Advertisement

CALL TOLL FREE 877-742-2878 FOR SALES AND SUPPORT

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

Refer to Model Description Chart to match the pump materi-

al options.

637434 for air section repair (see page 6).

637467-XX for fluid section repair (see page 4).

Models . . . . . . . . . . . . . . . . . see Model Description Chart for "-XXX"

Pump Type . . . . . . . . . . . . . Metallic Air Operated Double Diaphragm

Material . . . . . . . . . . . . . . . . see Model Description Chart

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118.32 lbs (53.67 kgs)

Maximum Air Inlet Pressure . . . . . . . . . . . 120 p.s.i.g. (8.3 bar)

Maximum Material Inlet Pressure . . . . . . 10 p.s.i.g. (0.69 bar)

Maximum Outlet Pressure . . . . . . . . . . . . . 120 p.s.i.g. (8.3 bar)

Maximum Flow Rate (flooded inlet) . . . 217 g.p.m. (821.3 l.p.m.)

Displacement / Cycle @ 100 psig . . . . . . . 2.08 gal. (7.9 lit.)

Maximum Particle Size . . . . . . . . . . . . . . . . 1" dia. (25.4 mm)

Maximum Temperature Limits (diaphragm / ball / seat material)

E.P.R. / EPDM . . . . . . . . . . . . . . . . . . . -60° to 280° F (-51° to 138° C)

Hytrel® . . . . . . . . . . . . . . . . . . . . . . . . . -20° to 180° F (-29° to 82° C)

Nitrile . . . . . . . . . . . . . . . . . . . . . . . . . . 10° to 180° F (-12° to 82° C)

Santoprene® . . . . . . . . . . . . . . . . . . . -40° to 225° F (-40° to 107° C)

PTFE . . . . . . . . . . . . . . . . . . . . . . . . . . . 40° to 225° F (4° to 107° C)

Viton® . . . . . . . . . . . . . . . . . . . . . . . . . . -40° to 350° F (-40° to 177° C)

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . see page 8

Noise Level @ 70 psig, 60 c.p.m. . . . . . . 86.3 dB(A)

Noise Level @ 70 psig, 60 c.p.m. . . . . . . 108.7 dB(A)

Tested with 94810 muffler assembly installed.

The pump sound pressure levels published here have been updated to

an Equivalent Continuous Sound Level (L

S1.13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

Tested with 97116 housing and 97110-2 ball installed. Hearing protec-

tion is recommended when using this product.

NOTICE: All possible options are shown in the chart, however, certain

combinations may not be recommended, consult a representative or

the factory if you have questions concerning availability.

INGERSOLL RAND COMPANY INC

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276

arozone.com

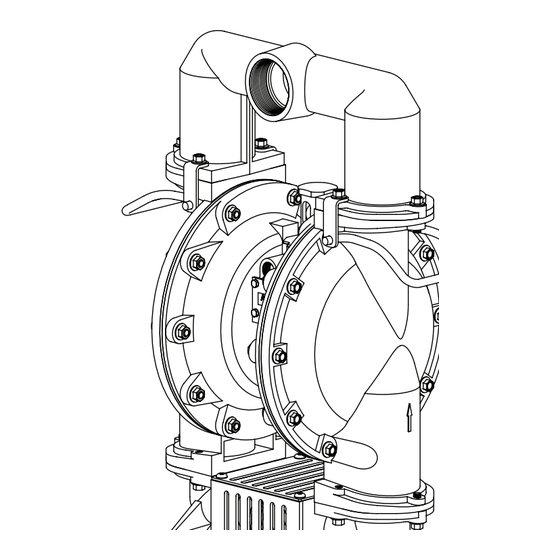

3" DIAPHRAGM PUMP

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

SERVICE KITS

PUMP DATA

) to meet the intent of ANSI

Aeq

FAX (800) 892-6276

© 2023

1:1 RATIO (METALLIC)

OPERATING OR SERVICING THIS EQUIPMENT.

Center Body Material / Fluid Connection

0 - Aluminum / 3 - 8 NPTF - 2

2 - Aluminum / Rp 3 (3 - 11 BSP parallel)

Fluid Cap & Manifold Material / Hardware

0 - Aluminum / Carbon steel

Seat Material

1 - Aluminum

Ball Material

2 - Nitrile

C - Hytrel

E - Santoprene

Diaphragm Material

2 - Nitrile

9 - Hytrel

B - Santoprene

Fluid Section Service Kit Selection

Example: Model #66M300-1EB-C

Fluid Section Service Kit # 637467-EB

CCN 15321482

Return to BurtProcess.com

66M3X0-XXX-C

Figure 1

MODEL DESCRIPTION CHART

RELEASED:

10-22-08

REVISED:

1-27-23

(REV: J)

66M3 X 0 - X X X - C

66M3X0 - X X X - C

637467 - X X

Ball

Diaphragm

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ingersoll-Rand ARO 66M3 0 C Series

- Page 1 CALL TOLL FREE 877-742-2878 FOR SALES AND SUPPORT Return to BurtProcess.com OPERATOR’S MANUAL 66M3X0-XXX-C INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE RELEASED: 10-22-08 REVISED: 1-27-23 (REV: J) 3" DIAPHRAGM PUMP 1:1 RATIO (METALLIC) READ THIS MANUAL CAREFULLY BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT. It is the responsibility of the employer to place this information in the hands of the operator.

-

Page 2: Operating And Safety Precautions

OPERATING AND SAFETY PRECAUTIONS READ, UNDERSTAND AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE. Disconnect air supply line and relieve pressure from EXCESSIVE AIR PRESSURE HAZARDOUS MATERIALS the system by opening dispensing valve or device and STATIC SPARK HAZARDOUS PRESSURE / or carefully and slowly loosening and removing out- let hose or piping from pump. -

Page 3: General Description

The Chemours Company y Loctite® is a registered trademark of Henkel Corporation y y Santoprene® is a registered trademark of Celanese y ARO® is a registered trademark of Ingersoll-Rand Company y y 262™, 271™ and 572™ are trademarks of Henkel Corporation y... - Page 4 PARTS LIST / 66M3X0-XXX-C FLUID SECTION 637467-XX Fluid section service kit includes: Balls (see Ball Option, refer to -XX in chart below), Diaphragms (see Diaphragm Option, refer to -XX in chart below) and items 2, 3, 19 and 196 (listed below) plus 94276 Lubriplate® FML-2 packet (page 6). SEAT OPTIONS BALL OPTIONS MATERIAL CODE...

- Page 5 PARTS LIST / 66M3X0-XXX-C FLUID SECTION COLOR CODE Diaphragm Ball Material Color Color Hytrel Cream Cream Nitrile Black Red (•) Santoprene (•) Dot FOR THE AIR 26 ( MOTOR SECTION, SEE PAGES 6 & 7. Torque Sequence 14 (d 19 c 27 ( 19 c 26 (...

- Page 6 PARTS LIST / 66M3X0-XXX-C AIR MOTOR SECTION Indicates parts included in 637434 air section service kit. AIR MOTOR PARTS Item Description Qty Part No. Item Description Qty Part No. (size) (size) 101 Motor Body (1) 96427 121 Sleeve Bushing (2) 98723-2 [Bz] ...

- Page 7 PARTS LIST / 66M3X0-XXX-C AIR MOTOR SECTION IMPORTANT BE CERTAIN TO ORIENT (115) SPACER LEGS AWAY FROM BLOCKING INTERNAL PORTS WHEN REASSEMBLING AIR SECTION. c 114 105 ( c 114 c 113 MAJOR VALVE Figure 3 g 128 g 126 195A d f) 123 102 c...

-

Page 8: Troubleshooting

TROUBLE SHOOTING Product discharged from exhaust outlet. Check for kinked (restrictive) or collapsed inlet material Check for diaphragm rupture. hose. Check tightness of (14) diaphragm screw. Check for pump cavitation - suction pipe should be sized at least as large as the inlet thread diameter of the pump Air bubbles in product discharge.

Need help?

Do you have a question about the ARO 66M3 0 C Series and is the answer not in the manual?

Questions and answers