Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tatu Marchesan RTA-6

- Page 1 RTA-6 RTA-6 OPERATOR’S MANUAL...

- Page 2 IDENTIFICATION Dealer: Owner: Firm / Farm: City: State: No. of the Certificate of Guarantee: Serial / No.: Date: Invoice No.: Product: Notes:...

- Page 3 MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. Marchesan Av., 1979 - Zip Code 15994-900 - Matão - SP - Brazil Telephone 55.16.3382.8282 www.marchesan.com.br RTA-6 - Rev. 07 - Jul/22...

-

Page 4: Table Of Contents

Replacing the bucket Hose routing Hydraulic circuit 52 & 53 Hydraulic cylinder maintenance / assembly 54 & 55 Hydraulic safety Cardan shaft maintenance / Backhoe maintenance Troubleshooting guide 58 & 59 9. Important data 10. Important RTA-6 - Rev. 07 - Jul/22... -

Page 5: To The Owner

- The warranty shall not be applied to any equipment or any part that has been altered elsewhere than at the place of manufacture, or which the original purchaser thereof at retail has used or allowed to be used parts, not made or supplied by Marchesan. RTA-6 - Rev. 07 - Jul/22... -

Page 6: To The Operator

Follow every recommendation, warning and safety practice that can be found inside this manual, as any accident may lead to injuries or death. REMEMBER, ACCIDENTS MUST BE AVOIDED! REMEMBER, ACCIDENTS MUST BE AVOIDED! RTA-6 - Rev. 07 - Jul/22... - Page 7 Never transport the equipment on highways or paved roads. Avoid that the tractor wheels touch the drawbar in sharp turns. Always use the safety locks to carry out any maintenance or to transport the equipment. RTA-6 - Rev. 07 - Jul/22...

- Page 8 Always use the seat belt during operation. Every professional should be oriented when lifting and carrying heavy loads to avoid any serious accident or injury that a bad execution of this process may cause. . RTA-6 - Rev. 07 - Jul/22...

- Page 9 Personal clothing must be used. Avoid tight or hanging clothes that may become entangled to the moving parts of the equipment may become entangled to the moving parts of the equipment. NOTE - Only certified PPE must be used. RTA-6 - Rev. 07 - Jul/22...

- Page 10 14. In case of a fire outbreak or any possible hazard, the operator must leave the area as fast as possible and look for a safe place. Always have emergency numbers in hands. 15. In case of emergency, know how to stop the tractor and equipment quickly. RTA-6 - Rev. 07 - Jul/22...

- Page 11 22. If there is any doubt after reading it, ask your dealer. For more complicated operations, there will be the right person to help you there. 23. Please check the general safety instructions on the back cover of this manual. RTA-6 - Rev. 07 - Jul/22...

- Page 12 11. Check all laws and regulations regarding the height limits and load width while transporting the equipment on truck or trailer. If necessary use banners, lights and other devices to give adequate warning to the other drivers. RTA-6 - Rev. 07 - Jul/22...

- Page 13 • This Regulatory Standard has the purpose to establish the precept to be applied on the organization and on the working environment, in order to make compatible the planning and development of agriculture, livestock, forestry, forest exploration and aquaculture with safety on the working environment. RTA-6 - Rev. 07 - Jul/22...

- Page 14 The equipment has adequate lifting points located on the frame. When lifting the equipment with a hoist, it is essential to hitch the cables to all of these points, retreat every cylinder and place the transport lock (A). RTA-6 - Rev. 07 - Jul/22...

- Page 15 • On long courses and on roads use the safety • En trayectos extensos y en carreteras use las • Em longos percursos e em estradas utilize os signs. señales de alerta. sinais de alerta. 05.03.03.0595 RTA-6 - Rev. 07 - Jul/22...

- Page 16 2. To the operator Safety decals RTA-6 - Rev. 07 - Jul/22...

- Page 17 Lifting points decal 05.03.03.4078 05.03.03.1428 Read the manual decal Lubricate and tighten daily decal 05.03.03.1827 05.03.03.1427 PTO decal 540 rpm decal 05.03.03.2949 05.03.03.4380 Precautions during work / transportation decal Danger decal 05.03.03.0594 05.03.03.0595 Attention decal RTA-6 - Rev. 07 - Jul/22...

- Page 18 T H E M A I N VA LV E I S C A L I B R AT E D F O R 1 8 0 k g f / c m ² I N T H E C O N T R O L VA LV E I N L E T. ( 2 , 5 6 0 p s i ) LA VÁLVULA PRINCIPAL, EN LA ENTRADA DEL COMANDO, SE CALIBRA PARA 180 kgf/cm² (2560 lbs/pulg²) 05.03.03.0596 NOTE - Never change the control valve adjustments. RTA-6 - Rev. 07 - Jul/22...

-

Page 19: Data Sheet

It is especially developed for agricultural use and it should be used with wheeled agricultural tractors (in a range from 60 - 70 cv). Our RTA-6 provides high performances in services such as drainage, canal opening and preservation, and to install underground lines up to three meters deep. - Page 20 C - Reach (from boom pivot point) ..............4400 mm D - Bucket rotation angle ................160 degrees NOTE - The measures above are approximated and may vary according to the brand, model and type of the tractor tires. RTA-6 - Rev. 07 - Jul/22...

- Page 21 G - Stabilizer pad transport width ................2050 mm H - Stabilizer pad working width ................3300 mm NOTE - The measures above are approximated and may vary according to the brand, model and type of the tractor tires. RTA-6 - Rev. 07 - Jul/22...

- Page 22 12" 16" 18" 20" 24" Total weight: (RTA-6 with a 16" bucket) ..............1,205 kg Hydraulic system Hydraulic gear pump with a 35 liters/minute flow at 540 rpm speed Hydraulic oil reservoir capacity ................55 liters Return filter and oil level indicator Hydraulic oil required ....................65 liters...

-

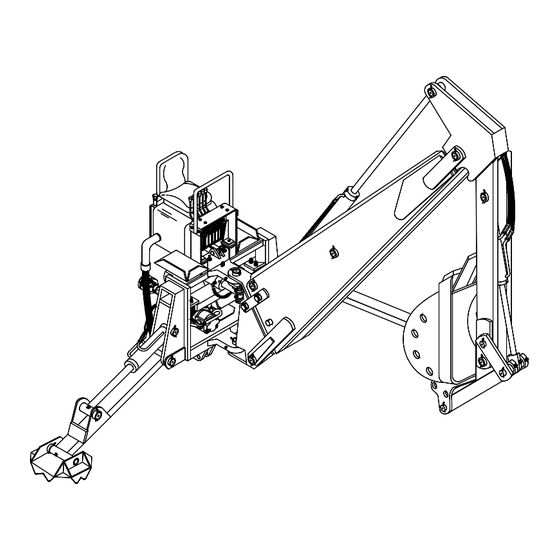

Page 23: Components

11 - Swing post 12 - Plateau 13 - Hydraulic gear pump 14 - Stabilizer pad 15 - Stabilizer arm 16 - Safety platform 17 - Cardan shaft 18 - Oil reservoir 19 - Ladder RTA-6 - Rev. 07 - Jul/22... - Page 24 4. Components Bucket models 12" 12" 16" 16" 20" 20" 18" 18" 24" 24" V-bucket - 12" V-bucket - 12" Exclusive use to Exclusive use to clean up canals clean up canals RTA-6 - Rev. 07 - Jul/22...

-

Page 25: Assembly

Assemble the hydraulic pump as follows: 1. Couple the pump (A) and the pump protection cover (C) to the support (B) using bolts (D), spring washers and nuts. 2. Assemble the cardan shaft (E) to the pump (A). RTA-6 - Rev. 07 - Jul/22... -

Page 26: Set-Up Instructions

The operator must known the tractor operation commands to assure safety, preservation and integrity of the tractor, as well as to allow an efficient and correct operation. RTA-6 - Rev. 07 - Jul/22... -

Page 27: Hitching To The Tractor

4. Couple the cardan shaft to the tractor power take-off and lock it using a pin. 5. Start the tractor engine and activate the power take-off, firstly in low rotation. NOTE - From this point on, make sure to use the levers and its respective cylinders properly. RTA-6 - Rev. 07 - Jul/22... - Page 28 Guide Guide Frame Frame PTO shaft PTO shaft Cardan Cardan shaft shaft Pump Pump Stabilizer Stabilizer NOTE - Always check the support bar (A) assembly before hitching the equipment to the tractor. RTA-6 - Rev. 07 - Jul/22...

- Page 29 - Maneuvers in reverse gear are not allowed when the cardan is stopped. This practice is extremely harmful to the terminals and universal joints. - If it is necessary to perform a maneuver, make it while the cardan is moving. RTA-6 - Rev. 07 - Jul/22...

-

Page 30: Reducing The Cardan Shaft Length

7. The chains of the protective covers should be fastened in the equipment and in the tractor, so that they will not get loose during maneuvers. RTA-6 - Rev. 07 - Jul/22... -

Page 31: Cardan Shaft Assembly

- When coupling the cardan shaft to the tractor PTO, fasten the chain on some point of the tractor so that the cardan cover will not turn and will not get loose during maneuvers. RTA-6 - Rev. 07 - Jul/22... -

Page 32: Longitudinal Leveling

- After hitching the backhoe to the tractor, the hydraulic lifting system (third point) can no longer be activated. Thus, position and undulation levers must be kept totally lowered, either during digging and transportation. RTA-6 - Rev. 07 - Jul/22... - Page 33 3. Lower the dipper and the bucket, resting them on the ground. 4. While still using the control levers, remove the hitching pins from the third point and from the lower arms. 5. Uncouple the cardan shaft from the tractor power take-off. RTA-6 - Rev. 07 - Jul/22...

- Page 34 6. Never leave the tractor with the engine running without the operator being present. 7. Check the tires inflation. 8. Be careful when hitching or unhitching the equipment, especially when using the power take-off. RTA-6 - Rev. 07 - Jul/22...

-

Page 35: Precautions With The Backhoe Transportation

(A) is activated. 6. Check if the ladder (B) is properly fastened by the ladder lock (C). 7. When going up or down the safety platform, always use the rope (D) to help the ladder displacement. RTA-6 - Rev. 07 - Jul/22... -

Page 36: Adjustments And Operations

- A l w a y s u s e t h e s e a t b e l t d u r i n g operation. ERGONOMY - This equipment follows the ITEM 17.6.3 of the NR-17 regulatory standard (version oct. 21). RTA-6 - Rev. 07 - Jul/22... -

Page 37: Operation Techniques

The operator must inspect the construction site to observe any potencial danger in the area. The operator must also have full compreension of every job that needs to be performed. RTA-6 - Rev. 07 - Jul/22... - Page 38 6. When operating the unit on a delicate surface (such as concrete, or stone work, or on sandy, loose, or soft ground), place plywood under the stabilizers to help distribute the load over a wider area. Plywood Plywood Plywood Plywood RTA-6 - Rev. 07 - Jul/22...

- Page 39 6. All the digging process must have a soft cycle, which should be repeated until the whole digging is completed. RTA-6 - Rev. 07 - Jul/22...

- Page 40 NOTE - Remember to make the cuttings in smooth cycles. This reduces the operator tiredness and the wear of the equipment, while increasing productivity and work efficiency at the same time. RTA-6 - Rev. 07 - Jul/22...

- Page 41 3. Position the unit so the backhoe swing post is over the center line of the trench connection. 4. Dig with the backhoe at extreme swing positions, and in as close to the stabilizers as possible. 5. Pile the soil on the opposite side of the trenches. RTA-6 - Rev. 07 - Jul/22...

- Page 42 7. Adjustments and operations Operation techniques 6. Position the unit forward so the two trenches can be connected. Pile the spoil on the opposite side of the trench. RTA-6 - Rev. 07 - Jul/22...

- Page 43 Operation techniques Special application - Digging on slopes: 1. When digging on slopes, keep the backhoe facing upwards. 2. If required, build a leveled surface in the hill for the backhoe to sit before digging. RTA-6 - Rev. 07 - Jul/22...

- Page 44 If a section of pipe is to be replaced, strip the soil from both ends of the bellhole. 4. Enlarge the hole enough to allow the workmen adequate working space in the leak area. RTA-6 - Rev. 07 - Jul/22...

- Page 45 1. Move the backhoe in at an angle to the wall. 2. Concentrate on getting the swing pin as close to the wall as possible while leaving enough swing arc left to dump the earth. RTA-6 - Rev. 07 - Jul/22...

- Page 46 4. Return the bucket to the spoil pile and continue the cycle until the job is completed. IMPORTANT - Avoid constant jarring or hammering contact between the spoil pile and the loaded bucket as this may cause premature wear to the backhoe pins and bushings. RTA-6 - Rev. 07 - Jul/22...

-

Page 47: Operations - Important Points

18. Be aware of your backhoe limitations. Do not use it in services to which it was not designed. 19. Never operate the backhoe sitting on the structure or beside it. Operate it from the seat. 20. Wear appropriate clothes and footwear to operate the tractor and backhoe. RTA-6 - Rev. 07 - Jul/22... -

Page 48: Maintenance

2. Remove the remainder old grease around the articulations. 3. Clean the grease fitting with a cloth before inserting lubricant and replace the defective ones. 4. Introduce an enough amount of new grease. 5. Use medium consistency grease. RTA-6 - Rev. 07 - Jul/22... -

Page 49: Lubrication / Lubrication Points

8. Maintenance Lubrication points Lubricate every 10 working hours: NOTE - Lubricate the points shown above and all grease fittings as well. RTA-6 - Rev. 07 - Jul/22... - Page 50 Hoses, cylinders, pumps and similars do not require periodic maintenance, but they should be kept in good conditions. RTA-6 - Rev. 07 - Jul/22...

- Page 51 4. Do not repair the hydraulic system while it is under pressure or the cylinders are under load. This behavior may cause severe accidents. 5. Follow the maintenance and repair plans in order to keep the equipment in safe working conditions. RTA-6 - Rev. 07 - Jul/22...

-

Page 52: Replacing The Bucket

6. Install the junction axle (D) and bushing, fastening it with a cotter pin. 7. Install the junction axle (E) and the flat washer, fastening them with a cotter pin. 8. Lubricate both grease fittings on the junction axles before operation. RTA-6 - Rev. 07 - Jul/22... -

Page 53: Hose Routing

Right stabilizer 01 - Left 01 - Left stabilizer stabilizer 06 - Right 06 - Right stabilizer stabilizer 07 - Left 07 - Left stabilizer stabilizer 12 - Right 12 - Right stabilizer stabilizer RTA-6 - Rev. 07 - Jul/22... -

Page 54: Hydraulic Circuit

8. Maintenance Hydraulic circuit RTA-6 - Rev. 07 - Jul/22... - Page 55 ATTENTION! RISK OF ACCIDENT - Do not make any repair when the system is pressurized or if the cylinder is under load. - Use proper hand and eye protection to search for high-pressure hydraulic leaks. RTA-6 - Rev. 07 - Jul/22...

-

Page 56: Hydraulic Cylinder Maintenance / Assembly

7. Inspect the inside of the cylinder barrel, piston, rod and other polished parts for burrs and scratches. Smooth areas as needed with an emery cloth. NOTE - Do not clamp rod by chrome surface. RTA-6 - Rev. 07 - Jul/22... - Page 57 IMPORTANT - Insert the gland (E) on the cylinder head and align it with the tube so it will fit correctly on the cylinder barrel. NOTE - Do not clamp rod by chrome surface. RTA-6 - Rev. 07 - Jul/22...

-

Page 58: Hydraulic Safety

Carry out the operations on a carefully and controlled manner. Avoid to let the hydraulic system working when it is not being used. Failure to follow these procedures may lead to fatal accidents or even death. RTA-6 - Rev. 07 - Jul/22... - Page 59 The operator must know the need to keep these decals in place and in good conditions. Also, the operator must be aware that an accident can occur if the instructions are not followed. NOTE - Use TATU original parts only. RTA-6 - Rev. 07 - Jul/22...

-

Page 60: Troubleshooting Guide

Dirt oil. replace the filter. backhoe. Oil leakage through the Replace the gaskets. cylinder gasket. IMPORTANT - Only QUALIFIED, CAPABLE and AUTHORIZED personnel must carry out the maintenance of the equipment. RTA-6 - Rev. 07 - Jul/22... - Page 61 Broken return spring connection. Replace the spring. Strange object on the reel hole. Clean the valve. IMPORTANT - Only QUALIFIED, CAPABLE and AUTHORIZED personnel must carry out the maintenance of the equipment. RTA-6 - Rev. 07 - Jul/22...

-

Page 62: Important Data

5008,386 c) Newton-meters M 39 x 1.5 1073 1454,988 2860,5 3878,84 4201,5 5697,234 d) Nominal thread diameter in millimeters x thread pitch Values are for reference and are based on average steel-to-steel friction conditions. RTA-6 - Rev. 07 - Jul/22... -

Page 63: Important

Serial number.: 05.01.09.0743 Revision: 07 MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. MARCHESAN IMPLEMENTOS E MÁQUINAS AGRÍCOLAS "TATU" S.A. Marchesan Av., 1979 - Zip Code 15994-900 - Matão - SP - Brazil Telephone 55.16.3382.8282 www.marchesan.com.br RTA-6 - Rev. 07 - Jul/22... - Page 64 Notes RTA-6 - Rev. 07 - Jul/22...

- Page 66 www.marchesan.com.br...

Need help?

Do you have a question about the RTA-6 and is the answer not in the manual?

Questions and answers