AMF S-4000 ISBH+I SM Parts And Service Manual

Electronic buttonhole machine

Hide thumbs

Also See for S-4000 ISBH+I SM:

- Parts and service manual (152 pages) ,

- Parts and service manual (76 pages) ,

- Parts and service manual (122 pages)

Subscribe to Our Youtube Channel

Summary of Contents for AMF S-4000 ISBH+I SM

- Page 1 S-4000 ISBH+I SM MODEL ELECTRONIC BUTTONHOLE MACHINE PARTS AND SERVICE MANUAL MACHINE SERIAL No: 97.2486.3.001 PART NUMBER 09 / 2015...

- Page 3 However, the satisfaction and goodwill of our customers are of pri- mary concern to AMF Reece, Inc. In the event that a warranty matter is not handled to your satisfaction, please contact AMF Reece office: AMF Reece - Cars s.r.o.

-

Page 5: Table Of Contents

S-4000 ISBH+I SM TABLE OF CONTENTS A - INTRODUCTION 1. Basic information............................1-1 2. Safety device and labels ..........................1-2 3. General machine parts descriptions......................1-3 4. Technical conditions.............................1-4 5. Instructions for operator safety and maintenance..................1-5 6. Special accessories............................1-7 B - MACHINE ASSEMBLY 1. - Page 6 S-4000 ISBH+I SM TABLE OF CONTENTS 2. Sewing head and indexer connection......................1-51 3. Indexer functions............................1-52 4. Adjustment of the indexer clamping feed movement...................1-53 5. The indexer clamping feed pressure adjustment..................1-54 6. Thread pick-up adjustment..........................1-55 F - INDEXER - ANGLE 20°...

-

Page 7: A - Introduction

NOTICE! Breaking procedures may cause functional problems of the machine. We recommend that servicemen from AMF Reece supervise the installation of the machines and initial training of your mechanics and operators. The most effective method ensuring safety of operators working on the machine is a strict safety program including instructions for safety operation. -

Page 8: Safety Device And Labels

S-4000 ISBH+I SM A - INTRODUCTION 2. SAFETY DEVICE AND LABELS AMF REECE S 4000 YEAR OF PRODUCTION VOLTAGE POWER OUTPUT CURRENT AMF REECE, a.s. CZECH REPUBLIC Warning Air pressure adjustment knob Covers removed, possible injury Manometer with pressure sensor... -

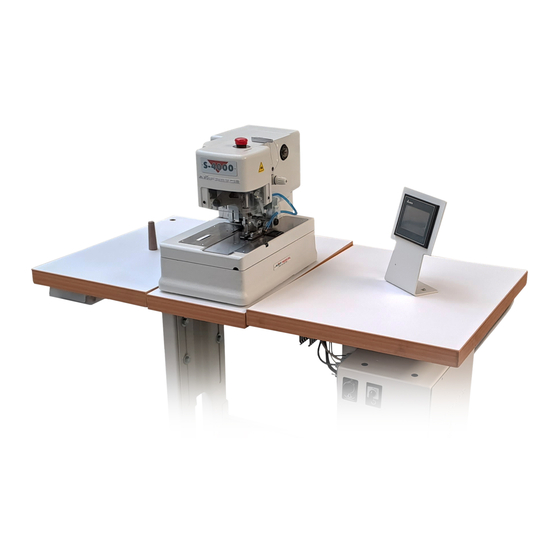

Page 9: General Machine Parts Descriptions

S-4000 ISBH+I SM A - INTRODUCTION 3. GENERAL MACHINE PARTS DESCRIPTIONS N IN IS C IE S IC IN Eye guard Control panel Table Table top Foot pedal Main Switch Halogen lamp Button Control box Emergency Stop Button Indexer Machine head... -

Page 10: Technical Conditions

S-4000 ISBH+I SM A - INTRODUCTION 4. TECHNICAL CONDITIONS Machine type S 4000 ISBH+I Electronic controller chains stitch straight buttonhole machine for sewing imitation buttonholes on cuff Wiggins. With the automatic indexer, preset Description programs automatically control the sewing of multiple buttonholes either... -

Page 11: Instructions For Operator Safety And Maintenance

S-4000 ISBH+I SM A - INTRODUCTION 5. INSTRUCTIONS FOR OPERATOR SAFETY AND MAINTENANCE When installing the machine we recommend the minimum clearances noted above around the machine. Read all of the instructions that follow. DO NOT PUT THE MACHINE INTO OPERATION UNTIL YOU ARE COMPLETELY FAMILIAR WITH ALL INSTALLATION AND OPERATING INSTRUCTIONS. - Page 12 S-4000 ISBH+I SM A - INTRODUCTION CAUTION: LASER RADIATION DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS Read carefully the supplemental rules described below before setting up laser system. C.C. E.A. laser product has been designed and manufactured specifically for the work place and for use in working, conditions.

-

Page 13: Special Accessories

S-4000 ISBH+I SM A - INTRODUCTION 6. SPECIAL ACCESSORIES - machine device, which is not included in the standard equipment of the machine and a customer can order it Sewing cam • it is possible to sew a different buttonhole shape... -

Page 14: B - Machine Assembly

S-4000 ISBH+I SM B - MACHINE ASSEMBLY 1. CONTENT OF THE SHIPPING BOX 1. The shipment contains one box. 2. There is a carton with accessories, service manual with parts section and thread stand in the box. 3. During unpacking the shipment, follow the labels which are on a cover. -

Page 15: Power And Air Connection

S-4000 ISBH+I SM B - MACHINE ASSEMBLY 3. POWER AND AIR CONNECTION 1. The machine is equipped with a quick coupler required with connector for inner Ø of the tube 10. The connector for inner Ø of the tube 8 is not supplied with the machine, customer has to order it. - Page 16 S-4000 ISBH+I SM B - MACHINE ASSEMBLY 4. Head Pneumatic - thread draw-off, tension release - speed controller J0I1 - J0I2 - air input - clamp feet 1 - thread BQ2 - regulator with air pressure switch air distribution Tubes 0, 1, 2 —...

- Page 17 S-4000 ISBH+I SM B - MACHINE ASSEMBLY 5. Indexer Pneumatic J12A J12B - clamp feet - thread pick-up (Extra part) - angle indexer clamp-feet swiveling 1-11 Released: 01/2024 E-mail: info@amfreece-cars.cz...

-

Page 18: Thread Stand Installation

S-4000 ISBH+I SM B - MACHINE ASSEMBLY 4. THREAD STAND INSTALLATION 1. Put the thread stand together a c c o r d i n g to the drawing. 2. Position of the locking ring a l l o w s assembly of the thread stand for various thickness of the table top. -

Page 19: C - Proper Application

S-4000 ISBH+I SM C - PROPER APPLICATION 1. POWER UP / HOME POSITION 1.1. Turn the main power switch on by turning clockwise to the I position. 1.2. The machine is ready for operation when the control panel display lights, the Ready message appears on the display. -

Page 20: Needle Installation

S-4000 ISBH+I SM C - PROPER APPLICATION 2. NEEDLE INSTALLATION WARNING! Before performing this adjustment, switch the main machine power off to prevent accidental starting of the machine. Disconnect the air supply and dissipate any stored energy. Use needles ordering number 02.0750.2.110 (750SC 90/14) only - see accessories. -

Page 21: Threading

S-4000 ISBH+I SM C - PROPER APPLICATION 3. THREADING WARNING! Switch the main machine power off to prevent accidental starting of the machine. Disconnect the air supply and dissipate any stored energy. When threading, see the pictures below. Change the thread tension by nut according to the sewing conditions. -

Page 22: D - Machine Controls

S-4000 ISBH+I SM D - MACHINE CONTROLS 1. HOW TO SEW A BUTTONHOLE 1.1. Bring the machine to the home position according to the section C1. a) sewing without indexer Check, if the message appears on the display. If not, follow steps below:... - Page 23 S-4000 ISBH+I SM D - MACHINE CONTROLS 1.4. When the foot pedal is pressed to its second position, the sewing is started with or without indexer, it depends on set program - see 1a, b. When the buttonhole is sewn and the thread is trimmed, the machine goes to the home position and clamp feet raise.

- Page 24 S-4000 ISBH+I SM D - MACHINE CONTROLS b) sewing with indexer If it is necessary to interrupt the cycle during the sewing with indexer (example: needle breakage, thread breakage ): b1) press the Cycle Interruption button on the indexer. The machine stops in the home position after buttonhole is finished.

-

Page 25: Operator Control Panel Push Buttons And Switches

S-4000 ISBH+I SM D - MACHINE CONTROLS 2. OPERATOR CONTROL PANEL PUSH BUTTONS AND SWITCHES Emergency Stop Button Indexer cycle Interrupt Button Switching of automatic mode (Moving the indexer clamp feet left-right; right-left) Daily cycle counter. (Entry in tests, Determine the direction of the buttonhole reset counter, program version) movement at the set program. - Page 26 S-4000 ISBH+I SM D - MACHINE CONTROLS Error message Motor not ready Low air pressure Home position time out Error setting It will be displayed if the value of the parameter is adjusted out of range. Press the display any where, you will return to the main screen.

- Page 27 S-4000 ISBH+I SM D - MACHINE CONTROLS 3. THE SEWING HEAD PROGRAMMING MENU Enter the sewing head program menu by pressing button Maximal speed. (Range 1000 - 3840 ppm) Correction of the needle bar upper position. (Range 0 - 600 imp) Setting the machine cycling.

-

Page 28: The Programming Menu Indexer

S-4000 ISBH+I SM D - MACHINE CONTROLS 4. THE INDEXER PROGRAMMING MENU Activation of the thread Activation of the thread catcher in the beginning catcher at the end Automatic mode of sewing. of automatic sewing cycle. (Moving the indexer clamp feet left - right; right - left) - Page 29 S-4000 ISBH+I SM D - MACHINE CONTROLS 5. THE INDEXER PROGRAMMING – entering space and button holes 5.1. Standard mode This mode is activated by this icon at indexer programming menu. Count of button hole and distance between button holes setting.

- Page 30 S-4000 ISBH+I SM D - MACHINE CONTROLS 5.2. Special mode This mode is activated by this icon at indexer programming menu. Count of button hole and distance between button holes setting. Note1: Distance between button hole are equal. Note2: Count of button hole and distance between button holes are possible to change directly from main screen.

-

Page 31: Tests

S-4000 ISBH+I SM D - MACHINE CONTROLS 6. TESTS Warning! Tests can be performed only by skilled service technicians. The end position sensor BQ1. Activate the sensor using a metal tool - icon starts lighting. If the air pressure is less than 0,5 MPa the button is underlighted. -

Page 32: Program Version

S-4000 ISBH+I SM D - MACHINE CONTROLS 7. PROGRAM VERSION 8. COUNTER RESET Daily cycle counter Servis cycle counter (not resettable) Daily cycle counter reset 9. BUTTONHOLES PARAMETERS SETTING Number of buttonholes Machine stops before buttonhole sewing activation (e. g.: when changing thread... -

Page 33: Factory Setting

S-4000 ISBH+I SM D - MACHINE CONTROLS 10. FACTORY SETTING - all the parameters are set according to table 1. Pass word 5632 Table 1 PARAMETER RANGE PARAMETER RANGE SETTING SETTING Indexer Indexer On Indexer Off Indexer On 2 poloha... -

Page 34: Dead Battery

S-4000 ISBH+I SM D - MACHINE CONTROLS 11. DEAD BATTERY If the PLC or display battery is dead, a flashing icon appears on the main screen. By pressing the icon, one can find out which battery needs to be replaced. -

Page 35: E - Machine Adjustments

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 1. MACHINE HOME POSITION 1. The needle bar is in the upper position. The needle descends to the right side of the throat plate slot during the first stitch. The marks on the handwheel and cover casting are aligned. -

Page 36: The Principles For The Machine Adjustment

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 3. THE PRINCIPLES FOR THE MACHINE ADJUSTMENT 1. Before making mechanical adjustment turn the machine to the service mode by pressing Emergency stop the button Emergency Stop release Ready - F1 Service - F6... -

Page 37: Needle Bar

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 4. NEEDLE BAR 1. Needle bar crank position Turn the handwheel and loosen the screw in the needle bar crank . Turn the handwheel until the needle bar reaches the upper position. Pulley screw... -

Page 38: Bite

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 5. BITE Before the bite adjustment, remove the pulley cover and the head cover . Loosen the indexer clamp feet screw and remove the indexer clamp feet Í from the machine. Disconnect the air tubes... - Page 39 S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 2. Bite width adjustment To adjust the bite width, first remove the head cover for access to adjustments. The S-4000 ISBH is fitted with a regular bite throat plate that allows a bite range of 1.5 mm (1/16“) to 2.3 mm (3-32“).

-

Page 40: Feeding

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 6. FEEDING 1. Tilt the sewing head on the rest pin. 2. Bevel Gear Adjustment Manually turn the hand wheel counter clockwise, until the drive spring in the main cam engages with a detent (first row of stitches). -

Page 41: Slip Clutch

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 7. SLIP CLUTCH The slip clutch pressure is factory set and under normal conditions will not need adjusting. The correct clutch torque setting is 0.43 Nm (60 to 65 inch ounces). Hold the nut and tighten the adjusting screws with a torque screwdriver. -

Page 42: Adjustment Of Barring Stitches

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 9. ADJUSTMENT OF BARRING STITCHES To properly set the first bar , the second bar must be properly adjusted. 1. Second bar adjustment Insert a piece of paper under the clamp feet. Turn the handwheel... - Page 43 S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 2. First bar adjustments Turn the handwheel until the control spring engages into a detent. Check the distance 1-2 mm between the control spring and the shifter arm. If the distance is different, move the shifter arm after which is locked by two M4 screws Check the quality of the sewn buttonhole on the paper.

-

Page 44: Space Between The First And Second Row Of Stitches

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 3. The clearance adjustment on the cam during the first bar sewing a) Turn the handwheel until the control engages into the detent of the left shifter arm b) Continue turning the handwheel. The main cam assembly... -

Page 45: Buttonhole Length Change

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 11. BUTTONHOLE LENGTH CHANGE To change the sewn buttonhole length, remove knob and the indexer clamp feet also 7 screws and the cover plate 1. Loosen the screw and move the stop as needed. To the right - the buttonhole is shortened, to the left - the buttonhole is extended. -

Page 46: Looper Adjustment

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 12. LOOPER ADJUSTMENT Before making this adjustment, follow the below described points: • Turn the handwheel and observe the position of the connecting link at both ends of the looper link arm travel . - Page 47 S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS The first looper adjustment 1. Bring the machine to the home position and loosen the screws of the looper cam and adjust the looper cam to the lowest position. 2. Loosen the looper set screw...

- Page 48 S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS The second looper adjustment 10. Insert the second looper on the looper shaft. 11. Loosen the looper holder screw and move the holder so that the needle passes the center of the looper recess.

-

Page 49: Thread Draw-Off

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 13. THREAD DRAW-OFF 1. Adjustment of the Draw-Off Lever Position The correct adjustment ensures a long enough thread tail for starting the sewing of the next buttonhole.Remove the covers because this mechanism adjustment is performed in the rear of the head. Air supply is necessary for this adjustment. -

Page 50: Thread Tension

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 14. THREAD TENSION The thread tension influences the appearance of the buttonhole. A thread tension change may be needed if the thread and fabric change. Check to be certain all parts, which contact the thread, are smooth and polished with no burrs or sharp edges. - Page 51 S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 2. The correct position of the tension mechanism a) remove the tension assembly from the shaft b) check if the distance between the stud slot edge and the pin is 3.5 mm If incorrect, it is necessary to adjust the position on the pin.

-

Page 52: Thread Trimming

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 15. THREAD TRIMMING Trimming mechanism ensures the correct thread trimming after sewing the last stitch. A the trimming hook moves in the direction of arrow, both thread loop legs A and B are pulled forward. When the thread hook approaches the end of the stroke, leg A contact the trimming knife, cutting the thread. -

Page 53: Machine Head Clamping Feed Adjustment

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 16. MACHINE HEAD CLAMPING FEED ADJUSTMENT 1. Adjustment for clamp height Be sure that air supply is switch on and the clamping feed are opened. If clamping feed are not opened, push the clamp Up / Down button. -

Page 54: Adjustment Of The Stopping Sensor Position

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 17. ADJUSTMENT OF THE STOPPING SENSOR POSITION Follow the below described steps to set the position of the sensor. 1. Put machine in the service mode (see E-3). 2. Turn the handwheel counter clockwise until the machine is in the position for sewing the second bar. The stop... -

Page 55: Changing The Drive Belt

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 18. CHANGING THE DRIVE BELT 1. Remove the pulley cover after loosing the M4 screws 2. By turning the handwheel adjust the position of the shaft so that the screw on the pulley is level with screw on the bearing carrier lower shaft. -

Page 56: The Main Cam Change

S-4000 ISBH+I SM E - MACHINE ADJUSTMENTS 19. THE MAIN CAM CHANGE 1. Loosen the screws and remove the holder 2. Unscrew the screws and remove the right control spring and the holder 3. Loosen the stud and remove the worm gea h u b and the main cam assembly . -

Page 57: F - Indexer - Straight

S-4000 ISBH+I SM S-4000 ISBH+I SM F - INDEXER - STRAIGHT 1. INTRODUCTION The indexer is used to clamp and feed sleeves wiggans while sewing Imitation Buttonholes. Programs can be set for any number of buttonholes up to 8 within a 63 maximum travel and the space between each is also adjustable. -

Page 58: Indexer Functions

S-4000 ISBH+I SM S-4000 ISBH+I SM F - INDEXER - STRAIGHT 4. The electrical signal for indexer electromagnetical valves (10, 11) is ensured by the connecting cable with cannon conector (X4), which is connected to the rear of the control box. -

Page 59: Adjustment Of The Indexer Clamping Feed Movement

S-4000 ISBH+I SM S-4000 ISBH+I SM F - INDEXER - STRAIGHT 4. ADJUSTMENT OF THE INDEXER CLAMPING FEED MOVEMENT 1. By pressing the key on the display, check that the distance X between the indexer clamping feed and the sewing head clamping feed is the same on both left and right side. -

Page 60: The Indexer Clamping Feed Pressure Adjustment

S-4000 ISBH+I SM S-4000 ISBH+I SM F - INDEXER - STRAIGHT 5. THE INDEXER CLAMPING FEED PRESSURE ADJUSTMENT 1. First place the material under the left clamping feed. 2. Press the button on display. Pull the clamped material and check if the material is held well. -

Page 61: Thread Pick-Up Adjustment

S-4000 ISBH+I SM S-4000 ISBH+I SM F - INDEXER - STRAIGHT 6. THREAD PICK-UP ADJUSTMENT If the thread is not caught and held after trimming it is necessary to adjust the thread pick-up. 1. The machine must be in the home position. -

Page 62: F - Indexer - Angle 20

S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 1. INTRODUCTION Indexer – Angle 20° is an additional device that allows automatic sewing of decorative holes with programming a number of holes and their distance. This type also allows angle positioning of decorative holes. As external parts of... -

Page 63: Indexer Functions

S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 3. INDEXER FUNCTIONS The indexer enables sewing of holes both with cross move of the clamping feet and angle move. a) Sewing with move straight is ensured by the sliding nut... - Page 64 S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 4. ADJUSTMENT OF THE CLAMPING FEET SHOULDER SIDE MOVE a) Setting of the basic position Do the setting while the air supply is disconnected and the clamping feet are in a position for cross move of the material –...

-

Page 65: Adjustment Of The Move Of The Clamping Feet Shoulder

S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 5. ADJUSTMENT OF THE MOVE OF THE CLAMPING FEET SHOULDER The clamping feet of the indexer must be shifted into the position for angle move of the material. The angle must be 20°. If this is not the situation, take off the cover and discon- nect the air supply. - Page 66 S-4000 ISBH+I SM F - INDEXER - ANGLE 20° Tighten screws Press the button . on the display of the main screen. Thus the indexer is set into the basic position. Check the distance X1, X2 by pressing buttons If needed, repeat the whole procedure several times.

-

Page 67: Setting Of The Indexer Clamping Feet Down Force

S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 6. SETTING OF THE INDEXER CLAMPING FEET DOWN FORCE 1. First put the material under the left fixing clamp. 2. Press the clamps button on the display. Pull the fixed material and find out if the material is well-held. -

Page 68: Setting The Distance Between The Hole And The Edge Of The Material

S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 7. SETTING THE DISTANCE BETWEEN THE HOLE AND THE EDGE OF THE MATERIAL This machine allows for mechanical adjustment of the indexer clamps - this is the distance between the decorative hole and the edge of material. - Page 69 S-4000 ISBH+I SM F - INDEXER - ANGLE 20° 8. CHANGE OF THE POSITION OF INDEXER CLAMPS Turning element of the indexer clamps is positioned on the mechanism of the clamping feet of the sewing head. To change its position it is necessary to demount the clamps.

-

Page 70: G - Machine Maintenance

S-4000 ISBH+I SM G - MACHINE MAINTENANCE Warning: • Check for damage to electrical cables • Check safety covers for damage and replace if needed immediately • Keep your hands out of the sewing area • Do not modify the machine in any way, which could eliminate safety parts •... - Page 71 S-4000 ISBH+I SM G - MACHINE MAINTENANCE 6. Remove the filter cover with cleaning pad Remove the dust from the cleaning pad or in case of considerable dirt, wash it using a mild detergent. Perform the same cleaning on the rear fan .

-

Page 72: Periodic Maintenance

S-4000 ISBH+I SM G - MACHINE MAINTENANCE 2. PERIODIC MAINTENANCE once a day (8 hours of operation) - cleaning of the sewing mechanism area and inner frame of the - machine - lubrication of mechanisms - see section G4. once a week (40 hours of operation) -

Page 73: Lubrication Diagram

S-4000 ISBH+I SM G - MACHINE MAINTENANCE 3. LUBRICATION DIAGRAM The machine is mostly equiped with needle and ball bearings, which in combination with single lubrication circuit decrease the requirements for maintenance. Circuit I - with the oil supply in oil indicator for lubrication of the bite, feeding and looper levers and worm gears. In case of replacement of any part of distribution, it is possible to order the tube kits and wicks. -

Page 74: Machine Lubrication

S-4000 ISBH+I SM G - MACHINE MAINTENANCE 4. MACHINE LUBRICATION 1. It is necessary to lubricate the places shown below before the machine is switched on for the first time or after a long idle period. Use oil ESSO TERESSO 32 or similar quality. - Page 75 S-4000 ISBH+I SM G - MACHINE MAINTENANCE 5. Tilt the machine head on the rest pin and lubricate the places shown in the picture. looper shafts looper cam surfaces roller feed cam surfaces shifter bite cam surfaces bevel gears trimmer shaft Tilt the sewing head back into the sewing position.

-

Page 76: Machine Disposal

S-4000 ISBH+I SM G - MACHINE MAINTENANCE 5. MACHINE DISPOSAL 1. To ensure machine ecological disposal, it is necessary to remove nonmetallic parts from the machine. To take these parts out, it is necessary to perform the partial dismantling of the machine, remove covers, dismantle the machine arm and remove the frame. -

Page 77: H - Pneumatic Diagram

S-4000 ISBH+I SM H - PNEUMATIC DIAGRAM ... -

Page 78: I - Electrical Diagram

S-4000 ISBH+I SM I - ELECTRICAL DIAGRAM 1-72 Released: 01/2024 E-mail: info@amfreece-cars.cz... - Page 79 S-4000 ISBH+I SM I - ELECTRICAL DIAGRAM 1-73 Released: 01/2024 E-mail: info@amfreece-cars.cz...

- Page 80 S-4000 ISBH+I SM I - ELECTRICAL DIAGRAM 1-74 Released: 01/2024 E-mail: info@amfreece-cars.cz...

- Page 81 S-4000 ISBH+I SM I - ELECTRICAL DIAGRAM 1-75 Released: 01/2024 E-mail: info@amfreece-cars.cz...

- Page 82 S-4000 ISBH+I SM I - ELECTRICAL DIAGRAM 1-76 Released: 01/2024 E-mail: info@amfreece-cars.cz...

- Page 83 S-4000 ISBH+I SM TROUBLESHOOTING TABLE OF CONTENTS 1. MECHANICAL FAULTS......................2. INDEXER FAULTS........................3. ERROR MESSAGES OF THE CONTROL PANEL DISPLAY............ 4. ERROR MESSAGES OF THE SERVO..................5. ELECTRICAL FAULTS......................Released: 01/2024 E-mail: info@amfreece-cars.cz...

-

Page 84: Mechanical Faults

S-4000 ISBH+I SM TROUBLESHOOTING 1. MECHANICAL FAULTS FAULT POSSIBLE CAUSE PROBABLE SOLUTION Needle, looper, throat plate damaged Change damaged parts Thread breakage Incorrect needle and sewing mechani- Check the adjustment of the mecha- sm adjustment nisms Thread tension is too tight... - Page 85 S-4000 ISBH+I SM TROUBLESHOOTING FAULT POSSIBLE CAUSE PROBABLE SOLUTION Trimming knife damaged Replace knife Thread not trim- Wrong adjustment of pulling hook See section E 15 (2) med at the end of Throttle valve regulating tension disc See section E14 point (3) the cycle is too loose.

-

Page 86: Indexer Faults

S-4000 ISBH+I SM TROUBLESHOOTING 2. INDEXER FAULTS FAULT POSSIBLE CAUSE PROBABLE SOLUTION Thread pick up Thread puller position adjusted incorrectly See section F7 for adjustment does not catch the Change Thread Pick-up delay parameter Thread Pick-up delay set incorrectly thread ( breaks... -

Page 87: Error Messages Of The Servo

The following messages can be seen on the servo, which is placed inside the control box. In order to eliminate these messages, switch off the machine for 1 minute. Then switch the machine on again. The error message should not appear on the display. If the message appears - call AMF Reece service. PWR - Power supply indication:... - Page 88 S-4000 ISBH+I SM TROUBLESHOOTING Alarm Alarm reset Error detection function Detection details and cause of error code possible Power supply The DC voltage of the main circuit fell beloww the specificed value while undervoltage the RUN Command Input was ON...

-

Page 89: Electrical Faults

Sensor BQ1 failure Replace the sensor 06.2400.0.009 To set the servo amplifier - call AMF Re- Check the servo amplifier and servo ece service, alternatively replace motor (page 2-9) and servo amplifier (page 2-9) When sewing operation... - Page 91 S-4000 ISBH+I SM TABLE OF CONTENTS Needle Bar ............................Clamping ............................Clamping Angle..........................Thread Trimmer..........................Shifter Mechanism ..........................3-10 Feed Mechanism ..........................3-12 Looper Mechanism........................... 3-16 Base..............................3-18 Bite Mechanism..........................3-20 Thread Draw-off Mechanism ......................3-22 Main Cam ............................3-24 Head Assembly ..........................

-

Page 92: Needle Bar

S-4000 ISBH+I SM NEEDLE BAR Released: 01/2024 3 - 2 E-mail: info@amfreece-cars.cz... - Page 93 S-4000 ISBH+I SM NEEDLE BAR PART NUMBER DESCRIPTION QTY. 22.0195.0.000 Needle Bar 01.2193.0.000 Screw 4-60 24.0510.0.000 Needle Bar Holder ● 08.6400.5.005 Set Screw M5 x 5 01.7447.1.000 Porcelain Guide ●●● 22.0520.0.000 Needle Bar Clamp 01.6551.0.000 Retaining Ring ●●● 22.0230.0.000 Cupped Washer 22.0239.0.000...

-

Page 94: Clamping

S-4000 ISBH+I SM CLAMPING Released: 01/2024 3 - 4 E-mail: info@amfreece-cars.cz... - Page 95 S-4000 ISBH+I SM CLAMPING PART NUMBER DESCRIPTION QTY. 07.6045.0.046 22.0173.0.000 Clamp Toggle Pivot Pin 24.0036.1.000 Cylinder Mounting Bracket See Page 3-45 Cylinder ● — 08.6000.5.022 Screw M5 x 22 24.0035.1.000 Cylinder Clevis 08.6000.5.012 Screw M5 x 12 08.6400.4.004 Set Screw M4 x 4 24.0158.1.000...

-

Page 96: Clamping Angle

S-4000 ISBH+I SM CLAMPING - ANGLE Released: 01/2024 3 - 6 E-mail: info@amfreece-cars.cz... - Page 97 S-4000 ISBH+I SM CLAMPING - ANGLE PART NUMBER DESCRIPTION QTY. 24.3028.1.000 Clamping Plate ISBH + I 24.4103.0.000 Indexer Bracket 08.6100.4.006 Screw M4 x 6 22.0164.0.000 Clamping Mat BH, ISBH 01.2376.0.000 Screw-flat Head 24.0158.2.000 Tail Bracket Clamp 08.6100.5.012 Screw M5 x12 08.6400.5.008...

-

Page 98: Thread Trimmer

S-4000 ISBH+I SM THREAD TRIMMER Released: 01/2024 3 - 8 E-mail: info@amfreece-cars.cz... - Page 99 S-4000 ISBH+I SM THREAD TRIMMER PART NUMBER DESCRIPTION QTY. 20.0093.2.004 Trimmer Hook 20.0092.0.004 Trimmer Actuator 01.2386.0.000 Hex Screw 3/16-36 x .5 12.1045.3.001 E-Clip 24.0080.0.000 Trimmer Shaft 24.0003.0.000 Trimmer Pivot 08.6000.4.012 Screw M4 x 12 24.0004.0.000 Trimmer Clamp Lever 07.6045.0.042 E-Clip 24.0005.0.000...

-

Page 100: Shifter Mechanism

S-4000 ISBH+I SM SHIFTER MECHANISM Released: 01/2024 3 - 10 E-mail: info@amfreece-cars.cz... - Page 101 S-4000 ISBH+I SM SHIFTER MECHANISM PART NUMBER DESCRIPTION QTY. 08.6000.4.010 Screw M4 x 10 22.2653.0.000 Left Shifter Arm Spring 08.6000.4.016 Screw M4 x 16 22.2652.0.000 Left Shifter Arm 08.6000.4.005 Screw 22.2657.0.000 Right Shifter Arm Spring 22.2656.0.000 Right Shifter Arm 24.3074.0.000 Nut M6 24.3073.0.000...

-

Page 102: Feed Mechanism

S-4000 ISBH+I SM FEED MECHANISM Released: 01/2024 3 - 12 E-mail: info@amfreece-cars.cz... - Page 103 S-4000 ISBH+I SM FEED MECHANISM PART NUMBER DESCRIPTION QTY. 08.6100.3.030 Screw M3 x 30 22.0114.0.000 Feed Brake Pressure Plate 22.0121.0.000 Slip Clutch Drive Washer 22.0354.0.000 Slip Clutch Feed Gear 24.0126.0.000 Friction Washer ●●● 22.0312.0.000 Slip Clutch Feed Shaft 22.0061.0.000 Clamp Plate Gear Rack Retainer 07.6440.0.033...

- Page 104 S-4000 ISBH+I SM FEED MECHANISM Released: 01/2024 3 - 14 E-mail: info@amfreece-cars.cz...

- Page 105 S-4000 ISBH+I SM FEED MECHANISM PART NUMBER DESCRIPTION QTY. 22.0021.0.000 Spring Retain Block 22.0353.0.000 Steel Bevel Gear 22.0032.0.000 Bearing Shoulder Screw 07.6321.0.025 Bearing 22.0031.0.000 Bearing Spacer 08.6710.5.000 Nut M5 22.0232.0.000 Washer 22.0110.0.000 Shoulder Nut M5 22.0022.0.000 Pivot Shaft 08.6850.8.000 Flat Washer M8 08.6700.8.000...

-

Page 106: Looper Mechanism

S-4000 ISBH+I SM LOOPER MECHANISM Released: 01/2024 3 - 16 E-mail: info@amfreece-cars.cz... - Page 107 S-4000 ISBH+I SM LOOPER MECHANISM PART NUMBER DESCRIPTION QTY. 08.6400.4.004 Set Screw M4 x 4 22.2442.0.000 Looper Spacer 22.2410.0.000 Looper Shaft Block 08.6100.5.020 Screw M5 x 20 22.2440.0.000 Looper Shaft 01.1382.0.000 Screw 20.0094.0.000 Trimmer Knife 20.0111.0.000 First Looper 23.2106.0.000 First Looper Holder 20.0112.0.000...

-

Page 108: Base

S-4000 ISBH+I SM BASE — S4000 ISBH Embedded Machine Released: 01/2024 3 - 18 E-mail: info@amfreece-cars.cz... - Page 109 S-4000 ISBH+I SM BASE PART NUMBER DESCRIPTION QTY. 24.0111.0.000 Base Sound Deadener ●●● 08.6100.5.012 Screw M5 x 12 08.6100.5.012 Screw M5 x 12 08.6200.5.012 Screw M5 x 12 22.1010.0.000 Base Hinge 24.0155.0.000 Base Hinge 24.0038.0.000 Base Gasket ●●● 12.8000.1.028 CE”” Label ●●●...

-

Page 110: Bite Mechanism

S-4000 ISBH+I SM BITE MECHANISM Released: 01/2024 3 - 20 E-mail: info@amfreece-cars.cz... - Page 111 S-4000 ISBH+I SM BITE MECHANISM PART NUMBER DESCRIPTION QTY. 08.6000.6.025 Screw M6 x 25 22.0008.0.000 Bite Lever ● 24.0055.0.000 Bite Shaft 22.0063.0.000 Bite Shaft Retainer 08.6100.3.008 Screw M3 x 8 08.6000.3.010 Screw M3 x 10 22.0183.0.000 Collar*Dia. 8 08.6000.4.014 Screw M4 x 14 22.0110.0.000...

-

Page 112: Thread Draw-Off Mechanism

S-4000 ISBH+I SM THREAD DRAW - OFF MECHANISM J 1 A Released: 01/2024 3 - 22 E-mail: info@amfreece-cars.cz... - Page 113 S-4000 ISBH+I SM THREAD DRAW - OFF MECHANISM PART NUMBER DESCRIPTION QTY. 08.6710.6.000 Nut M6 24.0037.0.000 Cylinder Clevis 08.6000.5.016 Screw M5 x 16 07.6045.0.042 E-Clip 24.0011.0.000 Knife Drive Lever 24.0014.0.000 Pivot 08.6000.4.010 Screw M4 x 10 24.0010.0.000 Clamp Collar 24.0009.0.000 Washer 08.6000.4.016...

-

Page 114: Main Cam

S-4000 ISBH+I SM MAIN CAM Released: 01/2024 3 - 24 E-mail: info@amfreece-cars.cz... - Page 115 S-4000 ISBH+I SM MAIN CAM PART NUMBER DESCRIPTION QTY. 22.2607.0.000 Drive Disk/Worm Gear Hub 22.2627.0.000 Shoulder Nut 22.2626.0.000 Drive Disk Switch Spring 07.6440.0.037 Spring 24.3076.0.000 Stop Disk 24.3070.0.000 Feed Reversing Cam 22.3069.0.000 Washer 24.3077.0.000 Barring Cam ISBH 08.6100.5.010 Screw M5 x 10 22.0137.0.000...

-

Page 116: Head Assembly

S-4000 ISBH+I SM HEAD ASSEMBLY 4 J B e e P - 5 3 27 28 15 16 S e e P a g e - 4 5 Released: 01/2024 3 - 26 E-mail: info@amfreece-cars.cz... - Page 117 S-4000 ISBH+I SM HEAD ASSEMBLY PART NUMBER DESCRIPTION QTY. Servomotor — See Page 3-37 08.6850.5.000 Washer M5 08.6000.5.016 Screw M5 x 16 24.6000.5.000 Head 08.6200.5.008 Screw M5 x 8 22.0054.0.000 Upper Thread Guide 08.6000.8.025 Screw M8 x 25 22.0058.0.000 Sewing Head Latch 07.6045.0.037...

-

Page 118: Bedplate

S-4000 ISBH+I SM BEDPLATE 12 13 15 16 29 30 31 26 32 33 33 36 37 38 39 40 33 37 - S 4000 ISBH + I SM - Angle Released: 01/2024 3 - 28 E-mail: info@amfreece-cars.cz... - Page 119 Screw (Only ISBH+I model) 24.3054.0.000 Material Guide 08.6120.3.008 Screw M3 x 8 24.3055.0.000 Cover Plate - Straight 24.3055.2.000 Cover Plate - Angle 05.1394.0.000 AMF Reece Label - small ●●● 22.0143.0.000 Screw 22.3022.0.000 Front Stop 08.6100.4.006 Screw M4 x 6 22.0408.1.000 Trimmer Cover Plate 24.6100.1.000...

-

Page 120: Covers

S-4000 ISBH+I SM COVERS Released: 01/2024 3 - 30 E-mail: info@amfreece-cars.cz... - Page 121 S-4000 ISBH+I SM COVERS PART NUMBER DESCRIPTION QTY. 08.6100.5.016 Screw M5 x 16 24.0068.0.000 ●●● 24.0067.0.000 Fan Rack 08.6850.5.000 Washer M5 Fan Assembly — See Page 3-37 24.6004.1.001 Pulley Cover ● 08.6000.4.070 Screw M4 x 70 08.6000.3.040 Screw M3 x 40 08.6000.3.016...

-

Page 122: Lubrication

S-4000 ISBH+I SM LUBRICATION Released: 01/2024 3 - 32 E-mail: info@amfreece-cars.cz... - Page 123 S-4000 ISBH+I SM LUBRICATION PART NUMBER DESCRIPTION QTY. 24.0141.0.000 Tubing ●●● 24.0139.0.000 Lubricating Wick ●●● 22.0229.0.000 Straight Fitting 08.6000.4.006 Screw M4 x 6 22.0120.0.000 Holder 22.0104.0.000 Oil Gauge Reservoir 17.0095.1.329 Wheel ●●● 22.0108.0.000 Wick Holder 17.0027.1.799 Spring 17.0082.6.000 Clamp 08.6000.3.006 Screw M3 x 6 17.0094.5.310...

-

Page 124: Table

S-4000 ISBH+I SM TABLE Modification — ISBH+I (Indexer) Modification — ISBH Released: 01/2024 3 - 34 E-mail: info@amfreece-cars.cz... - Page 125 S-4000 ISBH+I SM TABLE PART NUMBER DESCRIPTION QTY. 01** 24.0142.0.050 Table Assembly ISBH 04.9024.0.003 Table Assembly ISBH+I 08.6700.8.000 M8 Nut 17.0019.0.441 Washer 17.0095.1.272 Washer ●●● 12.0008.6.900 Machine Rest Table Pin 12.0008.6.801 Rubber Spring ●●● 12.1016.1.000 Nail ●●● 04.1416.0.003 Label “No. xxxx”...

-

Page 126: Electrical (Isbh+I) - I

S-4000 ISBH+I SM ELECTRICAL (ISBH+I) - I E C T S U P E R V Released: 01/2024 3 - 36 E-mail: info@amfreece-cars.cz... - Page 127 S-4000 ISBH+I SM ELECTRICAL (ISBH+I) - I PART NUMBER DESCRIPTION QTY. 03.5524.0.049 Panel Kit OMRON ISBH + I 24.8001.2.014 TOUCH SCREEN-OMRON ●●● 68.0358.0.800 PANEL COVER - OMRON 24.0168.0.000 DISPLAY HOLDER - OMRON 06.2400.0.002 CABLE DISPLAY 08.6032.4.010 SCREW M4-10 08.6662.3.006 SCREW 19.0014.7.003...

- Page 128 S-4000 ISBH+I SM ELECTRICAL (ISBH+I) - I E C T S U P E R V Released: 01/2024 3 - 38 E-mail: info@amfreece-cars.cz...

- Page 129 S-4000 ISBH+I SM ELECTRICAL (ISBH+I) - I PART NUMBER DESCRIPTION QTY. 12.0008.4.835 Switch ON — OFF 06.2400.0.913 Cable X4A 06.2400.0.910 Cable X3A 12.0008.4.216 Plug 12.0008.4.472 Fan Cover With Filter ●●● 24.0059.9.017 Fan assy.* 70.4165.1.125 Electrical Box 08.6032.4.010 Screw M4x10 12.8000.0.158 Electrical Diagram Label 12.0008.4.378...

-

Page 130: Electrical Ii

S-4000 ISBH+I SM ELECTRICAL II Released: 01/2024 3 - 40 E-mail: info@amfreece-cars.cz... - Page 131 S-4000 ISBH+I SM ELECTRICAL II PART NUMBER DESCRIPTION QTY. 24.0069.9.009 Pedal Assembly 06.8800.0.001 Pedal ●●● 12.0008.4.296 Bushing ●●● 06.2400.0.014 Cable 08.6312.8.020 Screw M8x20 08.6852.8.000 Washer M8 24.0097.0.000 Holder Pedal 08.6100.4.012 Screw M4x12 08.6802.8.000 Spring Washer M8 08.6702.8.000 Nut M8 12.0008.4.058 Clip 12.0008.4.072...

- Page 132 S-4000 ISBH+I SM ELECTRICAL III Released: 01/2024 3 - 42 E-mail: info@amfreece-cars.cz...

- Page 133 S-4000 ISBH+I SM ELECTRICAL III PART NUMBER DESCRIPTION QTY. Terminal x1 (X1) Terminal X0 - Power (X0) Terminal X12 - Fan (X12) 24.8001.2.005 Servodrive (U1) 12.0010.4.071 Extension Block 24.8001.2.001 12.0010.4.067 Port RS 232 12.0008.4.050 Bridge GND 12.0010.4.251 Filter (Z1) 12.0008.4.665...

-

Page 134: Pneumatics

S-4000 ISBH+I SM PNEUMATICS 10 15 18 16 X E R IN D E 20 21 11 14 16 18 27 26 Released: 01/2024 3 - 44 E-mail: info@amfreece-cars.cz... - Page 135 S-4000 ISBH+I SM PNEUMATICS PART NUMBER DESCRIPTION QTY. 08.6000.5.012 Screw M5x12 08.6832.5.000 Washer M5 12.0010.3.138 Regulator Holder 12.0010.3.137 Regulator 08.6850.5.000 Washer M5 08.6700.5.000 Nut M5 12.0008.3.420 Connector 12.0010.3.030 Silencer 12.0008.3.829 Air Supply Block Assembly 12.8000.0.016 Label Kit 12.0008.4.058 Clip ●●●...

-

Page 136: Indexer Linear Guide

S-4000 ISBH+I SM INDEXER LINEAR GUIDE Released: 01/2024 3 - 46 E-mail: info@amfreece-cars.cz... - Page 137 S-4000 ISBH+I SM INDEXER LINEAR GUIDE PART NUMBER DESCRIPTION QTY. 24.4087.0.000 Stud 12.2070.1.012 Linear Guide 08.6000.3.008 Screw M3-8 24.4067.1.000 Cross Lever 08.6100.3.006 Screw M3-6 24.4026.1.000 Pillow Block ● 08.6000.4.010 Screw M4-10 24.4027.0.000 Plastic Joint ●●● 24.4028.1.000 Stud Assembly Released: 01/2024 3 - 47 E-mail: info@amfreece-cars.cz...

-

Page 138: Indexer Clamping Assembly

S-4000 ISBH+I SM INDEXER CLAMPING ASSEMBLY J10A Released: 01/2024 3 - 48 E-mail: info@amfreece-cars.cz... - Page 139 S-4000 ISBH+I SM INDEXER CLAMPING ASSEMBLY PART NUMBER DESCRIPTION QTY. 24.4005.1.000 Clamp Rail 24.4006.1.000 Clamping Mat Left 24.4007.1.000 Clamping Mat Right 08.6000.3.005 Screw M3-5 24.4016.0.000 Holder Cylinder ● 08.6000.4.008 Screw M4-8 24.4013.0.000 Holder Cylinder ● 24.4009.0.000 Shaft 24.4017.1.000 Clamp Foot Left ●...

-

Page 140: Indexer Assembly

S-4000 ISBH+I SM INDEXER ASSEMBLY Released: 01/2024 3 - 50 E-mail: info@amfreece-cars.cz... - Page 141 S-4000 ISBH+I SM INDEXER ASSEMBLY PART NUMBER DESCRIPTION QTY. 24.4060.1.050 Indexer Cover Assembly 08.6842.5.000 Washer 5 08.6663.5.025 Screw 4,8-25 12.0008.4.631 Cable Bushing ●●● 12.0008.4.052 Label Ground ●●● 19.0082.3.433 Holder 08.6676.4.025 Sscrew 12.0008.4.742 Button ●●● 08.6832.4.000 Washer M4 08.6032.4.008 Screw M4-8 08.6032.4.010...

-

Page 142: Indexer Guide Assembly

S-4000 ISBH+I SM INDEXER GUIDE ASSEMBLY 26 25 27 Released: 01/2024 3 - 52 E-mail: info@amfreece-cars.cz... - Page 143 S-4000 ISBH+I SM INDEXER GUIDE ASSEMBLY PART NUMBER DESCRIPTION QTY. 12.2070.1.013 Guide 24.4061.1.600 Holder ● 08.6000.4.008 Screw M4-8 12.2070.1.014 Guide 08.6000.3.006 Screw M3-6 24.4062.1.000 Bracket ● 08.6000.3.008 Screw M3-8 12.2070.1.015 Guide 24.4065.1.000 Holder 24.4081.0.000 Stud 12.2070.1.016 Guide 08.6000.3.010 Screw M3-10 24.4076.0.000...

-

Page 144: Clamping Feed Straight

S-4000 ISBH+I SM CLAMPING FEED STRAIGHT Released: 01/2024 3 - 54 E-mail: info@amfreece-cars.cz... - Page 145 S-4000 ISBH+I SM CLAMPING FEED STRAIGHT PART NUMBER DESCRIPTION QTY. 24.4064.2.000 Support Plate 24.4077.1.000 Rack 08.6100.4.010 Screw M4-10 24.4074.0.000 Gear Cover 08.6000.3.004 Screv M3-4 08.6850.4.000 Washer M4 08.6800.4.000 Washer 4 08.6310.4.010 Screw M4x10 08.6000.6.010 Screw M6-10 08.6710.6.000 Nut M6 24.4029.1.000 Clamp Feet Holder ●...

-

Page 146: Indexer Clammping - Angle

S-4000 ISBH+I SM INDEXER CLAMPING - ANGLE J10A Released: 01/2024 3 - 56 E-mail: info@amfreece-cars.cz... - Page 147 S-4000 ISBH+I SM INDEXER CLAMPING - ANGLE PART NUMBER DESCRIPTION QTY. 24.4101.0.000 Clamp Rail 24.4006.2.000 Clamping MAT-Left 24.4007.2.000 Clamping MAT-Right 08.6000.3.005 Screw M3 x 5 24.4016.0.000 Holder Cylinder ● 08.6000.4.008 Screw M4 x 8 24.4013.0.000 Holder Cylinder ● 24.4009.1.000 Shaft 24.4017.2.000...

-

Page 148: Indexer Cover - Angle

S-4000 ISBH+I SM INDEXER COVER - ANGLE 17 18 Released: 01/2024 3 - 58 E-mail: info@amfreece-cars.cz... - Page 149 S-4000 ISBH+I SM INDEXER COVER - ANGLE PART NUMBER DESCRIPTION QTY. 24.4060.3.050 Indexer Cover Assy. 08.6842.5.000 Washer 5 07.6600.0.006 Clamp Cable ●●● 19.0082.3.433 Holder 08.6852.5.000 Washer 5,3 08.6676.4.025 Screw 4 x 25 08.6663.5.025 Screw 4,8 x 25 12.0008.4.631 Cable Bushing ●●●...

-

Page 150: Indexer Guide - Angle

S-4000 ISBH+I SM INDEXER GUIDE - ANGLE Released: 01/2024 3 - 60 E-mail: info@amfreece-cars.cz... - Page 151 S-4000 ISBH+I SM INDEXER GUIDE - ANGLE PART NUMBER DESCRIPTION QTY. 12.2070.1.032 Guide 08.6000.5.016 Screw M5 x 16 24.4061.2.000 Holder ● 08.6000.4.008 Screw M4 x 8 12.2070.1.019 Linear Guide 08.6000.3.006 Screw M3 x 6 24.4062.3.000 Bracket ● 06.2400.0.905 Motor - Indexer ●...

-

Page 152: Clamp Feet - Angle

S-4000 ISBH+I SM CLAMP FEET - ANGLE Released: 01/2024 3 - 62 E-mail: info@amfreece-cars.cz... - Page 153 S-4000 ISBH+I SM CLAMP FEET - ANGLE PART NUMBER DESCRIPTION QTY. 24.4064.3.000 SUPPORT PLATE 24.4080.2.000 STUD 24.4086.1.000 CYLINDER BRACKET ● 24.4063.2.000 HOLDER; ANGLE CLAMP ● 24.4032.1.000 LEVER 24.4085.0.000 08.6850.5.000 WASHER 5,3 08.6850.4.000 WASHER M4 08.6000.4.008 SCREW M4-8 08.6800.5.000 SPRING WASHER M5 17.0014.1.226...

- Page 154 S-4000 ISBH+I SM ACCESSORIES 1 / ” ” 1 / 8 N P T — EXTRA PARTS Released: 01/2024 3 - 64 E-mail: info@amfreece-cars.cz...

- Page 155 S-4000 ISBH+I SM ACCESSORIES PART NUMBER DESCRIPTION QTY. 12.0008.3.607 Connector Dia 8 12.0008.3.608 Connector Dia 10 20.0094.0.000 Trimmer Knife 22.0209.0.000 Looper Gauge 24.0030.0.000 Main Shaft Pulley Bracket 24.0024.0.000 Needle Bar Shaft Pulley Bracket 02.0750.2.110 Needles, Size 90 05.1322.0.000 Oiler ●●●...

-

Page 156: Accessories Extra Parts - Thread Pick-Up

S-4000 ISBH+I SM ACCESSORIES EXTRA PARTS - THREAD PICK-UP Released: 01/2024 3 - 66 E-mail: info@amfreece-cars.cz... - Page 157 S-4000 ISBH+I SM ACCESSORIES EXTRA PARTS - THREAD PICK-UP PART NUMBER DESCRIPTION QTY. 24.4001.0.050 Cylinder Holder Assembly ● 08.6100.5.016 Screw M5-16 24.4004.0.000 Stud 12.0008.3.499 Cylinder ● ●●● 24.4003.0.000 Support 24.4002.0.000 Pick-up 08.6700.3.000 Nut M3 12.0010.3.027 Connector ●● ●●● 12.0008.3.602 Connector ●●...

- Page 158 S-4000 ISBH+I SM ACCESSORIES EXTRA PARTS - THREAD PICK-UP Released: 01/2024 3 - 68 E-mail: info@amfreece-cars.cz...

- Page 159 S-4000 ISBH+I SM ACCESSORIES EXTRA PARTS - THREAD PICK-UP PART NUMBER DESCRIPTION QTY. 24.4004.0.000 Eccentric Stud 24.4001.0.050 Cylinder Holder Assembly ● ●●● 08.6100.5.016 Screw M5-16 12.0008.3.499 Cylinder 12.0010.3.027 Connector ●● ●●● 12.0008.3.416 Air Tube ●●● 12.0008.3.602 Connector ●● 12.0008.3.601 Connector ●●...

-

Page 160: Recommended Spare Parts

S-4000 ISBH+I SM RECOMMENDED SPARE PARTS Part Number Parts Description 07.6321.0.025 BRG, BALL CAM F. (INA)#LR605NPPU 20.0093.0.000 HOOK TRIMMER 20.0094.0.000 TRIMMER KNIFE 20.0111.0.000 LOOPER*FIRST 20.0112.0.000 LOOPER*SECOND 22.2657.0.000 RIGHT SHIFTER ARM SPRING 22.2653.0.000 LEFT SHIFTER ARM SPRING 23.2356.2.052 USA-KNIFE-1/2/13 M 23.2356.2.054 USA-KNIFE-5/8/16 MM 23.2356.2.055... - Page 161 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 00.2751.3.602 3-39 07.6045.0.037 3-13 08.6000.3.010 3-21 01.1382.0.000 3-17 07.6045.0.037 3-27 08.6000.3.010 3-53 01.1397.0.000 3-17 07.6045.0.042 08.6000.3.010 3-61 01.2084.0.000 07.6045.0.042 3-23 08.6000.3.012 3-61 01.2084.0.000 07.6045.0.046 08.6000.3.016 3-31...

- Page 162 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 08.6000.5.020 3-55 08.6100.5.012 08.6400.4.012 08.6000.5.016 3-61 08.6100.5.012 3-19 08.6400.5.004 3-61 08.6000.5.020 3-13 08.6100.5.012 3-19 02* 08.6400.5.005 08.6000.5.020 3-61 08.6100.5.012 3-49 08.6400.5.005 3-13 08.6000.5.022 08.6100.5.012 3-57 08.6400.5.005 3-27...

- Page 163 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 08.6702.4.000 3-37 08.6850.5.000 3-27 12.0008.3.499 3-67 08.6702.5.000 3-59 08.6850.5.000 3-29 12.0008.3.499 3-69 08.6702.8.000 3-35 08.6850.5.000 3-31 12.0008.3.575 3-67 08.6702.8.000 3-41 08.6850.5.000 3-45 12.0008.3.575 3-69 08.6710.3.000...

- Page 164 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 12.0008.4.598 3-27 12.0010.3.159 3-45 15.1436.0.100 3-29 12.0008.4.631 3-51 12.0010.4.025 3-61 17.0014.1.226 3-63 12.0008.4.631 3-59 12.0010.4.067 3-43 17.0019.0.441 3-35 12.0008.4.632 3-19 16* 12.0010.4.071 3-43 17.0019.0.517 3-13 12.0008.4.664 3-43...

- Page 165 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 22.0031.0.000 3-15 22.0186.0.000 3-13 22.1415.0.050 3-23 22.0031.0.000 3-17 22.0195.0.000 22.1422.0.000 3-27 22.0032.0.000 3-15 22.0208.0.000 3-13 22.1436.0.000 3-23 22.0046.0.000 3-23 22.0209.0.000 3-65 22.2410.0.000 3-17 22.0049.0.000 3-13 22.0213.0.000 3-65...

- Page 166 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 24.0005.0.000 24.0127.0.000 3-13 24.4001.0.050 3-69 24.0006.0.000 24.0139.0.000 3-33 24.4002.0.000 3-67 24.0009.0.000 3-23 24.0140.0.000 3-15 24.4003.0.000 3-67 24.0010.0.000 3-23 24.0141.0.000 3-33 24.4004.0.000 3-67 24.0011.0.000 3-23 24.0142.0.000 3-35 09**...

- Page 167 S-4000 ISBH+I SM INDEX PART NUMBER PAGE DET PART NUMBER PAGE DET PART NUMBER PAGE DET 24.4062.3.000 3-61 68.0358.0.800 3-37 24.4063.2.000 3-63 70.4165.1.125 3-39 24.4064.2.000 3-55 84.0005.7.135 3-35 25* 24.4064.3.000 3-63 24.4065.1.000 3-53 24.4065.2.000 3-61 24.4067.1.000 3-47 24.4074.0.000 3-55 24.4075.0.000 3-53 24.4075.2.000 3-61...

Need help?

Do you have a question about the S-4000 ISBH+I SM and is the answer not in the manual?

Questions and answers