MIMAKI JV5-130S Operation Manual

Color inkjet printer

Hide thumbs

Also See for JV5-130S:

- Operation manual (292 pages) ,

- Mechanical drawing (82 pages) ,

- Product manual (21 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operating Manual

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MIMAKI JV5-130S

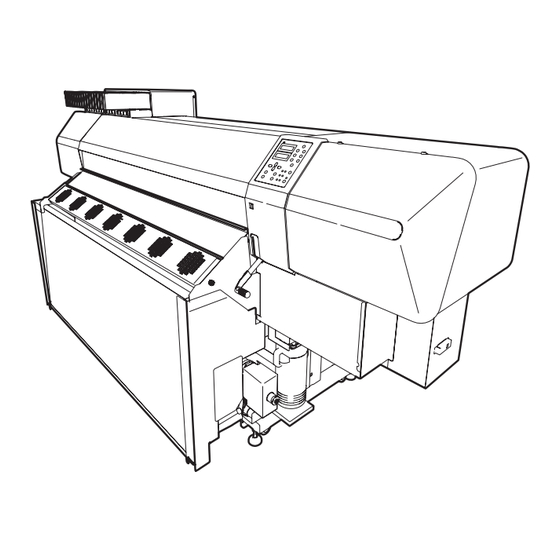

- Page 1 COLOR INKJET PRINTER OPERATION MANUAL MIMAKI ENGINEERING CO., LTD. TKB Gotenyama Building, 5-9-41, Kitashinagawa, Shinagawa-ku, Tokyo 141-0001, Japan Phone : +81-3-5420-8671 Fax : +81-3-5420-8687 URL : http://www.mimaki.co.jp/ D201515...

- Page 2 How to read this Operation Manual The following documents are attached to JV5-130S/160S: Operation Manual (this document) “Operation Manual” explains how to operate JV5-130S/160S. Request for daily care (separate volume) “Request for daily care” explains how to perform daily maintenance of JV5-130S/160S.

- Page 3 ITY OR MAKE ANY OTHER WARRANTY OR MAKE ANY OTHER WARRANTY IN CONNECTION WITH ANY PRODUCT WITHOUT MIMAKI’S PRIOR WRITTEN CON- SENT. IN NO EVENT SHALL MIMAKI BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR FOR LOSS OF PROFITS OF DEALER OR CUS- TOMERS OF ANY PRODUCT.

-

Page 4: Fcc Statement (Usa)

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. In the case where MIMAKI-recommended cable is not used for connection of this device, limits provided by FCC rules can be exceeded. -

Page 5: Foreword

Congratulations on your purchase of MIMAKI color ink jet printer “JV5-130S/160S” . The JV5-130S/160S is a color ink-jet printer for high quality printing with solvent ink. The printer is available with either of the two sets of color ink cartridges, namely, a four-color set of ink car- tridges (cyan, magenta, yellow and black, 4 each), and a six-color set of ink cartridges (cyan, magenta, yellow and black, 2 each, and light cyan and light magenta, 4 each). -

Page 7: Structure Of This Operation Manual

Structure of this Operation Manual Structure of this Operation Manual This manual consists of the following six chapters to describe the handling of the printer. TABLE OF CONTENTS Shows the contents of this manual. CHAPTER 1 Safety Precautions Describes the precautions to be taken for safe use of the printer. CHAPTER 2 Basic Use of Printer Describes the names of parts and how to use the operation panel. -

Page 9: Table Of Contents

TABLE OF CONTENTS TABLE OF CONTENTS CAUTION FCC Statement (USA)..................ii Interference to televisions and radios ............ii Foreword ......................iii On This Operation manual................iii Structure of this Operation Manual ..............v CHAPTER 1 Safety Precautions Checking the accessories ................1-2 Front exhaust unit Box ................1-4 Features......................1-6 Pictorial signs ....................1-9... - Page 10 TABLE OF CONTENTS Carriage ....................2-10 Capping station ..................2-10 Cutter blade and cutting line ..............2-11 Media sensor ..................2-11 Pinch rollers and Feed rollers ..............2-12 Heater ....................2-13 Operation Panel ....................2-14 Display ....................2-15 How to read the display .................2-15 How to read the LED indications............2-17 How to use the keys................2-18 Modes and Menu Screens ................2-20 Modes ....................2-20...

- Page 11 TABLE OF CONTENTS Checking for nozzle clogging, and unclogging nozzles......3-29 Printing a test pattern (test printing)............3-29 If the printed pattern is abnormal (Cleaning)..........3-30 If nozzles cannot be unclogged [FILL UP INK] ........3-32 Correcting the media feed rate [MEDIA COMP.]........3-34 If dots are not in alignment [DROP.POScorrect] ........3-36 Effective Plotting Area .................3-38 Establishing the Origin ................3-39 Printing an image ..................3-40...

- Page 12 TABLE OF CONTENTS Setting periodical operations in stand-by mode [ROUTINE SETUP]..4-33 Preventing ink condensation on the nozzle face [ROUTINE WIPING] ..4-33 Periodical refresh interval [REFERSH] ..........4-35 Periodical tube cleaning interval [TUBE WASH]........4-36 Periodical cleaning interval [CLEANING]..........4-37 Other maintenance functions..............4-39 Changing the time for warning of wiper replacement [WIPER LEVEL]..4-39 When the waste ink tank is full ..............4-41 Replacing the wiper [WIPER EXCHANGE] ..........4-43 Replacing the cutter blade................4-45...

- Page 13 TABLE OF CONTENTS Outline of the setup functions ..............6-5 Invoking MAINTENANCE functions ............6-12 List of functions ..................6-12 Setting a maintenance function..............6-13 Make setting of the media remaining amount display function [MEDIA RESIDUAL] 6-14 Moving the printer safely [BeforeMovingIt.]..........6-15 Invoking MACHINE SETUP functions............6-17 List of functions ..................6-17 Functions of [INFORMATION] key............6-17 Setting a MACHINE SETUP ..............6-18...

- Page 14 TABLE OF CONTENTS...

- Page 15 CHAPTER 1 Safety Precautions This chapter describes the precautions to be taken for safe use of JV5-130S/160S. Checking the accessories ............1-2 Features .................1-6 Pictorial signs .................1-9 Notes on Installation ............1-10 Power Supply Connection ............1-13 Warning for Use ..............1-14 Warning labels ..............1-18...

-

Page 16: Chapter 1 Safety Precautions

CHAPTER 1 Safety Precautions Checking the accessories Checking the accessories The articles illustrated below are supplied with your plotter as accessories. Check them for correct quantities and appearance. If you find any problem, please contact your distributor. - Page 17 CHAPTER 1 Safety Precautions Checking the accessories Name Remarks 1 Software CD-ROM (for JV5) 2 Operation Manual (JV5 series) 3 Request for daily care 4 Protective glasses 5 Plug for power cable 6 Connecting duct B4x12SMW (Black) 7 Screw 4 pcs. (for waste ink tank bracket assembly) 2 pcs.

-

Page 18: Front Exhaust Unit Box

CHAPTER 1 Safety Precautions Checking the accessories Front exhaust unit Box... - Page 19 CHAPTER 1 Safety Precautions Checking the accessories Name Remarks 1 Roll screen 160 (130) 2 Open and close cover assembly 160 (130) 3 Dry fan assembly 160 (130) 4 Front exhaust unit Box...

-

Page 20: Features

CHAPTER 1 Safety Precautions Features Features The features of the printer are described below. Understanding them together with the operating instructions given in this manual will help you use the machine properly. A new generation of print heads arranged in 4 staggered rows realize high-res- olution super-high-speed printing Newly developed print heads each of which has 1,440 nozzles (180 nozzle x 8 rows) are employed and 1- inch heads are arranged in four rows staggered from each other, realizing 4-inch print head width. - Page 21 CHAPTER 1 Safety Precautions Features Easy maintenance The automatic capping system for the heads eliminates the need of head cleaning before turning off the power. Nozzles can be unclogged by performing the cleaning function. If the printer is not in use for a prolonged period of time, it automatically performs nozzle clogging preven- tive operation at fixed intervals.

- Page 22 CHAPTER 1 Safety Precautions Features The nozzle missing automatic detection function reduces waste of media and ink that could be caused by faulty printing The printer automatically checks the printing result for nozzle missing after cleaning and during printing. And if necessary, it requires another cleaning or interruption of printing to prevent a waste of media and ink.

-

Page 23: Pictorial Signs

CHAPTER 1 Safety Precautions Pictorial signs Pictorial signs Pictorial signs are used in this Operation Manual for safe operation and for prevention of damage to the printer. Pictorial signs and their meanings are given below. Read and fully understand before reading the text. Icon Meaning Failure to observe the instructions given with this symbol will pose an imminent danger of death or serious... -

Page 24: Notes On Installation

Secure a suitable installation space before assembling the printer. The place of installation must have enough space for not only the printer itself but also for printing opera- tion. 500 mm 500 mm JV5-130S : 3860 mm JV5-160S : 4120 mm Model... -

Page 25: Notes On Location

CHAPTER 1 Safety Precautions Notes on Installation Notes on Location Do not locate the printer in any of the places listed below. A place where temperature or A place exposed to direct air flow A place exposed to direct sunlight humidity varies significantly from an air conditioner or the like. -

Page 26: Moving The Printer

When the printer is to be moved to any place other than on the same step-free floor, contact your distributor or a sales office of MIMAKI. If you move it by yourself, failure or damage may occur. Be sure to request your distributor or a sales office of MIMAKI to move the printer. -

Page 27: Power Supply Connection

Single-phase 200 to 240 Vac 15 A or less (cannot be used with 100 V system) You are not allowed to install the printer by yourself. Be sure to request MIMAKI’s service personnel and an electrician to install the printer. For the power supply to the main body of the printer, electrical work is required as described below. -

Page 28: Warning For Use

Check first that the machine no longer produces smoke, and then contact your distributor or a sales office of MIMAKI for repair. Never repair your printer by yourself since it is very dangerous for you to do so. -

Page 29: Precautions In Use

Moving the printer must be limited to on the same floor where there is no steps. When the printer is to be moved to any place other than on the same step-free floor, contact your distributor or a sales office of MIMAKI. -

Page 30: Cautions And Notes

Do not use the JV5 genuine ink with other printers, as doing so may cause damage to such printers. Never refill the ink cartridge with ink. Refilling the ink cartridge can cause a trouble. Remember that MIMAKI assumes no responsibility for any damage caused by the use of the ink cartridge replenished with ink. -

Page 31: Types Of Media That Can Be Used

The types and sizes of media that can be used with the printer are explained below. Recommended types of media Tarpaulin FF (Flexible Face) Weatherproof PVC Sizes of media that can be used JV5-130S JV5-160S Maximum width 1375 mm (54.13 inch) 1630 mm (64.17 inch) Minimum width... -

Page 32: Warning Labels

CHAPTER 1 Safety Precautions Warning labels Warning labels Warning labels are stuck on the printer body. Be sure to fully understand the warning given on the labels. If a warning label is illegible due to stains or has come off, purchase a new one from your local distributor or our office. -

Page 33: Basic Specifications

CHAPTER 1 Safety Precautions Basic specifications Basic specifications Item JV5-130S JV5-160S Print head Method Drop-on-demand piezoelectric print heads Specification 4-heads Staggerds Drawing mode (scan x feed) 720 x 540dpi 540or720 x 720dpi 540 x 900dpi 540or720 x 1080dpi 720 x 1440dpi... - Page 34 CHAPTER 1 Safety Precautions Basic specifications Item JV5-130S JV5-160S Outside dimensions Width 2860 mm 3120 mm Depth 900 mm (1050 mm *3) 900 mm (1050 mm *3) Height 1551 mm 1551 mm Basic specifications *1 Without deflection of the roll when it is retained at both ends.

-

Page 35: Specifications For Ink

CHAPTER 1 Safety Precautions Basic specifications Specifications for ink Item Specifications Supply Dedicated solvent ink cartridges Color Black ink cartridge Cyan ink cartridge Magenta ink cartridge Yellow ink cartridge Light cyan ink cartridge Light magenta ink cartridge Ink capacity 220 cc / 440 cc per cartridge Shelf life HS Ink : 14 months from the data of manufacture (at room temperature) ES3 Ink : Two year from the data of manufacture (at room temperature) -

Page 36: Notes On Usb 2.0 Interface

CHAPTER 1 Safety Precautions Basic specifications Notes on USB 2.0 Interface Your RIP must be compatible with USB 2.0. When two or more JV5 printers are connected to one personal computer When two or more JV5 printers are connected to one personal computer, the personal computer may not recognize all the JV5 printers normally. - Page 37 CHAPTER 1 Safety Precautions Basic specifications Notes on data output from USB memory When spool data stored on USB memory is to be output for printing, the data is transferred to the JV5 printer at a low speed. That can cause the head unit to stop temporarily at the right or left end during print- ing.

- Page 38 CHAPTER 1 Safety Precautions Basic specifications 1-24...

- Page 39 CHAPTER 2 Basic Use of Printer This chapter describes the names of parts and how to use the operation panel. Names of Parts and Functions ..........2-2 Operation Panel ..............2-14 Modes and Menu Screens ...........2-20 About Function Menus ............2-21...

-

Page 40: Names Of Parts And Functions

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Names of Parts and Functions Front... - Page 41 CHAPTER 2 Basic Use of Printer Names of Parts and Functions Name Function 1 Ink station Set the specified ink cartridges in the ink station. 2 Ink cartridges Each cartridge contains an ink of a particular color. 3 Cartridge LEDs The LEDs (green and red) in each slot indicate the cartridge status.

-

Page 42: Rear

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Rear... - Page 43 CHAPTER 2 Basic Use of Printer Names of Parts and Functions Name Function 1 Ink cartridge for cleaning Use this ink cartridge when performing maintenance. 2 Clamp lever (rear) Interlocked with the clamp lever in the font of the printer. 3 Media support bar This bar facilitates setting a roll media in position.

-

Page 44: Front Cover And Maintenance Covers

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Front cover and Maintenance covers Opening/closing the front cover and maintenance covers Do not open any of the front cover and maintenance covers during printing operation. Opening any cover during printing interrupts image printing, which can not be resumed from the interrupted point. -

Page 45: Relationships Between Ink Station And Head Row

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Relationships between ink station and head row The carriage mounts four heads each with eight rows of nozzles. One color ink is applied to each row of nozzles. Remember these relationships when checking the heads for clogged nozzles, replacing ink cartridge and replenishing inks. -

Page 46: Cartridge Control

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Cartridge control The printer uses two ink cartridges for each supply system (each nozzle row), i.e., 16 cartridges in total. For each supply system, always only one cartridge of the two works as the supply cartridge. Switching is made between the two cartridges so that the two cartridge locations are selected alternately for the supply cartridge. - Page 47 CHAPTER 2 Basic Use of Printer Names of Parts and Functions Relationship between warning and operation When switching in one supply system is impossible, the LCD panel displays the warning concerning the current supply cartridge. Local/remote idle warning Guidance function warning display detailed display Cleaning...

-

Page 48: Carriage

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Carriage The carriage is provided with the ink heads for printing, the cutter unit for cutting off the sheet of media, etc. Cutter unit Capping station The capping station consists of the ink caps, the wiper for cleaning the heads, etc. The ink caps prevent the nozzles in the ink heads from drying up. -

Page 49: Cutter Blade And Cutting Line

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Cutter blade and cutting line The carriage is provided with a cutter unit for cutting off the media that has been printed on. The cutter cuts off the sheet of media along the cutting line on the platen. (Refer to “Cutting the media after completion of printing (p.3-43)”... -

Page 50: Pinch Rollers And Feed Rollers

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Pinch rollers and Feed rollers This printer retains the media with the pinch rollers and feed rollers. During printing operation, the feed rollers feed the media forward. While the printer is not being used, raise the clamp lever to keep the pinch roll- ers in the raised position. -

Page 51: Heater

CHAPTER 2 Basic Use of Printer Names of Parts and Functions Heater The platen incorporates the pre-heater, print heater and after-heater. The pre-heater preheats the media before printing to prevent abrupt temperature change at start of printing. The print heater supports the high print quality and the after-heater dries the ink on the print. LEDs indicate the turning ON/OFF and status of the respective heaters. -

Page 52: Operation Panel

CHAPTER 2 Basic Use of Printer Operation Panel Operation Panel Use the operation panel to make settings for printing or operate the printer. The operation panel is equipped with one lamps (a) to indicate the status of the printer, two displays (b), eight keys (c) to be used for various operations, seven direct keys (d) to facilitate invoking various functions, and two keys and seven lamps (e) to control the three heater. -

Page 53: Display

CHAPTER 2 Basic Use of Printer Operation Panel Display Each setting or message displayed on the LCDs is enclosed in [ ], like [TYPE 1], [PLEASE WAIT], etc. in the text of this manual. The operation keys are shown enclosed in brackets [ ]. [ ] indicates that the down JOG key is to be pressed. - Page 54 CHAPTER 2 Basic Use of Printer Operation Panel Item / setting value indicating status The LCDs show the particular operation for a selected job. Choose a head Display 1 to fill. FILL UP INK Display 2 HEAD SELECT : 12. 34 Display 1 : There may be a case where nothing is displayed, depending on the selected item;...

-

Page 55: How To Read The Led Indications

CHAPTER 2 Basic Use of Printer Operation Panel How to read the LED indications The LEDs light up to indicate the status of the printer as described below. BUSY lamp Pre-heater Print heater HEAT SW lamp After-heater Name Function Lights up when the printer is currently executing some processing. BUSY lamp While this lamp is lit, never open any cover of the printer and never operate any key;... -

Page 56: How To Use The Keys

CHAPTER 2 Basic Use of Printer Operation Panel How to use the keys The functions of the operation panel are described below. 2-18... -

Page 57: Functions Of The Jog Keys

CHAPTER 2 Basic Use of Printer Operation Panel Name Function JOG keys Use these keys to shift the carriage or the media in [LOCAL mode]. Also use [ ] , [ ] , [ ] , [ ] them to select an item of printing conditions. 2 [FUNCTION] key Use this key to display function setting menu. -

Page 58: Modes And Menu Screens

CHAPTER 2 Basic Use of Printer Modes and Menu Screens Modes and Menu Screens Modes This printer is provided with the following four modes: NOT-READY mode This is the mode in which the media has not been detected yet. The keys other than the [REMOTE] key and the [TEST DRAW] key are effective. LOCAL mode The printer enters this mode when the media has been detected. -

Page 59: About Function Menus

CHAPTER 2 Basic Use of Printer About Function Menus About Function Menus Basic operation of a menu screen This printer incorporates various functions, which can be operated on the operation panel. The [FUNC- TION Mode] permits operating the functions for settings of the system and optional units, cleaning of the heads, test printing and so on. - Page 60 CHAPTER 2 Basic Use of Printer About Function Menus Operation to set function menus To set a function menu, press the [FUNCTION] key in LOCAL mode and press [ ], [ ], [ ] or [ ] or [ENTER] key as appropriate. If the printer is not in LOCAL mode, press the [REMOTE] key once. How to make setting As an example of setting procedure, that for [SET UP] →...

- Page 61 CHAPTER 2 Basic Use of Printer About Function Menus Press the [ ] or [ ] key to set ON/OFF of automatic cleaning. Press the [FUNCTION] key again if the setting of [CLEANING INTERVAL] and [CLEAN- ING TYPE] is needed. This setting is permitted only when automatic cleaning [ON] is selected.

-

Page 62: Outline Of Menu Hierarchy

CHAPTER 2 Basic Use of Printer About Function Menus Outline of menu hierarchy Function menu Press the [FUNCTION] key to invoke the function menu. 2-24... - Page 63 CHAPTER 2 Basic Use of Printer About Function Menus 2-25...

- Page 64 CHAPTER 2 Basic Use of Printer About Function Menus Direct keys Pressing direct keys will easily invoke frequently used functions. 2-26...

-

Page 65: Setting Values In Function Menus

CHAPTER 2 Basic Use of Printer About Function Menus Setting values in function menus The menus contain the following functions. SET UP functions Function name Sub function Setting value Function MEDIA COMP. (p. 3-34) -255 to 255 Corrects the feed rate of media. MediaFeed FEED METHOD DIRECT, NORMAL... - Page 66 CHAPTER 2 Basic Use of Printer About Function Menus Function name Sub function Setting value Function AUTO CLEAN- CLEANING 10 to 10000 mm Cleans the print heads automatically ING (p. 3-44) , INTERVAL every completion of printing. (p. 6-10) CLEANING SOFT, NORMAL, HARD TYPE HEAD GAP (p.

-

Page 67: Maintenance Functions

CHAPTER 2 Basic Use of Printer About Function Menus MAINTENANCE functions Function name Sub function Setting value Function ST.MAINTE- CARRIAGE OUT Move the carriage when cleaning the NANCE (Can be selected directly by pressing inside of the station and replacing [ST.MAINT] key.) (p. - Page 68 CHAPTER 2 Basic Use of Printer About Function Menus Function name Sub function Setting value Function PG DROP PATTERN 1 to 8 -40.0 to 40.0 dot Set the reference value for correct- ADJUST. ing the misalignment of the ink fall (p.

- Page 69 CHAPTER 2 Basic Use of Printer About Function Menus Function name Sub function Setting value Function MEDIA RESIDUAL (p. 6-14) ON, OFF Set ON/OFF of the media remaining amount display function. Input the media length (initial value of remaining amount ) when the roll media is detected.

- Page 70 CHAPTER 2 Basic Use of Printer About Function Menus MACHINE SET functions Function name Sub function Setting value Function DEODORIZE STOP TIME 0 to 240 Min, CONTINUE Make operation settings of the FAN (p. 6-19) exhaust fan. RENEW ON, OFF DRYNESS FEED (p.

- Page 71 CHAPTER 2 Basic Use of Printer About Function Menus NCU functions Function name Sub function Setting value Function NOZZLE CHECK (p. 6-26) ON, OFF Set whether or not to perform nozzle missing detection. NG ACTION (*1) CONTINUE Set the operation of the printer to be [DURING THE performed during printing in case a CLEAN-...

- Page 72 CHAPTER 2 Basic Use of Printer About Function Menus 2-34...

- Page 73 CHAPTER 3 Print Output This chapter describes a series of operations and settings, ranging from power-on to end of printing. Operation flow ................3-2 Turning the power on .............3-3 Adjusting the head gap ............3-5 Setting the media on the printer ..........3-7 Selecting and checking printing conditions ......3-20 Operating the heaters ............3-22 Operating the heaters ............3-22...

-

Page 74: Chapter 3 Print Output

CHAPTER 3 Print Output Operation flow Operation flow The following shows a series of operations and settings, ranging from power-on to end of printing. For details, refer to the appropriate page. Turning the power on p. 3-3 Adjusting the head gap p. - Page 75 CHAPTER 3 Print Output Turning the power on Turning the power on The printer is provided with the following two power switches. Power switch Main power switch Front of the printer body Rear of the printer body Main power switch : Located on the rear of the printer.

-

Page 76: Starting Up The Printer

CHAPTER 3 Print Output Turning the power on Starting up the printer Make sure that the front cover and maintenance covers are all closed. If any of the covers is open, the printer does not start up properly. STEPS: Turn on the power to the printer. Press the power switch located on the front of the printer once. -

Page 77: Adjusting The Head Gap

CHAPTER 3 Print Output Adjusting the head gap Adjusting the head gap Set the head gap (height from the media to the nozzle plane of the heads). When the carriage is to move above the platen for printing or maintenance, it moves while keeping the head gap at the preset value. -

Page 78: How To Check The Head Gap

CHAPTER 3 Print Output Adjusting the head gap How to check the head gap Check the head gap by the following procedure. STEPS: Make sure that the printer is in LOCAL mode. If it is in REMOTE mode, press the [REMOTE] key. 35°C 40°C 50°C... -

Page 79: Setting The Media On The Printer

Setting the media on the printer Setting the media on the printer This printer can be used with roll media and cut sheet media. Use the media recommended by MIMAKI. (Refer to “Sizes of media that can be used (p.1-17)” ) If a transparent media is set, the message [ERROR 50 MEDIA DETECT] is dis- played and the media may not be detected. -

Page 80: Changing The Angular Position Of The Drying Fan

CHAPTER 3 Print Output Setting the media on the printer Changing the angular position of the drying fan The angular position of the drying fan can be changed in two steps to meet the drying condition of the media. Change the position if necessary. Set the media with both the covers of the printer body and front exhaust unit open. -

Page 81: Setting Roll Media On The Printer

CHAPTER 3 Print Output Setting the media on the printer Setting roll media on the printer The procedure for setting roll media on the printer is described below. The roll media is heavy in weight. Take care not to drop it on your foot. Also take care not to throw out your back. - Page 82 CHAPTER 3 Print Output Setting the media on the printer Set the left end of the core of the roll media on the let roll holder. Push the roll media onto the roll holder until the roll core is all the way seated. The roll media can be set easily if you handle it while supporting it with the media support bar.

- Page 83 CHAPTER 3 Print Output Setting the media on the printer Insert the unrolled part of the roll media between the platen and the pinch rollers and pull the unrolled part until its leading edge is positioned on the front of the printer. Pinch roller Platen Push down the clamp lever at the rear of the printer.

- Page 84 CHAPTER 3 Print Output Setting the media on the printer Pull out the roll media gently and then stop pulling when locked lightly. Pull the roll media from side to side evenly and push down the clamp lever. 3-12...

- Page 85 CHAPTER 3 Print Output Setting the media on the printer Hold the medium with the media press gently. Take care not to cut your finger with the media press. Adjust the position of the roll holders so that the right end of the media on the media encoder roller is positioned to the right of the right-end pinch roller.

- Page 86 CHAPTER 3 Print Output Setting the media on the printer Adjust the level adjusters of the take-up device so that the bottom of each of them rests on the floor and secure them by tightening the thumb screws. Close the front cover and press the [ENTER] key. The printer performs initial operation and displays the screen for media selection.

- Page 87 CHAPTER 3 Print Output Setting the media on the printer Press the Jog key [ ] to feed the media up to the paper tube of the take-up device. Fix the media to the free paper tube with adhesive tape. 3-15...

- Page 88 CHAPTER 3 Print Output Setting the media on the printer When the media thickness cannot be detected There may be a case where the media thickness cannot be detected properly depending on the media. In such a case, the media thickness must be input manually. STEPS: An error is displayed, and the carriage returns to the station.

-

Page 89: How To Operate The Take-Up Device

CHAPTER 3 Print Output Setting the media on the printer How to operate the take-up device The take-up device is equipped with a switch that selects the direction in which the media is to be wound. Torque limiter Switch Lever in top position (REVERSE) The take-up device winds the media with the printed side facing in. -

Page 90: Setting Cut Sheet Media On The Printer

CHAPTER 3 Print Output Setting the media on the printer Setting cut sheet media on the printer Unlike roll media, cut sheet media need not be retained with the roll holders. When using cut sheet media, take care not to set it skew. STEPS: Open the front cover and raise the clamp lever. - Page 91 CHAPTER 3 Print Output Setting the media on the printer Push down the clamp lever. Clamp lever Press the [ ] key to select [LEAF]. The printer performs initial operation and displays the screen for media selection. Close the front cover and press the [ENTER] key. After detecting the media, the printer returns to LOCAL mode.

-

Page 92: Selecting And Checking Printing Conditions

CHAPTER 3 Print Output Selecting and checking printing conditions Selecting and checking printing conditions When the Type 1 to Type 4 printing conditions have already been registered, only selecting an appropriate Type is required to switch between the settings to meet the desired printing. How to select a user type STEPS: (Setting by [FUNCTION] key) Make sure that the printer is in LOCAL mode, and then select [SET UP] using the... -

Page 93: How To Check The User Type

CHAPTER 3 Print Output Selecting and checking printing conditions How to check the user type The user type currently used for printing can be identified by such an indication as [L.1] or [R.1] that is displayed in LOCAL mode or REMOTE mode. 35°C 40°C 50°C... -

Page 94: Operating The Heaters

CHAPTER 3 Print Output Operating the heaters Operating the heaters Turning on the power to the heaters Press the [HEAT SW] key on the operation panel to turn on the power to the heaters. The HEAT lamps are lit orange while the heaters are in heating operation, respectively. The CONSTANT lamps light up green when the temperatures of the heaters reach the preset temperature, respectively. -

Page 95: Checking The Preset Temperature And Setting A Temperature During Printing

CHAPTER 3 Print Output Operating the heaters Checking the preset temperature and setting a temperature during printing This section describes how to adjust the heater temperatures which have already been set in FUNCTION mode (Refer to “Setting the temperatures and standby time of heaters (p.6-31)” ). STEPS: Make sure that the Heater Switch is turned ON. -

Page 96: What Is Beading

CHAPTER 3 Print Output Operating the heaters What is beading ? Beading is a phenomenon that adjacent dots attracts each other and join. Beading causes speckled patterns or stripes along printing passes (banding.) Example of beading The area in 100% magenta looks fine. Generally, the area in 70-100% single color is easily affected by the unevenness of media feed rate. -

Page 97: Temperature Adjustment

CHAPTER 3 Print Output Operating the heaters Temperature adjustment This section describes the procedure for setting the heater temperatures properly. The proper heater tem- peratures depend on the media type and ambient temperature. Set temperatures that are appropriate to the media. For non-coated media or media on which ink is slow to dry, set the heater temperatures so that the ink fixing and drying characteristics will be improved. -

Page 98: In Case Of Heater Trouble

CHAPTER 3 Print Output Operating the heaters In case of heater trouble When the Power Switch of the heaters is turned off, or if heaters have developed problem, the display turns as shown below. For recovery from trouble, refer to “Warning messages” of “CHAPTER 5 In Case of Trouble”. -

Page 99: Setting The Reference Value For Dot Misalignment Correction

CHAPTER 3 Print Output Setting the reference value for dot misalignment correction Setting the reference value for dot misalignment correction [PG DROP ADJUST.] Correct the difference in the ink fall points between outward trip and homeward trip. Set the reference value for the automatic adjustment to be made when the head gap is changed. Print eight types of test patterns, compare the ink fall points of outward trip and those of homeward trip and adjust dot positions. - Page 100 CHAPTER 3 Print Output Setting the reference value for dot misalignment correction Press the [ ] or [ ] key to correct the dot position of pattern 1. Select the correct dot position on [PATTERN 1] using the JOG key [ ] or [ ]. Select the dot position where the dots of outward trip and those of homeward trip form a straight line on the test pattern.

-

Page 101: Checking For Nozzle Clogging, And Unclogging Nozzles

CHAPTER 3 Print Output Checking for nozzle clogging, and unclogging nozzles Checking for nozzle clogging, and unclogging nozzles Print a test pattern and check to see if there is no faulty print due to clogged nozzles. If any, execute the cleaning function. To print a test pattern on a cut sheet media, use a media whose size is not smaller than 350 mm in width and 600 mm in length (dimension in the media feed direction). -

Page 102: If The Printed Pattern Is Abnormal (Cleaning)

CHAPTER 3 Print Output Checking for nozzle clogging, and unclogging nozzles If the printed pattern is abnormal (Cleaning) STEPS: Make sure that the printer is in LOCAL mode. If it is in REMOTE mode, press the [REMOTE] key. 35°C 40°C 50°C L. - Page 103 CHAPTER 3 Print Output Checking for nozzle clogging, and unclogging nozzles Press the [ENTER] key. Cleaning starts. The second line of the lower LCD shows the progress of the operation as increase in the number of * marks . On completion of cleaning, the printer returns to LOCAL mode. 35°C 40°C 50°C...

-

Page 104: If Nozzles Cannot Be Unclogged [Fill Up Ink]

CHAPTER 3 Print Output Checking for nozzle clogging, and unclogging nozzles If nozzles cannot be unclogged [FILL UP INK] Execute the [FILL UP INK] function when the blocked nozzles are not unclogged even by executing head cleaning (See 3-30) and nozzle washing (Refer to “Cleaning the nozzle [NOZZLE WASH] (p.4- 10)”... - Page 105 CHAPTER 3 Print Output Checking for nozzle clogging, and unclogging nozzles Press the [END] key several times. The printer returns to LOCAL mode. 35°C 40°C 50°C L. ∗ > [JV5-01] width : ∗∗∗∗ mm 3-33...

-

Page 106: Correcting The Media Feed Rate [Media Comp.]

CHAPTER 3 Print Output Correcting the media feed rate [MEDIA COMP.] Correcting the media feed rate [MEDIA COMP.] The media feed rate changes when the media type or any heater temperature is changed, or depending on whether the take-up device is used or not. Be sure to correct the media feed rate. If the correction value is not appropriate, stripes may appear on the print, thus resulting in a poor print. - Page 107 CHAPTER 3 Print Output Correcting the media feed rate [MEDIA COMP.] By judging from the output pattern, enter a correction value using the [ ] or [ ] key. A change of the value of [VALUE] by 6 will move the band by about 0.01 mm. Remember this when determining the correction value.

-

Page 108: If Dots Are Not In Alignment [Drop.poscorrect]

CHAPTER 3 Print Output If dots are not in alignment [DROP.POScorrect] If dots are not in alignment [DROP.POScorrect] Dots may be slightly out of alignment even after [PG DROP ADJUST.] is made. In this case, execute [DROP.POScorrect] to correct the dot position. [DROP.POScorrect] corrects the difference in the ink fall points between outward trip and homeward trip. - Page 109 CHAPTER 3 Print Output If dots are not in alignment [DROP.POScorrect] Press the [ ] or [ ] key to correct the dot position of pattern 1. Select the correct dot position on [PATTERN 1] using the JOG key [ ] or [ ]. Select the dot position where the dots of outward trip and those of homeward trip form a straight line on the test pattern.

-

Page 110: Effective Plotting Area

CHAPTER 3 Print Output Effective Plotting Area Effective Plotting Area The printer has an area where printing is not permitted, for mechanical reasons. This area is called “non-printing area”. 0 mm 200 mm Effective Effective 15 mm 15 mm 15 mm 15 mm printing area printing area... -

Page 111: Establishing The Origin

CHAPTER 3 Print Output Establishing the Origin Establishing the Origin Establish the origin for printing the data on the media loaded on the printer. When printing requires an area other than that defined by the established origin, set the origin at another point by following the origin setting procedure again. -

Page 112: Printing An Image

Before printing, be sure to take up the slack, if any, in the roll media by hand; a loose roll media can result in an inferior image quality. Provide the following information when you consult MIMAKI’s service center on problems about printing. - Page 113 CHAPTER 3 Print Output Printing an image STEPS: Check the heater temperatures. Make sure that the CONSTANT lamps on the heater panel are lit. (See 3-22) Press the [REMOTE] key. The printer enters REMOTE mode. The currently selected type (printing conditions) can be confirmed. (Refer to “Registering printing condi- tions in a lump (type registration) (p.6-3)”...

-

Page 114: Interrupting The Printing Operation

CHAPTER 3 Print Output Printing an image Interrupting the printing operation To interrupt the printing operation, stop the carriage by pressing the [REMOTE] key and erase the received data from the printer. The next time the printer enters REMOTE mode, it would start printing with the data that was interrupted if the data has not been erased. -

Page 115: Cutting The Media After Completion Of Printing

CHAPTER 3 Print Output Printing an image Cutting the media after completion of printing After completion of printing, cut the media at any desired position without using the [AUTO CUT] func- tion. Do not turn off the main power switch at the rear of the printer even after com- pletion of printing. -

Page 116: Automatic Cleaning

CHAPTER 3 Print Output Printing an image Automatic cleaning Setting can be made to select whether or not to clean the heads automatically during printing. Reliable output results are always ensured if the heads are always kept clean. The first cleaning is performed immediately before the first printing after the printer is started. Then subse- quent cleaning is performed every printing on the specified length of media. - Page 117 CHAPTER 3 Print Output Printing an image Press the [FUNCTION] key. CLEANING INTERVAL 10 - 10000mm INTERVAL : TYPE 1000mm : NORMAL At this point, either of [CLEANING INTERVAL] and [CLEANING TYPE] can be selected by pressing the [ ] or [ ] key. CLEANING INTERVAL CLEANING TYPE 10 - 10000mm...

-

Page 118: Display Of [Ink Near End] Or [Ink End]

CHAPTER 3 Print Output Display of [INK NEAR END] or [INK END] Display of [INK NEAR END] or [INK END] A message appears when one of the two ink cartridges in a set is completely empty and the other is nearly empty. - Page 119 CHAPTER 3 Print Output Display of [INK NEAR END] or [INK END] STEPS FOR REPLACEMENT When a cartridge LED (red) is lit or flashing, replace the cartridge immediately. Never remove any cartridge if there is no cartridge to be installed in place of the cartridge to be removed.

- Page 120 CHAPTER 3 Print Output Display of [INK NEAR END] or [INK END] Display ink information The remaining amount of ink can be checked. STEPS: Press the [ENTER] key while the printer is in REMOTE mode. The remaining amount of ink is displayed in nine steps using numbers 1 to 9. “1” indicates that only a little amount of ink is remaining.

-

Page 121: Turning The Power Off

If the main power switch is left turned off for an extended period of time, noz- zles will be clogged. In such a case, the printer must be repaired by MIMAKI’s service engineer. Keep the front cover and maintenance covers all closed. If any of the covers is open, the nozzle clogging preventive function will not be activated. - Page 122 CHAPTER 3 Print Output Turning the power off 3-50...

- Page 123 CHAPTER 4 Daily Maintenance This chapter describes the recovery procedure for ink clogging and the cleaning pro- cedure for each section. Routine Maintenance ......................4-2 Cleaning the wiper and ink caps [CARRIAGE OUT] .............4-7 Cleaning the nozzle [NOZZLE WASH] ................4-10 Cleaning the ink discharge passage [DISWAY WASH] ............4-13 When the operation of the printer is to be suspended for a long time [CUSTODY WASH] .4-15 Before executing the [PUMP TUBE WASH] ................4-19 PUMP tube cleaning ......................4-22...

-

Page 124: Chapter 4 Daily Maintenance

CHAPTER 4 Daily Maintenance Routine Maintenance Routine Maintenance Be sure to perform maintenance of the printer periodically or whenever necessary so that the printer can be used with its inherent accuracy for a long time. Precautions in cleaning Icon Meaning When using the cleaning solution, be sure to wear the supplied protective glasses. -

Page 125: Notes On Cleaning Solution

CHAPTER 4 Daily Maintenance Routine Maintenance Notes on cleaning solution Use the cleaning liquid dedicated for the ink being used. ES3 INK Cleaning solution MS2/ES3/HS kit 100 (SPC-0369) HS INK Cleaning exterior surfaces If exterior surfaces of the printer is stained, dampen a soft cloth with water or a neutral detergent diluted with water, squeeze it and wipe the surfaces with the cloth. -

Page 126: Cleaning The Media Sensor

CHAPTER 4 Daily Maintenance Routine Maintenance Cleaning the media sensor Using a cotton swab, clean the surface of the sensor of dust and dirt. Cleaning the media press If media chips and dust accumulate between the media press and platen, there may be a case where media cannot be fed normally or chips or dust may adhere to nozzles, thus disturbing normal printing. -

Page 127: Opening A Maintenance Cover

CHAPTER 4 Daily Maintenance Routine Maintenance Opening a maintenance cover Remove a maintenance cover to clean the inside of the printer. It is necessary to remove the appropriate one of the right and left maintenance cover, depending on the part to be cleaned. Remove one of the main- tenance covers by the following procedure. - Page 128 CHAPTER 4 Daily Maintenance Routine Maintenance STEPS: Remove the top two screws for the maintenance cover. With the shaft of the frame as the fulcrum, turn over the maintenance cover toward the front so that it is placed in the vertical position. Pull out the maintenance cover upward.

-

Page 129: Cleaning The Wiper And Ink Caps [Carriage Out]

CHAPTER 4 Daily Maintenance Cleaning the wiper and ink caps [CARRIAGE OUT] Cleaning the wiper and ink caps [CARRIAGE OUT] The ink caps prevent the nozzles in the heads from drying and thus being clogged. The wiper wipes off the ink adhering to nozzles. As the printer is used, the wiper and ink caps gradually become stained with ink and dust. - Page 130 CHAPTER 4 Daily Maintenance Cleaning the wiper and ink caps [CARRIAGE OUT] Open the right maintenance cover. Pull out the wiper by holding the projections at both ends. Remove the ink from the wiper and the bracket using a cotton swab dampened with the cleaning solution.

- Page 131 CHAPTER 4 Daily Maintenance Cleaning the wiper and ink caps [CARRIAGE OUT] After cleaning the wiper, install it in position by holding the projections at both ends. Wipe off ink or dirt adhering to the rubbers of the caps and the wiper cover using a cotton swab dampened with the cleaning solution.

-

Page 132: Cleaning The Nozzle [Nozzle Wash]

(Refer to “[DISCHARGE&WASH] (p.5-6)” ) functions. If the remedies instructed here do not work, contact your dealer or an office of MIMAKI. If both of the two cartridges in a set are in [INK NEAR END] or [INK END] status, the nozzle cleaning function (ink suction) is not activated. - Page 133 CHAPTER 4 Daily Maintenance Cleaning the nozzle [NOZZLE WASH] Pull out the wiper by holding the projections at both ends. Remove the ink from the wiper, bracket and the vicinity of the wiper insertion hole using a cotton swab dampened with the cleaning solution. Replace the wiper with a new one if it is badly soiled or curled.

- Page 134 CHAPTER 4 Daily Maintenance Cleaning the nozzle [NOZZLE WASH] Press the [ENTER] key. Clean a wiper and bracket. WIPER CLEANING COMPLETED(NEXT) : ent Fill the caps with the cleaning solution using a dropper. Ink cap Close the maintenance cover and press the [ENTER] key. Fill a cap with washing liquid fully Fill the liquid.

-

Page 135: Cleaning The Ink Discharge Passage [Disway Wash]

In such a case, the pump may be clogged. If the pump is clogged, contact your dealer or a sales office of MIMAKI. STEPS: Make sure that the printer is in LOCAL mode, and then press the [ST.MAINT] key. - Page 136 CHAPTER 4 Daily Maintenance Cleaning the ink discharge passage [DISWAY WASH] Open the right maintenance cover. Take the cleaning solution into the dropper. During a pause of idle suction, drop cleaning liquid into a cap until just before it starts overflowing from the cap.

-

Page 137: When The Operation Of The Printer Is To Be Suspended For A Long Time [Custody Wash]

CHAPTER 4 Daily Maintenance When the operation of the printer is to be suspended for a long time When the operation of the printer is to be suspended for a long time [CUSTODY WASH] When the operation of the printer is to be suspended for a week or more, use the [CUSTODY WASH] func- tion to clean the nozzles in the heads and the ink discharge passage. - Page 138 CHAPTER 4 Daily Maintenance When the operation of the printer is to be suspended for a long time Pull out the wiper by holding the projections at both ends. Remove the ink from the wiper and the bracket using a cotton swab dampened with the cleaning solution.

- Page 139 CHAPTER 4 Daily Maintenance When the operation of the printer is to be suspended for a long time Press the [ENTER] key. Clean a wiper and bracket. WIPER CLEANING COMPLETED(NEXT) : ent Fill the caps with the cleaning solution using a dropper. Ink cap Close the maintenance cover and press the [ENTER] key.

- Page 140 CHAPTER 4 Daily Maintenance When the operation of the printer is to be suspended for a long time Open the maintenance cover, and fill the caps with the cleaning solution using a dropper. Since the printer performs idle suction operation intermittently, repeat this work several times to clean the ink discharge passage.

-

Page 141: Before Executing The [Pump Tube Wash]

CHAPTER 4 Daily Maintenance Before executing the [PUMP TUBE WASH] Before executing the [PUMP TUBE WASH] Before executing the [PUMP TUBE WASH] or [Wiper cleaning] function, the tubes must be filled with the cleaning solution. Filling the tubes with the cleaning solution [MaintWashLiquid] Supply and discharge the cleaning liquid for the wiper and pump tubes. - Page 142 CHAPTER 4 Daily Maintenance Before executing the [PUMP TUBE WASH] At this point, either of [FILLING UP] and [DISCHARGE] can be selected by pressing the [ ] or [ ] key. MaintWashLiquid MaintWashLiquid FILLING UP <ent> DISCHARGE <ent> To step 5 To step 10 Press the [ENTER] key to go to the lower level of hierarchy and supply the cleaning solution.

- Page 143 CHAPTER 4 Daily Maintenance Before executing the [PUMP TUBE WASH] Set a cleaning liquid cartridge according to the instruction on the display. Remove a filling Set a washing up cartridge. liquid cartridge. There is a CARTRIDGE CARTRIDGE : none Either of the following displays will appear if a problem with the cleaning liquid cartridge is detected.

-

Page 144: Pump Tube Cleaning

CHAPTER 4 Daily Maintenance PUMP tube cleaning PUMP tube cleaning Wash the two ink suction pumps of the four pumps installed in this printer. By driving the cleaning liquid suction pump, wash the ink caps, ink exhaust passages, and the inside of the tubes of the ink suction pumps. - Page 145 CHAPTER 4 Daily Maintenance PUMP tube cleaning STEPS: Make sure that the printer is in LOCAL mode, and then press the [ST.MAINT] key. If it is in REMOTE mode, press the [REMOTE] key. 35°C 40°C 50°C L. ∗ > [JV5-01] ST.MAINTENANCE width : ∗∗∗∗...

-

Page 146: Wiper Cleaning

CHAPTER 4 Daily Maintenance Wiper cleaning Wiper cleaning Bring the wiper into the wiper box and wash the wiper. Washing will not be started if the cleaning liquid has not been supplied or the cleaning liquid cartridge has not been installed. Before executing the [WIPER WASH] function, the tubes must be filled with the cleaning solution. - Page 147 CHAPTER 4 Daily Maintenance Wiper cleaning Open the right maintenance cover. Pull out the wiper by holding the projections at both ends. Remove the ink from the wiper and the bracket using a cotton swab dampened with the cleaning solution. Replace the wiper with a new one if it is badly soiled or curled.

- Page 148 CHAPTER 4 Daily Maintenance Wiper cleaning After cleaning the wiper, install it in position by holding the projections at both ends. Wipe off ink or dirt adhering to the rubbers of the caps and the wiper cover using a cotton swab dampened with the cleaning solution. Be careful not to leave lint of the cotton swab.

-

Page 149: Cleaning The Heads And Their Surrounding Parts

CHAPTER 4 Daily Maintenance Cleaning the heads and their surrounding parts Cleaning the heads and their surrounding parts [CR.MAINTENANCE] Take great care, especially during cleaning, not to damage the heads, which employ very precise mechanisms. Using a cotton swab, rub off the gelatinous ink that may be adhering to the lower part of the slider and sur- rounding parts of the heads. - Page 150 CHAPTER 4 Daily Maintenance Cleaning the heads and their surrounding parts Wipe ink and dirt off the head sides using a cotton swab. Never rub the nozzle part. Clean the sides of the heads using a cotton swab. After completing whole cleaning, press the [ENTER] key. CR.MAINTENANCE Close a cover.

-

Page 151: Cleaning The Head Media Sensor

CHAPTER 4 Daily Maintenance Cleaning the heads and their surrounding parts Cleaning the head media sensor Dust or ink sticking to the media sensor at the heads can cause a false detection of media. Wipe the dust and ink off with a soft cloth. Media sensor at the heads 4-29... -

Page 152: Preventing Nozzle Clogging While Power Is Off [Sleep Set Up]

CHAPTER 4 Daily Maintenance Preventing nozzle clogging while power is off [SLEEP SET UP] Preventing nozzle clogging while power is off [SLEEP SET UP] Even while the power switch is off, the printer starts periodically and executes various functions to prevent nozzle clogging. -

Page 153: Tube Cleaning Interval During Sleep Mode [Tube Wash]

CHAPTER 4 Daily Maintenance Preventing nozzle clogging while power is off [SLEEP SET UP] Tube cleaning interval during sleep mode [TUBE WASH] Set the interval at which cleaning of the caps and pump tubes is to be performed using the cleaning solu- tion during sleep mode. -

Page 154: Cleaning Interval During Sleep Mode [Cleaning]

CHAPTER 4 Daily Maintenance Preventing nozzle clogging while power is off [SLEEP SET UP] Cleaning interval during sleep mode [CLEANING] This function is to be executed instead of TUBE WASH after the cleaning solution has been used up. Set the cleaning type and the interval at which cleaning operation is to be performed during sleep mode. STEPS: Make sure that the printer is in LOCAL mode, and then select [MAINTENANCE] using the [FUNCTION] key and press the [ENTER] key. -

Page 155: Setting Periodical Operations In Stand-By Mode [Routine Setup]

CHAPTER 4 Daily Maintenance Setting periodical operations in stand-by mode [ROUTINE SETUP] Setting periodical operations in stand-by mode [ROUTINE SETUP] While the printer is waiting for the next printing job, it can perform various operations at fixed intervals to prevent ink clogging or the like. The [ROUTINE SETUP] function is available for the following items: During printing, the printer performs nozzle face wiping at fixed intervals to remove con- ROUTINE WIPING... - Page 156 CHAPTER 4 Daily Maintenance Setting periodical operations in stand-by mode [ROUTINE SETUP] At this point, either of [SCAN COUNT] and [TEMP.difference] can be selected by pressing the [ ] or [ ] key. The interval of Set up a difference wiping is set up.

-

Page 157: Periodical Refresh Interval [Refersh]

CHAPTER 4 Daily Maintenance Setting periodical operations in stand-by mode [ROUTINE SETUP] Periodical refresh interval [REFERSH] Set the interval at which refreshing operation is to be performed periodically. STEPS: Make sure that the printer is in LOCAL mode, and then select [MAINTENANCE] using the [FUNCTION] key and press the [ENTER] key. -

Page 158: Periodical Tube Cleaning Interval [Tube Wash]

CHAPTER 4 Daily Maintenance Setting periodical operations in stand-by mode [ROUTINE SETUP] Periodical tube cleaning interval [TUBE WASH] There may be a chance that ink tubes can be clogged with coagulated ink. To avoid clogging, clean the ink tubes at regular intervals. STEPS: Make sure that the printer is in LOCAL mode, and then select [MAINTENANCE] using the [FUNCTION] key and press the [ENTER] key. -

Page 159: Periodical Cleaning Interval [Cleaning]

CHAPTER 4 Daily Maintenance Setting periodical operations in stand-by mode [ROUTINE SETUP] Periodical cleaning interval [CLEANING] This function is to be executed instead of TUBE WASH after the cleaning solution has been used up. Set the cleaning type and the intervals at which cleaning operation is to be performed. This function does not operate when the error message relating to ink, such as INK NEAR END or INK END, is displayed. -

Page 160: Setting Periodical Operations In Stand-By Mode [Routine Setup

CHAPTER 4 Daily Maintenance Setting periodical operations in stand-by mode [ROUTINE SETUP] Select the interval at which cleaning is to be performed periodically, using the [ ] or [ ] key. Select [CLEAN. TYPE] using the [FUNCTION] key and set a cleaning type using the [ ] or [ ] key. -

Page 161: Other Maintenance Functions

CHAPTER 4 Daily Maintenance Other maintenance functions Other maintenance functions Changing the time for warning of wiper replacement [WIPER LEVEL] The wiper is consumable. The heads are easily soiled in a dusty environment. The heads cannot be cleaned adequately with a curled or worn wiper. This printer gives the wiper replace- ment warning earlier than standard depending on the operating environment. - Page 162 CHAPTER 4 Daily Maintenance Other maintenance functions Input the WIPER LEVEL, using the [ ] or [ ] key. Register the setting by pressing the [ENTER] key. 10/10 - 1/10 35°C 40°C 50°C L. ∗ > WIPER LEVEL [JV5-01] width : ∗∗∗∗ mm LEVEL : 10/10 Press the [END] key several times.

-

Page 163: When The Waste Ink Tank Is Full

CHAPTER 4 Daily Maintenance When the waste ink tank is full When the waste ink tank is full Waste ink, which was used for cleaning the heads and other parts, gathers in the waste ink tank. When either of the following error message is displayed, replace the waste ink tank with a new one without delay. - Page 164 CHAPTER 4 Daily Maintenance When the waste ink tank is full Raise the inserted waste ink tank and turn it by 90 degrees rearward. Make sure that the smaller handle is positioned in the front. Close the waste ink tank guard, and secure it with the screw so that the waste ink tank is secured.

-

Page 165: Replacing The Wiper [Wiper Exchange]

The wiper to be newly installed is available as an option. Order it from your dealer or a sales office of MIMAKI. STEPS: Make sure that the printer is in LOCAL mode, and then press the [ST.MAINT] key. - Page 166 CHAPTER 4 Daily Maintenance Replacing the wiper [WIPER EXCHANGE] Clean the wiper guide shaft using a cotton swab or cloth. If dirt is hard to remove, use a cotton swab dampened with the cleaning solution. Install the wiper by holding the projections at both ends. Close the maintenance cover, and press the [ENTER] key.

-

Page 167: Replacing The Cutter Blade

CHAPTER 4 Daily Maintenance Replacing the cutter blade Replacing the cutter blade The cutter blade is consumable. When the cutter blade gets dull, replace it with a new one (SPA-0126). The blade is sharp. Be careful not to hurt yourself or anyone else. Keep the cutter blades away from the reach of children. - Page 168 CHAPTER 4 Daily Maintenance Replacing the cutter blade Loosen the screw securing the cutter unit and remove the cutter unit. Remove the roller, and install it on the new cutter blade holder assembly. Roller of cutter unit Install the new cutter unit. Tighten the screw to secure the new cutter unit.

- Page 169 CHAPTER 5 In Case of Trouble This chapter describes the actions to be taken when the printer develops any trouble. Before taking a phenomenon as a failure ......5-2 If image quality is poor ............5-4 Ink cartridge trouble ............. 5-11 Troubles for which error messages are displayed ....5-13...

-

Page 170: Chapter 5 In Case Of Trouble

This section describes the corrective actions to be taken at the occurrence of trouble without any error mes- sage displayed. Take appropriate actions as described below before taking the trouble as a failure. If still the problem cannot be solved, contact your dealer or an office of MIMAKI. Power does not turn on In most cases, this is due to improper connection of the power cable for the printer or computer. -

Page 171: Media Jamming Arises / Media Is Soiled

CHAPTER 5 In Case of Trouble Before taking a phenomenon as a failure Media jamming arises / media is soiled Media jamming or stained media is considered to be due to the use of an unsuitable media or improper set- ting of media. -

Page 172: If Image Quality Is Poor

This section describes the corrective actions to be taken in case the image quality is not satisfactory. Take rem- edy for particular problems with image quality. If the remedy does not work, contact your dealer or an office of MIMAKI. White lines / blur (sprayed ink) / dark stripes (in the direction of travel of... -

Page 173: Disagreement In Print Positions Between Outward Trip And Homeward Trip (Jet Deviation)

CHAPTER 5 In Case of Trouble If image quality is poor Disagreement in print positions between outward trip and homeward trip (jet deviation) Remedy Execute the [DROP.POScorrect] function. (Refer to “If the printed pattern is abnormal (Cleaning) (p.3-30)” ) There is staggered print or nozzle missing Staggered print Nozzle missing Remedy... -

Page 174: If Nozzles Are Still Clogged Even After Head Cleaning

CHAPTER 5 In Case of Trouble If image quality is poor If nozzles are still clogged even after head cleaning Execute the following two functions if blocked nozzles are not unclogged even by executing HEAD CLEANING (Refer to “If the printed pattern is abnormal (Cleaning) (p.3-30)” ) and NOZZLE WASH (Refer to “Cleaning the nozzle [NOZZLE WASH] (p.4-10)”... - Page 175 CHAPTER 5 In Case of Trouble If image quality is poor Remove the ink cartridges. Ink is discharged to the waste ink tank. Ink discharge. Being discharged Remove cartridges. PLEASE WAIT ∗ ∗ ∗ ∗ ∗ ∗ ∗ − − − − − − − − − − − MMCC YYKK KKYY CCMM When the display shown below appears, set the cleaning liquid cartridge in the ink station.

- Page 176 CHAPTER 5 In Case of Trouble If image quality is poor On completion of one washing process, the display shown below appears. If the heads are to be washed again, return to step 5 by pressing the [ ] key. To terminate washing, press the [ ] key.

-

Page 177: When Nozzle Clogging Is Not Corrected [Head Select]

CHAPTER 5 In Case of Trouble If image quality is poor When nozzle clogging is not corrected [HEAD SELECT] If nozzles cannot be unclogged, make setting so that the printer will not use the head(s) with clogged noz- zles. However, this function is available for printing operation (including nozzle check) and cleaning; ink filling function is applied to all the heads. - Page 178 CHAPTER 5 In Case of Trouble If image quality is poor STEPS: Make sure that the printer is in LOCAL mode, and then select [MAINTENANCE] using the [FUNCTION] key and press the [ENTER] key. If it is in REMOTE mode, press the [REMOTE] key. 35°C 40°C 50°C...

-

Page 179: Ink Cartridge Trouble

If nozzles are clogged, the printer must be repaired by MIMAKI’s service engineer. Displaying the description of ink cartridge trouble The type of the cartridge trouble can be identified. (See 5-14) STEPS: Press the [ENTER] key while the printer is in LOCAL mode. -

Page 180: If Error 202 [Device Construction] Is Displayed

CHAPTER 5 In Case of Trouble Ink cartridge trouble If ERROR 202 [DEVICE CONSTRUCTION] is displayed This printer checks its configuration every time it starts. The configuration checking function checks the resource configuration necessary for use of this printer. When there is an error in any element of the printer, the printer can be started by disconnecting the faulty element. -

Page 181: Troubles For Which Error Messages Are Displayed

CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Troubles for which error messages are displayed If some trouble occurs, the buzzer sounds and the display shows a corresponding error message. Take an appropriate remedy for the displayed error. Checking error history [ERROR HISTORY] The information about the error or warning status the printer is currently in and the history of errors and warnings the printer has developed up to now can be checked by opening the [ERROR HISTORY] display. -

Page 182: Warning Messages

CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Warning messages Warning messages will appear chiefly to warn of the conditions of heaters or ink cartridges. Warning message Cause Remedy An open cover was detected. Check the front cover and maintenance covers. - Page 183 - - - - YYKK - - - - - - - - completely used up. warning with a new one. NON-ORIGINAL INK The ink cartridge is not MIMAKI gen- Replace the cartridge generating the - - - - - - - - KKYY - - - - uine.

- Page 184 CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Warning message Cause Remedy The waste ink tank is nearly full. Replace the waste ink tank with a new !NearFULL WASTE TANK one. (See 4-41) The cleaning liquid cartridge is empty. Replace the cleaning solution cartridge !Wash Liquid END with a new one.

-

Page 185: Error Messages

If any error message is displayed, turn off the power to the printer and turn it on after a while. If the same error message appears again, contact your dealer or an office of MIMAKI to call for service. Error message... - Page 186 CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Error message Cause Remedy ∗∗∗∗∗ ERROR 20 ∗∗∗∗∗ An error occurred in the control sys- Turn off the power to the printer and I/F BOARD 01 tem. turn it on after a while.

- Page 187 CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Error message Cause Remedy ∗∗∗∗∗ ERROR 40 ∗∗∗∗∗ An error occurred in the control sys- Turn off the power to the printer and MOTOR ALARM X tem. turn it on after a while.

- Page 188 CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Error message Cause Remedy The ambient temperature is outside the Adjust the ambient temperature of the ∗∗∗∗ ERROR 120 ∗∗∗∗ permissible temperature range (too printer. ENVIRONMENT TEMP(LO) low).

- Page 189 CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Error message Cause Remedy An error occurred in the control sys- Printing can be resumed after turning tem. off the nozzle missing detection func- ∗∗∗∗ ERROR 160 ∗∗∗∗ tion.

- Page 190 CHAPTER 5 In Case of Trouble Troubles for which error messages are displayed Error message Cause Remedy An error occurred in the control sys- Turn off the power to the printer and tem. turn it on after a while. If the same ∗∗∗∗...

- Page 191 CHAPTER 6 Operation for Functions This chapter describes the operating procedure for frequently used functions from the printer function menu, showing sample messages on the display. Functions Invoked by [FUNCTION] Key ........6-2 Invoking SET UP functions ............6-3 Invoking MAINTENANCE functions ........6-12 Invoking MACHINE SETUP functions ........6-17 Invoking NCU functions ............6-25 DISPLAY setting ..............6-28...

-

Page 192: Chapter 6 Operation For Functions

CHAPTER 6 Operation for Functions Functions Invoked by [FUNCTION] Key Functions Invoked by [FUNCTION] Key The following five types of functions can be invoked by pressing the [FUNCTION] key. Function name Description Refer to p. 6-3 SET UP Make various settings concerning print quality. Maintenance functions are to be executed to keep the printer in good condi- MAINTENANCE p. -

Page 193: Invoking Set Up Functions

CHAPTER 6 Operation for Functions Invoking SET UP functions Invoking SET UP functions Registering printing conditions in a lump (type registration) FUNCTION mode provides 17 setup functions. The setting value of each of the 16 functions other than SETUP RESET can be registered as any of the fol- lowing four types. - Page 194 CHAPTER 6 Operation for Functions Invoking SET UP functions Settings of the setup functions The operation described below on the operation panel is required to execute the setup functions. STEPS: Make sure that the printer is in LOCAL mode, and then select [SET UP] using the [FUNCTION] key and press the [ENTER] key.

-

Page 195: Outline Of The Setup Functions

CHAPTER 6 Operation for Functions Invoking SET UP functions Outline of the setup functions (See 3-34) MEDIA COMP. When the media type or any heater temperature is changed, be sure to correct the feed rate to meet the media thickness. (Correction value: -255 ~ 255) MediaFeed SETUP Set particulars related to media feed. -

Page 196: Print Mode

CHAPTER 6 Operation for Functions Invoking SET UP functions PRINT MODE Sets various conditions of printing. DRAFT quality Set a desired print quality in DRAFT mode (540 dpi resolution in the Y-axis direction). Available setting values: [STD., FINE, FAST] Press the [FUNCTION] key while the quality item is selected. Then the printer permits setting the number of passes for every resolution and setting high-speed printing ON/OFF. - Page 197 CHAPTER 6 Operation for Functions Invoking SET UP functions FINE quality Set a desired print quality in FINE mode (720 dpi resolution in the Y-axis direction). Available setting values: [STD., FINE, FAST] Press the [FUNCTION] key while the quality item is selected. Then the printer permits setting the number of passes for every resolution and setting high-speed printing ON/OFF.

-

Page 198: Drying Time

CHAPTER 6 Operation for Functions Invoking SET UP functions LOGICAL SEEK Set LOGICALseek ON / OFF. Available setting values: [ON, OFF] UNI-DIRECTIONAL BI-DIRECTIONAL Movement of heads when LOGICALseek is OFF UNI-DIRECTIONAL BI-DIRECTIONAL Movement of heads when LOGICALseek is ON INK LAYERS Set the number of layers in which ink is applied. -

Page 199: Right Margin

CHAPTER 6 Operation for Functions Invoking SET UP functions AUTO CUT Set whether or not to cut the media automatically after completion of printing. Available setting values: [ON, OFF] The media will be cut after the lapse of the time to wait for ink drying after completion of printing, if hav- ing been set. - Page 200 CHAPTER 6 Operation for Functions Invoking SET UP functions REFRESH Set the head refreshing level (running flush interval). Available setting values: [0 ~ 3] ( Enhancing the level shortens the interval) The setting values for each user type are stored separately from those for other user types. VACUUM Set the attracting force of the vacuum fan.

- Page 201 CHAPTER 6 Operation for Functions Invoking SET UP functions (See 3-5) HEAD GAP Set the head gap (height from the media to the nozzle plane of the heads). Available setting values: [1.5 mm ~ 7.0 mm] (In steps of 0.1 mm / Default: 1.5 mm) The upper limit of the head gap varies with media thickness.

-

Page 202: Invoking Maintenance Functions

CHAPTER 6 Operation for Functions Invoking MAINTENANCE functions Invoking MAINTENANCE functions The maintenance functions described here are to be executed to keep the printer in good condition. To carry out maintenance of the printer, select [MAINTENANCE] from the FUNCTION menu and make the necessary settings. -

Page 203: Setting A Maintenance Function

CHAPTER 6 Operation for Functions Invoking MAINTENANCE functions Setting a maintenance function Take the following steps on the operation panel to execute a maintenance function. STEPS: Make sure that the printer is in LOCAL mode, and then select [MAINTENANCE] using the [FUNCTION] key and press the [ENTER] key. -

Page 204: Make Setting Of The Media Remaining Amount Display Function [Media Residual]

CHAPTER 6 Operation for Functions Invoking MAINTENANCE functions Make setting of the media remaining amount display function [MEDIA RESIDUAL] Set ON/OFF of the media remaining amount display function. (Normally OFF) With the media remaining amount display function set to ON, the media remaining amount is displayed in REMOTE mode. -

Page 205: Moving The Printer Safely [Beforemovingit.]

Use this function when the printer is to be moved in such a way that some vibration is expected. However, when the printer is to be moved, be sure to contact your dealer or an office of MIMAKI. Move the printer with the level adjusters of the take-up device in the raised position. - Page 206 CHAPTER 6 Operation for Functions Invoking MAINTENANCE functions Turn the main power supply OFF, unplug the power cable, and move the printer. When moving the printer, it must be held up by at least two people as illustrated below. The cover of the printer may break if it is pressed hard. 6-16...

-

Page 207: Invoking Machine Setup Functions

CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions Invoking MACHINE SETUP functions List of functions This section describes briefly the machine setup functions and their setting values. Name Function Refer to DEODORIZE FAN Make operation settings of the exhaust fan. p. -

Page 208: Setting A Machine Setup

CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions Setting a MACHINE SETUP The operation described below on the operation panel is required to execute machine setup functions. STEPS: Make sure that the printer is in LOCAL mode, and then select [MACHINE SETUP] using the [FUNCTION] key and press the [ENTER] key. -

Page 209: Outline Of The Machine Setup Functions

CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions Outline of the machine setup functions DEODORIZE FAN Set operation of the exhaust fan. STOP TIME Set the time from the completion of printing to the stop of the fan. Available setting values: [ CONT. , 0 ~ 240 min ] ( Default: 120 min [In steps of 10 minutes] ) [CONT.] means that the fan is always kept operating. -

Page 210: Unit Setup

CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions UNIT SETUP Set the units of measure to be used with the printer. Temperature Set the unit of temperature. Available setting values: [° C ( Centigrade) , ° F ( Fahrenheit) ] Length Select the unit system for the units of length and area. -

Page 211: Machine Name

CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions MACHINE NAME When the printer is connected through the USB 2.0 interface to a system to which two or more machines are connected, set the identifier of the printer to have the system recognize it. As a machine name, enter only the printer number in the form [JV5 - ∗∗... -

Page 212: Error History

CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions INFORMATION INFORMATION, one of the MACHINE SETUP functions, consists of menus for checking the informa- tion of the printer. This function can be activated directly by pressing the [INFORMATION] key. Item Description ERROR HISTORY Displays the history of errors and warnings. - Page 213 CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions Settings of the setup functions (grouped for each user type) Settings of the maintenance functions 6-23...

- Page 214 CHAPTER 6 Operation for Functions Invoking MACHINE SETUP functions Settings of the machine setup functions Settings of NCU Settings of DISPLAY Date and time VERSION Displays version information of the equipment. Item Display Remarks Model JV5-1x0S ∗ . ∗∗ Main F / W Version ∗...

-

Page 215: Invoking Ncu Functions

CHAPTER 6 Operation for Functions Invoking NCU functions Invoking NCU functions List of functions This section describes briefly the NCU functions and their setting values. Name Function Refer to NOZZLE CHECK Set whether or not to perform nozzle missing detection. p. -

Page 216: Outline Of The Ncu Functions

CHAPTER 6 Operation for Functions Invoking NCU functions Outline of the NCU functions The NCU functions consist of operations concerning the nozzle missing detection function. Setting Make settings of the function that monitors nozzle missing with the nozzle check unit. Nozzle check Set whether or not to perform nozzle missing detection. - Page 217 CHAPTER 6 Operation for Functions Invoking NCU functions NG ACTION [AFTERtheDRAWend] (*1) Set the operation of the printer after completion of printing of one file in case a preset number of missing nozzles or more are detected and thus NG judgment is made. (*2) NG (*1): Bad nozzle condition.

-

Page 218: Display Setting

CHAPTER 6 Operation for Functions DISPLAY setting DISPLAY setting Set a language to be used with the printer. Language Japanese English German French Spanish Italian Portuguese The setting is reflected on the indications on the LCDs. 6-28... -

Page 219: Applied Settings Of Functions

CHAPTER 6 Operation for Functions Applied settings of functions Applied settings of functions Initial settings can be changed, as required. Settings of heaters Setting items for heaters The items that can be set for the three heaters are as described below. SET TEMP. -

Page 220: Detailed Settings Of Heaters

CHAPTER 6 Operation for Functions Applied settings of functions Detailed settings of heaters Make settings of the pre-heater, print-heater and after-heater built in the platen. The temperatures of heaters can be adjusted even during printing so that optimum temperatures can be obtained. - Page 221 CHAPTER 6 Operation for Functions Applied settings of functions Setting the temperatures and standby time of heaters Set the temperatures and standby time of heaters by the following procedure: STEPS: Make sure that the printer is in LOCAL mode. If it is in REMOTE mode, press the [REMOTE] key once. 35°C 40°C 50°C...

- Page 222 CHAPTER 6 Operation for Functions Applied settings of functions Press the [ ] key to go to the lower level of hierarchy and set [SET TIME]. Use the [ ] or [ ] key to change the seting value of the time, the [ ] or [ ] key to move the cursor, and the [ENTER] key to register the setting values in memory.

-

Page 223: How To Operate Function Menus

CHAPTER 6 Operation for Functions How to operate function menus How to operate function menus The following pages show the operating procedures and the messages displayed on the LCDs, using the fol- lowing icons. For detailed information of operation procedures, refer to the relevant pages. Icon Description This icon means pressing the [FUNCTION] key once. -

Page 224: Functions Related To The Cutter

Functions related to the cutter C HAP TE R 6 O p e r a tio n fo r F u n c tio n s Functions related to the cutter When the media is to be cut at a desired position Cut the media at any desired position without using the [AUTO CUT] function. -

Page 225: Functions Related To Print Quality

CHAPTER 6 Operation for Functions Functions related to print quality Functions related to print quality With function menus of the printer, the print quality can be checked and setting can be changed to improve the print quality. Correcting media feed during printing [FEED COMPENSATION.] With the [MEDIA COMP.] function, as already described, operation is executed in LOCAL mode. -

Page 226: Functions Related To Ink

CHAPTER 6 Operation for Functions Functions related to ink Functions related to ink When ink sets (4-color and 6-color) are to be changed 35°C 40°C 50°C L. ∗ > [JV5-01] width : ∗∗∗∗ mm MAINTENANCE <ENT> ST.MAINTENANCE <ent> HD.MAINTENANCE <ENT> FILL UP INK <ent>... - Page 227 CHAPTER 6 Operation for Functions Functions related to ink When ink sets (4-color and 6-color) are to be changed (continued) It'sBeingDischarged. Remove all washing PLEASE WAIT liquid cartridges. Remove the cleaning liquid cartridge. ∗ ∗ ∗ ∗ ∗ ------------------------------ 1234 5678 9ABC DEFG Processing Check the completed...

-

Page 228: Function Flowchart [Boot]

CHAPTER 6 Operation for Functions Function Flowchart [BOOT] Function Flowchart [BOOT] 6-38... - Page 229 CHAPTER 6 Operation for Functions Function Flowchart [BOOT] 6-39...

-

Page 230: Function Flowchart [Local Mode]

CHAPTER 6 Operation for Functions Function Flowchart [LOCAL mode] Function Flowchart [LOCAL mode] To p.6-42 6-40... - Page 231 CHAPTER 6 Operation for Functions Function Flowchart [LOCAL mode] 6-41...

- Page 232 CHAPTER 6 Operation for Functions Function Flowchart [LOCAL mode] From p.6-40 6-42...

- Page 233 CHAPTER 6 Operation for Functions Function Flowchart [LOCAL mode] 6-43...

-