Summary of Contents for DAV TECH DA 400 EVO

- Page 1 Installation and maintenance guide DISPENSING VALVE DA 400 EVO DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY Tel. 0039 0444 574510 - Fax 0039 0444 574324 davtech@davtech.it - www.davtech.it...

- Page 2 Installation and maintenance guide Index 1 INTRODUCTION pag. 3 2 USER INTRUCTIONS pag. 4 3 DESCRIPTION pag. 10 4 INSTALLATION pag. 11 5 OPERATION pag. 13 6 MANITENANCE AND SERVICING pag. 15 7 DIMENSIONS AND SPARE PARTS pag. 19 8 SPARE PARTS AND ACCESSORIES pag.

-

Page 3: Technical Description

Reproduction of any part of this manual, in any form, without the express written permission of DAV Tech. The text and illustrations in this manual are not binding, the DAV tech reserves the right, at any time and without notice, the right to make any changes to improve the product or for reasons of character manufacturing or commercial. - Page 4 Instructions. All such information should be observed in the interests of effective device operation. 2.3 Intended use The DA 400 EVO valve has been built according to the EC directive in line with the latest state of the art and the recognised rules of engineering.

- Page 5 DISPENSING VALVE DA 400 EVO 2.4 Reasonably foreseeable incorrect use WARNING! Risk of injury! Using the automatic valve in a way other than intended can lead to serious damage! Using them in a way that differs from or goes beyond the intended use is considered improper use! For damage arising from improper use: >...

- Page 6 Installation and maintenance guide 2.5 Risks associated with using the product During use, there is a possible risk of: > injury to life and limb of the operator or third parties. > damage to the product itself. > other damage. NOTE! Knowledge of the safety and user instructions in this manual is the basis for safe and fault fault-free operation.

- Page 7 DISPENSING VALVE DA 400 EVO WARNING! Danger! In addition to the precautions recommended by the manufacturer, the operator must take appropriate steps to guard against the risks arising from residual energy. Personnel must be instructed about the risks and the countermeasures to be taken.

- Page 8 Installation and maintenance guide 2.7 Obligations of the operator The operator is obliged only to allow persons to work with the product who: > are familiar with the fundamental regulations relating to work safety and accident prevention. > have been instructed in working with the product, and >...

- Page 9 DISPENSING VALVE DA 400 EVO NOTE! The use of personal protective equipment depends on the environment where the device is used and on the medium being employed. For this reason, also observe the risk assessment of the workplace prepared by the operator.

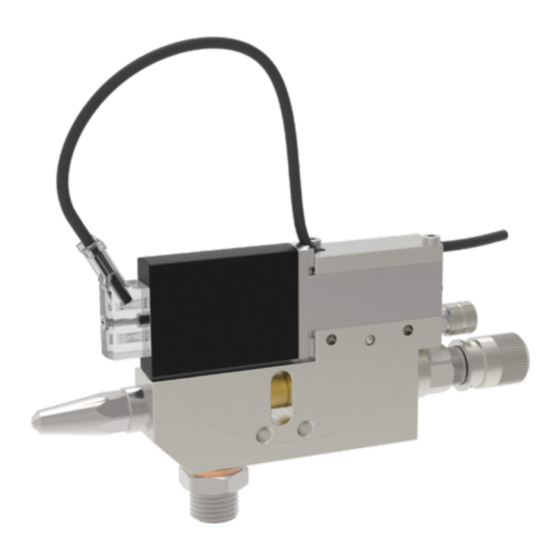

- Page 10 3.1 Functional description The DA 400 EVO extrusion valve is an electro- pneumatically controlled applicator for the application of materials such as sealants, adhesives, greases or oils. The process is generated by the control air and the material feed pressure, and can take the form of either an intermittent or a continuous process.

-

Page 11: Installation

4.1 Assembly The valve DA 400 EVO can be installed in any position. Securely and tightly screw the valve to the arm or machine. Natural oscillation occurs in intermittent operation. To achieve clean application, it is essential to avoid the transmission of natural oscillation both from the machine to the valve and from the valve to the machine. - Page 12 Installation and maintenance guide IMPORTANT! To prevent malfunctions and damage to the valve and machine or plant, it is essential to ensure that the pressure lines are connected up to the correct hose connections on the valve. Pressure line connection WARNING! Risk of injury due to compressed air and material pressure! Only qualified personnel may work on the pressure plant in accordance with the safety regulations.

-

Page 13: Operation

DISPENSING VALVE DA 400 EVO in the vicinity. To protect persons working on the device, machine or plant, effective safety devices and warning signs must be put in place. In addition, relevant safety instructions must be incorporated into the Operating/Installation Instructions for the machine or plant. - Page 14 Installation and maintenance guide If device faults cannot be corrected, inform the manufacturer’s Customer Service. Only deploy instructed personnel for regular cleaning. The device presents the following hazards during operation: WARNING! Risk of injury! Danger from the device out high high-pressure fluids. Always wear personal protective equipment when working on the device device! WARNING! Risk of hearing damage! Hearing damage may result from the volume and length of exposure to noise.

-

Page 15: Maintenance And Servicing

DISPENSING VALVE DA 400 EVO 5.3 Switching on WARNING! Risk of injury! Only trained qualified personnel may switch the device on and off in accordance with the safety and accident prevention regulations. 1. Switch on power supply. 2. Switch on the control air supply and material supply. - Page 16 Installation and maintenance guide Servicing The valve is a high-quality precision device, which will usually operate fault-free and without any servicing if handled correctly provided that only clean, filtered material is used. It is also essential that the control air is clean and, ideally, supplied to the valve lightly oiled.

- Page 17 DISPENSING VALVE DA 400 EVO 6.2 Changing the nozzle and nozzle needle 1. Depressurise all connections and stop the supply of energy and material! 2. Unscrew the lock (5) (Important: the lock is under spring tension). 3. Remove the pressure spring (4) and pull the old nozzle needle (3) out of the main body (2). As you do this, ensure that the pressure spring (4) does not get lost.

- Page 18 6. Screw in the new sealing screw (3), making sure that the sealing screw is lightly greased with technical Vaseline. (see Ch. 6.4) 7. Reassemble the DA 400 EVO in the reverse order. 6.4 Changing the sealing elements of the sealing screw 1.

- Page 19 DISPENSING VALVE DA 400 EVO 7 DIMENSIONS AND SPARE PARTS 7.1 Valve dimensions Main body with side connection NOZZLE DIMENSION IN MM DA 21.5 MA 42.5 approx. 125 DA 39.5 MA 50.5 approx. 143 . 19...

- Page 20 Installation and maintenance guide 7.2 Spare parts DA 400 EVO...

- Page 21 DISPENSING VALVE DA 400 EVO 7.3 Spare parts list DA 400 EVO Ref. Description Code NOZZLE see next table MAIN BODY DA 400 EVO 511051 O-RING 640021 VARISEAL 640004 PLASTIC COLLAR 640101 BUSH 810013 O-RING 640026 O-RING 640046 NEEDLE COMPLETE...

-

Page 22: Spare Parts And Accessories

Nozzles (1.0) The appropriate nozzle needle: carbide nozzle needle, KV 0.2/0.3mm Installation and maintenance guide 112455) 8.2.1 KV version 8 SPARE PARTS AND ACCESSORIES Nozzle, KV/B, stainless steel (B: Teflon coated) Nozzle, KV, stainless steel 8.1 General and safety instructions for use When ordering nozzle sets (nozzle needle and nozzle) as spare parts, please state the required size. - Page 23 112458 Carbide nozzle needle, LV, 0.4 mm, com In the DA 400 EVO it is possible to optionally install a raster needle sensor; The inductive sensor can be used to monitor whether the needle is open. a, 15 x min. 45 mm 112461 Carbide nozzle needle, LV, 0.5 mm, com...

-

Page 24: Adjusting The Sensor

Raster needle lock, dia, 15 x min. 45 mm Installation and maintenance guide Item no. Description 900053 Raster needle lock, dia, 15 x min. 45 mm 8.5 Adjusting the sensor The function of the raster needle sensor is depicted in the following image. 8.8.1 Adjusting the sensor The function of the raster needle sensor is depicted in Fig. - Page 25 DISPENSING VALVE DA 400 EVO 9 FAULTS 9.1 General and safety instructions in relation to faults Only qualified electricians/electronic technicians/engineers may rectify faults. Mechanical, pneumatic or hydraulic faults must be rectified by personnel trained and qualified in the relevant field.

-

Page 26: Transport, Packaging And Storage

Installation and maintenance guide 10 TRANSPORT, PACKAGING AND STORAGE 10.1 Transport Always transport and store the device with great care: > Do not throw or drop the device. > Do not place objects on the device or packaging. > Protect the device from dirt, damp, heat and cold. >... -

Page 27: Declaration Of Conformity

NEEDLE VALVE DA 400 EVO CONFORMS TO THE REQUIREMENTS FOR CE MARKING according to directives 2006/42/CE, 2014/30/UE, 2014/35/UE Any modification or tampering with them discharges DAV Tech from any responsibility. Montecchio Maggiore, 16 July 2018 The legal representative Andrea Grazioli... - Page 28 DAV TECH SRL Via Ravizza, 30 - 36075 Montecchio Maggiore (VI) - ITALY - Tel. 0039 0444 574510 - Fax 0039 0444 574324 davtech@davtech.it - www.davtech.it We reserve the right to modify at any time, without notice, the specifications, dimensions and weights in this manual.

Need help?

Do you have a question about the DA 400 EVO and is the answer not in the manual?

Questions and answers