Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE

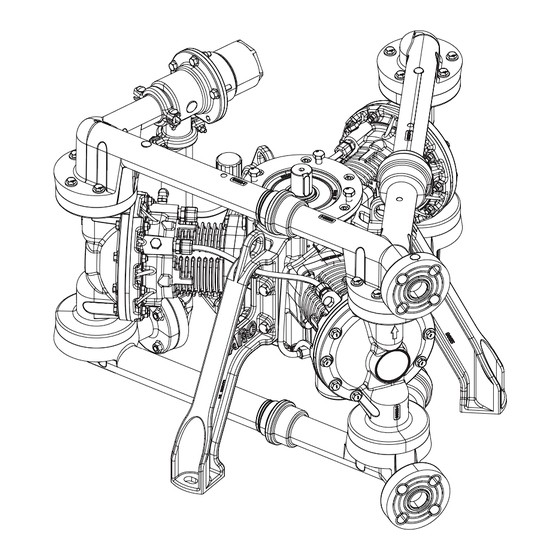

1" EVO SERIES DIAPHRAGM PUMP

INGERSOLL RAND COMPANY INC

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276

FAX (800) 892-6276

arozone.com

RELEASED 06/Feb/2024 12:24:58 GMT

(NON METALLIC FLUID SECTIONS)

© 2024

EB10-PXXXX-XXX-XXX

RELEASED:

2-1-24

(REV: A)

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Ingersoll-Rand ARO EVO EB10-P Series

- Page 1 RELEASED 06/Feb/2024 12:24:58 GMT OPERATOR’S MANUAL EB10-PXXXX-XXX-XXX RELEASED: 2-1-24 INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE (REV: A) 1” EVO SERIES DIAPHRAGM PUMP (NON METALLIC FLUID SECTIONS) INGERSOLL RAND COMPANY INC 209 NORTH MAIN STREET – BRYAN, OHIO 43506 (800) 495-0276 FAX (800) 892-6276 ©...

-

Page 2: Table Of Contents

RELEASED 06/Feb/2024 12:24:58 GMT TABLE OF CONTENTS 1. TECHNICAL SPECIFICATIONS ....3 8. MAINTENANCE ....... . 11 1.1. -

Page 3: Technical Specifications

RELEASED 06/Feb/2024 12:24:58 GMT 1. TECHNICAL SPECIFICATIONS 1.1. Pump Data Models ..See Model Description Chart for “-XXXXX”. Maximum Temperature Limits Pump Type . . Mechanically Driven Diaphragm Pump Material ..See Model Description Chart ... -

Page 4: Nameplate Details

Viton® is a registered trademarks of the Chemours Company Loctite® is a registered trademark of Henkel Corporation Santoprene® is a registered trademark of Celanese ARO® is a registered trademark of Ingersoll-Rand Company Page 4 of 32... -

Page 5: Model Description Chart

RELEASED 06/Feb/2024 12:24:58 GMT 2. MODEL DESCRIPTION CHART 2.1. Model Code Explanation Wetted Parts Polypropylene Port F - ANSI / DIN Hybrid Flange with integrated PRV G - ANSI / DIN Hybrid Flange without integrated PRV Seat H - 440 SST P - Polypropylene S - 316 SST Ball... -

Page 6: Model Code Details

RELEASED 06/Feb/2024 12:24:58 GMT 2.2. Model Code Details The EVO EB10-PXXXX-XXX-XXX model series is a pump only configuration that requires a customer-supplied power source, such as an electric motor, hydraulic motor, or gas powered engine. In most cases, a speed reducer will also be required which is not included. -

Page 7: Operating And Safety Precautions

RELEASED 06/Feb/2024 12:24:58 GMT 3. OPERATING AND SAFETY PRECAUTIONS READ, UNDERSTAND, AND FOLLOW THIS INFORMATION TO AVOID INJURY AND PROPERTY DAMAGE. HAZARDOUS MATERIALS. Can cause se- WARNING EXCESSIVE FLUID PRESSURE HAZARDOUS MATERIALS rious injury or property damage. Do not attempt to STATIC SPARK HAZARDOUS PRESSURE return a pump to the factory or service center that... -

Page 8: General Description

RELEASED 06/Feb/2024 12:24:58 GMT Prevent unnecessary damage to the = Hazards or unsafe practices which could CAUTION WARNING pump. Do not allow pump to operate when out of ma- result in severe personal injury, death or terial for long periods of time. substantial property damage. -

Page 9: Mechanical Installation

RELEASED 06/Feb/2024 12:24:58 GMT 5. MECHANICAL INSTALLATION 5.1. Pump Installation WARNING Pumps are industrial products. They must therefore be installed by qualified, experienced and authorized personnel. The safety of people, animals and property must be ensured when installing the pump. Once Pump has been fully unpackaged and inspected, use lifting points on Crankcase to move into final operating posi- tion (See Figure. -

Page 10: Grounding

RELEASED 06/Feb/2024 12:24:58 GMT 6. GROUNDING Before operating the pump, ground the system as explained below. All pumps have a ground screw installed in Crankcase housing. Connect one end of the grounding wire to ground screw and other end of the grounding wire to suitable earth ground. The cross section of grounding wire must be at least 4 mm ... -

Page 11: Maintenance

RELEASED 06/Feb/2024 12:24:58 GMT 8. MAINTENANCE Refer to the part views and descriptions as provided on page 12 through 23 for parts identification and Service Kit information. Service kits are divided to service four separate section: 1. Before disassembling ... -

Page 12: Subsystem Overview

RELEASED 06/Feb/2024 12:24:58 GMT 9. SUBSYSTEM OVERVIEW PARTS LIST / FLUID SECTION EB10-XXXXX-XXX-XXXX Fluid Section Service Kits: -XX Fluid Section Service Kits include: Balls (see BALL Option, refer to -XX in chart below), Diaphragms (see DIAPHRAGM Option, re- fer to -XX in chart below), and items 12 and 13 (listed below). EXTERNAL HARDWARE OPTIONS COMMON PARTS EB10-XXXXX-XXX-XXX... - Page 13 RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / FLUID SECTION EB10-XXXXX-XXX-XXX COLOR CODE )ASSEMBLY TORQUE REQUIREMENTS( NOTE: DO NOT OVERTIGHTEN FASTENERS. Material Diaphragm Ball Color Color (6) Diaphragm washer, 50 - 55 ft lbs (67.8 - 74.6 Nm). Santoprene® (26) Screws, 8 - 11 ft lbs (10.8 - 14.9 Nm). Santoprene®...

- Page 14 RELEASED 06/Feb/2024 12:24:58 GMT FLUID SECTION DISASSEMBLY FLUID SECTION REASSEMBLY Remove inlet Manifolds (60) and outlet Manifolds (61) to- Reassemble parts in reverse order from the sequence in gether. which they were removed. Refer to the torque require- Remove (22) balls, (19) “O”...

- Page 15 RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / PRV EB10-XFXXX-XXX-XXX PRV O-RING OPTIONS EB10-XFXXX-XXX-XXX Santoprene Diaphragm PTFE Diaphragm Item Description Qty Part No. [Mtl] Part No. [Mtl] Part List 41 O-Ring Y323-123 [EP] Y324-123 Page 17 (3/32" x 1-3/8" OD) - Primary ...

-

Page 16: Prv Section

RELEASED 06/Feb/2024 12:24:58 GMT PRV SECTION DISASSEMBLY PRV SECTION REASSEMBLY Disconnect 3/8” OD tube (196) between PRV cylinder (46) Reassemble parts in reverse order from the sequence in and air cap (147). which they were are removed. Loosen clam shell (37) between PRV return Manifold (66) Clean and inspect all parts. - Page 17 RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / PRV EB10-XFXXX-XXX-XXX See Detail A )ASSEMBLY TORQUE REQUIREMENTS( NOTE: DO NOT OVERTIGHTEN FASTENERS. (53) Nut, tighten to 7 - 10 ft lbs (10 - 14 Nm). (55) Bolt, tighten to 20 - 25 ft lbs (27 - 34 Nm). DETAIL A Figure 5 EB10-PXXXX-XXX-XXX (en)

- Page 18 RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / NO PRV EB10-XGXXX-XXX-XXX NO PRV O-RING OPTIONS EB10-XGXXX-XXX-XXX Santoprene Diaphragm PTFE Diaphragm Item Description Qty Part No. [Mtl] Part No. [Mtl] 41 O-Ring Y323-123 [EP] Y324-123 (3/32" x 1-3/8" OD) - Primary 59 O-Ring Y323-123 [EP] Y327-123...

-

Page 19: Crankcase Section

RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / CRANKCASE EB10-XXXXX-XXX-XXX Pump Crankcase Replacement Assembly EP10-CXVX-01-A : Includes all Items shown in the Crankcase parts list (below) except for item 74 and 197. Includes all items shown in the oil pump parts list (page 22). Includes items 13, 16 and 17 shown on page 12. Note: Crankcase components are designed for the intended life of the pump. - Page 20 RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / CRANKCASE EB10-XXXXX-XXX-XXX Grease inner diameter of seal only )ASSEMBLY TORQUE REQUIREMENTS( NOTE: DO NOT OVERTIGHTEN FASTENERS. (104) Screw, tighten to 10 - 15 ft lbs (14 - 20 Nm). (106) Screw, tighten to 20 - 25 ft lbs (27 - 33.9 Nm). (115) Screws, 8 - 12 ft lbs (10.8 - 16.3 Nm).

- Page 21 RELEASED 06/Feb/2024 12:24:58 GMT Remove internal snap ring (136) and the wrist pin (135). Lower Crankshaft assembly vertically inside Crankcase Remove the piston rod (134) and rider band (133). housing (101) and allow inner race of lower bearing to ...

-

Page 22: Oil Piston Pump Section

RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / OIL PISTON PUMP ASSEMBLY SECTION EB10-XXXXX-XXX-XXX Item Description Qty Part No. [Mtl] Item Description Qty Part No. [Mtl] 128 Plug Y17-52-S [SS] 164 Plug Y17-50-S [SS] (3/8” - 18 NPT) (1/8” -18 NPT ) (not shown) 129 Fitting 98059 (9/16”-18 STOR x 3/8”, 90°) - Page 23 RELEASED 06/Feb/2024 12:24:58 GMT PARTS LIST / OIL FILTER EB10-XXXXX-XXX-XXX )ASSEMBLY TORQUE REQUIREMENTS( NOTE: DO NOT OVERTIGHTEN FASTENERS. (129, 176) Straight Thread O-Ring, tighten to 20-25 ft lbs (27-33.9 Nm) (150) Screws, tighten to 6 - 8 ft lbs (8 - 11 Nm) (174, 175) Screws, tighten to 40 - 45 in lbs (4.5 - 5.1 Nm) (158) Plug, tighten to 45-50 ft lbs (61-67.8 Nm) )129...

-

Page 24: Troubleshooting

RELEASED 06/Feb/2024 12:24:58 GMT 10. TROUBLESHOOTING Issue Possible Cause Action Insufficient Torque. Increase torque to crankshaft. Pump will not operate Crankshaft bearing failure. Replace pump Crankcase. Excessive wear of wrist pin and /or journal. Replace wrist pin and journal. Excessive wear of piston rider band and/or wear ring. Replace rider band and/or journal. -

Page 25: Dimensional Data

RELEASED 06/Feb/2024 12:24:58 GMT 11. DIMENSIONAL DATA 11.1 Pump (with or without PRV) (Dimensions shown are for reference only, they are displayed in inches and millimeters (mm)). Ø 24.88” B.C (632 mm) Ø 0.63” (16 mm) 3 PLCS Ø 0.94” (24 mm) 3 PLCS 23.61”... -

Page 26: Pump Interface Details

RELEASED 06/Feb/2024 12:24:58 GMT 11.2. Pump interface details KEYED SHAFT Ø 165 B.C. RECOMMENDED INTERFACE FLANGE TYPE Ø 200 MM B5 FLANGE PER IEC 60072-1:2022 M10-1.5 x 15 MM FULL THREAD 4 PLCS EQUALLY SPACED (M10-1.5 X 25 MM HEX HEAD BOLTS INCLUDED) SHAFT KEY (INCLUDED) 8 X 10 MM, 40 MM long Ø... -

Page 27: Performance Curve

RELEASED 06/Feb/2024 12:24:58 GMT 12. PERFORMANCE CURVE EB10-PXXXX-XXX-XXA 1" EVO DIAPHRAGM PUMP (NON METALLIC FLUID SECTION) Performance based on water at ambient temperature. FLOW RATE IN U.S. GALLONS PER MINUTE Performance based on water at ambient temperature. FLOW RATE IN LITERS PER MINUTE NOTE: When selecting a shaft coupling, it is recommended to multiply the average torque (the published value in the per- formance curves above) at the desired operating condition by a factor of 1.5 to account for peak torque oscillations above the average value. - Page 28 RELEASED 06/Feb/2024 12:24:58 GMT EB10-PXXXX-XXX-XXA 1" EVO DIAPHRAGM PUMP (NON METALLIC FLUID SECTION) Performance based on water at ambient temperature. FLOW RATE IN U.S. GALLONS PER MINUTE Performance based on water at ambient temperature. FLOW RATE IN LITERS PER MINUTE Page 28 of 32 EB10-PXXXX-XXX-XXX (en)

-

Page 29: Certification

RELEASED 06/Feb/2024 12:24:58 GMT 13. CERTIFICATION 13.1 Certification Standards and Markings Description Directive Applicable Standards Marking EN ISO 12100:2010 Machinery Directive 2006/42/EC EN 809:1998 + A1:2009) RoHS Directive 2011/65/EU EN IEC 63000:2018 REACH Directive 1907/2006/EC See 97999-2052 (S-1656, Declaration of Conformity) EB10-PXXXX-XXX-XXX (en) Page 29 of 32... -

Page 30: Warranty Declaration

Internet sites and unauthorized storefronts on online marketplaces. Ingersoll-Rand/ARO® will provide a new part or repaired part, at its election, in place of any part which is found upon its inspec- tion to be defective in material and workmanship during the period described above. Such part will be repaired or replaced without charge to the initial end customer during normal working hours at the place of business of a Reseller authorized to sell the type of Product involved or other establishment authorized by Company. - Page 31 RELEASED 06/Feb/2024 12:24:58 GMT EB10-PXXXX-XXX-XXX (en) Page 31 of 32...

- Page 32 RELEASED 06/Feb/2024 12:24:58 GMT About Ingersoll Rand Ingersoll Rand Inc. (NYSE:IR), driven by an entrepreneurial spirit and ownership mindset, is dedicated to helping make life better for our employees, customers and communities. Customers lean on us for our technology-driven excellence in mission-critical flow creation and industrial solutions across 40+ respected brands where our products and services excel in the most complex and harsh conditions. Our employees develop customers for life through their daily commitment to expertise, productivity and efficiency.

Need help?

Do you have a question about the ARO EVO EB10-P Series and is the answer not in the manual?

Questions and answers