Advertisement

Quick Links

K-060VB-M1.IOM.ENG01

Installation, Operation & Maintenance

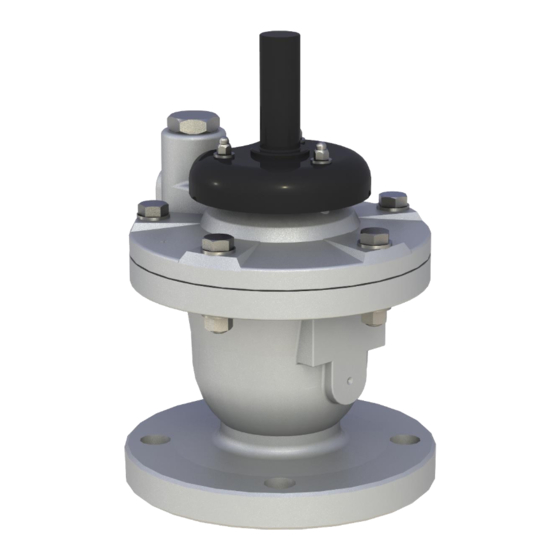

SPRING-LOADED VACUUM BREAKER

MODEL K-060VB M1

The following is a step by step narrated description of the A.R.I. K-060VB M1 Spring-Loaded Vacuum

Breaker installation, operation and maintenance processes.

The K-060VB M1 Spring-Loaded Vacuum Breaker is a normally closed full bore vacuum breaker which is

designed to open fully to allow the intake of air into the pipeline or system when vacuum conditions occur,

thus protecting the pipeline.

Negative pressure (vacuum) conditions are caused by sudden shutoff of pumps, pipe ruptures or rapid

draining of the pipeline. The K-060VB M1 can be installed both on potable water lines and on wastewater

lines.

The K-060VB M1 Spring-Loaded Vacuum Breaker is designed for water systems that operate within the

pressure and temperature framework of the model's specifications table. Please consult A.R.I. for products

designed for other wastewater or hazardous liquids systems.

Advertisement

Summary of Contents for A.R.I. K-060VB M1

- Page 1 Negative pressure (vacuum) conditions are caused by sudden shutoff of pumps, pipe ruptures or rapid draining of the pipeline. The K-060VB M1 can be installed both on potable water lines and on wastewater lines. The K-060VB M1 Spring-Loaded Vacuum Breaker is designed for water systems that operate within the pressure and temperature framework of the model's specifications table.

-

Page 2: Table Of Contents

IOM K-060VB-M1 TABLE OF CONTENTS 1. SAFETY INSTRUCTIONS ............................. 3 2. INSTALLATION ..............................6 3. OPERATION ..............................9 4. TROUBLE SHOOTING ............................9 5. PERIODIC MAINTENANCE ..........................10 6. ASSEMBLY BOM TABLE AND DRAWING ......................12 7. A.R.I. LIMITED WARRANTY ..........................14 Disclaimer This document is an Installation, Operation and Maintenance (IOM) manual for A.R.I. -

Page 3: Safety Instructions

IOM K-060VB-M1 1. SAFETY INSTRUCTIONS General 1. A.R.I. products always operate as components in a larger system. It is essential for the system designers, installers, operators and maintenance personnel to comply with all the relevant safety standards. 2. Installation, operation or maintenance of the product should be done only by qualified workers, technicians and/or contractors using only good engineering practices, complying with and observing all conventional safety instructions in order to minimize risk and/or danger and/or hazard to workers, the public or to property in the vicinity in accordance with all relevant local standards. - Page 4 IOM K-060VB-M1 Installation 1. Install the product according to the detailed Installation Instructions provided with it by A.R.I. and according to the description given in this manual. 2. The user should install a manual Isolation Valve under the product's inlet port. 3.

- Page 5 IOM K-060VB-M1 Before returning to regular operation 1. Re-assemble any protection covers or protection mechanisms removed during service or maintenance operations. 2. Make sure that all the tools, ladders, lifting devices, etc. used during the maintenance procedures are taken away from the product area and stored. 3.

-

Page 6: Installation

IOM K-060VB-M1 2. INSTALLATION Important: Before performing any work on the air valve make sure that all workers on site are familiar with the safety instructions and the relevant local and general safety instructions and work regulations. 2.1. Installation Recommendations Single Vacuum Breaker on an Isolating Valve at 45°... - Page 7 IOM K-060VB-M1 2.2. Conventions and Measurements This paragraph presents and explains the terms and measurements used for the Installation process. Isolation Valve D = Diameter of pipeline d = diameter of riser H = Height of riser on the pipeline (Measured from crown of pipeline) •...

- Page 8 3. Install an isolating valve below the vacuum breaker, connected by a riser to the crown of the pipe. 4. The K-060VB M1 Vacuum Breaker should be installed vertically on a riser on the crown of the pipeline. The riser diameter must be of an equal or greater diameter than the vacuum breaker.

-

Page 9: Operation

Orifice seat & Orifice again, very fast. If leaking continues, follow the Leakage from the Valve’s seat Sealing Assembly instructions in the Maintenance of the K-060VB M1 Inlet (Number 3, 4 & 5 on the BOM Vacuum Breaker section of this document. -

Page 10: Periodic Maintenance

IOM K-060VB-M1 5. PERIODIC MAINTENANCE Please note that the periodic maintenance of the vacuum breaker is an integral part of the proper pipeline maintenance regime; it should be maintained at least once a year in accordance with the quality and composition of the fluid in the system. - Page 11 IOM K-060-M1 5.2. Maintenance – See drawing on Section 6 of this document • Unscrew the Domed nuts (16) that connect the Screen Cover (12) to the valve’s Cover (2). • Unscrew the Bolts (22) that connect the valve Cover (2) to the Body (1). •...

-

Page 12: Assembly Bom Table And Drawing

IOM K-060-M1 6. ASSEMBLY BOM TABLE AND DRAWING Part name Material Body ASTM A744 CF8M Cover ASTM A744 CF8M Orifice Seal EPDM Orifice Seat ASTM A744 CF8M Float SAE 316 O-ring EPDM Spring SAE 302 Bridge SAE 316 Bushing AKULON Circlip SAE 304 Screen... - Page 13 IOM K-060-M1...

-

Page 14: Limited Warranty

IOM K-060-M1 7. A.R.I. LIMITED WARRANTY A.R.I. Standard International Warranty A.R.I. manufactured products are guaranteed to be free from defect in material and/or workmanship and to perform as advertised when properly installed, used and maintained in accordance with current instructions, written or verbal. Should any item prove defective within the time period set forth for that item(s), but in any case not later than within 12 (twelve) months of that product having left A.R.I.’s premises, and subject to receipt by A.R.I.

Need help?

Do you have a question about the K-060VB M1 and is the answer not in the manual?

Questions and answers