Summary of Contents for Gradall G880

- Page 1 OPERATORS MANUAL G880 8680-1019 July 2002 Starting Machine 5 of Lot 84 GRADALL 406 Mill Avenue, S.W. New Philadelphia, OH, 44663, USA Telephone: (330) 339-2211 Fax: (330) 339-3579...

- Page 4 Safe operation depends on reliable equipment and the use of proper operating procedures. Performing the checks and services described in this manual will help to keep your Gradall in reliable condition and use of the recommended operating procedures can help you avoid unsafe practices. Because some pro- cedures may be new to even the experienced operator we recommend that this manual be read, understood and followed by all who operate the carrier.

- Page 6 SAFETY HIGHLIGHTS Read and understand this manual and “CIMA Hydraulic Excavator User’s Safety Manual” before operating. Serious injury or death can result from unsafe operating practices. Inspect your machine daily before operating and before engine startup. Correct all faulty conditions before operating the unit.

- Page 7 Be sure you have enough clearance for upperstruc- ture tail swing, especially if there are cars or people in the area. Always have a flagman to direct traffic. On truck-mounted Gradalls, watch out for the car- rier cab when swinging the boom. Keep the boom high, and if possible, do not swing close to the cab.

- Page 8 Safety Highlights (Cont.) When parking or traveling with boom in cradle, allow to prevent damage to cab or sufficient clearance windows in case bucket were to close. Be especially careful when operating carrier in remote control; never assume a clear path. Always sound horn before moving carrier.

- Page 9 12. Boom Tilt Lever 13. Horn Button 14. Boom Raise & Lower Lever 15. Open Bucket Pedal 16. Close Bucket Pedal 17. Swing Boom Left Pedal 18. Swing Boom Right Pedal WARNING Know and understand controls and instru- ments before operating the Gradall.

- Page 10 CONTROL VARIATIONS (Upperstructure only) CONTROLS COMMON TO CRAWLER CONTROLS COMMON TO UNITS MOUNTED UNITS EQUIPPED FOR REMOTE CONTROL CONTROLS COMMON TO UNITS EQUIPPED WITH DETROIT DIESEL MODEL 4-71N ENGINE...

- Page 11 WARNING Use extreme caution when checking items beyond your normal reach. WARNING Any defects or deficiencies noted must be cor- rected before the Gradall is placed in service. Check for adequate and refill as necessary fuel supply using specified fuel. Tank should be kept filled to min- imize condensation.

- Page 12 Checks and Services Before Starting Upper Engine Check coolant level in radiator and fill as necessary. Check coolant for proper protection against freezing and add anti-freeze as necessary. Check Replace ele- air cleaner condition indicator. WARNING ment when orange band rises to top of indicator win- dow.

- Page 13 Make daily inspections of your crawler. Check for loose bolts, leaky seals and abnormal wear. Report all items needing attention to maintenance personnel for adjustment or repair. If a is required by law or jobsite con- spark arrester ditions, make sure that one is attached and that it is in good working condition.

-

Page 14: Cold Weather Starting Aids

UPPER ENGINE OPERATION NOTE: If engine is being started at beginning of work shift be sure to perform all “CHECK AND SERVICES BEFORE STARTING UPPER ENGINE” (pages 7 through 9). Starting Detroit Diesel and Caterpillar Engines (cold start) 1. It is recommended that the engine clutch be thirty seconds, release key and allow starting engaged when starting the engine under normal motor to cool for a few minutes before trying... -

Page 15: Stopping The Engine

Be alert for unusual noises or vibration. Once engine has reached operating temperature run at unusual condition is noticed, stop machine in a safe full throttle for efficient Gradall operation. position and shut off engine. Determine cause and cor- rect problem before continuing. -

Page 16: Checks After Starting Engine

Proper operating BEFORE DIGGING (To be performed at beginning of each work period) 5. Operate the Gradall slowly through a few com- WARNING plete digging cycles to warm the hydraulic oil throughout the system. Always apply digging brake in carrier cab before operating the upperstructure. -

Page 17: Bucket Installation

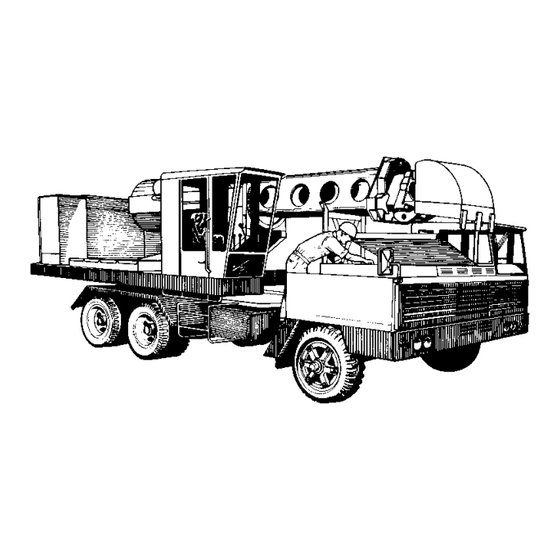

BUCKET INSTALLATION WARNING: Keep boom in fully extended position while installing bucket. Stay clear of bucket and boom until bucket adapter has been fitted to bucket as shown in step 3. WARNING: Digging with a loose or an improperly fitted bucket can shear adapter bolts and cause excessive wear, injury and damage to your unit. - Page 18 Conventional Carrier Mounted Units (without remote control) Gradalls mounted on conventional 6x4 or 6x6 carriers be used when the unit is to be moved during Gradall are highly mobile and can travel between job sites operation. Complete instructions for the operation of quickly.

-

Page 19: Remote Control

REMOTE CONTROL NOTE: Remote control is to be used for positioning unit at job site, not for over-the-road travel. Preparing Carrier for Remote Control Operation 1. Apply parking brake (pull knob up). WARNING Keep feet clear of clutch pedal when moving 2. - Page 20 REMOTE CONTROL (Cont.) Precautions for remote control operation Be sure of unobstructed visibility in direction of Never tow load using remote control drive. travel; use a signalman to compensate for blind spots. Always give audible signal before moving unit. Be sure upperstructure swing brake functions Never permit bucket to drag while moving unit.

- Page 21 Crawler undercarriages are furnished to enable the 6. Mud and debris can prevent rollers from turning Gradall to travel over rough terrain and reach work and cause flat spots. Clean track components as sites which would not be accessible to the ordinary often as necessary.

- Page 22 HOW TO OPERATE THE CRAWLER...

- Page 23 TO MAKE A TYPICAL GRADALL CUT IMPORTANT Your Gradall has sufficient power to permit a fast efficient digging cycle. The procedure on the following pages describes a typical cycle in separate steps; as you gain experience, combine control functions for a smooth cycle with no lost time.

- Page 24 To Make A Typical Gradall Cut Press outer right pedal to swing the boom right (J), Push right lever forward to extend boom and at the inner right pedal to swing left (I), out over the pro- same time push left lever forward to lower boom (B), posed digging site.

- Page 25 Position bucket open or closed for correct pen- Pull center lever back to tilt boom clockwise etration while boom is being lowered. Push forward push center lever forward to tilt boom counterclock- on left lever to force boom down for penetration wise if necessary.

- Page 26 To Make A Typical Gradall Cut Pull right lever back to retract boom (E), and at the The bucket cutting edge raises as the boom retracts. same time push left lever forward to apply down pres- Slight adjustment of bucket open pedal...

- Page 27 Pull left lever back and as the boom rises, press When bucket is raised high enough to clear obstruc- inner left pedal to close the bucket and prevent tions, swing boom left or right to dump location, excess spillage. Do not raise the boom higher than is and if required, extend boom by pushing right lever necessary.

- Page 28 To Make A Typical Gradall Cut Press outer left pedal to open bucket and release Swing boom left or right to align boom for next dirt. cut and repeat steps 4 through 11.

-

Page 29: Parking Precautions

2. Set brakes using crawler brake lever. 6x6 carriers is fully explained in the “G-880 3. Fill fuel tank to minimize condensation. GRADALL 6x4 and 6x6 CARRIERS OPERATOR’S MANUAL”. The following procedure is intended for 4. Lock cab and install protective window covers if crawler mounted units only. -

Page 30: Operating Tips

2. When ditch cleaning from the road on a rubber tired carrier truck-mounted Gradall, travel with traf- fic toward the unclean end of the ditch, for a clear view of the cleaned ditch, the road shoulder, and the truck hauling the spoil. - Page 31 Emergency Parts Kits If the Gradall is working in remote or hard-to-get-to areas, one of the emergency parts kits available should be kept with the machine. These kits are good insurance against downtime due to minor repairs or replacements.

- Page 34 LUBRICATION RECOMMENDED LUBRICANTS * Viscosity ASTM: (SSU at 100 F.) Rust Test (ASTM D 665): Pass (Procedure A) Viscosity #215: (ASTM D 88) 194–235 (Centistokes at 100 F.) Oxidation Test (ASTM D 943): 1000 hr. min. to a Neut No. of 2 (ASTM D 445) 41.9–51.0 (See Notes 4 and 5 ASTM D943) Viscosity Index...

-

Page 35: Scheduled Maintenance

SCHEDULED MAINTENANCE Check drive belts monthly ....... . Adjust tension or replace as required. Check steering reservoir monthly. - Page 36 Gradall Industries, Inc. 406 Mill Ave SW New Philadelphia OH. 44663 Phone: (330) 339-2211 Customer Support Toll Free: (800) 445-4752 Fax: (330) 339-3579...

Need help?

Do you have a question about the G880 and is the answer not in the manual?

Questions and answers