E-one EXTREME Series Typical Installation Instructions & Warranty Information

Hide thumbs

Also See for EXTREME Series:

- Service manual (84 pages) ,

- Typical installation instructions & warranty information (23 pages) ,

- Installation instructions & warranty information (20 pages)

Summary of Contents for E-one EXTREME Series

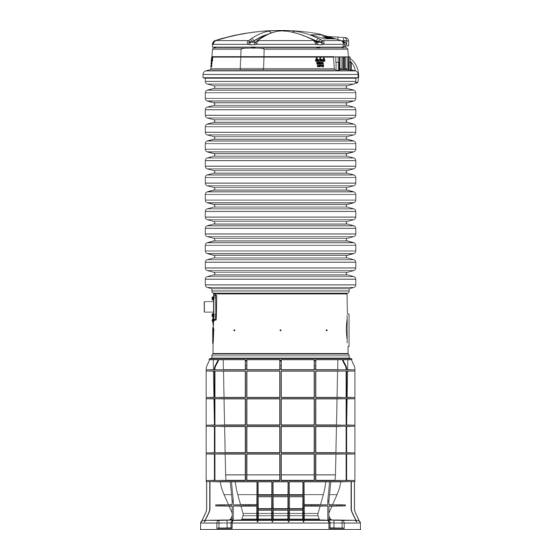

- Page 1 DH071 & DR071 Typical Installation Instructions & Warranty Information Simplex Station 70-Gal. Capacity...

- Page 2 Environment One Grinder Pump Feature Identification 1. GRINDER PUMP BASIN – High density polyethylene (HDPE). 2. ACCESSWAY COVER – HDPE 3. ELECTRICAL QUICK DISCONNECT (EQD) – Cable from pump core terminates here. 4. POWER AND ALARM CABLE – Circuits to be installed in accordance with local codes. 5.

- Page 3 Figure 1a Figure 1b FAILURE TO COMPLY WITH INSTALLATION INSTRUCTIONS WILL VOID WARRANTY...

-

Page 4: Tank Installation

The Environment One grinder floor, it must be a flat and level with an 8” tube before pouring. pump is a well-engineered, bearing surface. If the tank is There must be a minimum reliable and proven product; to go into the basement floor, clearance of three feet directly proper installation will assure it must be anchored to prevent... - Page 5 The unit should be leveled 4. DISCHARGE: The use possible. Check local codes for and the wetwell filled with water of 1-1/4” PVC pressure pipe applicable requirements. to the bottom of the inlet to help Schedule 40 and polyethylene CAUTION: Redundant check prevent the unit from shifting.

-

Page 6: Electrical Connection

the native soil is sand or if a the wetwell or through the cover must be contained in high, fluctuating water table incoming sewer line with a 2” suitable conduit. This includes is expected. Class I, angular pipe (the vent must be within the vertical portion dropping crushed stone, offers an added 4 feet of the grinder pump,... -

Page 7: Test Procedure

station to protect the exposed discharge shutoff valve is fully d) Verify that the high level cable where it enters the open. This valve must not alarm turns off and then the station. Four self-tapping be closed when the pump is pump turns off. - Page 8 Field Joint Assembly Instructions IT IS EXTREMELY IMPORTANT THAT THE JOINT IS SEALED PROPERLY BEFORE BACKFILLING. EXCAVATING A UNIT FOR REPAIR IS VERY EXPENSIVE AND CAN BE EASILY AVOIDED BY USING PROPER CAUTION DURING THE FOLLOWING PROCEDURE. Parts included in Field Joint to keep the exposed sealant to tighten one bolt and then clean and dry.

-

Page 9: Lifting Instructions

Lifting Instructions FAILURE TO FOLLOW THESE INSTRUCTIONS COMPLETELY WILL VOID THE WARRANTY. Transporting unit to installation site: Always lift a unit from the bottom for the purpose of transportation. The station should be received attached to a pallet for this purpose. - Page 10 Grinder Pump Station Ballast Calculation and Assumption Grinder Pump Station Ballast Calculation and Assumption Any buried vessel that is submerged or partially submerged in water will be acted on by an upward buoyant force that attempts to return the vessel to a non-submerged state. The magnitude of this Any buried vessel that is submerged or partially submerged in water will be acted on by an upward buoyant force is equal to the volume of the vessel that is submerged multiplied by the density of water.

- Page 11 ���� ���� ���� = ���� ���� ���� ���� ( − ���������������� �������������������� ���� ���� ������������ ���� ���� = 92 ���� 3.14 ���� ( − ������������ ���� ���� = 8381 ���� ���� 3 = 4.85 �������� 3 ������������ ���� ���� ���� ���� ����...

- Page 12 Adjusting the Height of the Grinder Pump Station TO INCREASE STATION HEIGHT 6 INCHES 1. Increasing station height can be done without cutting the station. Use the E/One Extender cover shroud kit (ND0082G01) and follow the instructions that are included with the kit. TO INCREASE STATION HEIGHT MORE THAN 6 INCHES or TO REDUCE THE STATION HEIGHT: REMOVE EXISTING COVER ASSEMBLY (Fig.

- Page 13 11. Attach the vent pipe extension with the 2” vent coupling, bringing the vent well above grade. 12. Clean all dirt and debris from top four corrugations on tank. Install the 24” coupler O-ring on the tank between the top two corrugations with the white or yellow line facing out and on top. 13.

- Page 15 A Precision Castparts Company Environment One Corporation 2773 Balltown Road Niskayuna, New York 12309–1090 Voice: (01) 518.346.6161 Fax: 518.346.6188 NA0061P01 Rev F www.eone.com 09/23...

-

Page 16: General Information

User Instructions for the Environment One Grinder Pump General Information Your home is served by a low pressure sewer system; the key element is an Environment One grinder pump. The tank collects all solid materials and wastewater from the house. The solid materials are then ground to a small size suitable for pumping as a slurry with the wastewater. -

Page 17: Limited Warranty

E/One Sewers Limited Warranty For E/One Extreme D-Series, W-Series & Upgrade Environment One Corporation offers a limited warranty that guarantees its product to be free from defects in material and factory workmanship for a period of two years from the date of installation, or 27 months from the date of shipment, whichever occurs first, provided the product is properly installed,...

Need help?

Do you have a question about the EXTREME Series and is the answer not in the manual?

Questions and answers