Advertisement

Quick Links

Bulletin MSG11-5715-729/UK

Brief Operation Manual

Series

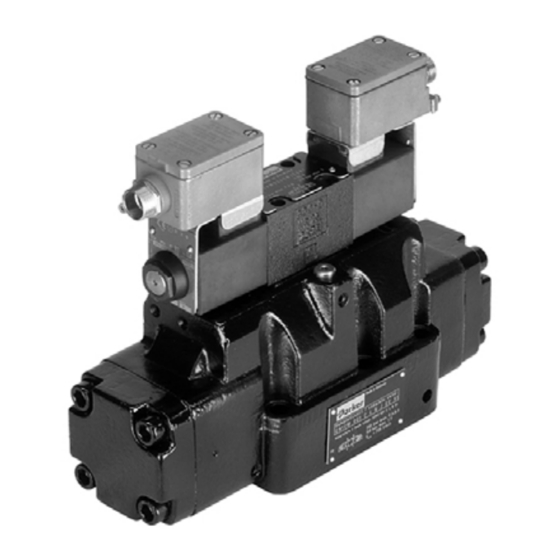

D1VW*EE (Design series 93)

D31DW*EE, D31NW*EE, D*1VW*EE

(Design series 93)

II 2 G c T4 Gb

-20 °C < Ta < +60 °C

Direct and Pilot Operated

DC Valves

Parker Hannifin

Manufacturing Germany GmbH & Co. KG

Industrial Systems Division Europe

Gutenbergstr. 38

41564 Kaarst, Germany

Tel.: (+49) 181 99 44 43 0

E-mail: valvesisde@parker.com

Copyright © 2020, Parker Hannifin Corp.

Advertisement

Summarization of Contents

User Responsibility and Safety Notices

Warning: User Responsibility

Highlights critical user responsibilities for product selection, use, and safety to prevent death, injury, or damage.

Important Safety Notices

Advises reading the manual before use and observing all safety instructions to avoid liability for damages.

EC Declaration of Conformity (ATEX)

Applicable Standards and Regulations

Lists harmonized standards applied for conformity with ATEX directive, ensuring explosion protection.

Identification Marking and Classification

Details the ATEX marking (II 2 G c T4 Gb) and temperature range (-20°C to +60°C).

EC Declaration of Conformity - Product Series

Covered Product Series List

Enlists specific product series that comply with the ATEX directive requirements.

General and Specific Safety Instructions

General Safety Instructions (A1-A5)

Covers delivery check, information obligation, intended use, marking, and work on electronics/hydraulics.

Product Specific Safety Notes (P1-P2)

Details requirements for electronic control systems and potential temperature hazards.

ATEX Specific Safety Notes (E1-E3)

Outlines ATEX requirements, explosion risk responsibility, and pressure fluid considerations.

Product Name Plate Information

D1VW*EE Nameplate Details

Describes the information present on the D1VW*EE series valve nameplate, including CE mark, ATEX symbols, serial numbers.

D31DW*EE Series Nameplate Details

Details the information found on the D31DW*EE, D31NW*EE, D*1VW*EE series valve nameplates.

Technical Data Specifications

General Valve Specifications

Covers design, actuation, size, mounting interface, ambient temperature, and MTTFD values.

Hydraulic and Electrical Data

Details hydraulic parameters like pressure, fluid, viscosity, and electrical characteristics like voltage, current, and protection class.

Valve Diagrams and Mounting Data

Direct Operated DC Valve (D1VW) Diagram

Illustrates the D1VW direct operated DC valve with manual override and port identification.

Pilot Operated DC Valve (D91VW) Diagram

Shows the D91VW pilot operated DC valve with manual override and port identification.

Electrical Connection and Torque Specifications

Provides ISO interface standards, surface finish, and mounting torque data for valve connections.

Relevant Standards and Regulations

Explosive Atmospheres Standards

Lists key EN standards for explosive atmospheres, covering general requirements, protection methods, and installations.

Industrial Safety and Health Regulations

References directives and ordinances related to industrial safety, risk assessment, and electrostatic charge avoidance.

Solenoid Operation and Specifications

Solenoid Diagram and Components

Illustrates solenoid parts and provides notes on external/internal earth, cable entry, and terminal box warnings.

Coil Size Chart and Safe Use Conditions

Presents a chart for coil dimensions and lists special conditions for safe use of solenoids.

Solenoid AC Coil Ratings and Variations

AC Solenoid Coil Data Table

Provides maximum stabilised power ratings for AC solenoids across different ambient temperatures and classifications.

Solenoid Variation Notes

Details minor design changes and improvements made to the solenoid specifications.

Solenoid Component Details

Solenoid Tube Assembly Diagram

Detailed diagram of the solenoid tube assembly, showing thread specifications and manual override.

Solenoid Component Notes

Provides specific notes regarding the solenoid component, including finish, concentricity, and edge treatment.

Solenoid Component Details (Continued)

Solenoid Tube Assembly Diagram (Continued)

Further detailed diagram of a solenoid tube assembly, illustrating dimensions and seals.

Solenoid Component Notes (Continued)

Additional notes on solenoid components, including pressure limits and thread protection.

EC Type Examination Certificate (ATEX)

Certificate Details and Scope

Provides the EC Type Examination Certificate number, manufacturer, and scope of equipment for ATEX compliance.

Compliance and Marking Requirements

Confirms compliance with ATEX directives and details the required equipment marking for explosive atmospheres.

EC Type Examination Certificate - Schedule

Equipment Description and Type Designation

Describes the solenoid equipment and explains the meaning of the type designation codes used.

Maximum Stabilised Power Ratings

Presents a table of maximum permitted stabilised power (Watts) for solenoids based on size, temperature, and classification.

EC Type Examination Certificate - Conditions and Documents

Special Conditions for Safe Use

Outlines mandatory conditions for the safe installation and operation of the certified equipment.

Referenced Drawings and Documents

Lists essential drawings and documents that form part of the ATEX certification for the equipment.

Supplementary EC Type Examination Certificate

Certificate Extension Details

Extends the original EC Type Examination Certificate to cover variations in design and construction.

Certificate Scope and Variations

Specifies how the supplementary certificate applies to variations within the original certificate's schedule.

Supplementary EC Type Examination Certificate - Schedule

Description of Variations

Details specific variations applied to the equipment, including standard reviews and design changes.

Special Conditions and Documents

Lists any additional special conditions for safe use and relevant documents related to the variations.

Supplementary EC Type Examination Certificate (Update)

Certificate Number and Scope Update

Confirms an update to the certificate number and scope, reflecting new standards compliance.

Marking Changes

Notes changes in the required equipment marking as specified in the updated certificate.

Supplementary EC Type Examination Certificate - Schedule (Update)

Description of Variations and Power Ratings

Details variations including alternative ambient temperature ratings and supersedes previous power wattages.

Specific Conditions of Use

Specifies conditions for using fuses and notes on thermal fuses for the solenoid protection.

ATEX Certificate Drawings and Documents

List of Referenced Drawings

Provides a comprehensive list of drawings and documents referenced within the ATEX certificate.

Supplementary EC Type Examination Certificate (Revision)

Certificate Number and Extension

Introduces a new supplementary certificate number and details its extension to the original EC Type Examination Certificate.

Scope of Extension

Explains that the supplementary certificate applies to equipment designed per specified variations and documents.

Supplementary EC Type Examination Certificate - Schedule (Revision)

Description of Variations

Details new variations, including alternative terminal enclosures and minor rewording of conditions.

Specific Conditions and Drawings

Lists specific conditions of use and provides an updated list of drawings related to the revisions.

IECEx Certificate of Conformity

Certificate Details and Scope

Provides the IECEx Certificate of Conformity number, issuing body, and details of the electrical apparatus.

Electrical Apparatus and Marking

Describes the apparatus, type of protection (Increased safety and Encapsulation), and required marking for explosive atmospheres.

IECEx Certificate of Conformity - Standards and Reports

Applicable Standards

Lists the IEC standards to which the electrical apparatus was assessed and tested for conformity.

Test and Assessment Reports

References the test and quality assessment reports that confirm the equipment's compliance.

IECEx Certificate of Conformity - Schedule and Conditions

Equipment Description and Sizes

Details the equipment covered, including solenoid types, terminal enclosures, and available sizes.

Conditions of Certification

Outlines the mandatory conditions for the safe use and installation of the certified solenoids.

ATEX/IECEx Quality Assessment Report Schedule

Product Manufacturing and Design Control

Details products manufactured by the company and controlled by G.W. Lisk Company Inc., including certificate numbers.

Solenoid Declaration of Conformity and IP Rating

Manufacturer's Statement on Hazardous Locations

Declares solenoids are rated for hazardous locations and meet specific ingress protection requirements.

Ingress Protection Rating (IP66)

Specifies the Ingress Protection Rating of IP66 for certified solenoids in accordance with BS5490.

Cable Gland Mounting Instructions

Cable Gland Mounting Diagram and Torque

Provides a diagram for mounting cable glands and specifies required torque values for electrical connection.

ATEX Cable Gland Specifications

Details specifications for ATEX cable glands, including permitted cable diameter and tolerances.

Need help?

Do you have a question about the D31NW Series and is the answer not in the manual?

Questions and answers