Table of Contents

Advertisement

Quick Links

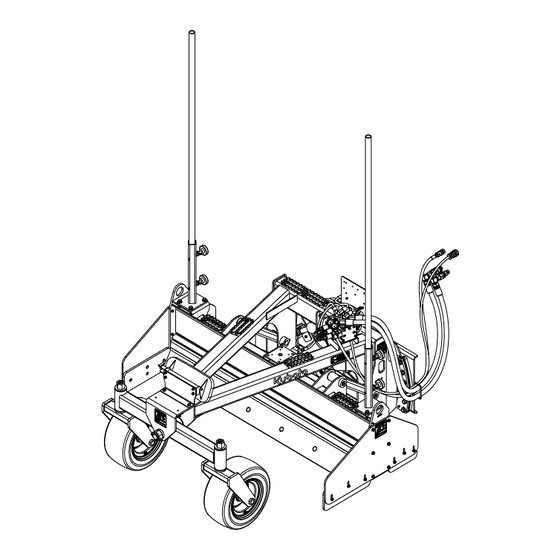

Grading Box Blade

AP-BB3072, AP-BB3084, & AP-BB3096

72617

Table of Contents

Read the Operator's Manual entirely. When you see this symbol,

!

the subsequent instructions and warnings are serious - follow

without exception. Your life and the lives of others depend on it!

Cover photo may show optional equipment not supplied

with standard unit.

For an Operator's Manual and Decal Kit in French

Language, please see your Kubota dealer.

301-635MK

Operator's Manual

Printed 12/13/23

Advertisement

Table of Contents

Summary of Contents for Kubota AP-BB3072

- Page 1 Your life and the lives of others depend on it! Cover photo may show optional equipment not supplied with standard unit. For an Operator’s Manual and Decal Kit in French Language, please see your Kubota dealer. Printed 12/13/23...

-

Page 2: Machine Identification

Machine Height Machine Length Machine Width Machine Weight Delivery Date First Operation Accessories Dealer Contact Information Name: Street: City/State: Telephone: Email: California Proposition 65 WARNING: Cancer and reproductive harm - www.P65Warnings.ca.gov AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... - Page 3 Copyright 2023 All rights Reserved Kubota provides this publication “as is” without warranty of any kind, either expressed or implied. While every precaution has been taken in the preparation of this manual, Kubota assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained herein. Kubota reserves the right to revise and improve its products as it sees fit.

- Page 4 Download the appropriate for Kubota products. Refer to app on your smart phone. Scan the QR Parts Manual QR Locator on code and take a picture. this page for detailed instructions. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

-

Page 5: Safety At All Times

Important Safety Information Important Safety Information Listed below are common practices that may or may not be applicable to the products described in this manual. Safety at All Times Look for the Safety Alert Symbol The SAFETY ALERT SYMBOL indicates there is a potential hazard Careful operation is your best to personal safety and extra precaution must be taken. - Page 6 Lower attachment to the ground and Replace parts on this attachment correct tools and equipment. follow all shutdown procedures with genuine Kubota parts only. Do Always properly match the wheel before leaving the operator’s seat to not alter this attachment in a way size to the properly sized tire.

- Page 7 Important Safety Information These are common practices that may or may not be applicable to the products described in this manual. Prepare for Emergencies Wear Personal Protective Avoid High Pressure Equipment (PPE) Fluids Be prepared if a fire starts. ...

-

Page 8: Important Safety Information

Important Safety Information Listed below are common practices that may or may not be applicable to the products described in this manual. Be aware of and follow OSHA If possible, change into disposable Avoid Crystalline Silica or washable work clothes at the (or other local, State, or Federal) (Quartz) Dust guidelines for exposure to airborne... - Page 9 Important Safety Information This page left blank intentionally. 12/13/23...

-

Page 10: Safety Labels

Refer to this section for proper label placement. Replace surface. all damaged or missing labels. Order new labels from your nearest Kubota dealer. To find your nearest dealer, visit Squeeze out air bubbles with edge of a credit card or our dealer locator at www.landpride.com. - Page 11 Important Safety Information 72618 70400 838-112C Danger: Pinch Point Hazard 3 Places 72618 72624 844-033C Crushing Hazard - Automatic Machinery Hazard 2 Places 70372 72618 818-339C Warning: High Pressure Fluid Hazard 1 Place 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK...

-

Page 12: Using This Manual

The Kubota AP-BB30 Series Grading Box Blades come 72690 in three working widths: 72" (1.83 m), 84" (2.13 m), and 96" (2.44 m). They are designed for attaching to Kubota’s 65-95 hp skid steers and track loaders. Kubota’s BB30 Series Grading Box Blades allows users the option of rough or precision grading finishes. -

Page 13: Section 1: Assembly & Set-Up

Be sure to use a spreader bar on the chain to keep the chain near vertical and to prevent bending of the sling brackets. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... - Page 14 Valve Controller Mount & Valve Controller Assembly (#10) V CW Gray Figure 1-3 V CCW Pink If applicable, disconnect and remove pre-existing (#12) Gray wire harness from proportional valve (#9). (#13) Black AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

- Page 15 (#10) and screw coupler (#9) to hose (#10) until tight. If coupler (#9) is not used, customer must supply all fittings to complete the connection between the power machine sump and hydraulic hose (#10). 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK...

-

Page 16: Hitch Hook-Up

Push lock handles down to drive lock pins through bottom slots in the hitch plate. Make sure handles lock down. 11. Check hitch hook-up to verify it is locked properly. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... -

Page 17: Hydraulic Hook-Up

• Hydraulic fluid under high pressure will penetrate the skin 3. If attaching the grading blade to a Kubota skid steer or eyes causing serious injury. Wear protective gloves and or track loader, see note under Figure 1-8. Route safety glasses or goggles when working with hydraulic hoses through hose stay. - Page 18 Self-Leveling Mast Mounts Figure 1-10 If attaching the Grading Box Blade to a Kubota skid steer or track loader, route wire harness (#11) Laser/2D Mast Mounts (Optional) through hose stay shown in Figure 1-8 on page 13.

-

Page 19: Check Equipment Clearances

5. With the grading blade on the ground, start the power machine and carefully rotate the top of the loader hitch plate fully back while watching hydraulic hoses to make sure they do not become pinched or kinked. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... - Page 20 3/8"-16 GR5 bolts. 2. Raise loader arms up and tilt top of hitch plate 9. Raise loader arms slightly. forward until grading blade is hanging straight down as shown in Figure 2-1. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

-

Page 21: Section 2: Adjustments

2. Attach blade locks (#5) to center gussets (#6) with existing 3/8"-16 x 4 1/2" GR5 bolts (#4) and flange nuts (#7). 3. Tighten flange nuts (#7) to the correct torque. 4. Complete steps 9-12 above. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... -

Page 22: Side Cutters

10. Once all side cutters (#15 & #16) are adjusted to be dismounting. Follow “Power Machine Shutdown even with the bottom of grader blades (#15 & #16), Procedure” on page 21. tighten bolts (#12 & #14) to the correct torque. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... - Page 23 5. Have a second person loosen hand knob (#22) and adjust mirror (#21) up or down as needed for the operator to see product in front the grader blade. 6. Hand tighten knob (#22) once the mirror is adjusted. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK...

-

Page 24: Operating Checklist

Riders can obstruct the operator’s view, interfere with controls, be pinched by moving components, become entangled in rotating components, struck by objects, thrown about, fall off and be run over, etc. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... -

Page 25: Section 3: Operating Instructions

The operator could lose control resulting in equipment damage and/or tipping hazard. IMPORTANT: Use grading blade for light grading and leveling only. Do not use unit to move hard surfaces such as rocks, concrete, asphalt, etc. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... - Page 26 Always drive up a ramp with heavy end uphill. • Shut power machine down before dismounting. Follow “Power Machine Shutdown Procedure” on page 21. • Secure power machine and attachment using tie downs and chains. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

- Page 27 11. Back power machine slowly away from the grading blade making sure the power machine does not interfere with the attachment’s hitch plate, hydraulic hoses, or wire harness. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK...

- Page 28 15. Remove jack stand (#5). • Check hydraulic hoses and fittings frequently for leaks or damage. Fluid escaping under pressure can penetrate skin. Large leaks can drop the attachment. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

-

Page 29: Section 4: Maintenance & Lubrication

(#5) as shown with plow bolts (#3) and flange nuts (#4). Draw flange nuts up snug, do not tighten. 9. Remove jack stand (#6). 10. Adjust side cutters to the correct height. Refer to “Side Cutters” on page 18. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... - Page 30 (#8 shown in Figure 2-2 on page 18) until grader blades are resting on the ground. 13. Shut power machine down before dismounting. Follow “Power Machine Shutdown Procedure” on page 21. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

- Page 31 (#5) without play. hitch plate (#6) with six 5/8"-18 GR5 bolts (#1). 6. Tighten bolts (#1) to the correct torque. Repeat steps 1-6 on the left-hand side of hitch plate (#6). 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK...

-

Page 32: Long Term Storage

4. Repaint parts where paint is worn or scratched to prevent rust. Ask your Kubota dealer for touch-up paint. Paint is available in aerosol can, quarts, and gallon sizes. See chart below. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... -

Page 33: Lubrication Points

Type of Lubrication: Multi-Purpose Grease Quantity: Add grease until grease begins to emerge. 72689 Hours Gauge Wheel Axle Pivot Pin 1- Zerk Type of Lubrication: Multi-Purpose Grease Quantity: Add grease until grease begins to emerge. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... - Page 34 Base End of Lift Cylinder 2 - Zerks (One at each end of the cylinder.) 72693 Type of Lubrication: Multi-Purpose Grease Quantity: Add grease until grease begins to emerge. Rod End of Lift Cylinder AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23...

- Page 35 Type of Lubrication: Multi-Purpose Grease Quantity: Add grease until grease begins to emerge. 72777 Hours Blade Pivot Rods 10 - Zerks Type of Lubrication: Multi-Purpose Grease Quantity: Add grease until grease begins to emerge. 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK...

-

Page 36: Section 5: Specifications & Capacities

Front and rear Floating blades 72695 Optional 107 1/2" (2.73m) 40 1/4" (1.02m) BB3072 = 74 1/2" (1.89 m) 72" (1.8m) BB3084 = 86 1/2" (2.20 m) BB3096 = 98 1/2" (2.50 m) AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... -

Page 37: Section 6: Features & Benefits

Parallel links keep the blade angle to the soil consistent throughout the blade’s range of Lift/tilt motions kept constant with parallel links motion. Tires won’t go flat. Foam-filled turf tires 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... -

Page 38: Section 7: Troubleshooting

Variance in the ground elevation is too great Rough-out the area being worked without the causing the receivers to go below or above lasers. Switch to the lasers to finish the job. the laser beam. AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK 12/13/23... -

Page 39: Section 8: Torque Values Chart

Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above. All locknuts or lubricated fasteners: Use 75% of torque value. (i.e. 1/2"-13 GR5 = 76 ft-lb; 75% of 76 or .75 x 76 = 57 ft-lb) 12/13/23 AP-BB3072, AP-BB3084, & AP-BB3096 Grading Box Blade 301-635MK... - Page 40 Claims under this Warranty should be made to the dealer which originally sold the product and all warranty adjustments must be made through an authorized Kubota dealer. Kubota reserves the right to make changes in materials or design of the product at any time without notice.

-

Page 41: Section 9: Warranty & Legal Disclaimer

Kubota used reasonable efforts to set forth and include accurate and up to date information in this publication. Kubota disclaims all representations and warranties, whether express or implied, including, but not limited to, warranties of merchantability... - Page 42 Kubota HP: https://www.kubota.com/network/index.html...

Need help?

Do you have a question about the AP-BB3072 and is the answer not in the manual?

Questions and answers