Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Alliance Laundry Systems UW35B2

- Page 1 Washer-Extractors UW Pocket Hardmount B-Series Microcomputer 2 Speed Models UW35B2 and UW60B2 NOTA: El manual en español aparece después del manual en inglés. PHM1379C PHM1379C Part No. F232223R1 www.comlaundry.com November 2005...

-

Page 3: Table Of Contents

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed written consent of the publisher. F232223 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT... - Page 4 Notes © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 5: Safety Information

8. Do not reach into the washer if the wash drum is moving. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 6 19. Keep washer in good condition. Bumping or dropping the washer can damage safety features. If this occurs, have washer checked by a qualified service person. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

- Page 7 SW020 SW004 CAUTION Be careful around the open door, particularly when loading from a level below the door. Impact with door edges can cause personal injury. SW025 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 8: Key To Symbols

Moving mechanical potentially dangerous drive mechanisms within the parts can crush and/or sever body parts. machine. Guards should always be in place when the machine is in operation. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 9 To provide personal safety and keep the machine in proper working order, follow all maintenance and safety procedures presented in this manual. If questions regarding safety arise, contact the manufacturer immediately. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 10: Operator Safety

Operating the machine with severe out-of-balance loads could result • Chemicals. Keep stainless steel surfaces free of in personal injury and serious equipment chemical residues. damage. SW039 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 11: Machine Location

Always disconnect power and water supplies before a service technician performs any service procedure. Where applicable, steam and/or compressed air supplies should also be disconnected before service is performed. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 12 Notes © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 13: Introduction

Refer to Figure 2. PHM598N Top Rear of Control Module Cage Wrap (Below Plumbing Bracket) Figure 2 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 14 200 – 240 50 – 60 Drawings: ETL Listed Conforms To ANSI/UL Std. 1206, 3rd Ed Certified To CAN/CSA Std. C22.2 No.53-1968 EXAMPLE OF NAMEPLATE PHM599N PHM599N Figure 3 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 15: Operation

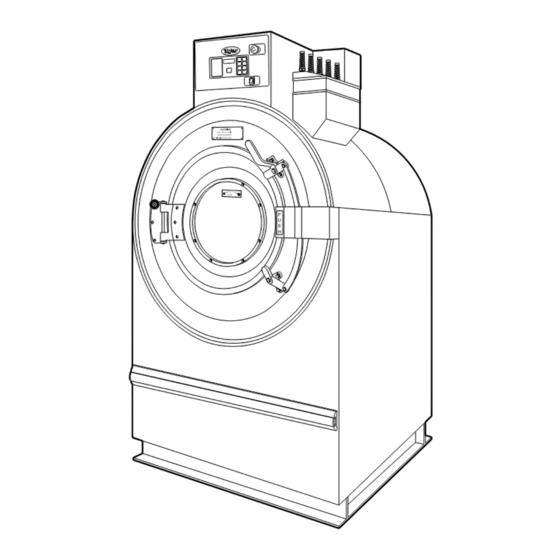

Door Unlock Button Side Panel Supply Valve Box Rub Rail Supply Dispenser Shell Front Door Handle Door Hinge Door Box Control Module Door Latch Extension Arm Figure 4 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 16: Introduction

This is located behind the machine control control power/output unit. panel. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 17: Control Panel

Low Water Level Indicator Dot (Active only for C80F, C80 and C125 models) Figure 5 †Set Up (*) keypad is used in cycle programmings in program mode. Refer to Programming Manual. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 18: Summary Of Major Features

0 to 9999 cannot be reset – Rolls over after 9999 Rapid Advance Mode Rapid Advance can be enabled or disabled. Enabled allows user to advance through a cycle. Refer to Programming Manual. Table 1 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 19: Display Indicators

Display all temperatures in degrees Celsius Display all temperatures in degrees Fahrenheit The first 3 digits are reserved for temperature reading, C indicates “degrees Celsius” ___C Table 2 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 20 Machine set up for Rapid Advance Machine is not set up for Rapid Advance noAd The number of times power has been interrupted during a cycle E Pr Cycle counter © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 21: Operating Instructions

W528 WARNING Do not operate machine in a cycle or if spinning with program keymode switch in program position. W529 PHM593N Figure 7 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 22 7. Dry supplies can be placed in the supply dispenser compartment cups prior to the start of each cycle. Be sure to return the supply dispenser compartment cups before the start of each cycle. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 23: Maintenance

3. Verify that insulation is intact on all external properly. wires and that all connections are secure. If bare wire is evident, call a service technician. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 24: Monthly

Figure 9 and Figure 10. DESIGN 5 AND LATER PHM613N Example of Bearing Lubrication Decal* * For U5 models, decal located on plumbing bracket. Figure 9 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... - Page 25 Maintenance DESIGN 1-4 PHM616N PHM616N Example of Bearing Lubrication Decal* * For U5 models, decal located on plumbing bracket. Figure 10 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

- Page 26 Refer to Figure 12. * Tolerance: ± 5 pounds Set initial tension toward high end of these ranges. Table 3 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

-

Page 27: Quarterly

9. Clean interior of washer-extractor, both basket and shell, by wiping with a water-soaked sponge or cloth. 10. Use compressed air to ensure that all electrical components are free of moisture and dust. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 28: Care Of Stainless Steel

Never use ordinary steel wool or steel brushes on chemicals into the washer-extractor. Refer to the the stainless steel. Use stainless steel wool or soft Installation manual. non-metal bristle brushes. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 29: Daily Preventive Maintenance Checklist

NOTE: Unload the washer-extractor promptly after each completed cycle to prevent moisture buildup. NOTE: Leave loading door open after each completed cycle to allow moisture to evaporate. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 30: Weekly Preventive Maintenance Checklist

Start an unloaded cycle to fill the washer-extractor. b. Verify that door and door gasket do not leak. c. Verify that the drain valve is operating. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 31: Monthly Preventive Maintenance Checklist

8. Clean interior of washer-extractor, both basket and shell, by wiping with a water-soaked sponge or cloth. 9. Use compressed air to clean moisture and dust from all electrical components. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223... -

Page 32: Quarterly Preventive Maintenance Checklist

3. Verify that the drain motor shield is in place and secure. 4. Check all painted surfaces for bare metal. Repair, if necessary. 5. Clean steam filter, if applicable. © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232223...

Need help?

Do you have a question about the UW35B2 and is the answer not in the manual?

Questions and answers