Table of Contents

Advertisement

Quick Links

OWNER'S OPERATION AND INSTALLATION MANUAL

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

For more information, visit www.desatech.com

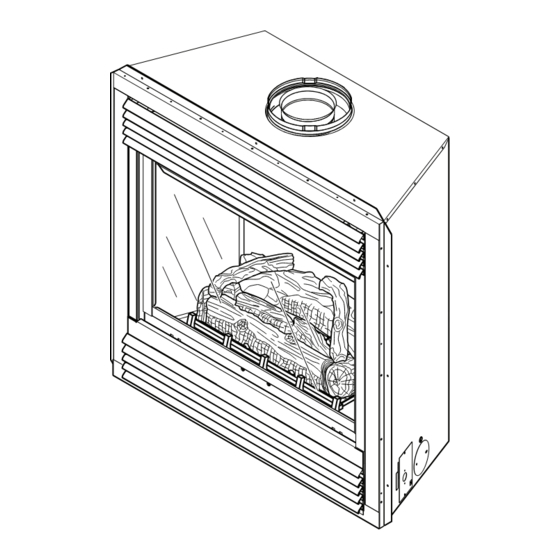

DIRECT-VENT FIREPLACE

NATURAL OR PROPANE/LP GAS

MODEL CD36T-M

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Vexar CD36T-M

- Page 1 DIRECT-VENT FIREPLACE OWNER’S OPERATION AND INSTALLATION MANUAL NATURAL OR PROPANE/LP GAS MODEL CD36T-M WARNING: If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal injury or loss of life. — Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

-

Page 2: Table Of Contents

A conversion kit is supplied with the fireplace. This fireplace is manufactured for Stylecrest Inc. under the Vexar brand name by DESA Heating, LLC. TAbLE OF CONTENTS Safety ..............3 Conversion Instructions ........31 Product Identification ........... -

Page 3: Safety

SAFETy WARNING: Any change to this fireplace or it’s controls can WARNING: This product con- be dangerous. Do not modify tains and/or generates chemicals this fireplace under any circum- known to the State of California stances. Any parts removed for to cause cancer or birth defects servicing must be replaced prior or other reproductive harm. -

Page 4: Product Identification

SAFETy 6. Have venting system inspected annually by a qualified service person. If needed, Continued have venting system cleaned or re- paired. See Cleaning and Maintenance, Carefully supervise young chil- page 33. dren when they are in the room 7. Do not use any solid fuels (wood, coal, with fireplace. -

Page 5: Local Codes

REqUIREMENTS Z223.1/NFPA 54* (USA). Determine the safest and most efficient loca- *Available from: tion for your DESA/Vexar direct-vent fireplace. American National Standards Institute, Inc. Make sure that rafters and wall studs are not 1430 Broadway in the way of the venting system. Choose a... - Page 6 PRE-INSTALLATION PREPARATION Continued • When locating termination cap, it is impor- CLEARANCES tant to observe the minimum clearances Minimum clearances to combustibles for the shown in Figure 7, page 8. fireplace are as follows: • If recessing into a wall, you can avoid extra *Back and sides 0"...

- Page 7 PRE-INSTALLATION PREPARATION Continued " 2 - 2"x4" Vertical Double Stud 21" TO CENTER OF TOP VENT " " TO NAILING FLANGES " OPENING 36" " These dimensions allow for 1" of clearance at the sides and back of " fireplace. 0" clearance is also permitted "...

- Page 8 PRE-INSTALLATION WARNING: When finishing PREPARATION appliance, do not overlap com- Continued bustible materials onto the black MANTEL CLEARANCES front face. Brick, tile, or other Figure 7 shows projected mantel depths at non-combustible materials may various heights above the top of the louver be applied to the face provided opening.

-

Page 9: Location Of Termination Cap

LOCATION OF TERMINATION CAP Fixed Openable Fixed Closed Closed Openable TERMINATION CAP AIR SUPPLY INLET GAS METER RESTRICTED AREA (TERMINATION PROHIBITED) A = clearance above grade, veranda, porch, deck, or balcony I = clearance to service regulator vent outlet [*72" (182.9 cm) [*12"... -

Page 10: Venting Installation

These models are tested and approved for NOTICE: Do not seal termination use with DESA/Vexar (direct-vent) pipe com- cap to vent pipe. Cap must be ponents and terminations. removable for vent inspection The venting system must terminate on the and maintenance. -

Page 11: Installation Planning

VENTING INSTALLATION Continued INSTALLATION pLANNING 4. Assemble desired combination of pipe and elbows to fireplace flue collar. If there There are two starter vent kits available for are long portions of venting run, pre- either a horizontal or a vertical installation: assembled pipe sections may be installed •... - Page 12 VENTING INSTALLATION Continued Inner Wall WARNING: Do not recess Firestop vent termination into any wall. Cut Siding Away to Fit Standoff This will cause a fire hazard. Standoff 6. Combustible Exterior Wall: For vinyl Vent siding, stucco or wood exteriors, a siding standoff may be installed between vent cap and exterior wall.

- Page 13 VENTING INSTALLATION Not to Exceed 90° Elbow (H) Limits Continued Square Termination Required for (V), Horizontal Termination Configurations See Chart Figures 14 through 18 show different con- for Pipe figurations and alternatives for venting with Section horizontal termination. Each figure includes a Required chart with critical minimum and maximum di- Wall...

- Page 14 VENTING INSTALLATION Continued HORIZONTAL VENT INSTALLATIONS USING MULTIPLE 90° ELBOWS The following configurations show the mini- mum vertical rise requirements for a horizontal system using two 90° elbows. 90° Elbow 90° Elbow Venting with Two 90° Elbows Horizontal (H)+ Vertical (V) Horizontal (H 7' Min.

- Page 15 VENTING INSTALLATION Continued INSTALLATION FOR vERTICAL Flat Ceiling Installation 1. Cut a 10 " square hole in the ceiling using TERMINATION locating hole as a center point. Opening Note: Vertical restrictor must be installed in should be framed to 10 "...

- Page 16 VENTING INSTALLATION 4. Attach thimble into firestop plate using 4 hex screws provided (see Figure 21). Continued 5. Refit assembly into opening and attach 5. Place flashing over pipe section(s) extend- to framing with 8 Phillips screws provided ing through roof. Secure base of flashing (see Figure 20, page 15).

- Page 17 VENTING INSTALLATION Continued Note: Install a Firestop Plate FP-58 or a Firestop Venting with Two 90° Elbows Thimble FTA-58 to Vertical (V) Horizontal (H) maintain cleaance to 8' Min. 6' Max combustible ceiling or 9' Min. 8' Max insulating materials. 10' Min.

-

Page 18: Fireplace Installation

VENTING INSTALLATION FIREPLACE Continued INSTALLATION ELECTRICAL SUppLY CONNECTION Number Description CAUTION: Disconnect the CVVK-58 Ceiling Vertical Vent Kit electrical power to the supply (Includes: 30° Offset Return, 7"-12" circuit before attempting to con- Adjustable Pipe, Flue Restrictor, Vertical High Wind Termination, nect or service this appliance. - Page 19 FIREPLACE Model BK Installation Follow all instructions provided in the blower INSTALLATION accessory kit. Continued 1. Attach power cord to blower motor by firmly pushing two female terminals at end of 5. Remove two screws and outer cover on power cord onto two spade terminals on left side of the outer cabinet.

- Page 20 FIREPLACE Model BKT Installation Note: When installing BKT thermostatically- INSTALLATION controlled blower, you must first secure Continued thermal switch bracket to blower if it has not already been factory installed. 6. While supporting speed control, secure 1. Place green ground wire with ring ter- control shaft with lock nut by pushing and minal between bottom hole on thermal turning lock nut with pliers clockwise until...

-

Page 21: Fireplace Installation

FIREPLACE INSTALLATION Continued 3. Place blower against lower rear wall of 11. Peel off backing paper and stick supplied firebox outer wrapper with exhaust port wiring diagram decal on firebox bottom directed upward and thermodisc positioned approximately 12" in front of blower (see up near the fireplace bottom. - Page 22 FIREPLACE 4. Connect wires from receiver to TH and TPTH to control valve (see Figure 33). INSTALLATION 5. Locate the two plastic mounting clips Continued provided with kit. INSTALLING OpTIONAL WALL 6. Use the clips to mount receiver on remote mounting bracket as shown in MOUNT SWITCH - GWMS2 Figure 35.

- Page 23 FIREPLACE For propane/LP connection only, the installer must supply an external regulator. The external INSTALLATION regulator will reduce incoming gas pressure. Continued You must reduce incoming gas pressure to between 11" and 14" of water. If you do not CHECK GAS TyPE reduce incoming gas pressure, fireplace Use proper gas type for the fireplace unit you regulator damage could occur.

- Page 24 FIREPLACE through one of the access holes on side of fireplace. INSTALLATION 3. Attach flexible gas line from gas supply to Continued control valve (see Figure 39). 4. Check all gas connections for leaks. See WARNING: Use pipe joint Checking Gas Connections. sealant that is resistant to liquid To Gas Supply petroleum (LP) gas.

- Page 25 FIREPLACE Equipment Shutoff Valve INSTALLATION Continued Meter 4. Check all joints of gas supply piping sys- tem. Apply noncorrosive leak detection fluid to all joints. Bubbles forming show a leak. Correct all leaks at once. 5. Reconnect fireplace and equipment Gas Valve shutoff valve to gas supply.

- Page 26 FIREPLACE WARNING: Handle glass door INSTALLATION panel with care. Do not strike, slam, Continued or otherwise abuse glass. Do not operate fireplace with glass door WARNING: If fireplace has removed, cracked, or broken. been running, turn off and un- Panel Tabs plug fireplace.

- Page 27 FIREPLACE 4. Open bag of ember materials. 5. Break apart about quarter sized pieces INSTALLATION and place a single layer along full length Continued of ember tray to hide bottom edge of base log (see Figure 47). 6. Remount new frame in reverse order by placing positioning tabs on the glass frame 6.

-

Page 28: Operation

OPERATION 6. The pilot is located by the main burner and should not require accessing for lighting. FOR YOUR SAFETY 7. Turn gas control knob counterclockwise READ BEFORE LIGHTING to PILOT (see Figure 45). 8. Push in gas control knob all the way and WARNING: If you do not fol- hold. - Page 29 OPERATION Continued MANUAL LIGHTING IMPORTANT: Do not leave the selector switch in the REMOTE or ON position when the pilot pROCEDURE is not lit. This will drain the battery. 1. Remove glass door (see Removing/Re- placing Glass Door, page 25). ON/OFF SERIES MODEL HRC100 2.

- Page 30 OPERATION Key Pad Lock Feature This feature allows the user to lock/unlock the Continued keypad on the hand-held remote in the MANU 3. Set the desired room temperature by or AUTO mode to prevent inadvertent op- pressing the TEMP + or - buttons. eration (i.e.

-

Page 31: Inspecting Burners

INSPECTING bURNERS Check pilot flame pattern and burner flame patterns often. PILOT ASSEMBLy The pilot assembly is factory preset for the proper flame height. Alterations may have occurred dur- ing shipping and handling. Call a qualified service person to readjust the pilot if necessary. The position and pattern of the pilot flames in relation to the sensing devices should be as shown in Figure 52. -

Page 32: Conversion Instructions

CONVERSION INSTRUCTIONS Continued 7. Loosen set screw on main burner air shut- Set Screw Air Shutter ter, rotate to fully open, and retighten set Opening screw (see Figure 56). 8. Reposition burner with air shutter placed over orifice mount and replace two screws on rear log stand and two screws at pilot assembly. -

Page 33: Cleaning And Maintenance

CONVERSION INSTRUCTIONS Mounting Continued Screws GAS CONTROL CONvERSION Convert gas control by swapping out valve regulator portion of gas valve. 1. Using a Torx T20 or slotted screwdriver, remove and discard three mounting screws, pressure regulator tower, and diaphragm/spring components (see Figure 58). - Page 34 CLEANING AND substitutions may be made. See Removing/ MAINTENANCE Replacing Glass Door, page 25 for instruc- tions for replacing glass door. Continued WARNING: Do not operate WARNING: Do not use abra- fireplace with the glass door sive cleaners as this may damage unlatched, removed, cracked glass.

-

Page 35: Troubleshooting

TROUbLEShOOTING WARNING: Turn off heater and let cool before servicing. Only a qualified service person should service and repair heater. CAUTION: Never use a wire, needle or similar object to clean pilot. This can damage pilot unit. Note: All troubleshooting items are listed in order of operation. The two most common causes of a malfunctioning gas appliance are: 1. - Page 36 TROUbLEShOOTING Continued OBSERVED PROBLEM POSSIBLE CAUSE REMEDY Pilot lights but flame goes 1. Gas control knob not fully 1. Press in gas control knob out when control knob is pressed in fully released 2. Gas control knob not 2. After pilot lights, keep gas pressed in long enough control knob pressed in 30 seconds...

- Page 37 TROUbLEShOOTING Continued WARNING: If you smell gas • Shut off gas supply. • Do not try to light any appliance. • Do not touch any electrical switch; do not use any phone in your building. • Immediately call your gas supplier from a neighbor’s phone. Fol- low the gas supplier’s instructions.

-

Page 38: Specifications

SPECIFICATIONS REPLACEMENT PARTS Note: Use only original replacement parts. CD36T-M Natural Gas This will protect your warranty coverage for • Rating: 15,000/21,000 Btu/hr parts replaced under warranty. • Gas Type: Natural Gas Only pARTS UNDER WARRANTY •... -

Page 39: Service Hints

SERVICE hINTS WALL MOUNTED ON/OFF SWITCH GWMS2 When Gas pressure Is Too Low Allows burner system to be turned on and off • pilot will not stay lit with a wall switch. • burners will have delayed ignition • fireplace will not produce specified heat •... -

Page 40: Parts

PARTS FIREPLACE ASSEMBLy FOR MODEL CD36T-M www.desatech.com 118531-01C... - Page 41 PARTS FIREPLACE ASSEMBLy FOR MODEL CD36T-M This list contains replaceable parts used in your fireplace. When ordering parts, follow the instructions listed under Replacement Parts on page 38 of this manual. PART NO. DESCRIpTION QTy. 116108-01 Log Set 116109-01 Burner Base Log...

- Page 42 PARTS BURNER ASSEMBLy FOR MODEL CD36T-M www.desatech.com 118531-01C...

- Page 43 PARTS BURNER ASSEMBLy FOR MODEL CD36T-M This list contains replaceable parts used in your fireplace. When ordering parts, follow the instructions listed under Replacement Parts on page 38 of this manual. NO. PART NO. DESCRIpTION QTy. 116317-01 Remote Ignitor Bracket...

-

Page 44: Warranty

WARRANTy KEEP ThIS WARRANTy Model (located on product or identification tag) _____________________________ Serial No. (located on product or identification tag) __________________________ Date Purchased __________________________ Keep receipt for warranty verification. DESA hEATING, LLC LIMITED WARRANTIES New products Standard Warranty: DESA Heating, LLC warrants this new product and any parts thereof to be free from defects in material and workmanship for a period of two (2) years from the date of first purchase from an authorized dealer provided the product has been installed, maintained and operated in accordance with DESA Heating, LLC’s warnings and instructions.

Need help?

Do you have a question about the CD36T-M and is the answer not in the manual?

Questions and answers