Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Sears Craftsman C950-52943-0

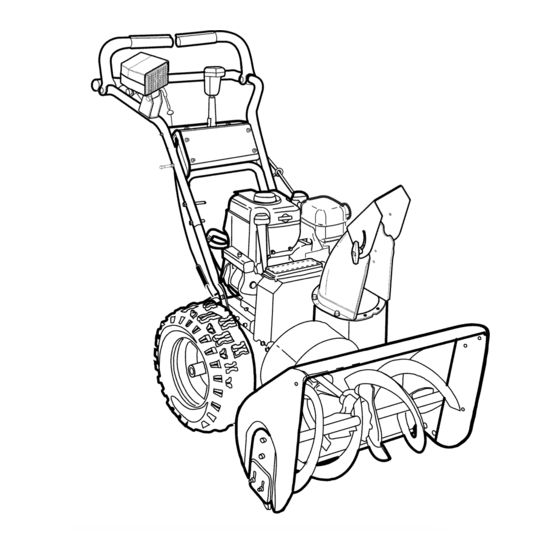

- Page 1 OW T ROW IVlodel C950-52943-0 13.5 T.P. 27 inch CAUTION: You must read and understand this owner's manual before operating unit. Serial No. 1738165 Sears Canada inc., Toronto, Ontario M5B 2C3 Revision A Visit our Craftsman website: www.sears.ca/craftsman Rev.Date 07/2009...

- Page 2 Thankyou for purchasing this quality-built Craftsman snow thrower. We're pleasedthat you've placedyour confidence in the Craftsman brand. When operated and maintained according to the instructionsin this manual, your Craftsman product will provide many years of dependable service. This manual contains safety information to make you aware of the hazards and risks associated with snow throwers and how to avoid them.

-

Page 3: Table Of Contents

TABLEOFCONTENTS OPERATOR SAFETY ..................ASSEMBLY ....................TOOLS REQUIRED FOR ASSEMBLY ......................CONTENTS O FSHiPPiNG CARTON ......................PARTS BAG CONTENTS ..........................UNPACKING .............................. UPPER HANDLE ANDCRANK ASSEMBLY ....................CHECK THECABLES ..........................SET THELENGTH OFTHE CABLES ......................SPEED SELECT LEVER ASSEMBLY ......................SNOW CHUTE ASSEMBLY ........................ -

Page 4: Operator Safety

OPERATORSAFETY Hazard Symbols and Meanings DAHGER- Amputation Hazard The dischargechute containsa rotating Safety Alert - identifies safety informationabout impeller to throwsnow. Never clear or unclog hazardsthat can result in personal injury. the dischargechutewith your hands. Fingers can quickly become caughtand traumatic Operator's Manual- Read and understand before amputation or severe lacerationwill result. - Page 5 OPERA TORSAFETY Readthe Manual Control Symbols on Equipment DANGER Read, understand, and follow all theinstructions onthe snowthrower andintheoperator's manual before o perating thisunit. Forward Fuel Failure t oobserve thesafety instructions in thismanual will result i n death orserious injury. Neutral On Off ,, Bethoroughlyfamiliarwith thecontrolsandthe properuse ofthe snow thrower.

- Page 6 OPERATORSAFETY Fuel Handling Operationand EquipmentSafety DANGER DANGER Thissnowthrower is only assafeas theoperator. If it is Fuelandits vaporsareextremely flammable andexplosive, Alwayshandlefuel withextreme care. misused, or notproperly maintained, it canbe dangerous. i Remember youareresponsible for yoursafety andthat of Failureto observethesesafetyinstructionscancausea fire those around you. Ior explosion whichwill resultin severeburnsor death.

- Page 7 OPERATORSAFETY Children Moving Parts DANGER DANGER Keep hands, feet, a ndclothing away f romrotating parts. Tragic a ccidents canoccur if theoperator is notalert t o the Rotating p arts cancontact or entangle h ands, feet,hair, presence ofchildren, Children a reoften attracted totheunit clothing, or accessories.

- Page 8 OPERATORSAFETY Maintenanceand Storage Engine Safety (Continued) WARNING This snowthrower m ustbeproperlymaintained to ensure safe j Startingenginecreatessparking. operationand performance. F ailure to observethe safety WARNING j Sparkingcanignitenearbyflammable gases. instructionsin this manual c ould resultin deathor serious Explosion andfire could result. injury. o Whenperforming any maintenance o r repairson the snowthrower, shut OFF theengine,disconnect s parkplug wire,andkeepthewire away from the * Ifthereis naturalor LPgas leakage in area,do not startengine.

- Page 9 OPERA TORSAFETY Lookfor this symbol to indicate importantsafety precautions.This symbolindicates: "Attention! Become cannotbe read,orderreplacement decals from yourlocaldealer. ARNING:If anysafety decalsbecome wornor damaged and Alert! Your Safety is At Risk." Before operatingyour snow thrower, read the safety decals as shown on yoursnow thrower. The cautionsand warnings are for yoursafety.

-

Page 10: Assembly

ASSEMBLY TOOLSREQUIREDFORASSEMBLY CONTENTS OF SHiPPiNGCARTON 1 - Knife 1 - SnowThrower 2 - 1/2" wrenches (or adjustable wrenches) 1 - Container o f FuelStabilizer ( Located in Parts Bag) 2 - 9/16"wrenches (or adjustable wrenches) 1 - SnowChute Assembly 2 - 3/4" wrenches (or adjustable wrenches) 1 - Crank Assembly 1 - 3/8"... -

Page 11: Unpacking

ASSEMBLY NOTE: Reference t o rightand lefthandsideof thesnowthrower is fromthe operator's p ositionatthe handle. UNPACKING 1. Usingknife,cut alongthedottedlinesaroundthetop andbottomof carton. T henremove cartonmaterial a sshownin Figure2. 2. Remove shearpinsandcotterpinsfrompartsbagand placein shear boltstorage box. 3. Locate and remove thepartsbag. NOTE: Setthefuelstabilizer a sideuntiladdinggasoline to thefuel tank.Werecommend t hatfuelstabilizerbeadded to thefueleachtime thetankis filled. -

Page 12: Upperhandleand Crankassembly

ASSEMBLY UPPERHANDLEAND CRANKASSEMBLY 1. Loosen, b utdo not remove thescrews, f latwashers, Iockwashers, and hexnutsin theupperholesof thelowerhandle (seeFigure4). Adaptor Boot _olt 2. Remove t hefasteners a ndthecrankassembly eyeboltfromthelower holesofthe lowerhandle. 3. Raise upperhandleintooperating position.Upperhandle shouldbeto theoutsideof thelowerhandle. NOTE: Makesurethecables arenotcaughtbetween theupperand lowerhandle. -

Page 13: Speed Select Lever Assembly

ASSEMBLY SPEED SELECT LEVER ASSEMBLY 1. Cutplastictie(A,Figure7) securing speedselectlever a ssembly (B) to theshifterbracket ( C). 2. Remove Iocknut ( A, Figure8),washer (B),spring(C),andbolt (D). NOTE: Viewis fromright sideof unit standing in operator's p osition. 3. Positionspeed selectorleverassembly as shownin Figure9. 4. -

Page 14: Snow Chuteassembly

ASSEMBLY SNOW CHUTEASSEMBLY NOTE: Thechuteringassembly (A,Figure10)comesinstalled on theunit fromthefactory. 1. Turncrankassembly (Figure4) untilthearrowon outerring (B, Figure 10)of chuteringassembly pointsforward. NOTE: Makesuretheslot in thechutering alignswith thearrowonthe outerring. 2. Installchutedeflector ( C) usingfourscrews (D)and nuts(E)in holes asshown.Thechutedeflector m ustpointforwardfor properinstalla- tion. 3. Tightenscrews snuglybutbecarefulnotto over-tighten. Snow Chute Assembly Figure 18 HEADLIGHT ASSEMBLY... -

Page 15: Features And Controls

FEATURES AND CONTROL S © 1 _-- I;__-->- ® ® ® ,_-,llllt o___ ® -tS- ® "iJ Snow Thrower Controls figure 12 SNOWTHROWER AND ENGINECONTROLS SNOWTHROWERCONTROLS E. ChuteDeflectorWing Nut -- Used to controltheangleof the chutedeflector ( up or down). A. Speed Select Lever- Allowstheoperator t o useoneof six (6) forwardandtwo(2)reversespeeds (seeFigure12).Toshift, move f. - Page 16 FEATURES A ND CONTROLS ® ® I÷1I×l ® ® ® Engine Controls Figure 13 ENGINECONTROLS E. Starter Cord Handle -- Usedto starttheenginemanually. A. Choke Control Knob-- Usedto starta cold engine (seeFigure Fo ON/OFFSwitch -- Usedto startand stoptheengine. 13). G. Fuel Tank and Cap-- Fill thefueltankto approximately 1 -1/2 in. B.

-

Page 17: Operation

OPERATION BEFOREOPERATING SNOW THROWER NOTE: This snow thrower was shipped WiTH OiL in the Checkthe fasteners.Makesureall fastenersare tight. engine. See "Before Starting Engine" instructions in the OPERATION section of this manual before starting engine. Readthis OPERATOR'S M ANUAL and OPERATOR S AFETY before operatingyoursnow thrower. -

Page 18: Stopthesnowthrower

OPERATION TRACTIONLOCKPiNS WARNING: Read Operator's Manual before operating machine. This machine can be dangerousif used Therighttractionwheelcanbecompletely released usingthe lockingpin carelessly. (A,Figure16).This allowstheunit to beeasilymoved withtheengineoff. ,, Never operatethe snowthrower without all guards,covers, shields in place. ,, Never direct dischargetowards windows or allow bystandersnear machine while engine is running. -

Page 19: Fillthefuel Tank

OPERATION FiLL THE FUEL TANK ARNING:Gasolineis flammable. Always use caution when handlingor storinggasoline. Turnengineoff and Thisengineis certifiedto operate on gasoline. E xhaust EmissionControl let enginecoolat least two minutes beforeremovingthe gas System: E M(Engine Modifications). cap. Do not add gasoline tothe fuel tankwhile snowthrower Fillthefueltankwithfresh, c lean, u nleaded r egular, unleaded p remium, o r re- is running,hot, or when snow throweris in an enclosed area. -

Page 20: Stop Theengine

OPERATION 9. Electric Start: Depress thestarter p ushbutton (A,Figure 2 1).Afteryou start t heengine, firstdisconnect theextension c ordfromthewallreceptacle andthen fromthepower c ordreceptacle (B). Starting with CordHandle Inserting S afety K ey Figure 19 Figure 20 7. Rewind Start: Firmlyholdthestarter c ordhandle (A,Figure 2 0).Pull thestarter c ordhandle slowlyuntilresistance isfelt,thenpullrapidly. -

Page 21: Cleara Clogged Discharge Chute

OPERATION OPERATING TIPS CLEARA CLOGGED DISCHARGE CHUTE 1. Mostefficient s nowthrowing is accomplished w hensnowis removed immediately a fterit falls. WARNING:Handcontactwith the rotating impeller inside the dischargechute is the most common cause of 2. Forcomplete s nowremoval, slightlyoverlap eachswath previously taken. injury associated with snow throwers. -

Page 22: Maintenance

MAINTENANCE SERVICERECOMMENDATIONS FIRST BEFORE AFTER EVERY EVERY EVERY BEGINNING BEFORE PROCEDURE EACH EACH EACH STORAGE HOURS HOURS HOURS HOURS SEASON Check to MakeSure AugerBladeStopsWithin 5 Seconds AfterRight v" SAFETY ControlLeveris Released Lubricate ControlLevers andLinkages CheckSnowthrower for LooseHardware v" ,,," Lubricate HexShaft a nd Chains v"... -

Page 23: Lubricate Augergearbox

MAINTENANCE LUBRICATE AUGERGEARBOX LUBRICATE CHUTEROTATION GEAR Theaugergearboxis lubricated atthefactory and shouldnotrequire Lubricate t hechute rotation gear(A,Figure 25)andshaft (B)withautomo- additional l ubrication. I f for somereason thelubricantshouldleakout, tivetypeoil every twenty-five ( 25)operating h ours. or if theaugergearboxhasbeenserviced, a dd Lubriplate GR132 Grease or equivalent. -

Page 24: Engine Maintenance

MAINTENANCE ENGINE MAINTENANCE Check Crankcase Oil Level - Beforestartingengine and aftereach8 hoursof continuous use.Add therecommended m otoroil asrequired. NOTE:Over filling the engine can affect performance.Tighten Full the oil fill cap securely to prevent leakage. Change Oil - Every 50 hoursof operation or atleastoncea year,evenif thesnowthroweris not usedfor fifty hours.Use a clean,high quality detergent oil. -

Page 25: Change Thespark Plug

MAINTENANCE CHANGE THESPARK PLUG Remove the Snow Hood 1. Remove thechokecontrolknob(A,Figure28). 2. Remove thesafety key(B). 3. Remove themounting screws (A, Figure29). 4. Slowlyremove thesnowhood(B) Makesurethat theprimerbutton hose(C)andtheignitionwire(D)arenotdisconnected. 5. Thesparkplug (E)cannowbe accessed. 6. Toinstallthe snowhood,first make surethatthe primerbuttonhose andtheignitionwireareconnected. 7. Mountthesnowhoodto theengine andsecure with themounting screws. -

Page 26: Adjust Skidheight

MAINTENANCE Checkand Replace Spark Plug Check thespark plugevery twenty-five (25) hours. R eplace thesparkplug (Figure 31)if theelectrodes arepittedor burned or if theporcelain is cracked. 1. Remove snowhood(see"Remove theSnowHood"section). 2. Cleansparkplugandresetgapperiodically. 3. Cleanareaaroundsparkplug basebeforeremoval, t o prevent d irt fromenteringengine. 4. Replace sparkplug if electrodes arepittedor burned or if porcelain is cracked. -

Page 27: Beltadjustment

MAINTENANCE BELTADJUSTMENT TractionDrive Belt Thetractiondrivebelthasconstant s pringpressure anddoesnotrequire anadjustment. I f thetractiondrivebelt is slipping,replace thebelt. Seeau- thorized dealer. Auger Drive Belt If yoursnowthrower will notdischarge s now, c heck thecontrol c ableadjust- ment.If it iscorrect, t hencheck thecondition oftheauger drivebelt.If it is damaged o r loose, r eplace it (see authorized dealer). -

Page 28: Belt Guide Adjustment

MAINTENANCE BELT GUIDE ADJUSTMENT 1. Remove sparkplug wire. 2. Have someone engage theaugerdrive.This will engage augeridler ® pulley(A, Figure35). 3. Measure thedistance between the beltguide(B)and belt(C).The distance shouldbeabout1/8inch(3 ram). 4. If adjustment i s necessary, loosenbeltguidemountingbolt. Move beltguideto thecorrectposition.Tighten mountingbolt. 5. - Page 29 MAINTENANCE TractionDrive Cable 1. Remove thegasfromthegastank.Standthesnowthrowerupon the frontendof theaugerhousing. ARNING:Drain the gasoline outdoors, away from fire or flame. 2. Loosenthebolts(A,Figure38)on eachsideof thebottompanel(B). 3. Remove thebottompanel. 4. Disconnect the"Z" fittingfrom thedrivelever(seeFigure36). 5. Slidethecableboot(A, Figure39) offthecableadjustment b racket )|1111|!_ (B) I 6. Pushthebottomofthetractiondrivecable(C)throughthecable adjustment b racket u ntilthe "Z"...

-

Page 30: Augershearpin Replacement

MAINTENANCE AUGERSHEARPiN REPLACEMENT Theaugers aresecured totheaugershaftwith special s hearpinsthatare designed to breakif an objectbecomes lodgedin theaugerhousing.Use of a harder grade shearpinwill reducetheprotectionprovidedbythe shearpin. WARNING: Do not go near the dischargechute or auger when the engine is running. Do not run the engine if any cover or guard is removed. -

Page 31: Storage

STORAGE OFFSEASONSTORAGE LUBRICATE HE× SHAFTAND CHAINS WARNING:Never store the engine, with fuel in the tank, CAUTION:Do not allow grease or oil to contactthe rub- indoorsor in a poorventilated enclosurewhere fuel ber friction wheel or the disc drive plate, if the disc fumes could reach an open flame, spark or pilot light drive plate or frictionwheel come in contactwith as on a furnace, water heater, clothes dryer, etc. -

Page 32: Troubleshooting

TROUBLESHOOT/NG PROBLEM LOOKFOR REMEDY Free-Hand controlisACTIVE. Release bothaugercontrolandtraction/Free-Hand controllevers to stop auger. Auger does not stop within Augerdrivebeltout of Adjustaugerbelt. j5 secondsafter right adjustment. controllever is released. Augerbeltguideoutof Adjustaugerbeltguide. adjustment. Discharge chute or Electrical failure. Seeauthorized dealer. deflectordoes not work (electric). - Page 33 TROLIBLESHOOT/NG PROBLEM LOOKFOR REMEDY Scraper bar does not clean Skidshoesimproperly adjusted. Raiseor lowerskid shoes. hard surface. Drivebelt looseor damaged. Replace drivebelt.Seeauthorized dealer. Unit fails to propel itself. Incorrect a djustment o f traction Adjusttractioncontrolcable.Refer to "CheckandAdjusttheCables"in the drivecable. MAINTENANCE sectionof this manual. Wornor damaged frictiondisc.

-

Page 34: Warranties

Craftsman Limited Warranty General: Craftsman products are warranted to be free from defects in materials or workmanship for a specific time period as set-out below (the "Warranty Period"). Warranties extend to the original purchaser of a Craftsman product only. Pur- chases made through an online auction or through any website other than www.sears.ca are excluded. - Page 35 WARRANT/ES 1 year: Craftsman power cutters, stump grinders, pole pruners, gas chain saws, electric chain saws, trimmer attach- ments, baggers and pole saws for noncommercial, nonprofessional, non-institutional, or non-income-producing use. 90 days: All defective batteries, which will be replaced during this g0-day Warranty Period.

- Page 36 The California Air Resources Board, U.S. EPA, and Briggs & Stratton (B&S) are pleased Owner's Warranty Responsibilities: to explain the emissions control system warranty on your Model Year 2008 and later engine/equipment. In California, new small off-road engines must be designed, built, and As the small engine/equipment owner, you are responsible for the performance...

-

Page 37: Specifications

SPECIFICAT/ONS ENGINE: Brand Briggs & Stratton IVlodelSeries Snow Series GrossTorque* 13.50 T.P.@3060 rpm Type 4-Cycle - OHV Displacement 18.6 cu in. (305 cc) Starting System 110V Electric, Recoil Alternator 60W AC Spark Plug Gap 0.030 in. (0,76 ram) 481055 Spark Ping 5066 Long Life Platinum Spark Ping Oil Capacity... - Page 39 RepairParts PTS - 1...

- Page 40 Engine & Frame Craftsman 27" Snowthrower C950-52943-O NOTE: Unless noted otherwise, use the standard hardware torque specification chart. 20 \ SeeTraction DriveGroup PTS - 2...

- Page 41 Engine & Frame Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 20M1140141E1 ENGINE 6219MA CORD, STARTER 002X97MA BOLT, Carriage, 5/16-18 x 1-1/2 028X76MA NUT, Speed, 1/4 1960686SM NUT-HEX FLANGE.312-18 ESNA 1501109MA PULLEY, Engine 1922755SM WASHER, Fiat, 3/8 1916965SM...

- Page 42 Traction Drive Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. 34-54 Nm 27-40 ft.-Ibs, oi PTS - 4...

- Page 43 Traction Drive Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 579851MA CHAIN, Roller 334163MA RETAINER & BUSHING ASSEMBLY 1924856SM SCREW, Hex Washer Head Taptite, 5/16-18 x 1/2 579868MA CHAIN, Roller 11X30MA RETAINER, Ring 7/16 1502105YZMA SPRING LINK ASSEMBLY...

- Page 44 Auger Housing Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Gear Case Assy 525' PTS - 6...

- Page 45 Auger Housing Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 583146MA PULLEY, 4L 8.40 OD. 2001022MA KEY, SQUARE 3/16 X 3/4 15X112MA NUT, .50-20 HEXWDFLLK 1501158MA SPACER, FRICTION PULLEY 582957YZMA RETAINER, BALL BEARING 1705897SM BEARING, BALL 001X45MA BOLT, HEX 5/16-18 X .62...

- Page 46 Discharge Chute Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Auger Housing Page PTS - 8...

- Page 47 Discharge Chute Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 1736380HYP CHUTE ASSEMBLY 305216MA 2860210SM WASHER, PLASTIC 1501260MA KNOB, T 3.00 002X97MA BOLT, Carriage, 5/16-18 x 1-1/2 2X100MA CARRIAGE BOLT, 5/16-18 x 1.00 71071MA WASHER 71038MA NUT, Hex, NyIock, 5/16-18...

- Page 48 Handle Assembly Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Engine Page PTS - 10...

- Page 49 Handle Assembly Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 1741120AYP HANDLE, UPPER 7288MA SCREW, 3/8- 16 X 3 71072MA WASHER, FLAT 71062MA WASHER 71044MA NUT, 3/8- 16 7289MA STOP, PLASTIC 71007MA SCREW, 3/8- 16 X 2 71072MA...

- Page 50 Chute Rod Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Handle Assy Ref. Auger Housing Assy 852=6 852-7__._ _._ 852-3 PTS - 12...

- Page 51 Chute Rod Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 852-1 1501533YZMA ASSEMBLY, YOKE & ROD 852-2 164X37MA SPRING 852-3 1501067MA GEAR, CHUTE ROTATION 9T 852-4 017X48MA WASHER 852-5 579493MA PIN, COTTER 852-6 1740591AYP BRACKET, CHUTE GEAR 852-7...

- Page 52 Control Panel Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Handle Page ® Ref. Handle Page 811 _ PTS - 14...

- Page 53 Control Panel Craftsman 27" Snowthrower C950-52943-0 DESCRIPTION REF NO PART NO. QTY. 71045MA NUT, 3/8-16 HEXJAM 1741119AYP BRACKET, SHIFT CONTROL 1931323SM CARRIAGE BOLT, 1/4-20 x 2.00 71059MA WASHER, SPLIT 71034MA NUT, 1/4-20 HEX 1741123BNYP CONTROL PANEL 3809MA CARRIAGE BOLT, 1/4-20 X .63...

- Page 54 Decals Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. PTS - 16...

- Page 55 Decals Craftsman 27" Snowthrower C950-52943-0 DESCRIPTION REF NO PART NO. QTY. 1737865YP DECAL DANGER CHUTE HAND 1737866YP DECAL DANGER FOOT 1741432MA DECAL CRAFTSMAN 1350/27 1737870YP DECAL DRIVE CLUTCH 1737869YP DECAL AUGER CLUTCH 1737872YP DECAL GEAR SELECTOR 48X5565MA DECAL CRAFTSMAN DECAL...

- Page 56 Gear Case Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. PTS - 18...

- Page 57 Gear Case Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 896MA CASE, GEAR, RH 895MA CASE, GEAR, LH 910828MA SCREW, 5/16-24 x 1.00 71100MA NUT, 5/16-24 330434MA SCREW, 5/16-24 X 1.50 53749MA PLUG, PIPE 0.25-18 780151MA SEAL, OIL...

- Page 58 Wheels Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Drive Page PTS - 20...

- Page 59 Wheels Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 1501563MA SHAFT, AXLE 1501089MA SPRKT & HUB 01X193MA SCREW, 1/4-20 X 1.75 15X145MA NUT, 1/4- 20 HEX NYLOCK 1501114MA BEARING, AXLE 712120MA WASHER, Fiat .765 x 1.12 x .06 YZ...

- Page 60 Headlight Craftsman 27" Snowthrower C950-52943-0 NOTE: Unless noted otherwise, use the standard hardware torque specification chart. Ref. Handle Page PTS - 22...

- Page 61 Headlight Craftsman 27" Snowthrower C950-52943-0 REF NO PART NO. QTY. DESCRIPTION 583490MA HOUSING, HEADLIGHT UPPER 762343MA HEADLIGHT ASSEMBLY * 1501514MA HOUSING, HEADLIGHT LOWER 307781MA SCREW, #8 X 1.75 1738347YP WIRING HARNESS, HALOGEN 4029YZMA BRACKET, HEADLIGHT 002X88MA BOLT, CARRIAGE - 5/16-18 X 2.00...

- Page 62 20Ml14-0141 1329 REP'AOEMENT ENG,_ ] I 1330 R_PA,_ MANUAL I 48 SHORT BLOCK I I 1058 OPE_TO_'S MANUAL 307 _ "f- _s// 718A Assemblies include all parts shown in frames. Cylinder Assembly Engine: Briggs & Stratton Model 20M114-0141-E1 ReL No. Refi No.

- Page 63 20Ml14-0141 24 <_ Assemblies include all parts shown in frames. Crankcase Cover, Crankshaft & Piston/Ring Assemblies Engine: Briggs & Stratton Model 20M114-0141-E1 Ref No Part No Description Ref No Part No Description 694953 Gasket-Crankcase 690975 Lock-Piston 794720 Crankshaft 696581 Pin-Piston 791965 Cover-Crankcase 694691...

- Page 64 20Ml14-0141 914 ,_ ........................1171 1026 _::::::::::S:: -..45 (> _ <::: ..Assemblies include all parts shown in frames. Cylinder Head Assembly Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty.

- Page 65 20Ml14-0141 1°9 i 95 _ 957A .............._,:_ 1127 Assemblies include all parts shown in frames. Carburetor and Fuel Supply Assemblies Engine: Briggs & Stratton Model 20M114-O141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 694874 Gasket-Intake 698781...

- Page 66 20Ml14-0141 r-..........604A 188 _ 1230 883A 613A_ Assemblies include all parts shown in frames. Muffler and Controls Assembly Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 699479 Screw 695917 Spring/Link- Mechanical Governor (Control Bracket)

- Page 67 20Ml14-0141 278 @ \,,_j (_;_' Assemblies include all parts shown in frames. Governor Spring and Governor Lever Assembly Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 691251 694867 Spring-Governor (Red) (Governor 695307 Spring-...

-

Page 68: Blower Housing And Rewind Starter Assemblies

20Ml14-0141 326 _ 1392 326 _ Assemblies include all parts shown tn frames. Blower Housing and Rewind Starter Assemblies Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Ref. No. Part No. Qty. Description Part No. Qty. Description 699047 691696 Screw Guard-Flywheel 696710 Housing-... - Page 69 20Ml14-0141 1070 1005 1070 Assemblies include all parts shown in frames. Flywheel Assembly Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 794812 Flywheel 1005 794815 Fan-Flywheel 794824 1070 794821 Screw (Flywheel) (Flywheel Fan) 795011...

- Page 70 20Ml14-0141 727_ ..851A(_ 1009 Assemblies include all parts shown in frames. Starter Motor and Ignition Assemblies Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 795909 Motor-Starter 795901 Cord-Starter 692424 492341 Armature-Magneto Terminal-Spark...

- Page 71 20Ml14-0141 1196_ 1288 '_ 1318_i 668_4 1352_ 1251A 1230_ 1252 1251 Assemblies include all parts shown in frames. Snow Hood Assemblies Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 696750 Tube-Breather 1230 699847...

- Page 72 20Ml14-0141 358 ENGINE GASKET SET 1022 1095 VALVE GASKET SET 868 ¢-_ Assemblies include all parts shown in frames. Engine Gasket and Valve Gasket Set Assemblies Engine: Briggs & Stratton Model 20M114-O141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No.

- Page 73 20Ml14-0141 121 CARBURETOR OVERHAUL __:_J Assemblies include all parts shown in frames. Carburetor Overhaul Kit Assembly Engine: Briggs & Stratton Model 20M114-0141-E1 Ref. No. Part No. Qty. Description Ref. No. Part No. Qty. Description 694874 Gasket-Intake 690727 Plug-Welch 694875 Gasket-Intake 698781 Gasket-Float Bowl...

- Page 74 Hardware identification& TorqueSpecifications Common Hardware Types Torque Specification Chart Hex Head Capscrew FOR STANDARD MACHINE HARDWARE (Tolerance + 20%) Washer Lockwasher _raardde ware Carriage Bolt SAE Grade2 SAEGrade 5 SAEGrade8 [((((((((((((((((((( Hex Nut in/Ibs Size Of in/Ibs ft/Ibs Hardware ft/I bs ft/I bs Standard Hardware Sizing 8-32...

- Page 75 PHAS S C950-52943-0 13.5 T.P. 27 pouces Attention" Lire et bien comprendre ce manuel avant d'utiliser le chasse-neige. Num_ro de serie Manuel n ° 1738165 Sears Canada inc., Toronto, Ontario M5B 2C3 R6v. A Visit our Craftsman website: www.sears.caJcraftsman 07/2009...

- Page 76 Merci d 'avoir achet6 cette souffleuse _ neige C raftsman. Nous s ommes heureux que vous ayez p lac6 v otre confiance dans l amarque Craftsman. Sivous utiHsez etentretenez ceproduit Craftsman conform6ment auxinstructions dumanuel, vous_ourrez I'utiHser pendant denombreuses ann6es. Cemanuel contient desinformations relatives 9.las6curit6 afinque vous connaissiez lesdangers etrisques qu= sont l i6s auxsouffleuses J.

- Page 77 TABLE D ES MAT/ERES SI_CURITI_ D E L'OPI_RATEUR ................. ASSEMBLAGE ................... OUTILLAGE REQUIS POUR L'ASSEMBLAGE ..................... CONTENU DEL'EMBALLAGE ........................SACDEPIECES CONTENANT ........................DBALLAGE .............................. MONTAGE D ELAPOIGNEE S UPERIEURE ETDELA MANIVELLE ............12 VERIFICATION DESCABLES ........................REGLAGE D ALA LONGUEUR D ESCABLES .....................

- Page 78 SECUR/TE BE L'OPERATEUR Renseignements et symbolesde danger DAHGER- Risque d'amputatien Le conduitd'6jection contJent u n irnpuiseur Alerte de s_curit_ - Identifie I'inforrnationde rotatif pour _jecter la neige. Ne d_bouchez ou s_curit_ des dangers qni peuventr6sulter en ne d_gagez jarnais le conduitd'_jection avec blessurecorporelle.

- Page 79 SECUR/TEBE L'OPERATELIR Lecturedu manuel Symboles de commande sur Yequipement DANGER Huile Lisez,comprenez, etsuiveztous leeinstructionsur la Carburant Marche avant souffleuse _ neigeet le manuel d 'utilisationavant d e faire fonctionner e etappareil. Lafaillite d'observer l esinstructionsdesdcuritddansce Neutre Marche/Arr_t manuel r dsultera _ lamort oublessuregrave. Volet de d6part Recuie .

-

Page 80: Si_Curiti_ D E L'opi_Rateur

SECURITE DEL'OPERATEUR Manutention de carburant S6curit6de 1'6quipement e t de son fonctionnement DANGER DANGER ettesoufiJeu neigeest een&nt ei;op rateu; oui Lecarburant etses vapeurs s ontextremement flammables et explosifs. Veuillez b ien prendre s oinavec pr_aution du s curit . Si mal ut,is e ou mal entretenue, ceci tre carburant,... - Page 81 SECUR/TE BE L'OPERATELIR Pi_ces amovibles Enfants DANGER DANGER Gardez lesmains,tespie@et lesv_tements Joindespi_ces Lesaccidents tragiques p euvent arriv&s s i l'operateur n'est pasattentif &la presence desenfants. Lesenfants sont rotatives. L espi_cesrotatives peuvent contacter o u souvent attir_ parla machine etlesoufflage d eneige. Ne enchev_trer t esmains,lespieds,lescheveux,lesv_tements ou accessoires.

- Page 82 SECUR/TE BE L'OPERATEUR S6curit6du moteur suivre) Efltretienet entreposage AVERTISSEMENT Lamise enmarche d u moteur cr66e une gerbe d'6tincelles, Cette souffleuse_ineigedolt e"tre proprement e ntretenue pour assurerun fonctionnement et uneperformance e n toute L'6tincelle peutmettre lefeuaugazinflammable toutpr_s. AVERTISSEMENT s6curit6./!,d6fautd'observer l esinstructionsde s6curit6dans Explosion etfeupeuenr6sulter.

- Page 83 SECUR/TE DEL'UT/L/SATEUR ,& AVERTISSEIVlENT : Si desdtiquettes des_curit_sontusdes Ce symboJe signale des consignesde s_curit_ irnportantes.II signifie" g< Attention! Prenezgarde ! ou endommag_es et nesont pluslisibies, commander der Votre s_curit_est menac_e, g, etiquettes de rechange a upr_sdu concessionnaire local. Avantd'utiliserlasouffleuse _ neige,fireles6tiquettes d es6curitd ap- pos6es surla souffleuse _ neige.Losavertissements et misesengarde visent_ prot_ger r utiiisateur.

-

Page 84: Assemblage

ASSEMBLAGE OUTILLAGE REQUIS POUR L'ASSEIVIBLAGE CONTENU DE L'EIVIBALLAGE 1 - Couteau 1 - Souffleuse a neige 2 - Clesde 1/2 pouce(ou des a molette) 1 - Recipient d estabilisateur d ecarburant ( dansle sacde pieces) 2 - Clesde 9/16pouce(ou clesa molette) 1 - Goulotte d'ejection 1 - Manivelle 2 - Clesde 3/4 pouce(ou clesa molette) -

Page 85: Dballage

ASSEMBLAGE REMARQUE : Lec8t6droitou gauche de lasouffleuse _ neigeest indiqu6 parrapport_ ia positionde rutiiisateurtenantia poign6e. DEBALLAGE 1. A I'aided'uncouteau, c oupez ensuivantlespointill6sautourdu hautet dufonddu carton.Puisretirez le cartonselonI'illustrationFigure2. 2. Rep6rez e t retirez le sacde pieces d6tach6es. 3. Retirez lesgoupillesdecisaillement, les boulonset lesentretoises d u sacde pieces d6tach6es e t rangez-les d ansla boTte de stockage des boulonsde cisaillement. -

Page 86: Montage D Elapoignee S Uperieure Etdela Manivelle

ASSEMBLAGE MONTAGE DELAPOIGNEE SUPERIEURE ET DELAIViANIVELLE Manivelle 1. Desserrer lesvis, lesrondelles plates,lesrondelles deblocageet les ecrous hexagonaux d esorificesdu hautdela poignee inferieure, s ans Rondelle Boul plate lesretirer(voir Figure4). 2. Retirer t outeslesfixationsetle boulona oeilletde la manivelle des Ecrou de trous inferieurs dela poignee inf6rieure. //biocage 3. -

Page 87: Montage D Elaselecteur Devltesse

ASSEMBLAGE MONTAGE DELASI_LECTEUR DEVITESSE 1. Couper I 'attache enplastique (A, Figure7) maintenant le selecteur d e vitesse(B)au supportdu selecteur ( C). 2. %poserI'ecroude blocage (A, Figure8), la rondelle (B), le ressort(C) etle boulon(D). 3. Placerle selecteur d evitessecommeillustreenFigure9. REMARQUE: Vuede I'int6rieur de runiteIorsque r utilisateuresten position pourfairefonctionner l echasse-neige 4. -

Page 88: Montage D Elagoulotte

ASSEMBLAGE MONTAGE DE LA GOULOTTE REMARQUE : L'ensemble d e ranneau de la chute(A) est install6 sur I'appareN _ I'usine(Figure10). 1. Tourner l a manivelle (Figure4)jusqu'acequela %chede la bague ex- t6rieure(B,Figure10)de I'anneau de la chutepointevers ravant. REMARQUE: S'assurer q ueia fentedansI'anneau de la chutesoit align6e avecia fiechesur i'anneau ext6rieur, commeiNustr6. -

Page 89: Fonctions Etcoivllviandes

FONCTION$ ET COMMA/l/DES © ® 1 -_-- [__--> ® ® "-__-Iillil ® -tS- Commandes de la soufleuse a neige figure 12 C01VlIVlANDES DELA SOUFFLEUSE A NEIGE D. Manivelle de rotationde !loulolle -- Serta fairepivoterla goulotted'ejection vers la gauche ou vers la droite. Levier du selecteur de vitesse-- Permet d e choisirun rapport E. - Page 90 FONCTION$ ET COMMANDES ® I÷1 I'-,I ® ® Commandes de moteur Figure 13 COlVlIVlANDES DU IVlOTEUR Interrupteur MARCHE/ARR[:T -- Utiliserpourmettreen marche et F° arreterle moteur. A. Boutonde cornrnande du volet de depart -- Utiliserpourfaire fonctionner l e moteur(voirFigure13). Reservoirde carburantet bouchon -- Remplissez l e reservoir peupres38 mm(1-1/2 po)dessousle hautdu coupour permettre B.

-

Page 91: Utilisation

UTILISATION AVANT D'UTILiSATiON SOUFFLEUSE A NEiGE REMARQUE : Cette sonffiense _ neigeest iivr_eAVEC DEL'HUiLE dans ie motenr. Voir les instructions _,Avantde d_marrer le Contrgler ia visserie.V_rifier que routeia visserieest bien moteur ,, duns ia sectionUTILISATION de ce manuel avant de serr_e. -

Page 92: Arreter La Souffleuse A Neige

UTILISATION TRACTION GOUPILLE DE SURET! f: ,_L AVERTISSEIVlENT : Life le manueld'instruction a vantd'utiliser la machine. U neutilisation imprudente d e cettemachine pout Ledroit detractiondesrouespeut_trecompletement lib6re enutilisantla s'av_rer dangereuse. goupille de s_ret_ (A, Figure16).Celapermet a I'unit_ de led_placer * Nejamaisutiiiser la souffleuse _ neigesanstoussoscapers, facilement aveclemoteur coupe. -

Page 93: Remplir Lereservoir D'essence

UT/L/SAT/ON REIVlPLIR LE Ri_SERVOIR D'ESSENCE AVERTISSEIVlENT "L'essence est inflammable, Toujours fake preuve (le precaution pourmanipuler ou entreposer Cemoteurestcertifiepourfonctionner a I'essence. Systeme de contrOle ressence. Couperle moteur et le laisserrefroi(lir pen(lantau desemissions d'echappement : EM(modifications moteur). racine (leux minutesavant (l'ouvrir le bouchon(lu reservoir. He Remplir lereservoir d'essence avec deI'essence automobile o rdinaire ou super pusverser(l'essence(fans le reservoir alors que la souffleuse sansplombou reformulee, fratche et propre, d 'indiced'octane minimumde... -

Page 94: Arreter Le Moteur

UT/USAT/ON 9. Demarrage electrique : Appuyersurle bouton-poussoir de demarrage ( A,Figure21). Unefois quele moteur a demarre, debrancher d'abordle cordonde la prisemuraleetpuisde la prise pourcordond'alimentation ( B). Insererlacle desecurite Figure19 7. Demarrage par lanceur : Tenirfermement l a poignee du cordonde lanceur(A, Figure20). -

Page 95: Degager U Ne Goulotte D 'Ejection Obstruee

UT/L/SAT/ON Di_GAGER UNE GOULOTTED'i_JECTIONOBSTRUi_E CONSEILS D'UTILISATION 1. Ledeneigement seferadefacond'autant p lusefficace que la neigeest AVERTISSEMENT : Le contactdes mains avec la turbine deblayee immediatement apresetretombee. en rotation_ I'int_rieurde la gouiotte d'_jection est la causela pluscourantede blessure associ_e aux 2. Pour enlever r oute la neige, c hevaucher legerement chaque b ande souffleuses _ neige. -

Page 96: Entretien

ENTRETIEN RECOIVlMANDATIONS D ESERVICE AVANT APRES CHAQUECHAQUE CHAQUE COMMENCEMENT PREMIER AVANT PROCEDURE CHAQUECHAQUE DECHAQUE 5 HEURES L'ENREPOSAGE USAGE USAGE HEURES HEURES HEURES SAISON Verifiez que I'ailette de la tarierearr_,te dans5 secondes a presquele V" levierdroitde commande SF:CURITE estrel_che Lubrifiez losleviersde V"... -

Page 97: Graissage Delabo

ENTRET/EN GRAISSAGE DE LABO'iTED'ENGRENAGE D EVIS LUBRIFIERLEPIGNONDEROTATION DE GOULOTTE SANSFiN Lubrifier l epignonde rotation degouiotte (A,Figure 25)etarbre avec (B) La botted'engrenage d evis sansfin estgraissee d'usineetne necessite unehuiledetypeautomobile t outes losvingt-cinq (25)heures d'exploitation. normalement aucungraissage supplementaire. Si, pour unequelconque raison,lagraisses'estvideoou suitea unereparation de la botte d'engrenage, ajouterde lagraisseLubriplate GR132 ou equivalent. -

Page 98: Entretien Dumoteur

ENTRET/EN ENTRETiEN DU iVIOTEUR ContrSlerle niveaud'huile rnoteuravantde demarrer l e moteuret toutesles8 heuresd'utilisation continue. A jouterde I'huilemoteur preconisee le casecheant. REIVlARQUE : Un exc_',sd'huiie pent perturberle fonctionnernent du rnoteur.Bien serrer le bouchon d'huiie pour6viter les fuites. Changer i'huiie toutesles50 heures d'exploitation ou,au minimum,une fois paran,meme si la souffleuse a neigen'apaseteutiliseependant cinquante heures. -

Page 99: Changer L Abougie D'allumage

ENTRETIEN CHANGER LA BOUGIE D'ALLUIVlAGE D6poserle capot_ neige 1. %poser leboutonde commande d e starter(A,Figure28). 2. Retirer la cle desecurite (B). 3. Deposer lesvis de fixation(A,Figure29) 4. Enlever l entement le capota neige (B).Verifierquele tuyaudu bouton d'amoLcage (C)et le cabled'allumage ( D) nesont pasdebranches. 5. -

Page 100: Reglage L Ahauteur Despatins

ENTRETIEN R_gler ou changerla bougie ContrOler la bougie touteslesvingt-cinq(25)heuresde marche. Changer la bouge (Figure31)si leselectrodes sentpiquees ou brOlees o u si la porcelaine estfissuree. 1. %poser lecapeta neige(Voir lasection"DEPOSER L ECAPOT A NEIGE). 2. Nettoyer la bougieetreglerI'ecartement a intervalles reguliers. 3. -

Page 101: Ajustement Descourroies

ENTRET/EN AJUSTEIVlENT D ESCOURROIES Courroie d'entrainementde traction La courroied'entratnement detractionsubit unepression de ressort constante etne necessite aucunajustement. Si la courroied'entratnement detractionpatine, c hangerla courroie. C onsulterledistributeur homologue. Courroie d'entrainementde vissansfin Si la souffleuse a neige n'ejecte p asdeneige, v erifier l e reglage ducgblede commande. -

Page 102: Ajustement Duguide Decourroie

ENTRET/EN AJUSTEIVlENT D U GUIDEDECOURROIE 1. Debrancher lefil debougie. 2. Faireengager la commande d evis sansfin paruneautrepersonne. ® Celaengager l a galettendeur d e vis sansfin (A,Figure35). 3. Mesurerladistanceentrele guidede courroie(B)et la courroie(C). La distance doltetrecomprisentre3 mm(1/8 pouce). 4. Si unajustement est necessaire, desserrer l eboulondefixationdu guidedecourroie.Placerle guidede courroiedansla positionqui convient. - Page 103 ENTRET/EN Reglage du c_ble de corflrnande de la traction 1. Viderlereservoir d'essence. Basculer lasouffleuse a neige sur ravant du carterdevis sansfin. AVERTISSEiVlENT" Vidanger J'esseflce_ J'ext_rieur, r_cart de feu ou de fJarnrnes. 2. Desserrer l esboulons(A, Figure38) dechaquecotedu panneau inferieur(B). 3. Deposer lepanneau inferieur. 4.

-

Page 104: Changer L Esgoupilles Decisaillement Devlssansfin

ENTRET/EN CHANGER LESGOUPILLES DE CISAILLEIVlENT DEVIS SANSFiN Lavis sansfin est rendue solidairede I'arbre devis sansfin au moyen de goupillesdecisaillement c on%es sp6cialement pourrompre en casde blocage d'unobjetsdanle carter devis sans fin. L'utilisation d'unegoupille decisaillement d eplusgrande duretereduitla protection offerte par la goupille.Unegoupillede cisaillement cassee sechange dela maniere suivante : AVERTISSEMENT : Ns pas s'approchsrde la goulotts... -

Page 105: Reiviisage

REMISAGE REIVUSAGE H ORSSAISON LUBRIFIER L'ARBREHEXAGONALET CHA'iNES AVERTiSSEIVlENT "Ne jamais remiser ie moteur, avec ATTENTION"Ne pus iaisser de graisse ou d'huile venir de I'essence darts ie rGservoir, _ I'int_rieur ou darts un au contactde la roue de friction en caoutchoucou du espace clos real ventil_ oiJ les vapeursd'essence sent disque d'entra'inement. -

Page 106: Di_Pannage

DEPANNAGE PROBLi:ME CHERCHEZ POUR SOLUTION Free-Hand commande est Rel_chez a la fois lesleviersde commande de la tariereet de la traction/Free- La tari_re n'arr_te pus ACTIVE. Hand pourarreterla tariere. duns 5 secendes apr_s que Dereglage de la courroie Ajustezla courroiede la tariere. le levier droit de d'entratnement de la tariere. - Page 107 DEPANNAGE PROBLF:IVlE CNERCNEZ POUR SOLUTION La pression du pneun'estpas Verifierla pression despneus. ta souffleuse_ egale. neige vire d'un c0t6. Uneroueest en modede Assurez-vous q ue la goupilled'arretde la tractiongaucheestdansle trou roulageen rouelibre.(Les INT%IEURE (pourembrayer I'entratnement de traction). goupillesd'arretde la traction sontdansle trou EXTERIEUR.) La barre de raclage ne Lesplaques d'usuresont mal...

-

Page 108: Garanties

Garantie limit e de Craftsman G_n_ralit_s : Les produits Craftsman sont garantis contre tout defaut de mat@iaux ou de fabrication pendant une p@iode de temps precise, telle qu'etablie ci-dessous (la ,, p@iode de garantie >_). En outre, cette garantie est offerte uniquement &... - Page 109 : La liste ci-dessous indique la p@iode de garantie applicable aux divers produits Craftsman qu'elle couvre; la p@iode accordee tient compte du type de produit ou de composants et du type d'utilisation prevue ou effective de I'appareil ou du composant : 90 jours- Produits Craftsman devant _tre ou etant effectivement utilises &...

- Page 110 Le California Air Resources Board (CARB), I'U.S. EPA et Briggs & Stratton (B&S) ont le Responsabilit_s du propri_taire au titre de la garantie: plaisir de vous expliquer la garantie du systeme de contr61e des _missions pour votre En tant que proprietaire d'un moteur/_quipement, vous _tes responsable moteur/_quipement fabrique depuis 2008.

-

Page 111: Caracti_Ristiques Techniques

CARACT -R/ST/QUESTECHNIQUES iViOTEUR: Marque Briggs & Stratton S_ries du module S@ieneige Couple de serrage brut* 13,50 T.R @3060 rpm Type 4-Cycle - 0HV Cylindric 305 cc (15,26 po3) D_marrage du syst_me Lanceur electrique 110V Alternateur 60W CA I':'cartement des _lectrodes 0,76 mm (0,030 in.) 491055 8ougie _ r6sistance... - Page 112 Your Home For expert troubleshooting and home solutions advice: home manage www.managemyhome.com For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories...