Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Ducati SPORT TOURING ST3

- Page 1 Owner’s manual DUCATISPORTTOURING...

- Page 3 Ducati motorcycle for long whatsoever for any mistakes incurred in drawing up this journeys as well as short daily trips. Ducati Motor Holding manual. The information contained herein is valid at the S.p.A. wishes you smooth and enjoyable riding.

-

Page 4: Table Of Contents

TABLE OF CONTENTS Throttle twistgrip 33 Front brake lever 34 Rear brake pedal 34 Gear change pedal 34 Setting the gear change and rear brake pedals 35 Main components and devices Location 37 General Tank filler plug 38 Warranty 6 Seat catch and helmet hooks 39 Symbols 6 Side stand 40... - Page 5 Side panniers 62 Brakes 89 Lifting the fuel tank 63 Transmission 90 Cleaning and changing air filters 64 Suspensions 91 Checking the coolant level 65 Exhaust system 91 Checking brake and clutch fluid level 66 Available colours 91 Checking brake pads for wear 67 Electric system 92 Lubricating cables and joints 68 Throttle cable adjustment 69...

-

Page 6: General

Ducati Motor Holding S.p.A. advises you to read this booklet carefully so as to become familiar with your motorcycle. In case of any doubts, please call a Ducati dealer or authorized workshop. The information contained herein will prove useful on your trips - and Ducati Motor Holding S.p.A. -

Page 7: Useful Information For Safe Riding

Useful information for safe riding Be sure you are clearly visible and do not ride within the blind spot of vehicles ahead. Warning Be very careful when tackling road junctions, or when Read this section before riding your motorcycle. riding in the areas near exits from private grounds, car parks or on slip roads to access motorways. -

Page 8: Carrying The Maximum Load Allowed

Carrying the maximum load allowed Information about carrying capacity Your motorcycle is designed for long-distance riding, The total weight of the motorcycle in running order carrying the maximum load allowed in full safety and including rider, pillion passenger, luggage and additional comfort. - Page 9 Do not insert any objects you may need to carry into the gaps of the frame as these may foul moving parts. If you install the side panniers (available from Ducati Spare Parts Department): sort luggage and accessories so to distribute weight evenly and then arrange them in the panniers so that they are well balanced;...

-

Page 10: Identification Data

Identification data All Ducati motorcycles have two identification numbers, for frame (fig. 2) and engine (fig. 3). Frame number Engine number Note These numbers identify the motorcycle model and should always be indicated when ordering spare parts. fig. 2 fig. 3... -

Page 11: Controls

CONTROLS Warning This section details the position and function of all the controls you need to drive your motorcycle. Be sure to read this information carefully before you use the controls. Position of motorcycle controls (fig. 4) 1) Instrument panel. 2) Key-operated ignition switch and steering lock. -

Page 12: Instrument Panel

These menus are for the trained personnel only; do not use them for any reason. Should you accidentally enter this function, turn the key to OFF and contact an authorised Ducati Service Center for the necessary inspections. 4) Revolution counter (rpm). -

Page 13: Lcd Unit Functions

LCD unit functions 5) EOBD light (amber). When on, this light is used by the control unit to signal Warning the presence of errors and sometimes the consequent Stop the motorcycle before using the instrument engine disabling. panel controls. Never operate the instrument panel controls while riding. - Page 14 The system shall be reset by the This function indicates the quantity of fuel in the fuel DUCATI Authorised Service Center that has serviced the tank. When the last bar stays on (flashing), the low fuel vehicle.

-

Page 15: Lcd - Parameter Setting/Display

LCD - Parameter setting/display When turning the key from OFF to ON (Key-ON) the instrument panel carries out a Check of the whole instruments: indexes, displays and pilot lights (see fig. 7). CHECK 1 km/h miles km/L mpgal CHECK 2 km/h fig. - Page 16 Water temperature indicator (fig. 8) It indicates engine cooling water temperature. If temperature drops under 40°C/104°F, “LO” will start flashing on the display. If water temperature ranges between 40 °C/104 °F and 120 °C/248 °F, temperature value is displayed in fixed mode.

- Page 17 Clock setting function Hold down button (A, see page 12) for 2 seconds, the wording AM begins to flash. If button (B) is pressed again, PM begins to flash; press button (B) to go back to ODOMETER previous step. Press button (A) to confirm and start setting hours that shall begin to flash.

- Page 18 "Odometer" indication (fig. 10) Indicates total distance covered by the vehicle. "TRIP meter" indication This function indicates the distance covered since the meter was last reset. It is possible to reset this indication by entering the relevant function and holding down button (A, see page 12), for at least 2 seconds.

- Page 19 "Average consumption" indication (fig. 11) This function indicates the vehicle average consumption when in motion. The calculation is based on the distance travelled since the "TRIP meter" was last reset. When the vehicle is stopped, either with the engine off or running, the last value stored is displayed until indication is refreshed.

- Page 20 "Range" indication This function indicates how far the vehicle can travel using the fuel left in the tank. When this display function is not selected, the display automatically switches to "Range" indication as soon as the LOW FUEL LIGHT (10, fig.

- Page 21 Beam vertical adjustment (fig. 12.1-12.2) This function allows headlight beam height setting. To enter this function, hold down button (B, see fig. 5.1) and turn the key to ON; the display shows a value (fig. 12.2) corresponding to beam position and the pilot light on the display, indicating beam vertical setting mode (12, fig.

- Page 22 Special selection function: vehicle model and unit of measurement (fig. 13) The control unit automatically informs the instrument panel about the vehicle model and unit of measurement to be displayed; hold down buttons (A) and (B) and turn ignition switch from OFF to ON to force the system and change these parameters.

-

Page 23: The Immobilizer System

Backlighting function Note Instrument panel backlighting is active only if the parking While starting the engine, the system switches off light or the low/high beam is on. the headlight and turns it back on again after engine has In this case the instrument panel automatically turns on started, or anyway when the button (3, fig. - Page 24 Keys (fig. 14) Note The Owner receives a set of keys comprising: The three keys have a small plate (1) attached that - 1 RED key (A) reports their identification number. - 2 BLACK keys (B) Warning Warning Keep the keys in different places. Store the plate (1) Red key has a rubber cover for preserving it in and the red key in a safe place.

-

Page 25: Keys

Code card A CODE CARD (fig. 15) is supplied together with the keys, it indicates the electronic code (A, fig. 16) to be used in case of emergency start-up and the engine will not start up after the key-ON. Warning Keep the CODE CARD in a safe place. -

Page 26: Procedure To Disable Imobilizer Engine Block Through Throttle Twistgrip

Procedure to disable immobilizer engine block 6) If the code is NOT correct, the EOBD warning light and through throttle twistgrip the IMMO light stay on and it is then possible to repeat 1) Turn the key to ON and fully open throttle. Keep it the procedure, starting from point 2, as many times as open. -

Page 27: Duplicate Keys

Operation Duplicate keys When the ignition key is turned to OFF, the immobilizer If you need any additional key, contact the DUCATI inhibits engine operation. Service network with all the keys you have left and your When the ignition key is turned back to ON to start the CODE CARD. -

Page 28: Key-Operated Ignition Switch And Steering Lock

Key-operated ignition switch and steering lock (fig. 17) It is located in front of the fuel tank and has four positions: A) ON: lights and engine on; B) OFF: lights and engine off; C) LOCK: steering locked; D) P: parking light and steering lock. Note To move the key to the last two positions, press it down before turning it. -

Page 29: Left Switch

Left switch (fig. 18) 1) Dip switch, light dip switch, two positions: position = low beam on; position = high beam on. 2) Switch = 3-position turn indicator: centre position = OFF; position = left turn; position = right turn. To cancel turn indicators, push in once switch returns to central position. -

Page 30: Clutch Lever

Clutch lever (fig. 19) Lever (1) disengages the clutch. It features a dial adjuster (2) for lever distance from the twistgrip on handlebar. To set lever distance from twistgrip, push lever (1) fully forward and turn the dial adjuster (2) to one of its four positions. -

Page 31: Cold Start Lever

Cold start lever (fig. 20) Use this device to start the engine from cold. It will increase the engine idling speed after starting. Lever positions: A) closed B) fully open. The lever can be opened and closed gradually to adjust speed until engine is fully warm. -

Page 32: Right Switch

Right switch (fig. 21) 1) Switch, light switch, three positions: right position = light off; centre position = front and rear parking lights, number plate and instrument panel lights on; left position = headlight, front and rear parking lights, number plate and instrument panel lights on. 2) Switch for ENGINE STOP, two positions: position (RUN) = run. -

Page 33: Throttle Twistgrip

Throttle twistgrip (fig. 22) The twistgrip on the right handlebar opens the throttles. When released, it will spring back to the initial position (idling speed). Front brake lever (fig. 22) Pull in the lever (1) towards the twistgrip to operate the front brake. -

Page 34: Rear Brake Pedal

Rear brake pedal (fig. 23) Push down on the pedal (1) to apply the rear brake. The system is hydraulically operated. fig. 23 Gear change pedal (fig. 24) The gear change pedal is at rest when in the central position N, is moved up and down to change gears and then returns to the central position. -

Page 35: Setting The Gear Change And Rear Brake Pedals

Setting the gear change and rear brake pedals (fig. 25 and 26) The gear change and rear brake pedals can be adjusted to suit the preferred riding position of each rider. To set the gear change pedal, lock linkage (1) and loosen the check nuts (2) and (3). Note Nut (2) has a left-hand thread. - Page 36 To set the rear brake pedal, loosen check nut (4). Turn pedal travel adjusting screw (5) until pedal is in the desired position. Tighten check nut (4). Work pedal by hand to make sure it has 1.5 - 2 mm free play before brake begins to bite.

-

Page 37: Main Components And Devices

MAIN COMPONENTS AND DEVICES Location (fig. 27) 1) Tank filler plug. 2) Seat catch and helmet hook. 3) Side stand. 4) Lifting handgrip. 5) Centre stand. 6) Rear view mirrors. 7) Front fork adjusters. 8) Rear shock absorber adjusters. 9) Power outlet. 10) Catalyzer. -

Page 38: Tank Filler Plug

Tank filler plug (fig. 28) Opening Lift the protection lid (1) and fit the ignition key into the lock. Turn the key clockwise 1/4 turn to unlock. Lift the OPEN plug. Closing Refit the plug with the key in it and push it down into its seat. -

Page 39: Seat Catch And Helmet Hooks

Seat catch and helmet hooks Opening (fig. 29) Fit the ignition key into the lock (4) and turn the key clockwise about 1/4 turn until the rear end of the seat lifts up. Pull the seat backwards to slide it off its front holders (1). -

Page 40: Side Stand

Anti-theft padlock (fig. 31) Side stand (fig. 32) The anti-theft padlock (1) is stored under the seat. Remove strap (2) to take padlock out. Important Use the padlock in addition to the steering lock when Put the motorcycle on the side stand only when parking your motorcycle in unsafe areas. -

Page 41: Lifting Handgrip

Lifting handgrip Note A handgrip (1, fig. 33) that pivots on the left pillion Check for proper operation of the stand mechanism passenger footpeg is provided to help you place the (two springs, one into the other) and the safety sensor motorcycle on the centre stand or keep it upright when (2) at regular intervals. -

Page 42: Centre Stand

Centre stand Always use the centre stand (1, fig. 34) to support the motorcycle steadily when parked. It is designed to support the motorcycle even when carrying the maximum load allowed. Warning Before putting the motorcycle on the centre stand, make sure the bearing surface is hard and flat. -

Page 43: Rear View Mirrors

Important If either of the mirror parts comes off, have the mirror repaired or replaced by a Ducati Dealer or Authorized Workshop. Warning Never ride with a missing rear view mirror: the fig. -

Page 44: Front Fork Adjusters

Front fork adjusters The front fork has preload adjuster only. This adjustment is done using the following outer adjuster: 1) (fig. 37) to adjust inner springs preload. To change the preload of the spring inside each fork leg turn the hex. adjuster (1) with a 22-mm hexagon wrench. Height A (fig. -

Page 45: Rear Shock Absorber Adjusters

Rear shock absorber adjusters The rear shock absorber has outer adjusters that enable you to adjust your motorcycle to the load. The adjuster (1, fig. 38) located on the rear right hand side - at the control unit - sets rebound damping. The adjuster (2, fig. - Page 46 Warning Turn the preload adjusting ring nut using a pin wrench. Proceed with utmost care to avoid hitting the motorcycles and cut your hand if the wrench pin looses suddenly its grip while turning. Important The shock absorber is filled with gas under pressure and may cause severe damage if taken apart by unskilled persons.

-

Page 47: Directions For Use

DIRECTIONS FOR USE another and above all not to adversely affect the life of basic engine parts, it is advisable to avoid harsh accelerations and not to run the engine at high rpm for too long, especially uphill. Furthermore, the drive chain should be inspected frequently. - Page 48 Warranty Card should be observed carefully. Have the service inspections performed as recommended in the Warranty Card. Failure to comply with these rules will release Ducati Motor Holding S.p.A. from any liability whatsoever for resulting engine damage or shorter engine life.

-

Page 49: Pre-Ride Checks

Warning Fuel level in the tank In case of malfunctioning, do not start the Check fuel level in the tank. motorcycle and call a Ducati Dealer or Authorized Fill tank if needed (page 55). Workshop. Engine oil level Check oil level in the sump through the sight glass. Top up if needed (page 81). -

Page 50: Starting The Engine

Starting the engine Note Follow the “High ambient temperature” procedure to start the engine when it is warm. Warning Before starting the engine, become familiar with the controls you will need to use when riding. Regular ambient temperature (10 °C/50 °F to 35 °C/ 95 °F): 1) Move the ignition key to ON (fig. - Page 51 2) Move the cold start lever to the B position (fig. 42). 3) Check that the stop switch (1, fig. 43) is positioned to (RUN), then press the starter button (2). Let the engine start without using the throttle control. Important Never operate the electric start button more than 5 seconds at a time.

- Page 52 High ambient temperature (over 35 °C/95 °F): Follow the same procedure, however, do not use the cold start device. Cold ambient temperature (below 10 °C/50 °F): Follow the procedure for “Regular ambient temperature”, however allow 5 minutes for the engine to warm up (see step 5).

-

Page 53: Moving Off

Moving off Braking 1) Disengage the clutch squeezing the control lever. Slow down in time, shift down to engine-brake first and 2) Push down on gear change lever sharply with the tip then brake applying both brakes. Pull the clutch lever of your foot to engage the first gear. -

Page 54: Stopping The Motorcycle

Stopping the motorcycle If you let go of the throttle twistgrip, the motorcycle will slow down gradually and smoothly. Then, shift down releasing the clutch, and finally change from first to neutral. Apply brakes and you will bring the motorcycle to a complete stop. -

Page 55: Refueling

Important Do not leave the key turned to P for long periods or the battery will run down. Never leave the ignition key in the switch when you are leaving your bike unattended. Warning The exhaust system might be hot, even after engine is switched off;... -

Page 56: Tool Kit And Accessories

(8) (page 39). Tool bag holds (fig. 48) 1) Box wrench for spark plugs. 2) Double-bit screwdriver. 3) Allen wrenches. 4) Helmet fastening cable. fig. 47 5) Extension. 6) Box wrench. 7) Pin wrench for shock absorber ring nut. DUCATI fig. 48... -

Page 57: Main Maintenance Operations

MAIN MAINTENANCE OPERATIONS Removing the fairing Some servicing operations need the motorcycle fairing to be removed. Warning Firmly secure all removed parts when refitting them, otherwise some of them might suddenly come off fig. 49 when riding and you may lose control of your motorcycle. Important At reassembly always use nylon washers when tightening fastening screws, not to damage painted parts... - Page 58 Undo one of the two lower screws (2, fig. 50) securing one fairing to the other. Keep the washer (5, fig. 50) and the wellnut (6, fig. 50) of the plate (4, fig. 50). Keep the plate connected to a lower fairing.

- Page 59 Instrument panel covers Undo the two screws (1) securing the rear control panel (2) to the headlight fairing. Pull out the rear control panel (2) from the front control panel (3). Undo the screws (4) and remove the windscreen (5) to remove the front control panel (3).

- Page 60 Headlight fairing Remove the instrument panel covers. Detach the rear view mirrors from the headlight fairing by unscrewing the four inner screws (1, fig. 54). Disconnect the cables (2, fig. 55) of the turn indicators. fig. 54 fig. 55...

- Page 61 Unscrew the 8 fastening screws (3, fig. 56-57) that hold the headlamp fairing to the side body panels. Remove the fairing sliding it off the headlamp. Important When refitting, it is necessary to loosen the screws of both rear-view mirror mounts and then fit the headlight fairing.

-

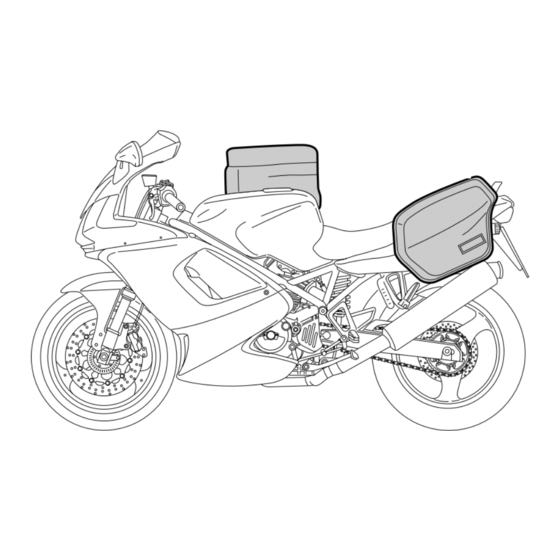

Page 62: Side Panniers

The motorcycle comes ready to fit the side panniers. Side panniers kit in the same colour as the motorcycle is available from Ducati Spare Parts Department. Kit includes all parts needed to install the panniers as well as the relevant instructions. -

Page 63: Lifting The Fuel Tank

Lifting the fuel tank Unscrew the 2 screws (1, fig. 60) that hold the cover to the tank support. Remove the cover sliding it off the ignition switch. Pull and lift the clip (2, fig. 61) off the tank support. Lift the tank and unhook the support rod (3, fig. -

Page 64: Cleaning And Changing Air Filters

Cleaning and changing air filters Replace air filter at the required intervals shown in the routine maintenance chart (see Warranty Card). The air box is accessible after lifting the fuel tank. Undo the clips (1, fig. 63) of the cover on both sides of the air box, then remove cover (2). -

Page 65: Checking The Coolant Level

Checking the coolant level Check the coolant level in the expansion tank, on the RH side of the motorcycle. The coolant level must be between the MAX and MIN marks (fig. 65). Top up if the level is too low. Remove the r.h. -

Page 66: Checking Brake And Clutch Fluid Level

If you find exceeding play on brake lever or pedal and Fluid level should never fall below the MIN mark on brake pads are still in good condition, contact your Ducati each reservoir (fig. 67). If level drops below the limit, air... -

Page 67: Checking Brake Pads For Wear

Rear brake (fig. 68) The friction material on each pad should be at least 1 mm thick. Important Have the brake pads replaced at a Ducati Dealer or fig. 68 Authorized Workshop. -

Page 68: Lubricating Cables And Joints

Work the controls to make sure the cable slides smoothly inside the sheath: if you feel any friction or hard spots, have the cable replaced by a Ducati Dealer or Authorized Workshop. To prevent these failures, smear the ends of the Bowden cables with SHELL Advance Grease or Retinax LX2 at regular intervals. -

Page 69: Throttle Cable Adjustment

Throttle cable adjustment The throttle twistgrip must have a free play of 1.5 - 2 mm measured at the edge of the twistgrip, at all positions of the handlebars. If it needs adjusting, use the suitable adjuster (1, fig. 70) provided on the throttle control. fig. -

Page 70: Charging The Battery

Charging the battery (fig. 71) Warning Before charging the battery, it is best to remove it from Keep the battery out of the reach of children. the motorcycle. Remove the r.h. side fairing (see page 62), undo the Charge the battery at 1 A for 5-10 hours. screw (1) and remove the upper bracket. -

Page 71: Chain Tensioning

Chain tensioning Turn the rear wheel slowly until you find the position where chain is tightest. Put motorcycle on the centre stand and push the chain up pressing with a finger at mid-length of swingarm. The lower stretch of chain must have a slack (fig. 72) of 30 mm. -

Page 72: Chain Lubrication

Chain lubrication The chain fitted on your motorcycle has O-rings that keep dirt out of and lubricant inside the sliding parts. The seals might be irreparably damaged if the chain is cleaned using any solvent other than those specific for O-ring chains or washed using steam or water jets. -

Page 73: Replacing Bulbs

Replacing bulbs Before replacing a burnt-out bulb, make sure that the new one complies with voltage and wattage as specified on the“Electric System” for that lighting device (page 92). Removing the headlight bulbs (fig. 78-79-80-81-82) Remove the instrument panel covers (see page 59) and release the clamps (1) of the light cover (2) to reach the headlight bulbs. - Page 74 R.h. Hi-beam light-bulb (fig. 76-77): Disconnect the connector (4). Release the clip (5) keeping the bulb cable (6). Refit following the removal procedure in the reverse order. fig. 76 fig. 77...

- Page 75 To change the parking light bulb, pull out the bulb holder (7, fig. 78) from the rear of headlamp first. Remove the bulb and fit a new one. fig. 78...

- Page 76 Turn indicators The bulbs of the turn indicators are accessible after removing the instrument panel side guards. Front: Turn the bulb holder (1, fig. 79) anticlockwise and remove OPEN it from indicator body. Withdraw the burnt-out bulb and replace it. Refit the bulb holder with the round slot pointing upward and turn it clockwise until it locks in place in the indicator CLOSED...

- Page 77 Number plate light To expose the number plate bulb, withdraw the bulb holder from the number plate holder, then extract the bulb and replace it. fig. 81 Stop light To replace the stop and parking light bulb, unscrew the two screws (1, fig. 81) that secure the glass and remove glass.

-

Page 78: Beam Setting

Beam setting (fig. 83) When checking beam setting, put the motorcycle upright. Tyres should be inflated at the correct pressure and one person should be sitting astride the motorcycle, keeping it at right angles to its longitudinal axis. Place the motorcycle opposite a wall or a screen, 10 meters apart from it, then draw a horizontal line dictated by headlamp center and a vertical one in line with the longitudinal axis... -

Page 79: Tyres

Tyres Warning Tyre pressure A tyre must be replaced when punctured. Replace Rider + luggage tyres with recommended standard tyres only. Front: Be sure to tighten the valve caps securely to avoid leaks 2.1 bar - 2.3 Kg/sq cm when riding. Never use tube type tyres. Failure to heed Rear: this warning may lead to sudden tyre bursting and to 2.2 bar - 2.4 Kg/sq cm... - Page 80 Minimum tread depth Measure tread depth (S, fig. 85) at the point where tread is most worn down. It should not be less than 2 mm and anyway not below the legal limit. Important Visually inspect the tyres at regular intervals for detecting cracks and cuts, especially on the side walls, bulges or large spots that are indicative of internal damage.

-

Page 81: Checking Engine Oil Level

Undo the filler plug (2) and top up to correct level. Refit the plug. Important Engine oil and oil filters must be changed by a fig. 86 Ducati dealer or authorized workshop at regular intervals, as specified in the routine maintenance chart (see Warranty Card). Viscosity SAE 10W-40... -

Page 82: Cleaning And Replacing The Spark Plugs

Cleaning and replacing the spark plugs (fig. 87) If you do not have a torque wrench, you can use the Spark plugs are essential to smooth engine running and wrench supplied with the tool kit to tighten the spark should be checked at regular intervals. This is done quite plug an additional 1/2 turn. -

Page 83: Cleaning The Motorcycle

Cleaning the motorcycle Warning To preserve the finish of metal parts and paintwork, Braking performance may be impaired immediately wash and clean your motorcycle at regular intervals, after washing the motorcycle. anyway according to the road conditions you ride in. Never grease or lubricate the brake discs. -

Page 84: Storing The Bike Away

Ducati original spare parts complying with few times so a protective film of oil will spread on local law. -

Page 85: Technical Data

TECHNICAL DATA Overall dimensions (mm) (fig. 88) Weights 1430 Dry weight: 2070 214 Kg Carrying full load: 420 Kg. Warning Failure to observe weight limits could result in poor handling and impair the performance of your motorcycle, and you may lose control of the motorcycle. fig. -

Page 86: Top-Ups

Top-ups Type of fluid cu dm(liters) Fuel tank, including a reserve Unleaded fuel of 6 cu dm (liters). 95 fuel octane rating (at least) Oil sump and oil filter SHELL Advance Ultra 4 Front/Rear brake and clutch circuits Special fluid for hydraulic systems —... -

Page 87: Engine

Desmodromic timing system (fig. 89 Engine 1) Opening (or upper) rocker. Twin cylinder, four-stroke, 90° “L” type, longitudinal. 2) Opening rocker shim. Bore: 3) Split rings. 94 mm 4) Closing (or lower) rocker shim. Stroke: 5) Return spring for lower rocker. 71.5 mm 6) Closing (or lower) rocker. -

Page 88: Performance Data

Performance data Wheels Maximum speed in any gear should be reached only after Three-spoke, light-alloy rims. a correct running-in period with the motorcycle properly serviced at the recommended intervals. Front wheel Max. speed (rider alone): Dimensions: 235 Km/h. 3.50x17" Rear wheel Spark plugs Dimensions: Make:... -

Page 89: Brakes

Rear brake Brakes With fixed drilled steel disc. Disc diameter: Front brake 245 mm With double drilled disc. Hydraulically operated by a pedal on RH side. Material: Braking surface: steel 25 sq cm Disc diameter: Brake calipers with separate pistons. 320 mm Make: Hydraulically operated by a control lever on right... -

Page 90: Transmission

Gear ratio: If you wish to tune up your motorcycle for competitive 32/59. trials, you may refer to Ducati Motor Holding S.p.A. who 6-speed gearbox with constant mesh gears, gear change will be glad to provide information about the special pedal on left side of motorcycle. -

Page 91: Suspensions

Suspensions Available colours Ducati anniversary red 473.101 Front Ducati yellow 473.201 Hydraulic upside-down fork provided with outer adjuster Metallic light grey PPG*0026. for inner springs preload. metal-color frame and rims. Stanchion diameter: 43 mm Travel along leg axis: 130 mm... -

Page 92: Electric System

Electric system Fuses Basic electric items are: The main fuse box (fig. 90) is located on the frame left Headlamp consisting of the following: side, behind the headlamp. 12V-55W low beam unit, poly-ellipsoidal with capacitor; To access the fuse box, remove the rear guard of the 12V-55W high beam unit instrument panel (see page 59). - Page 93 IN GOOD CONDITION BLOWN fig. 90 fig. 92 fig. 91...

- Page 94 Legend wiring/injection diagram 31) Neutral switch 1) R.h. switch 32) Oil pressure switch 2) Key operated switch 33) Rear stop switch 3) Fuse box 34) Fan relay 4) Fuses 35) Ignition/injection control unit 5) Fan 36) Clutch switch 6) Starter motor 37) Front stop switch 7) Solenoid starter 38) Releasing connection...

- Page 95 Wire color coding Legend to fuse box P Pink G Green Pos. Amp. W White O Orange Key-on 7.5A Y Yellow B Blue 2-10 Parking lights, high and low beam Bn Brown R Red 3-11 Stops, horn, turn indicators V Violet and solenoid starter Gr Grey Lb Light blue...

-

Page 96: For United States Of America Version Only

Such use could lead to upset or other accident. Noise emission warranty Ducati Motor S.p.A. warrants that this exhaust system, at Reporting of safety defects the time of sale, meets all applicable U.S. EPA Federal If you believe that your vehicle has a defect which could noise standards. - Page 97 Tampering with Noise Control System Prohibited. Federal If you are aware of any of the following symptoms, have Law prohibits the following acts or causing thereof: the vehicle inspected and repaired by your local Ducati (1) the removal or rendering inoperative by any person, dealer.

- Page 98 Riding safety When the roadway is wet, rely more on the throttle to The points given below are applicable for every day control vehicle speed and less on the front and rear motorcycle use and shoud be carefully observed for safe brakes.

- Page 99 Do not inhale exhaust gases and never run the Vehicle identification number (VIN); engine in a closed garage or confined area. Every Ducati motorcycle is identified by two identification Use only Ducati approved parts and accessories. numbers (see page 10). Figure A specifically shows the This motorcycle was not intended to be equipped with a frame identification numbers.

- Page 100 Label location (fig. B) 11 • 8• fig. B 7•...

- Page 101 THIS VEHICLE CONFORMS TO U.S. EPA AND CALIFORNIA REGULATIONS PRESSED GAS. USE ONLY APPLICABLE TO 1998 MODEL YEAR NEW MOTORCYCLES. EVAP FAMILY : PERFECTLY DRY NITROGEN GAS. OTHER GASES MAY CAUSE EXPLOSION. DO NOT TO HORIZONTAL MANIFOLD TO VERTICAL MANIFOLD Via A.C.Ducati,3 40132 BOLOGNA ITALY WARM AIR INLET...

- Page 102 Ducati North America, Inc., 10443 Bandley Drive, 2) Canister; Cupertino, California, 95014 warrants that each new 3) Dell’Orto jet; 1998 and later Ducati motorcycle, that includes as 4) Intake manifolds; standard equipment a headlight, tail-light and stoplight, 5) Breather pipe;...

- Page 103 30 days. Any replacement part can defects in material or workmanship by an authorized be used in an emergency repair. Ducati will reimburse the Ducati motorcycle dealer at its place of business during owner for the expenses, including diagnosis, not to customary business hours.

- Page 104 Ducati maintenance or repairs. However, Ducati is not liable for dealer. Ducati shall not be liable for any other expenses, these parts. The owner is responsible for the loss or damage, whether direct, incidental, consequential performance of all required maintenance.

-

Page 105: Routine Maintenance Record

ROUTINE MAINTENANCE RECORD km/miles Ducati Mileage Date Service Name 1,000 10,000 20,000 30,000 40,000 50,000... - Page 106 HAZARD STARTER ENGINE STOP BW Bk G/Bk FREE Bn/Y LOCK PUSH PUSH R/Bk PARK 40 A Y Y Y V/Bk Bn/Y Bk/Gr Bk/Gr B/Bk P/Bk B/Bk R/Bk 10 W Bk/Gr 10 W Gr/R Gr/R 5/21 W 12V/65W Y/Bk n.c. n.c. Bk/Gr Bk/Gr Bk/Gr...