38: Setting Up The Machine For Emergency Operation

Transport, Set−up and Connection 4.5 Setting up the If you want to set up the machine for emergency operation, proceed as follows: machine for emergency operation WGA nipple " Remove WGA nipple å A 12 L hydraulic connection remains on the pressure connection Oil−pr essure hose "... - Page 39 Transport, Set−up and Connection Water intake hose " Remove the water intake hose. Oil intake hose " Fit the oil intake hose. Note Bypass the filter when connecting the oil intake because the high−pr essure pump only has a low intake capacity. Continuation next side 4 —...

- Page 40 Transport, Set−up and Connection Ball valve for venting the oil intake hose " Vent the oil intake hose via the yellow ball valve. Continuation next side 4 — 6 APS04_012_0404GB...

-

Page 41: Oil Pressure Hose Diagram

Transport, Set−up and Connection Oil pressure hose diagram Dynajet mg Plus High−pr essure filter Boom pump Hydr. hose (4SP DN10x 5000) Connection (GS 12L ) Connection (REDSD 18/12L) Connection (GES 18LM) Connection (ETSD 18L) Connection (SNV 18L) Screw joints (BO−RV 18L−SA5) 4 —... -

Page 42: Starting Up

The entire system should be observed during the initial hours of operation to identify possible malfunctions. 5.1 Use as an emergency When using the Dynajet mg Plus as an emergency unit for operating Putzmeister concrete pumps for boom and support operation, hydraulic unit commission as described, without water operation. -

Page 43: General

Starting up 5.2 General When you accept the machine, you must make yourself familiar with the equipment so that damage and accidents cannot occur. Every time operators use the high−pressure cleaner, they accept full responsibility for the safety of anyone located in the machine’s danger zone. -

Page 44: Water Filter

Starting up Water filter A contaminated filter may damage the high−pressure water pump. The filter system cleans the supplied water, thus safeguarding the high−pr essure water pump. The filter element from the water filter must be replaced if it becomes soiled. -

Page 45: High−Pressure Gun

Starting up Caution Fill the high−pressure cleaner with fuel only when the engine is at a standstill! When filling the high−pressure cleaner with fuel, pay particular attention to cleanliness! Do not spill fuel! Danger Do not smoke when you are filling up! Never fill the fuel tank near naked flames or ignitable sparks. -

Page 46: Test Run

Starting up 5.5 Test run Starting the motor Proceed as follows to start the engine: Danger During and after completion of work, there is a risk of burns from hot parts on the drive motor and the silencer. Choke lever "... -

Page 47: Checking Functions

Starting up " Switch on the ignition by turning the ignition key to "1". å All pictograms on the operating module flash three times (self test) å After the self test, the green LED lights up permanently. å The status of all inputs is displayed at the same time. "... - Page 48 Starting up Stopping the machine If the machine runs perfectly during the test run, you can use it for after a test run the intended task or switch it off. If you want to continue using the machine, proceed as described in the chapter "Operation".

-

Page 49: Starting The Motor Using The Manual Starting Device

Starting up 5.6 Starting the motor If the battery voltage is insufficient, the motor can be started using the manual starting device. using the manual starting device " Activate the choke lever. Danger Never direct the water jet at persons or animals − the high operating pressure can lead to serious injuries. -

Page 50: Operation

Operation 6 Operation This chapter contains information on machine operation. You will learn what operations are required for setting up the machine, operation and for cleaning. Do not direct the cleaning jet vertically onto the surfaces to be Tip for cleaning surfaces cleaned. -

Page 51: Pressure Adjustment

Operation Danger Always wear your own personal protective equipment when working. Never direct the water jet at persons or animals − the high operating pressure can lead to serious injuries. Never direct the water jet at electric components. The activated high−pressure gun produces recoil and torque. Ensure equipment is secure and stable. -

Page 52: Switching Off The Machine On Completing The Work

Press the spray gun trigger to relieve pressure. å The residual pressure in the line and spray gun is relieved. 6.3 Use as an emergency When using the Dynajet mg Plus as an emergency unit for operating Putzmeister concrete pumps for boom and support operation, hydraulic unit proceed as follows: "... -

Page 53: Cleaning

Operation 6.4 Cleaning After completion of work, clean the machine and the delivery and high−pr essure hoses. This ensures that the key components continue to function correctly. Environmental protection During all cleaning work, observe the waste disposal regulations that apply to your region. Do not allow cleaning additives to enter the sewage system. - Page 54 Operation Water sprayed at the machine from all directions does not have any damaging effect. The system is splash−proof but not waterproof. Remove all the covers / seals after the cleaning process! Caution The machine and lines must be completely drained of residual water if there is a risk of freezing.

-

Page 56: Fauls, Cause And Remedy

Observe the safety regulations when searching for a fault. Only suitably trained technicians may work on the electrical system. 7.1 High-pressure cleaner The Dynajet 350 mg Plus high−pressure cleaner (with the other Dynajets mg optional) is fitted with an operating module. Any faults with operating module relating to the assigned parameters are displayed here. -

Page 57: High−Pressure Cleaner, General

Faults, Cause and Remedy 7.2 High-pressure clea- This chapter describes the possible causes of faults and how to rectify them. ner, general Operating pressure fluctuates Cause Remedy Water filter soiled. Clean or replace the water filter. Spray nozzle blocked or worn. Clean or replace the spray nozzle. -

Page 58: Maintenance

Maintenance 8 Maintenance This chapter contains information on the maintenance work necessary for the safe and efficient operation of the machine. We would like to emphasise here that all specified checks, inspections and preventive maintenance work must be conscientiously carried out. Otherwise we will refuse any liability or warranty claim. -

Page 59: Maintenance Intervals

Maintenance 8.1 Maintenance intervals The following table shows the intervals for the various maintenance tasks listed by assembly. The associated maintenance charts can be found further on in this chapter. Note Have the initial After Sales service carried out by a Putzmeister Mörtelmaschinen GmbH After Sales service engineer, or by a dealer authorised by Putzmeister Mörtelmaschinen GmbH. -

Page 60: Water Pump

Maintenance Measurement Frequency inspection every ... Action equipment, Remarks operating hours operating / at least and auxiliary materials Water pump See the manufacturer’s documentation for information on how to carry out the work after the Filling capacity first 50, then Full oil change SAE 30 W 1.125 l... - Page 61 Maintenance 8.2 Operating materials This chapter lists all the operating materials used in your machine. Fuel: Regular fuel capacity 20 L SAE 30 W Engine oil: Motor oil quantity 1.6 l with filter, 1.4 without filter High−pr essure water pump: SAE 30 W 1.125 l Gear unit: SAE 90 W 0.2625 l...

-

Page 62: Decommissioning

Decommissioning 9 Decommissioning This chapter contains information on decommissioning the machine. 9.1 Temporary If the machine is to taken out of service temporarily, the following measures are sufficient: decommissioning " Switch off machine. " Stop the water supply. " Release the pressure in the high−pressure gun until no more water flows out. -

Page 63: Frost Protection

Decommissioning Frost protection At the end of work, the machine must be completely drained of residual water if there is a risk of freezing. " Disconnect the machine from the water supply. " Completely drain the water from the hoses. Caution The machine and lines must be completely drained of residual water if there is a risk of freezing. -

Page 64: Preservation

Decommissioning To bypass the pressure gauge, which prevents the machine starting up without water pressure, a special adapter (GEKA on compressed−air connection, not supplied) is used to connect to compressed air instead of water. " Connect the adapter. " Open the air supply. "... -

Page 65: Storing The Machine

Decommissioning 9.2 Storing the machine The high−pressure cleaner should only be stored in a dry, clean and well ventilated area. Danger There is a risk of fuel vapours building up and igniting if the high−pr essure cleaner is stored in a poorly ventilated area. "... -

Page 66: Material Used

Decommissioning Material used The main materials used for machine construction were: Material Used for / in Copper − Cables − Machine frame − Pump parts Steel − Motor parts Galvanised steel − Water valve fitting screws − Gaskets − Hoses Plastic rubber PVC Plastic, rubber, PVC −... -

Page 68: Hot Machine Components 2

Index of Key Words Index of Key Words This chapter contains the main key words with the number of the page on which they are to be found as a header in the left−hand margin. This Index of key words is listed alphabetically by the main concepts. -

Page 69: Safety Equipment 2

Index of Key Words Maintenance intervals, 8 — 2 Rating plate, 3 — 4 Technical data, 3 — 3 − Drive motor, 8 − Dimensions, 3 Refuelling, machine, 5 — 3 − General, 8 − Operating materials, 3 − Transmission, 8 −... - Page 70 Putzmeister Limited Putzmeister France Putzmeister Chesterfield Trading Estate Zone Industrielle Mörtelmaschinen GmbH Carrwood Road Rue Jean Jaurès Max−Eyth−Straße 10 Sheepbridge/Chesterfield/ 91861 Epinay sous Sénart 72631 Aichtal Derbyshire S41 9QB Tel. (1) 69 39 69 39 Postfach 21 52 Tel. (0 12 46) 45 45 46 Fax (1) 60 47 20 68 72629 Aichtal Fax (0 12 46) 126 00 77...

- Page 71 Putzmeister Mörtelmaschinen GmbH Postfach 2152 D−72629 Aichtal Telefon (07127) 599−0 Telefax (07127) 599−743 Internet: http://www.moertelmaschinen.de E−mail: pmm@pmw.de...

Need help?

Do you have a question about the 350 mg Plus and is the answer not in the manual?

Questions and answers