Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Tatu Marchesan ROAT2 1700

- Page 1 O P E R AT O R ' S M A N U A L ROAT² 1700 ROAT² 3400 ROAT² 3400 TL...

- Page 2 IDENTIFICATION Dealer: Owner: Firm / Farm: City: State: No. of the Certificate of Guarantee: Serial / No.: Date: Invoice No.: Product: Notes:...

- Page 3 Introduction The ROAT² 1700, ROAT² 3400 and ROAT² 3400 TL rotary cutters are used mainly on irregular soils to eliminate stubbles and clean pastures, keeping a constant blade rotation depending only on vegetation and soil conditions. The three models are provided with Duromark blades, which have an exclusive manufacturing process with a thermal treatment that allows a high resistance to wear.

-

Page 4: Table Of Contents

Table of contents 1. To the owner 2. To the operator 4 to 12 3. Data sheet 13 to 15 4. Components 16 to 18 ROAT² 1700 ROAT² 3400 ROAT² 3400 TL 5. Set-up instructions 19 to 28 Preparing the tractor / Hitching to the tractor Coupling the cardan shaft Reducing the cardan shaft length Cardan shaft assembly... -

Page 5: To The Owner

To the owner The acquisition of any Tatu product assures to the original purchaser the following rights: • Warranty certificate; • Operator's manual; • Technical assistance by the dealer on equipment delivery. However, the owner must check the condition of the equipment on delivery, as well as knowing the warranty terms. -

Page 6: To The Operator

To the operator Be careful with the environment Dear operator! Respect the ecology. Do not throw trash away. This gesture of goodwill helps to protect our environment. Products such as oil, fuel, filters, batteries and others are spilt over the soil and can penetrate to the underground layers, compromising nature. - Page 7 To the operator Never use your bare hands to check hydraulic leaks, the high pressure can cause several injuries. Never attempt to change the adjustments, clean or lubricate the equipment when the same is switched on or in movement. Be careful while driving on slopes. Risk of overturn. Prevent that chemical products (i.e.: fertilizers, treated seeds) make any contact with your skin or clothes.

- Page 8 To the operator • Only trained and qualified personnel are allowed to operate the equipment. • While working or during transportation, only the presence of the operator is allowed on the tractor. • Do not allow children to play near or over the equipment while it is operating, during transportation or storage.

- Page 9 To the operator Transportation over truck or trailer Marchesan does not advise the equipment traffic on highways, because this practice involves serious risks in addition to being prohibited by the current existing traffic law. The transportation for long distances should be done on truck, trailer or others by following these safety guidelines: •...

- Page 10 To the operator Lifting points These rotary cutters have adequate lifting points as shown on the illustration below. When lifting with a hoist, it is essential to hitch the cables to these points. Use chains, of at least 3 meters long, to lift the equipment safely. Use the adequate points for lifting and be sure that the equipment is safe.

- Page 11 To the operator Safety decals The safety decals warn about the equipment points that require more attention and they should be kept in good repair. If these decals become damaged or illegible, replace them. Marchesan provides decals, upon request and indication of the respective serial number. A A T T E E N N Ç...

- Page 12 To the operator Safety decals P P E E R R I I G G O O / / D D A A N N G G E E R R / / P P E E L L I I G G R R O O MANTENHA -SE DISTANTE - FACAS ROTATIVAS Ferimentos graves ou morte podem resultar de fragmentos ou contato com as facas.

- Page 13 To the operator Decal spots - ROAT² 1700 Item Serial number Description 05.03.03.4453 ROAT² 1700 decal set 05.03.03.4333 Marchesan logotype decal 05.03.03.1428 Read the manual decal 05.03.03.1427 PTO decal 05.03.03.2949 540 RPM decal 05.03.03.1931 Freewheeling gearbox decal 05.03.03.1929 DM special blades decal 05.03.03.1930 Rotary cutters decal 05.03.03.4247...

- Page 14 To the operator Decal spots - ROAT² 3400 Item Serial number Description 05.03.03.4454 ROAT² 3400 decal set 05.03.03.4333 Marchesan logotype decal 05.03.03.1428 Read the manual decal 05.03.03.1931 Freewheeling gearbox decal 05.03.03.1929 DM special blades decal 05.03.03.2949 540 RPM decal 05.03.03.4247 Lubrication points decal 05.03.03.1427 PTO decal...

-

Page 15: Data Sheet

Data sheet ROAT² 1700 Model: ......................ROAT² 1700 Cutting width (mm):....................1680 Number of blades: ...................... 02 Cutting height (adjustable) minimum: ..............120 mm maximum: ..............280 mm Hitching (Drawbar): ....................PTO Blades rotation (PTO at 540 rpm): ..............940 rpm Number of belts: ......................03 Tractor required (hp): .................... - Page 16 Data sheet ROAT² 3400 TL Model: ....................ROAT² 3400 TL Cutting width (mm):....................3350 Number of blades: ...................... 04 Cutting height (adjustable) minimum: ..............120 mm maximum: ..............280 mm Hitching (Drawbar): ....................PTO Blades rotation (PTO at 540 rpm): ..............940 rpm Number of belts: ......................

- Page 17 Data sheet Equipment dimensions Models ROAT² 1700 2035 ----- ---- 1360 ---- 2845 ROAT² 3400 3735 ---- ---- 1375 ---- 2990 ROAT² 3400 TL 4180 5250 1705 1375 2840 2990 NOTE • Measures in millimeters. • These measures may change due to the equipment adjustment. ROAT²...

-

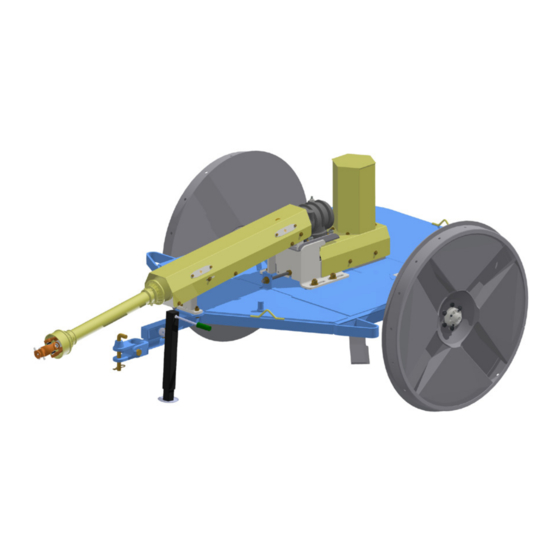

Page 18: Components

Components ROAT² 1700 01 - Frame 02 - Wheels 03 - Cardan shaft 04 - Cardan support 05 - Gearbox 06 - Tractor hitch 07 - Protection cover 08 - Parking jack 09 - Blades axle 10 - Cutting height adjustment 11 - Belts 12 - Tractor hitch pin Marchesan Implementos e Máquinas Agrícolas “TATU”... -

Page 19: Roat² 3400

Components ROAT² 3400 01 - Frame 02 - Wheels 03 - Cardan shaft 04 - Cardan support 05 - Gearbox 06 - Tractor hitch 07 - Protection cover 08 - Parking jack 09 - Blades axle 10 - Cutting height adjustment 11 - Belts 12 - Tractor hitch pin ROAT²... -

Page 20: Roat² 3400 Tl

Components ROAT² 3400 TL 01 - Frame 02 - Wheels 03 - Cardan shaft 04 - Cardan support 05 - Gearbox 06 - Tractor hitch 07 - Protection cover 08 - Parking jack 09 - Blades axle 10 - Cutting height adjustment 11 - Belts 12 - Transport wheels 13 - Transport drawbar... -

Page 21: Set-Up Instructions

Set-up instructions Preparing the tractor Before starting working, prepare the tractor and equipment properly. Check the general condition of the tractor, giving special attention to the hydraulic system. The addition of water ballasts on the tires, a set of weights on the front part of the tractor or on the rear wheels are the most used means to increase soil traction and to give a greater stability to the set. -

Page 22: Coupling The Cardan Shaft

Set-up instructions Coupling the cardan shaft First of all, check the cardan shaft length as follows: 1) Separate the cardan shaft and couple the female part to the power take- off. To do so, turn the quick lock on the clockwise direction and push it until the locking device fits. -

Page 23: Reducing The Cardan Shaft Length

Set-up instructions Reducing the cardan shaft length If it is necessary, cut similar parts of the male and female drive shaft as well as the protecting covers. But before cutting the shaft, verify all possibilities of usage without reducing its length. The length adjustment will be done when the distance between the equipment and the tractor do not allow coupling. -

Page 24: Cardan Shaft Assembly

Set-up instructions Cardan shaft assembly When assembling the cardan shaft, it is necessary to be careful and leave the terminals on both ends aligned. The discrepancy of the terminals in 90° will cause vibrations and a greater wear on the universal joints, reducing the lifetime of the set. Observe the internal forks alignment Correct assembly Correct assembly... -

Page 25: Procedures For Longitudinal Transportation

Set-up instructions Procedures for longitudinal transportation Remove the protection cover (A) from the cardan shaft by loosening up the bolts (B), nuts and washers. Also remove the cardan (C) shaft by loosening up the bolts (D) fastened to the axle (E). ROAT²... - Page 26 Set-up instructions Procedures for longitudinal transportation Loosen up the pin (G) and cotter pin and place the parking jack (F) over the rotary cutter. Then, lock it using the same pin and cotter pin. Marchesan Implementos e Máquinas Agrícolas “TATU” S.A. ROAT²...

- Page 27 Set-up instructions Procedures for longitudinal transportation Remove the semi drawbar (H) by loosening up the bolts (I), washers and nuts. L o c k t h e d r a w b a r f o r longitudinal transportation (J) to the tractor and fasten it to the hitch that can be found on the center of the right side wheel...

- Page 28 Set-up instructions Procedures for longitudinal transportation For hitching, choose a place as flat as possible. Drive the tractor slowly in reverse gear and be ready to brake. When close enough, use the lever to control the hydraulic position and leave the left lower arm on the same level as the rotary cutter hitch pin.

- Page 29 Set-up instructions Procedures for longitudinal transportation Remove the pin (M) to let the wheelsets (N) go forward. Then, use the same pin (M) and cotter pin to lock the wheelset (N) to transport position, as shown on the illustration below. Working position Working position Transport position...

-

Page 30: Assembly Of The Oil Level Marker With Breather

Set-up instructions Assembly of the oil level marker with breather Remove the plug (A) from the gearbox and place the oil level marker with breather (B). At this moment, check the oil level by just placing the marker on the hole without tightening it;... -

Page 31: Adjustments And Operations

Adjustments and operations Direction of blades rotation and serial number These rotary cutters have blades that turn in a counterclockwise direction. Counterclockwise Counterclockwise ROAT² 1700 ROAT² 1700 Counterclockwise Counterclockwise Counterclockwise Counterclockwise ROAT² 3400 ROAT² 3400 ROAT² 1700 / ROAT² 3400 / ROAT² 3400 TL Marchesan Implementos e Máquinas Agrícolas “TATU”... -

Page 32: Daily Working Preparation

Adjustments and operations Direction of blades rotation and serial number ROAT² 1700 / ROAT² 3400 - Duromark blades ......... 06.22.40.0054 Counterclockwise Counterclockwise Counterclockwise Counterclockwise ROAT² 3400 TL ROAT² 3400 TL Daily working preparation Before starting working it is advisable to do a complete check on the rotary cutter. Retighten nuts and bolts. -

Page 33: Blades Cutting Height

Adjustments and operations Blades cutting height The blades cutting height is determined by the adjustment found on their axles. To carry out the adjustment, proceed as follows: Remove the protection cover (A) by loosening up the bolts (B), spring and flat washers. Then, loosen up the lock (C) and turn the adjuster (D) to get the desired position. -

Page 34: Tension Adjustment And Belt Replacement

Adjustments and operations Tension adjustment and belt replacement Check the belts tension after the first working hour. After that, they must be adjusted daily after every 8 working hours. To adjust the belts tension, it is necessary to loosen up the four bolts (A) that fasten the gearbox base. -

Page 35: On-Field Rotary Cutter Articulation

Adjustments and operations On-field rotary cutter articulation When starting the job, lift the equipment a little to remove the blades direct contact with the field. Couple the PTO and gradually start to increase the rotation to give movement to the set of blades. Right after, move the tractor by releasing the clutch gradually and increase the rotation on the range of the allowed rotation (540 rpm) simultaneously. - Page 36 Adjustments and operations Tension adjustment and belt replacement To adjust the belts (A) tension, it is necessary to loosen up the four bolts (B) that fasten the gearbox base; then loose the counter nuts and adjust the axle (C) to stretch them.

-

Page 37: Troubleshooting Guide

Adjustments and operations Troubleshooting guide PROBLEM CAUSES POSSIBLE SOLUTIONS Worn out or broken blades. Replace them. Incorrect PTO rotation speed. Correct rotation speed: 540 rpm. Excessive speed. Reduce the speed. Blades do not work when the PTO Check the connection of the transmission Blades do not is switched on. -

Page 38: Operations - Important Points

Adjustments and operations OPERATIONS - Important points • Before starting working, it is advisable to do a complete check on the rotary cutter. Grease the universal joints, check the oil level in the gearbox and tighten nuts and bolts. • In order to couple and to uncouple the cardan shaft, the PTO should be disengaged. -

Page 39: Maintenance

Maintenance Lubrication Observe daily if the nuts and bolts are tightened and the conditions of the pins and cotter pins. The maintenance of the gearbox should be done in the following way: • When starting to work and everyday of the first working week, check the oil level through the indicators of level and fill up if necessary. - Page 40 Maintenance Lubrication points - Lubricate daily Manufacturer Specification FL-Lubrificantes Tutela Alfa 2K grease Castrol EPL 2 grease Shell Alvania EP(LF) 2 grease Ipiranga Ipiflex EP 2 grease Ipiranga Litholine EP 2 grease ATTENTION • Besides the indicated spots, it is necessary to lubricate all grease fittings.

-

Page 41: Replacement Of The Blades

Maintenance Replacement of the blades Inspect blades before each use to determine if they are properly installed and in good conditions. Replace any blade that is bent, excessively nicked, worn or has any other damage. Besides that, the blades must be replaced as soon as some cutting imperfection is being noticed. - Page 42 Maintenance NOTE • When replacing the blades it is necessary to replace the bolts (B), spring washers and nuts as well. • Use TATU original blades only, as they are made of special heat-treated alloy steel. Other blades may not meet the specifications and cause flaws. ATTENTION When replacing the blades, observe that they are supplied in pairs, which should be kept together until assembled on the rotary cutter spindle.

-

Page 43: Pulley Nuts Adjustment

Maintenance Pulley nuts adjustment During 50 - 70 hours of use, it is necessary to check the tightening of the pulley nuts in the following way: • Uncouple the cardan shaft (A) from the gearbox (B); • Loosen up the four bolts (C) that fasten the gearbox base; •... -

Page 44: Wheelset Hubs Lubrication

Maintenance Wheelset hubs lubrication The wheelset hubs must be lubricated every 150 hours. When the existence of any clearance is noticed, carry out a maintenance on the wheel hubs. Disassemble the hubs and remove their internal components. Clean all parts using diesel oil or kerosene. - Page 45 Maintenance Gearbox The gearbox must be inspected every time the rotary cutter is about to operate. If the oil level is low, fill up the rotary cutter. The oil level verification must be done in a flat place and adjusted according to the indications of the marker.

-

Page 46: Important Data

Important data Torque table The table below gives correct torque values for various bolts. Tighten all bolts to the torques specified in chart unless otherwise noted. Check the tightness of bolts periodically, using this bolt torque chart as a guide. Replace hardware with the same strength (Grade/ Class) bolt. -

Page 47: Important

Important MARCHESAN S/A reserves the right at any time to make improvements ATTENTION in the design, material or specifications of machinery, equipment or parts without thereby becoming liable to make similar changes in machinery, equipment or parts previously sold. Images are for illustration purposes only. Some illustrations in this manual appear without the safety devices, removed to allow a better view and detailed instructions. -

Page 48: Notes

Notes Marchesan Implementos e Máquinas Agrícolas “TATU” S.A. ROAT² 1700 / ROAT² 3400 / ROAT² 3400 TL...

Need help?

Do you have a question about the ROAT2 1700 and is the answer not in the manual?

Questions and answers