Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Burkert 2034-T

- Page 1 Operating Instructions Beispielhafte Darstellungen/ Exemplary presentations Typ / Type 2034-T Aseptic Multiway Valve System Bedienungsanleitung: © 2017-2024 Bürkert Werke GmbH & Co. KG Bedienungsanleitung 2408/0A_Ml-ml_00810620 / Original DE...

-

Page 2: Table Of Contents

Table of Contents Table of Contents OPERATING INSTRUCTIONS Symbols INTENDED USE Restrictions BASIC SAFETY INSTRUCTIONS GENERAL INFORMATION Contact address Warranty Information on the Internet SYSTEM DESCRIPTION Intended application area General description 5.2.1 Label information Operating instructions actuator; automation unit 5.3.1 Actuator 5.3.2 Automation unit for pneumatic actuators... - Page 3 Table of Contents Maintenance work Malfunctions Recommended auxiliary materials SPARE PARTS SHUTDOWN Safety instructions Removing the multiway valve PACKAGING AND TRANSPORT STORAGE DISPOSAL - 3 -...

-

Page 4: Operating Instructions

Operating instructions Operating instructions The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is easily accessible to every user and make these instructions available to every new owner of the device. WARNING! The operating instructions contain important safety information! Failure to observe these instructions may result in hazardous situations. -

Page 5: Intended Use

Intended use Intended use WARNING! General hazard information Unauthorised use of the device may be hazardous to persons, systems in the vicinity and the environment. To use the device, observe the authorized data, operating instructions and application areas specified in the contract documents and in the operating instructions! The aseptic multiway valve system Type 2034, referred to below as multiway valve only, •... -

Page 6: Basic Safety Instructions

Basic safety instructions Basic safety instructions These safety instructions do not make allowance for any • eventualities and events which may occur during installation, operation and maintenance of the devices. • local safety regulations – the operator is responsible for observing these regulations, also in relation to the installation personnel. - Page 7 Basic safety instructions CAUTION! Medium will escape if the diaphragm is worn → Regularly check relief bore for escaping medium. → If medium is escaping from the relief bore, change the diaphragm (see chapter Maintenance work). → If media is hazardous, protect the area around the discharge point from hazards NOTE! Electrostatic sensitive components / modules The device may contain electronic components which react sensitively to electrostatic...

-

Page 8: General Information

General information General information Contact address Bürkert Fluid Control Systems Tel. + 49 (0) 7940 – 10 91 111 Sales Center Fax + 49 (0) 7940 – 10 91 448 Christian-Bürkert-Straße 13-17 Email: info@de.buerkert.com D-74653 Ingelfingen www.buerkert.de Warranty A precondition for the warranty is that the multiway valve is used as intended in consideration of the specified operating conditions. -

Page 9: System Description

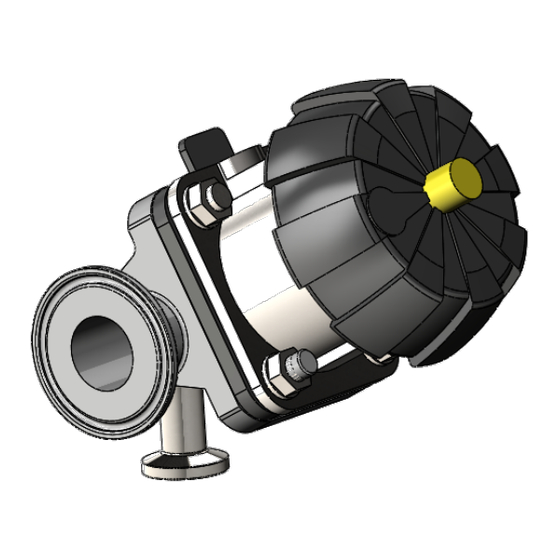

System description System description Intended application area The multiway valve is designed for use with ultra-pure, sterile, aggressive or abrasive media which will not attack the housing or the seal material. Observe the maximum pressure range on the system type label! General description The multiway valve consists of: •... - Page 10 System description Actuator label example: Actuator type Exemplary presentation Automation unit label: Automation unit type Exemplary presentation - 10 -...

-

Page 11: Operating Instructions Actuator; Automation Unit

System description Operating instructions actuator; automation unit Operating instructions of respective device types can be found on our homepage www.buerkert.com. Please refer to the dimensional drawing for the actuator types or automation units that belong to your system or read the type information directly on the label of the installed actuator or automation unit (see chapter 5.2.1). -

Page 12: Automation Unit For Pneumatic Actuators

System description Type 2973 Type AM297x Type 3323 Type AE33S Type 3363 Type AE33R 5.3.2 Automation unit for pneumatic actuators type presentation QR-Code Type 8690 Type 8691 Type 8692 - 12 -... -

Page 13: Functions

System description Type 8693 Type 8694 Type 8695 Type 8696 Type 8697 Functions The multiway valve is designed for the distribution, collection, blocking and releasing of product and cleaning media. - 13 -... -

Page 14: Technical Data

Technical data Technical data Operating conditions Protect this device from UV radiation and from the effects of weather if used outside. WARNING! If laminated EPDM/adv. PTFE diaphragms are used, the max. media temperature is +90°C. These diaphragms have not been approved for steam. Permitted operating conditions: •... - Page 15 Technical data Actuators (see system dimensional drawing, actuator type label) Type 2103 / AP09 PPS (polyphenylene sulphide) + VA (stainless steel) Type 2031 / AP2030 PPS (polyphenylene sulphide) or PA (polyamide) Type 2063 / AP2063 VA (stainless steel) Attachment + handwheel PPS (polyphenylene sulphide) Type 3233 / AM3232 Attachment VA + handwheel PPS (polyphenylene sulphide) Attachment + handwheel PPS (polyphenylene sulphide)

-

Page 16: Pneumatic Data

Technical data 6.2.2 Pneumatic data Information on the control medium: • See type labels on the multiway valve and on the components used. • For further specifications see operating instructions of the types and components used (compare section 5.3). • For information on the pilot air ports see operating instructions of the types and components used (compare section 5.3) 6.2.3 Electrical data... -

Page 17: Assembly And Installation

Assembly and installation Assembly and installation Safety instructions DANGER! Risk of injury from high pressure in the system! Before loosening lines and valves, turn off the pressure and vent the lines! Risk of injury due to electric shock! Before reaching into the device or the system, switch off the power supply and secure it against reactivation! Observe applicable accident prevention and safety regulations for electrical equipment! WARNING! -

Page 18: Pneumatic Installation

Assembly and installation Pneumatic installation DANGER! Risk of injury from high pressure in the system! Before loosening lines and valves, turn off the pressure and vent the lines! Electrical installation DANGER! Risk of injury due to electric shock! Before reaching into the device or the system, switch off the power supply and secure it against reactivation! Observe applicable accident prevention and safety regulations for electrical equipment! - 18 -... -

Page 19: Assembling And Installing The Multiway Valve

Assembly and installation Assembling and installing the multiway valve 7.4.1 Housing with welded connections Procedure: For information on installing/removing the actuators from the housing, see operating instructions of the types and components used (compare section 5.3). → Identify installation position of the actuators and other components mounted directly on the housing and on the components. -

Page 20: Start-Up

Start-up Start-up Safety instructions WARNING! Risk of injury due to improper operation! Improper operation may result in injuries as well as damage to the device and its environment! Before start-up, ensure that the operating personnel are aware of and have completely understood the contents of the operating instructions. -

Page 21: Maintenance And Troubleshooting

Maintenance and troubleshooting Maintenance and troubleshooting Safety instructions DANGER! Risk of injury from high pressure in the system! Before loosening lines and valves, turn off the pressure and vent the lines! Risk of injury due to electric shock! Before reaching into the device or the system, switch off the power supply and secure it against reactivation! Observe applicable accident prevention and safety regulations for electrical equipment! WARNING! -

Page 22: Malfunctions

Spare parts Malfunctions For information on malfunctions see operating instructions of the types and components used (compare section 5.3). Recommended auxiliary materials for operation, maintenance and repair: For information on recommended auxiliary materials see operating instructions of the types and components used (compare section 5.3) Spare parts WARNING! Risk of injury when opening the actuator housings! -

Page 23: Shutdown

Shutdown Shutdown Safety instructions DANGER! Risk of injury from high pressure in the system! Before loosening lines and valves, turn off the pressure and vent the lines! Risk of injury due to electric shock! Before reaching into the device or the system, switch off the power supply and secure it against reactivation! Observe applicable accident prevention and safety regulations for electrical equipment! WARNING! -

Page 24: Packaging And Transport

Packaging and transport Packaging and transport NOTE! Transport damage! Inadequately protected devices may be damaged during transportation. - Protect the device from moisture and dirt in shock-resistant packaging during transportation. - Avoid exceeding or dropping below the permitted storage temperature. - Protect the electrical interfaces of the coil and the pneumatic connections from damage by placing protective caps on them.

Need help?

Do you have a question about the 2034-T and is the answer not in the manual?

Questions and answers