Advertisement

Quick Links

OWNER'S GUIDE & INSTALLATION INSTRUCTIONS

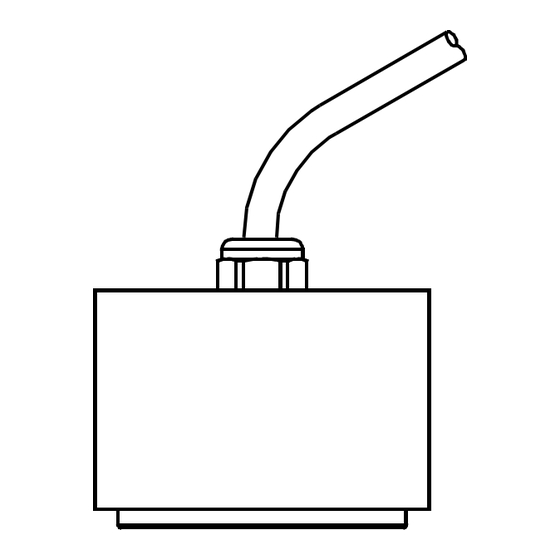

Cavity or Welded-tank Mount:

Sealcast

Model: CM422

Patent http://www.airmar.com/patent.html

WARNING: The transducer must be professionally installed

using accepted practices. The cavity or welded tank must be

strong and watertight to reduce the risk of property damage,

personal injury, and/or death.

Follow the safety precautions below for optimal

product performance and to reduce the risk of

property damage, personal injury, and/or death.

WARNING: Always wear safety glasses, a dust mask,

and ear protection when installing.

WARNING: Use marine sealant to seal the hull and hold

the transducer firmly in place. When the boat is underway,

especially at high speeds, water will enter any gaps and

push against the transducer with considerable force.

WARNING: A faceplate is required to secure the

transducer to the hull. When the boat is underway,

especially at high speeds, water will push against the

transducer with considerable force.

WARNING: Immediately check for leaks when the boat is

placed in the water. Do not leave the boat unchecked for

more than three hours. Even a small leak may allow

considerable water to accumulate.

CAUTION: Orient the transducer so the bosses on the

top are facing fore and aft—parallel to the centerline of

the boat.

CAUTION: The transducer must be flush with the bottom

of the hull for good performance.

CAUTION: Never pull, carry, or hold the transducer by

the cable. This may sever internal connections.

CAUTION: Never strike the transducer.

CAUTION: Never power sand or pressure wash the

transducer. It may weaken the structure or damage the

internal components.

1kW

Depth Transducer

™

with Temperature Sensor

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz

CAUTION: Never use solvents. Cleaners, fuel, sealants,

paint, and other products may contain solvents that can

damage plastic parts, especially the transducer's face.

IMPORTANT: Please read the instructions completely

before proceeding with the installation. These instructions

supersede any other instructions in your instrument

manual if they differ.

Applications

• Cavity mounting recommended for fiberglass hulls.

• Cavity mounting recommended for high-speed boats.

Tools & Materials

NOTE: Making a fiberglass cavity in the hull, a faceplate, or a

welded tank requires additional tools and materials not listed.

Safety glasses

Dust mask

Ear protection

Scissors

Masking tape

Electric drill

Drill bits and hole saws:

Hole saw for cavity

Hole saw for faceplate opening

Pilot hole

Cable hole

Sandpaper (coarse grit 120)

Tack cloth

Marine sealant (suitable for below waterline)

Grommet(s) (some installations)

Cable ties

Water-based anti-fouling coating (mandatory in salt water)

6mm

(1/4")

120mm or 4-3/4"

95mm or 3-3/4"

3mm or 1/8"

large enough to accommodate

the bushing

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Airmar Sealcast CM422

- Page 1 Sealcast Depth Transducer ™ with Temperature Sensor Model: CM422 Patent http://www.airmar.com/patent.html (1/4") WARNING: The transducer must be professionally installed using accepted practices. The cavity or welded tank must be strong and watertight to reduce the risk of property damage, personal injury, and/or death.

- Page 2 Follow the “Transducer lip: cutting line for the opening in the bosses faceplate.” 3. Drill holes for the fasteners that will hold the faceplate securely Figure 4.Orient bosses fore and aft to the hull. Fasteners must be suitable for below waterline. Copyright © 2013 - 2019 Airmar Technology Corp.

- Page 3 6. Remove the excess sealant on the outside of the hull to ensure smooth water flow under the transducer. Email: sales@airmar-emea.com 35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA • www.airmar.com Copyright © 2014 - 2020 Airmar Technology Corporation. All rights reserved.

- Page 4 Template CM422 IMPORTANT: Some printers and printer settings can alter the size of the template. Verify the template’s size before cutting. Place the transducer on the template to be sure it is the exact size. If necessary, redraw the template.

Need help?

Do you have a question about the Sealcast CM422 and is the answer not in the manual?

Questions and answers