Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Wilkinson Star Jasic JM-250C

- Page 1 www.jasic.co.uk MIG Series MIG 250 Compact (JM-250C) Operator Manual...

- Page 2 Please ensure that you carry out daily and periodic maintenance checks to ensure years of reliable and trouble free operation. Wilkinson Star Limited are a leading supplier of equipment in the UK and our products are supported by our extensive service network.

-

Page 3: Safety Precautions

Safety Precautions These general safety norms cover both arc welding Insulate yourself from work and ground using dry insulating mats or covers big enough to prevent any physical contact machines and plasma cutting machines unless with the work ground. otherwise noted. Never touch the electrode if you are in contact with the work The equipment must only be used for the purpose it was ground, or another electrode from a different machine. - Page 4 Do not weld on coated metals, unless the coating is Replace the coverings and protections and close all doors removed from the weld area, the area is well ventilated, and when the intervention is finished, and before starting the while wearing an air-supplied respirator. The coatings on equipment.

- Page 5 Keep your head and face away from the cylinder valve outlet RF Declaration when opening the cylinder valve. Equipment that complies with directive 2004/108/EC Always secure the cylinder safely concerning electromagnetic compatibility (EMC) and the technical requirements of EN60974-10 is designed for use in Never deface or alter any cylinder industrial buildings and not those for domestic use where electricity is provided via the low voltage public distribution...

-

Page 6: Product Overview

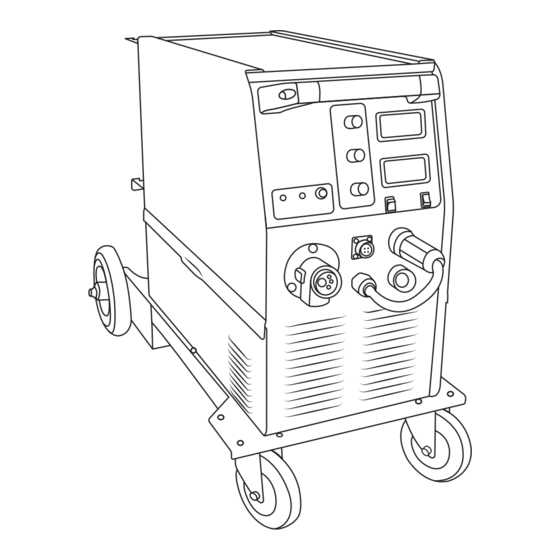

Product Overview The MIG 250 is an inverter power source that can provide MIG, MMA and gas less self- shielded welding welding options. Its IGBT power device with unique control mode provides excellent reliability with a high duty cycle. The system has a closed loop feedback control, constant voltage output, which allows it to operate with a wide tolerance to mains fluctuation, within ±15%. -

Page 7: Technical Data

Technical data MODEL MIG250 Single-phase Input voltage (V) AC230V±15%,50/60Hz Rated input current (A) Rated power supply capacity (KVA) 10.4 Recommended fuse capacity (A) MMA welding current range (A) 10〜~250 MIG current range (A) 25〜~250 MIG voltage range (V) 11〜~29 No-load voltage (V) Wire feed speed range(m/min)... - Page 8 Controls Front view Power LED Overheating LED Wire inching button Current control knob in MMA Voltage control knob in MIG Wire feed control knob in MIG Voltage meter Current meter MMA/MIG switch Pull torch switch Socket of wire pull torch control cable “+”...

- Page 9 Rear View 16. Power switch 17. Input cable 18. Power socket 19. 20. Ground connection 21. Gas solenoid inlet fitting 21. Burn back control...

-

Page 10: Installation

Installation Unpacking MMA welding Check the packaging for any signs of damage. Insert the cable plug with electrode holder into the “+” socket on the front panel of Carefully remove the machine and retain the packaging until t h e w e l d i n g the installation is complete. - Page 11 and into the drive roll groove. Adjust the pressure arm, Insert the quick plug of the gas / no gas selector into the “-” ensuring no sliding of the wire. Too high pressure will lead to output terminal on the middle plate of the welding machine, wire distortion, which will affect wire feeding.

- Page 12 Operation One second after the arc stops, the gas supply will be cut Before starting any welding activity ensure that you have off. suitable eye protection and protective clothing. Also take the necessary steps to protect any persons within the area.

-

Page 13: Maintenance And Troubleshooting

Maintenance and troubleshooting The following operation requires sufficient professional Troubleshooting knowledge on electric aspects and comprehensive Before arc welding machines are dispatched from the safety knowledge. Make sure the input cable of the factory, they have already been checked thoroughly. The machine is disconnected from the electricity supply and machine should not be tampered with or altered. - Page 14 Symptom Solution 1. Check the welding current and welding time. Refer to the manual, and operate according to the specifications.! 2. Check the running status of the fan when welding. If the fan does not The overheat LED is on. work, check if the power supply of the fan is 230V: If the power supply is normal, check the fan;...

-

Page 15: Electrical Schematic

Electrical schematic... -

Page 16: Parts List

Parts list... - Page 17 Part no Description Part no Description 10020951 10016534 Swivel wheel 10021881 Square sockets 10006625 Silicon bridge 10021912 Line button 10020611 Output absorbing board 10004951 Air Switch 10020477 Filter board 10020512 Control Board 10006231 Power supply transformer 10001256 Burn back potentiometer 10020408 Secondary Rectifier board 10002343 Output absorbing board...

- Page 18 JM MIG Series MIG/MAG/MMA WELDING MACHINE Order code ! JM-250C (MIG 250) © Wilkinson Star Limited Issue 1 January 2014 Product is subject to change without notice xvii...

Need help?

Do you have a question about the Jasic JM-250C and is the answer not in the manual?

Questions and answers