Table of Contents

Advertisement

Quick Links

KEEP FOR FUTURE REFERENCE

INSTRUCTIONS

International Version

P.O. Box 368 – 908 West Main

Laurel, MT USA 59044

MODEL NUMBER: PT410AC

phone 800-548-7341

phone 406-628-8231

SERIAL NUMBER: ___________

fax 406-628-8354

(please see serial label and record number here)

"WINDSHIELD LIFTER"

POWER TILTER

AC-VOLTAGE

READ ALL INSTRUCTIONS AND WARNINGS

BEFORE OPERATING THIS LIFTER

DESIGNED FOR THE MATERIALS HANDLING PROFESSIONAL

Advertisement

Table of Contents

Summary of Contents for WPG PT410AC

- Page 1 KEEP FOR FUTURE REFERENCE INSTRUCTIONS International Version P.O. Box 368 – 908 West Main Laurel, MT USA 59044 MODEL NUMBER: PT410AC phone 800-548-7341 phone 406-628-8231 SERIAL NUMBER: ___________ fax 406-628-8354 (please see serial label and record number here) "WINDSHIELD LIFTER"...

-

Page 3: Table Of Contents

MAINTENANCE ......................16 ....................16 NSPECTION CHEDULE Every-Lift Inspection ..........................16 Frequent Inspection ........................... 16 Periodic Inspection ............................ 16 Infrequent Use ............................17 ......................17 ESTING CHEDULE Operational Tests............................17 Load Test ..............................17 ....................17 AINTENANCE CHEDULE Rev 14.0/4-18 PT410AC: #35140... - Page 4 F) Replacing O-Rings and Reassembling the Head Assembly .................23 ....................24 INEAR CTUATOR ..................25 ACUUM WITCH DJUSTMENT Vacuum Switch Function ..........................25 Conditions Requiring Readjustment ......................25 Adjustment Procedure ..........................25 REPLACEMENT PARTS LIST ..................26 LIMITED WARRANTY ....................27 Rev 14.0/4-18 PT410AC: #35140...

-

Page 5: Specifications

SPECIFICATIONS Model Number: PT410AC Description: Designed for use with a crane or other hoisting equipment, the PT410AC lifter employs vacuum to hold a load for lifting, and it provides powered 90° tilt movement for load manipulation. Power Source: See serial number plate for specific AC voltage, frequency and amperage. -

Page 6: Warnings

For consultation, contact Wood's Powr-Grip (see LIMITED WARRANTY). Always employ a ground fault circuit interrupter when connecting the power cable to the power source. Rev 14.0/4-18 PT410AC: #35140... -

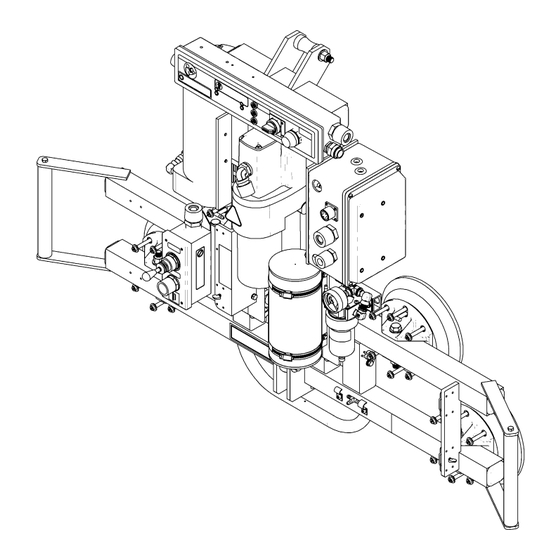

Page 7: Operating Features

OPERATING FEATURES Note: Components featured in the following instructions for assembling, operating or maintaining the vacuum lifter are underlined on their first appearance in each section. Standard PT410AC shown. 1 LIFT SPOOL 6 VACUUM GAUGE 12 PAD FRAME 2 POWER SWITCH... -

Page 8: Assembly

Then attach the hoisting equipment hook to the lift spool. WARNING: Hoisting equipment hook must be fitted with restraining latch to prevent lift spool from slipping off under any circumstances. Rev 14.0/4-18 PT410AC: #35140... - Page 9 Remove the pad covers and save them for use whenever the lifter is stored. Now the lifter is operational. 4) Perform Operational and Load Tests for the lifter as directed in MAINTENANCE: T ESTING CHEDULE Rev 14.0/4-18 PT410AC: #35140...

-

Page 10: Intended Use

The minimum continuous radius at the attachment area of the load must be either 45" [115 cm] around an axis parallel to the lifter's tilt axis or 95" [242 cm] around an axis perpendicular to the tilt axis (but not both). However, compound curves and complex shapes may permit loads with tighter radii to be lifted. Rev 14.0/4-18 PT410AC: #35140... -

Page 11: Operating Environment

ISPOSAL OF THE IFTER After the vacuum lifter has reached the end of its service life, you must dispose of the lifter in compliance with all local codes and regulatory standards that are relevant for the geographical region. Rev 14.0/4-18 PT410AC: #35140... -

Page 12: Operation

In order for the operator to use the lifter on wet load surfaces, it must be equipped with 2 or more filters that are connected series . However, see MAINTENANCE: V : Friction Coefficient before using the lifter on wet load surfaces. ACUUM AINTENANCE Rev 14.0/4-18 PT410AC: #35140... -

Page 13: T O Apply The Pads To A Load

2" [5 cm] of the pad frame’s center point. Occasional loading deviations are permissible, provided that the operator can maintain control of the load at all times and that the load weight is low enough to avoid damaging the lifter. Rev 14.0/4-18 PT410AC: #35140... -

Page 14: Reading The Vacuum Gauge

Certain load materials are too rough or porous to allow the lifter to form a seal which can be maintained for 5 minutes without power. However, in geographical locations where CE Standards do not apply, it may be possible to use the lifter to lift such loads. Contact Wood’s Powr-Grip for more information. Rev 14.0/4-18 PT410AC: #35140... -

Page 15: Load Capacity And The Lift Light

Use the control handles to keep the lifter and load in the desired orientation while they are suspended from the crane. Once sufficient clearance is established, the load can be tilted as desired (see T ILT THE follow). Rev 14.0/4-18 PT410AC: #35140... -

Page 16: In Case Of Power Failure

After the pads have disengaged completely from the load, move the lifter away. Continue to hold the release button until the pads are well away from the load; otherwise, the lifter would reattach itself to the load. Rev 14.0/4-18 PT410AC: #35140... -

Page 17: After Using The Lifter

Avoid placing the lifter in this position; or if this is unavoidable, place a support under the lift bar. Also be sure to provide manual assistance to the tilt actuator when raising the lift bar to the vertical position (see ASSEMBLY). Rev 14.0/4-18 PT410AC: #35140... -

Page 18: Maintenance

• Keep a written record of all Periodic Inspections. If any deficiency is detected during the inspection, correct it before using the lifter. If necessary, return the lifter to Wood’s Powr-Grip or an authorized dealer for repair (see LIMITED WARRANTY). Rev 14.0/4-18 PT410AC: #35140... -

Page 19: Infrequent Use

Any maintenance warranted must be performed before resuming normal operation of the lifter. ASME Standard B30.20 requires the lifter to be tested to 125% of its Load Capacity. Flat Lifters are exempt from this requirement. Rev 14.0/4-18 PT410AC: #35140... -

Page 20: Vacuum Pad Maintenance

If the lifter is equipped with VPFS10T or VPFS625 pads, the sealing edge is the replaceable sealing ring. When it is damaged, install a new sealing ring insert. In such cases, see T to follow. EPLACE EALING NSERT IN ACUUM Rev 14.0/4-18 PT410AC: #35140... -

Page 21: Cleaning

If these cleaning methods are not successful, contact Wood’s Powr-Grip or an authorized dealer for assistance. Any test material used must be fully and independently supported, and capable of bearing the lifter’s weight. Do not use the lifter to lift the test material during the vacuum test. Rev 14.0/4-18 PT410AC: #35140... -

Page 22: Air Filter Maintenance − Large

When the air filter is being used on a system, rather than with Never pressure, using the twist drain to remove liquid from the bowl is recommended. disturb the twist drain, as contaminants could lodge in the drain seal and cause a vacuum leak. Rev 14.0/4-18 PT410AC: #35140... -

Page 23: Vacuum Pump Maintenance − Gast 0523-101Q-Sg588Dx

(10). 1 SHROUD 6 SOUND CHAMBER 2 VANES (4x) 7 BOLTS FOR SOUND CHAMBER (5x) 3 ENDPLATE 8 AIR FILTER (2x) 4 BOLTS FOR ENDPLATE (6x) 9 O-RING (2x) 5 GASKET 10 END CAP (2x) Rev 14.0/4-18 PT410AC: #35140... -

Page 24: Vacuum Pump Maintenance − Gast N70

2) Remove the four retainer screws (4) from the two retainer plates (5). Remove the cylinders (7), leaving the retainer plates and cups (6) inside. 3) Invert the cylinders (7) and push the retainer plates (5) out through the top. The cylinders and cups (6) will be replaced next. Rev 14.0/4-18 PT410AC: #35140... -

Page 25: E) Replacing The Cylinders And Cups

Cylinder O-ring Long Valve Screw (T15 Torx) Valve Limiter Leaf Valve (Exhaust) Short Valve Screw (T15 Torx) Retainer Plate Leaf Valve (Intake) * Special Order – Non-Stocked Item Included in service kit #66178 Rev 14.0/4-18 PT410AC: #35140... -

Page 26: Linear Tilt Actuator

If the actuator is not used for a week or more at a time, oil may begin to separate from the lubricant and leak out. Although this leakage is not detrimental to the lubrication or operation of the actuator, you can avoid this condition by simply running the actuator for a few cycles each week. Rev 14.0/4-18 PT410AC: #35140... -

Page 27: Vacuum Switch Adjustment

In order to observe lifter functions while vacuum is decreasing, it may be necessary to create a controlled leak in the vacuum system (eg, by breaking the seal between one or more vacuum pads and the test surface). Rev 14.0/4-18 PT410AC: #35140... -

Page 28: Replacement Parts List

Pad Filter Screen - Small 10904AM Shoulder Bolt - Socket Head - 5/16" x 2-1/4" x 1/4-20 Thread (for mounting pads) SERVICE ONLY WITH IDENTICAL REPLACEMENT PARTS, AVAILABLE AT WPG.COM OR THROUGH AN AUTHORIZED WPG DEALER Rev 14.0/4-18 PT410AC: #35140... -

Page 29: Limited Warranty

Contact your dealer or the Technical Service Department at Wood’s Powr-Grip Co. for assistance. Wood's Powr-Grip Co., Inc. 908 West Main St. / P.O. Box 368 Laurel, MT USA 59044 phone 800-548-7341 phone 406-628-8231 fax 406-628-8354 Rev 14.0/4-18 PT410AC: #35140... - Page 30 Rev 14.0/4-18 PT410AC: #35140...

- Page 31 Rev 14.0/4-18 PT410AC: #35140...

- Page 32 Rev 14.0/4-18 PT410AC: #35140...

- Page 33 Rev 14.0/4-18 PT410AC: #35140...

- Page 34 Rev 14.0/4-18 PT410AC: #35140...

- Page 35 Rev 14.0/4-18 PT410AC: #35140...

- Page 36 Rev 14.0/4-18 PT410AC: #35140...

- Page 37 Rev 14.0/4-18 PT410AC: #35140...

- Page 38 Rev 14.0/4-18 PT410AC: #35140...

Need help?

Do you have a question about the PT410AC and is the answer not in the manual?

Questions and answers