Summary of Contents for Rockwell Automation 6000G

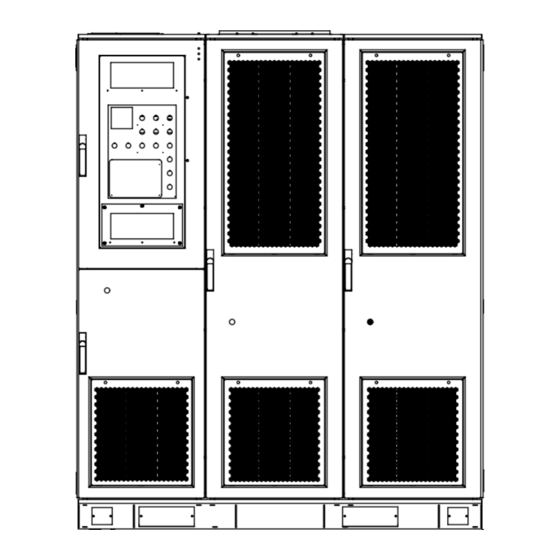

- Page 1 PowerFlex 6000 Medium Voltage Variable Frequency Drive Catalog Number 6000G Installation Instructions Original Instructions...

- Page 2 If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

- Page 3 Connect the System Ground Cable ....... . 45 Insulation Resistance (IR) Test of Power Cables ....46 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 4: Table Of Contents

Schematic Diagrams ..........73 Standard Input/Output Connection Points ......76 Wiring Details Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 5 ..............83 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 6 Table of Contents Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 7 Paper copies of the DDs and EDs are placed in the document/ hardware box in the Isolation Transformer Cabinet before shipment. Contact the local Rockwell Automation office to obtain digital copies, if necessary. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 8 This publication contains the following new or updated information. This list includes substantive updates only and is not intended to reflect all changes. Topic Page Updated table Cable Insulation Requirements for Outgoing Motor Cables Updated Important information under Power Cable Design Considerations Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 9 • Affix the cabinets to the floor (1) All or part of these activities could be provided by Rockwell Automation or its representatives, based on contract Incoterms and negotiated scope of supply/services agreement. Contact the local Rockwell Automation office for further information.

-

Page 10: Connect Incoming Line And Outgoing Motor Power Cables

Rockwell Automation to perform the power cable and control wiring interconnection work immediately before the commissioning process. - Page 11 Then remove the covers. 2. Arrange the sections as described in the Dimensional Drawings and move the sections together. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 12 DV/DT Filter Cabinet Front Front Side View 2. Secure the cabinets together using two L-shaped brackets and four M12 hexagon socket bolts, D12 washers, and D12 lock washers at the front and rear side. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 13 Access to the interior of the cabinet is required to make these connections. Access for the front connections requires only opening the doors. Access for the rear connections requires removing the back plates of the cabinet. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 14 •18 cables per motor phase (54 total) of 6.6 kV •24 cables per motor phase (72 total) for 10 kV ❹ ❹ • 27 cables per motor phase (81 total) for 11 kV ❺ ❺ Front Front Side View Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 15 • 27 cables per motor phase (81 total) for 11 kV ❼ (2) 6/6.6 kV configurations only require 18 cable hole locations per phase. Extra cable hole locations allow ❺ for added installation flexibility. Front Front Side View Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 16 (10 places) Cabinet sidesheets M10x25 hex bolt Lock washer Flat washer (x2) M10 hex nut Figure 6 - Secure the Cabinets, B-Frame Secure with M6 hardware (8 places) 2-socket screw M6x16 Combination pillar Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 17 Power Module/LV Control Cabinet Bottom View Secure the cabinet to the channel steel base using M16 bolt, lock washer, two flat washers, and a nut. (1) Mounting holes are represented as + in Figure Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 18 Figure 9 - Bolt Cabinet to Steel Base, H-Frame M16 bolt Lock washer Flat washer Figure 10 - Bolt Cabinet to Steel Base, B-Frame Lock washer M16 bolt Flat washer Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 19 Figure 11 - Welding locations Recommended weld locations Channel steel base ATTENTION: Failure to correctly anchor the cabinet may result in damage to the equipment or injury to personnel. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 20 Chapter 1 Drive Mechanical Installation Figure 12 - Typical Floor Drawing, A-Frame Non-seismic Seismic Secure the cabinet to the channel steel base using M12 bolt (recommended), lock washer, two flat washers, and a nut. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 21 1. Open MV front door and back door. 2. Remove the JC front barrier. 3. Remove two thermostats from the DIN rail in PC and TC at the right- hand side of the cabinet. Step 1 Step 2 Step 3 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 22 8. Drill anchor holes at the left-hand side of the cabinet. 9. Drill anchor holes at the right-hand side of the cabinet, then install the anchors. Step 7 Step 8 Step 9 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 23 3. Remove the back horizontal baffles, cable bracket, and all seismic covers. Step 1 Step 2 Step 3 4. Drill anchor holes at the back of the cabinet. 5. Drill anchor holes at the front of the cabinet. Step 4 Step 5 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 24 3. Remove the back horizontal baffles and all seismic covers. Step 1 Step 2 Step 3 4. Drill anchor holes at the front of the cabinet. 5. Drill anchor holes at the back of the cabinet. Step 4 Step 5 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 25 Wall bracket B Wall bracket A Wall bracket B M12xL35 Based on bracket thickness of 11 mm (0.43 in.) Frame 1 Wall bracket B Wall bracket A Wall bracket A Frame 2 Frame 3 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 26 For condition 1, installation of transformer cabinets, follow these instructions: 1. Disassemble the grounding busbar, wire duct, and barrier bracket at the front of the cabinet. 2. Disassemble the anchor cover at the front of the cabinet. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 27 1. Disassemble the grounding busbar at the front of the cabinet. 2. Disassemble the anchor cover at the front of the cabinet. 3. Drill an anchor hole. Grounding busbar Anchor cover Standard or filter cabinet Step 1 Step 2 Step 3 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 28 Wall bracket B Wall bracket A M12xL35 Based on bracket thickness of 11 mm (0.43 in.) Figure 14 - ASTM A36 Angle Bracket Dimensions Wall bracket A Wall bracket B Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 29 3. Connect the aviation plug located on top of the cabinet with the socket on the fan housing. Figure 15 - Main Cooling Fan Housing, H-Frame Main Cooling Fan housing M6 tapping screws or bolts Socket Aviation plug Rear View Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 30 3. Connect the aviation plug located on the top of the cabinet with the socket on the fan housing. Figure 17 - Main Cooling Fan Housing, A-Frame Main Cooling Fan housing Socket Noise reduction barrier Aviation plug Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 31 4. Secure the air hood with 12 M16x16 hexagon combination screws. 5. Put the fan modules onto the air hood and align with the provisions on the air hood. 6. Secure the fan modules with 16 M16x16 hexagon combination screws. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 32 Store the lift cart with the tray fully lowered. The lift cart’s hydraulic cylinder can be operated by either a hand or foot crank. The lifting capacity is 400 kg (882 lb). Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 33 552.5 x 244.5 x 663 mm (21.8 x 9.6 x 26.1 in.) 70 kg (154 lb) 351…680 A 471 x 354 x 746 mm (18.5 x 13.9 x 29.4 in.) 95 kg (209 lb) ATTENTION: Two people are required to handle the Power Modules. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 34 Power Module to confirm that there is no damage and moisture. 1. Push the Power Module slowly along the guide rails until it cannot be pushed in further. 2. After installing the Power Module in place: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 35 Power Module Guide rail Mounting brackets b. For 70 A rating – use M16x16 large flat pad galvanized nickel screws to secure two bottom corners directly. Power Module Guide rail Secure points Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 36 Screens must be installed in the air inlet. • The air inlet and outlet must not be at the same side of the drive room. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 37 Drive Mechanical Installation Chapter 1 Figure 21 - Cabinet Airflow, A-Frame Figure 22 - Cabinet Airflow, H-Frame (1) Top ducting shown by contractor. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 38 – --------------------------------------------- - tons of AC required This is for a general estimate. See the actual heat loss data to calculate air conditioning sizing. Contact the local Rockwell Automation office for actual data. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 39: Introduction

ATTENTION: The national and local electrical codes outline provisions for safely installing electrical equipment. Installation must comply with specifications regarding wire type, conductor sizes, branch circuit protection, and disconnect devices. Failure to do so may result in personal injury and/or equipment damage. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 40 4V over ground potential • the current flowing into a ground fault is of sufficient magnitude to cause the protection to operate. The general grounding point must be reliably connected with the grounding network. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 41 Follow the recommended field power cabling insulation levels to help ensure IMPORTANT trouble-free startup and operation. The cable insulation level must be increased over that which would be supplied for an across-the-line application with the same rated line-to-line voltage. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 42 Consult the Electrical Drawings and appropriate national and local electrical codes to determine correct power wiring. If assistance is needed, contact your local Rockwell Automation Sales Office. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 43 – Leave the metal sheath or foil insulated from ground, and ground the other conductors and the mesh cable screen at one end only, as stated above. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 44 Insulation Resistance (IR) Test of Power Cables Connect Incoming Line and Outgoing Motor Power Cables Connect Control Power Wiring Connect External Control Signal Wiring Connect Electrical Safety Interlock Circuit to Input Circuit Breaker Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 45 Customer/Contractor supplied Terminal Box System Ground cable Ground Bus Figure 27 - Ground Cable Connection in the Isolation Transformer Cabinet, B-Frame Customer/Contractor supplied System Ground cable Ground Bus Lock washer Flat washer M8x25 bolt Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 46 2. Connect three-phase medium voltage inputs U, V, and W for top or bottom entry to the user-provided three-phase asynchronous motor. 3. Cable clamps are provided in the cabinet to aid in routing and supporting the incoming line and outgoing motor power cables. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 47 2. Pull out the removable barrier. 3. Connect the cables. 4. Install the removable barrier in the reverse order of removal. Removable barrier Plastic M6x25 bolt, plastic nut, and plastic washer (3) Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 48 Cable clamp Bottom entry Front View Side View Figure 29 - Isolation Transformer Cabinet, A-Frame (DV/DT filter cabinet applied) Input Output Shielded cable Non-shielded cable Input Output Top entry Bottom entry Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 49 Figure 30 - Isolation Transformer Cabinet, H-Frame (Junction cabinet not applied) Outgoing motor power Voltage Sensing cable connections Board Incoming line power cable connections Isolation transformer Power cable connections to Power Modules Cable clamp Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 50 Cable clamp Figure 32 - Isolation Transformer Cabinet, B-Frame (Junction cabinet applied for cable connection) Junction cabinet Incoming line power cable connections Outgoing motor power cable connections Isolation Transformer Front View Side View Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 51: Wiring Routing And Connection

LV Control Cabinet Figure 34 - Control Power Wiring Opening, H-Frame Cable entrance in top of LV Control Cabinet Cable entrance in bottom rear of LV Control Cabinet Top Entry Design Bottom Entry Design Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 52 LV Control cabinet (Figure 36). See Figure 45 Figure 46 general overview. See Electrical Drawings for actual connection points. Figure 36 - Terminal Block Strip locations DTB1 Terminal DTB2 Terminal Block strip Block strip Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 53: Analog And Digital I/O Overview

The wiring terminates either to the DTB1 or DTB2 terminal block strips on either side of the LV Control cabinet (Figure 36). See Figure 45 Figure 46 general information. See Electrical Drawings for actual connection points. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... -

Page 54: Connect Electrical Safety Interlock Circuit To Input Circuit Breaker

Lock out and tagout the input circuit breaker before performing any work on the drive or bypass units. Figure 37 - Interlock for Cabinet Doors Door Position Limit Switch Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 55 The wiring terminates to the X1 terminal block strip on the right side of the LV Control cabinet (Figure 36). See Figure 45 Figure 46 for general information. See Electrical Drawings for actual connection points. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 56 Chapter 2 Drive Electrical Installation Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 57: Introduction

Power Module/LV Control Cabinet would be rotated 90º counter clockwise. The U phase is the top horizontal row, the V phase is the middle horizontal row, and the W phase is the bottom horizontal row. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... -

Page 58: Connect Isolation Transformer Secondary Power Cables

U output phase. The middle third are to feed the power modules in the V output phase. The bottom third are to feed the power modules in the W output phase (Figure 39). Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 59 U phase, the middle third feeds the power modules in the V phase, and the bottom third feeds the power modules in the W phase. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 60: Cable Routing And Connection

Figure 40 - 6.0/6.6 kV Power Module Configuration (1-n) U (1-n) V (1-n) W Secondary Winding Connections Secondary Winding Connections Secondary Winding Connections Power Cable to Power Module M8 Hex Nut M8 Flange Nut Front View Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... -

Page 61: Connect Motor And Voltage Sensing Board Cables

(Figure Figure 42). Figure 41 - 4.16 kV Power Module Configuration – A-Frame U Phase V Phase M6x16 bolt Motor cable to Junction cabinet W Phase VSB cable Front View Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... -

Page 62: Introduction

(Figure 43). Ground bus connection openings are provided in the cabinet sidesheets for this connection. See Table 1 on page 14 Table 2 on page Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... -

Page 63: Complete The Installation

4. Check that all electrical connections have been made and torqued as specified. 5. Verify that the safety circuit is working properly (see page 54). 6. Reinstall all cabinet back plates. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 64 Chapter 3 Drive Electrical Interconnection Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 65: Pre-Commissioning Responsibilities

Appendix Pre-Commissioning Pre-Commissioning Rockwell Automation manages the startup service for each installed drive at the customer’s site, but there are a number of tasks the customer or its representatives Responsibilities must complete before scheduling Rockwell Automation personnel for drive commissioning. -

Page 66: Pre-Commissioning Checklist

Pre-Commissioning Checklist Once all points of the checklist are complete, initial each checkbox and provide the date. Photocopy the checklist and fax the copy to the Rockwell Automation Startup Manager, along with the planned startup date. Upon receiving this checklist, the Project Manager will contact the site to finalize arrangements for a startup engineer to travel to the site at your convenience. - Page 67 The cable terminations, if stress cones are used, adhere to the appropriate standards. Appropriate cable insulation levels are adhered to, as per Rockwell Automation specifications. All shields for shielded cables must be grounded at the source end only.

- Page 68 Table 13 - Drive Line-up Status Initials Date Check The medium voltage and low voltage power is available for startup activities. The motor is uncoupled from the driven load. The load is available for full load testing. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 69: Torque Requirements

Proper tightening torque must be used for installation and wiring. Table 14 - Torque Requirements Torque Thread Size Class 8.8 N•m lb•ft 10.5 26.0 19.2 51.0 37.6 89.0 65.7 141.0 104.1 215.0 158.7 420.0 310.0 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 70 Appendix B Torque Requirements Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 71: General Wire Categories

76.2 mm Belden 9460 communication (3 in.). Belden 9463 (1) 18 AWG, twisted-pair, shielded (2) 18 AWG, 3 conductor, shielded (3) 18 AWG, twisted-pair, shielded (4) 24 AWG, twisted-pair, shielded Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 72 Appendix C General Wire Categories Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 73: Schematic Diagrams

Figure 44 - Schematic Diagram of the Drive System without a Bypass Cabinet, A-Frame (1) Wiring locations are for design reference only; actual wiring must comply with the drawings that are provided with the drive. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 74 Figure 45 - Schematic Diagram of the Drive System without a Bypass Cabinet, H-Frame (1) Wiring locations are for design reference only; actual wiring must comply with the drawings that are provided with the drive. Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 75 Power Cabling and Control Signal Wiring Details Appendix D Figure 46 - Terminal Strip Wiring Diagram for Drive System without a Bypass Cabinet Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

-

Page 76: Standard Input/Output Connection Points

User-provided normally open passive dry contact (switch quantity) Remote DCS alternate (448, 401) User-provided normally open passive dry contact (switch quantity) Remote DCS fault reset command (412, 401) User-provided normally open passive dry contact Rockwell Automation Publication 6000-IN006H-EN-P - October 2020... - Page 77 VFD-provided normally closed passive dry contact (voltage class ≤220V AC, 5 A) (used for Remote DCS) Remote control indication (948, 948A) VFD-provided normally closed active dry contact (voltage class ≤220V AC, 5 A) (used for Remote DCS) Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 78 Appendix D Power Cabling and Control Signal Wiring Details Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 79 Maximum sizing stated accounts for minimum rated cable insulation requirements and the next higher-rated cable (that is, 8 kV is not commercially available in many areas of the world, therefore Rockwell Automation provides an 8 kV (minimum rating) and a 15 kV rating, when applicable. Enclosure openings accommodate the thicker insulation on the higher-rated cable. IEC ratings show the equivalent to the NEMA sizes.

- Page 80 Maximum sizing stated accounts for minimum rated cable insulation requirements and the next higher-rated cable (that is, 8 kV is not commercially available in many areas of the world, therefore Rockwell Automation provides an 8 kV (minimum rating) and a 15 kV rating, when applicable. Enclosure openings accommodate the thicker insulation on the higher-rated cable. IEC ratings show the equivalent to the NEMA sizes.

- Page 81 Maximum sizing stated accounts for minimum rated cable insulation requirements and the next higher-rated cable (that is, 8 kV is not commercially available in many areas of the world, therefore Rockwell Automation provides an 8 kV (minimum rating) and a 15 kV rating, when applicable. Enclosure openings accommodate the thicker insulation on the higher-rated cable. IEC ratings show the equivalent to the NEMA sizes.

- Page 82 Maximum sizing stated accounts for minimum rated cable insulation requirements and the next higher-rated cable (that is, 8 kV is not commercially available in many areas of the world, therefore Rockwell Automation provides an 8 kV (minimum rating) and a 15 kV rating, when applicable. Enclosure openings accommodate the thicker insulation on the higher-rated cable. IEC ratings show the equivalent to the NEMA sizes.

- Page 83 Install Cooling Fans 29 Routing 43 Install Power Modules 32 Shield Grounding 43 Power Module Lift Cart 32 Shielded cables 43 Summary 11 Torque Requirements 69 Control Signal Wiring Details Schematic (No Bypass) 73 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 84 Isolation Transformer Cabinet Power Module Lift Cart 32 Ground Bus 62 Lifting Capacity 32 Layout 48 Operating Procedure 32 Remove Back Plates 17 Precautions 32 Secondary Power Cables 58 Secondary Winding Connections 60 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 85 Safety 66 Required Supplemental Information 7 Safety and Codes 39 ASHRAE Standard 52.2 MERV 11 36 Checklist 66 EU EN779 Class F6 36 IEC721-1 36 Lockout and tagout 39 Safety Door Switches Location 50 Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 86 Index Notes: Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 87 PowerFlex 6000 Medium Voltage Variable Frequency Drive Installation Instructions Rockwell Automation Publication 6000-IN006H-EN-P - October 2020...

- Page 88 At the end of life, this equipment should be collected separately from any unsorted municipal waste. Rockwell Automation maintains current product environmental compliance information on its website at rok.auto/pec. Allen-Bradley, expanding human possibility, FactoryTalk, Guardmaster, PowerFlex, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc. EtherNet/IP is a trademark of ODVA, Inc.

Need help?

Do you have a question about the 6000G and is the answer not in the manual?

Questions and answers