Summary of Contents for MDB MP100 Plus

- Page 1 ENGLISH Instructions USE AND MAINTENANCE MANUAL MP100 Plus MDB004AEN COMPANY WITH QUALITY MANAGEMENT SYSTEM CERTIFIED BY DNV GL ISO 9001:2015 01/2022...

- Page 2 To be completed with the actual details of the machine concerned. See chapter 3 for an explanation of the fields shown on the machine NOTICE nameplate.

-

Page 3: Table Of Contents

MP100 Plus CONTENTS CONTENTS 1 SAFETY GENERAL SAFETY REGULATIONS ........................................1.1.1 Safety procedures ................................................1.1.2 Emergency prevention ..............................................1.1.3 Preparing the work area .............................................. 1.1.4 Notice of maintenance work in progress ......................................1.1.5 Lightning precautions ..............................................1.1.6 Parking the machine safely ............................................ - Page 4 MP100 Plus CONTENTS 3.2.1 List of units ................................................... TECHNICAL SPECIFICATIONS ..........................................3.3.1 Dimensions ................................................... 3.3.2 Weight ....................................................3.3.3 Flow rate ....................................................3.3.4 Other technical specifications ........................................... 3.3.5 Engine specifications ..............................................WORK AREA ..................................................3.4.1 Operator position ................................................3.4.2 Machine directional points ............................................

- Page 5 MP100 Plus CONTENTS 5.4.3 Coolant refill 5-14 ..................................................5.4.4 Hydraulic oil refill 5-14 ................................................5.4.5 Battery connection/presence check 5-14 ........................................START-UP 5-15 ..................................................5.5.1 Manual start 5-15 ..................................................5.5.2 Remote control start 5-16 ..............................................5-17 ....................................................... 5.6.1 Main controls 5-17 ..................................................

- Page 6 MP100 Plus CONTENTS 6.4.20 Track check and tensioning 6-17 ............................................. 6.4.21 Periodic lubrication 6-18 ..............................................6.4.22 Checking tightening elements 6-19 ..........................................6.4.23 Checking lifting elements 6-19 ............................................6.4.24 Cooling system check 6-19 ..............................................6.4.25 Hydraulic system check 6-19 .............................................. 6.4.26 Electrical system check 6-19 ...............................................

-

Page 7: Safety

MP100 Plus 1 - SAFETY SAFETY GENERAL SAFETY REGULATIONS 1.1.1 SAFETY PROCEDURES Carefully read the safety information contained in this manual and follow the safety signs on the machine. › Safety signs must be affixed, periodically maintained (cleaned) and, if damaged, replaced. -

Page 8: Emergency Prevention

MP100 Plus 1 - SAFETY 1.1.2 EMERGENCY PREVENTION It is necessary to be prepared in the event of fire or accidents. › Establish general emergency procedures to be implemented in the event of fires and/or accidents. › Always keep a first aid kit and fire extinguisher within reach. -

Page 9: Safe Handling Of Fluids And Fire Prevention

MP100 Plus 1 - SAFETY 1.1.7 SAFE HANDLING OF FLUIDS AND FIRE PREVENTION DANGER Handle fuel with extreme care because it is highly flammable. In the event of combustion, explosions and fires can occur with the risk of serious injuries. -

Page 10: Precautions Against Contact With High-Pressure Liquids

MP100 Plus 1 - SAFETY 1.1.9 PRECAUTIONS AGAINST CONTACT WITH HIGH-PRESSURE LIQUIDS Pressurised liquids can penetrate the skin and eyes, causing serious injury. › To avoid this risk, the residual pressure must be discharged. › WARNING The operator must wear the following personal protective equipment: Safety footwear ›... -

Page 11: Precautions For Use Of Flammable Liquids

MP100 Plus 1 - SAFETY 1.1.12 PRECAUTIONS FOR USE OF FLAMMABLE LIQUIDS DANGER Any leakage of fuel, hydraulic oil and/or lubricant can lead to fires, with the consequent risk of serious injury. Prevent the risk of fire by performing a daily check and cleaning of the machine and immediately removing any traces or ›... -

Page 12: Precautions Against Exposure To Exhaust Gases

MP100 Plus 1 - SAFETY 1.1.15 PRECAUTIONS AGAINST EXPOSURE TO EXHAUST GASES WARNING Engine exhaust gases are toxic. If the machine has to be operated inside buildings, ensure that the space is adequately ventilated. › 1.1.16 PREVENTION OF BATTERY EXPLOSIONS DANGER The liquid contained in the battery can explode. -

Page 13: Precautions For Use Of Coolant

MP100 Plus 1 - SAFETY 1.1.17 PRECAUTIONS FOR USE OF COOLANT WARNING Contact of coolant with eyes or skin can cause serious injury, burns and permanent damage. When using coolant, always read the warnings on the package. Use a recovery and recycling system to prevent the emission of coolant liquid into the atmosphere. -

Page 14: Proper Waste Disposal

MP100 Plus 1 - SAFETY 1.1.19 PROPER WASTE DISPOSAL CAUTION Incorrect waste disposal can cause environmental and ecological damage. Contact the nearest environmental protection or recycling centre for information on the correct disposal procedures for hazardous waste such as oil, fuel, coolant, filters and electrolyte liquid. -

Page 15: Safety Pictogram Legend

MP100 Plus 1 - SAFETY SAFETY PICTOGRAM LEGEND The following safety signs have been placed on the machine. 1.2.1 WARNING PICTOGRAMS GENERAL HAZARD DANGER HOT SURFACES DANGER SUSPENDED LOADS DANGER EXPLOSIVE MATERIAL DANGER FORKLIFT TRUCKS DANGER TOXIC SUBSTANCES CRUSHING HAZARD... -

Page 16: Prohibition Pictograms

MP100 Plus 1 - SAFETY HAND-CUTTING HAZARD DANGER OF ENTANGLEMENT/SHEARING OF UPPER LIMBS 1.2.2 PROHIBITION PICTOGRAMS GENERIC PROHIBITION LUBRICATING AND CLEANING THE MACHINE WHEN IN MOTION IS PROHIBITED REMOVAL OF THE GUARDS IS PROHIBITED THE USE OF OPEN FLAMES IS PROHIBITED... -

Page 17: Requirement Pictograms

MP100 Plus 1 - SAFETY 1.2.3 REQUIREMENT PICTOGRAMS THE INSTRUCTIONS MUST BE READ BEFORE WORKING ON THE MACHINE PROTECTIVE GLOVES MUST BE WORN PROTECTIVE EYEWEAR MUST BE WORN PROTECTIVE CLOTHING MUST BE WORN SAFETY FOOTWEAR MUST BE WORN HEARING PROTECTION MUST BE WORN... -

Page 18: Hand Signals

MP100 Plus 1 - SAFETY HAND SIGNALS When the operator has to position loads in conditions with a reduced field of vision, assign a person (signaller) to signal the manoeuvres to be performed, using the specific signals established by the standards. - Page 19 MP100 Plus 1 - SAFETY MOVE THE LOAD CLOSER HORIZONTALLY Stretch one arm out in front of you, with your hand in a vertical position facing the signaller, and move your hand in the direction of the movement to be performed.

- Page 20 MP100 Plus 1 - SAFETY DISTANCE TO BE COVERED With your hands raised and facing inwards, move your hands laterally to indicate the distance to be covered. PERFORM THE MOVEMENTS SLOWLY Hold one hand still in front of the hand indicating the movements to be performed (the figure shows the command to slowly raise the load).

-

Page 21: General Information

01960690699 2.1.1 TECHNICAL SUPPORT Technical support will be provided by the Manufacturer via the portal set up by MDB (https://cloud.interactivespares.com/mdb) after logging in with the required credentials. The customer must fill out a support request, carefully following the manufacturers indications, by entering the following details: Machine model ›... - Page 22 Manufacturer, affect safety and operation, and reduce the operating life of the machine, thereby invalidating the warranty. The customer should make the request for original MDB parts through the portal established by MDB (https://cloud.interactivespares. com/mdb), after entering his or her credentials.

-

Page 23: Warranty

Unless otherwise agreed in writing, the Manufacturer guarantees that its products are free from defects, including those due to manufacturing or the material used, for a period of 12 (twelve) months, starting from the registration of the data of the MDB machine (based on the serial number displayed on the identification plate) valid for the duration of and no longer than the period indicated in the general conditions of sale, under penalty of forfeiture. -

Page 24: Preservation Of The Manual

MP100 Plus 2 - GENERAL INFORMATION PRESERVATION OF THE MANUAL The manual and its attachments: Are an integral part of the machine and must always accompany it. › Should always be kept in an easily accessible place and protected from environmental agents that could affect their integrity ›... -

Page 25: Machine Features

MP100 Plus 3 - MACHINE FEATURES MACHINE FEATURES NAMEPLATE The nameplate is positioned on the machine in the area shown in the figure. The nameplate displays the following details: Description Type of machine Model Machine model Power Engine power (kW) -

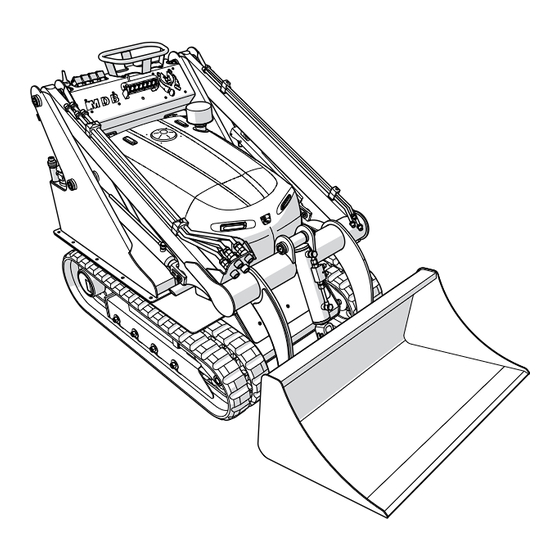

Page 26: Description

MP100 Plus 3 - MACHINE FEATURES DESCRIPTION The machine is designed for moving loads with the characteristics given in paragraph “3.10 Permitted uses” and paragraph “3.3 Technical specifications”. The machine control operations are performed by means of a remote control device, which allows the operator to operate the machine from a distance. -

Page 27: List Of Units

MP100 Plus 3 - MACHINE FEATURES 3.2.1 LIST OF UNITS 12 Control unit (receiver) Bonnet 13 Arm Engine Water-oil radiator 14 Arm movement cylinders Hydraulic oil tank 15 Blade Fuel tank 16 Bucket carriage Pump unit 17 Bucket movement cylinder... -

Page 28: Technical Specifications

MP100 Plus 3 - MACHINE FEATURES TECHNICAL SPECIFICATIONS 3.3.1 DIMENSIONS The dimensions of the machine are shown in the figure. 2177 2257 1030 1390 2330 1000 2410 Minimum overall dimensions 2230 mm x 1030 mm x 1236 mm Working configuration... -

Page 29: Weight

MP100 Plus 3 - MACHINE FEATURES 3.3.2 WEIGHT For this information, see the figures given on the inside front cover of this manual. 3.3.3 FLOW RATE For this information, see the figures given on the inside front cover of this manual. -

Page 30: Work Area

MP100 Plus 3 - MACHINE FEATURES WORK AREA The work area A where the machine operates must be cordoned off by appropriate signalling devices before the start of the work. WARNING During the use of the machine, the work area A is out-of-bounds to all people. -

Page 31: Machine Directional Points

MP100 Plus 3 - MACHINE FEATURES 3.4.2 MACHINE DIRECTIONAL POINTS In this manual, the terms Forward/Front (1), Back/Rear (2), Left (3) and Right (4) refer to the machine's travel directions, as shown in the figure RUNNING IN Each machine is carefully adjusted and tested before delivery. -

Page 32: Machine Configurations

MP100 Plus 3 - MACHINE FEATURES MACHINE CONFIGURATIONS The machine is used in the following configurations: Work and movement configuration Work-only configuration MDB004AEN_03... -

Page 33: Safety Signs

MP100 Plus 3 - MACHINE FEATURES SAFETY SIGNS MDB004AEN_03... -

Page 34: Safety Devices

MP100 Plus 3 - MACHINE FEATURES SAFETY DEVICES Control panel emergency button Bonnet maintenance position safety gas spring Remote control emergency button Ignition key switch Arm descent locking and control valve 10 “Battery disconnector” key Track motor brake release solenoid valve... -

Page 35: Professional User Profiles

MP100 Plus 3 - MACHINE FEATURES PROFESSIONAL USER PROFILES The machine is designed for professional use. The End customer is responsible for ensuring that the persons assigned to the various tasks: Read and understand the manual. › Receive adequate instruction and training for their assigned tasks, in order to perform them safely. -

Page 36: Maintenance Technician

No other use is envisaged (other than those specified in the preceding paragraph), unless expressly authorised by MDB. MDB disclaims any and all liability for malfunctions or damage to persons or property due to uses other than those indicated in this manual. -

Page 37: Personal Protective Equipment

MP100 Plus 3 - MACHINE FEATURES 3.13 PERSONAL PROTECTIVE EQUIPMENT The employer is obliged to provide personal protective equipment and to NOTICE instruct the personnel on its correct use and maintenance. The operator and/or maintenance technician must use the following personal protective equipment for all machine use and maintenance operations. -

Page 38: Remote Control Case, Documentation And Equipment

MP100 Plus 3 - MACHINE FEATURES 3.14 REMOTE CONTROL CASE, DOCUMENTATION AND EQUIPMENT The technical documentation for the machine, the various annexes and the specific equipment supplied are stored in the special case provided, in which the remote control is also housed. -

Page 39: Residual Risks

MP100 Plus 3 - MACHINE FEATURES 3.16 RESIDUAL RISKS Pay attention to the operating range of the machine. Move on a level surface. Drive the machine with the load lowered. Avoid sudden manoeuvres (acceleration, deceleration or steering). CAUTION Do not use in adverse weather conditions. - Page 40 MP100 Plus 3 - MACHINE FEATURES All fuels, many lubricants and some coolants are flammable. Check for flammability and toxicity before use. Follow the supplier's instructions, particularly with regard to storage, disposal and emergency procedures. Store flammable fluids away from any contact with fire.

-

Page 41: Emergency Devices

MP100 Plus 3 - MACHINE FEATURES 3.17 EMERGENCY DEVICES The hook 1 is an emergency device that should be used only and exclusively in the situations listed below: Machine breakdown. › Engine fault with no possibility of moving the machine. - Page 42 MP100 Plus 3 - MACHINE FEATURES 3-18 MDB004AEN_03...

-

Page 43: Unpacking, Lifting And Transport

MDB declines all liability for damage to persons or property due to failure to comply with current safety regulations with regard to the lifting and handling of the load inside the user's factory. -

Page 44: Unpacking

MP100 Plus 4 - UNPACKING, LIFTING AND TRANSPORT UNPACKING The package, upon arrival at the user's premises, must be handled with the utmost care and moved, both outdoors and indoors, with lifting devices NOTICE of adequate capacity, in accordance with the indications given on the packaging and/or on the documents accompanying the package. - Page 45 MP100 Plus 4 - UNPACKING, LIFTING AND TRANSPORT Unpack the machine as follows: Move the package to the designated location, using a forklift 4 of adequate capacity. › For the weight of the machine, see the details given on the inside front cover NOTICE of this manual.

-

Page 46: Lifting

MP100 Plus 4 - UNPACKING, LIFTING AND TRANSPORT LIFTING The machine can be lifted using the following methods: Lifting with a crane, hoist or bridge crane › Lifting with forklift › The above-mentioned method may only be used for lifting the machine onto a suitable means of transport (as indicated in paragraph “4.3 Transport”). -

Page 47: Lifting With A Crane, Hoist Or Bridge Crane

4.2.1 LIFTING WITH A CRANE, HOIST OR BRIDGE CRANE The lifting equipment (ropes or chains) must be adequately sized for the weight of the machine. CAUTION Lifting equipment (ropes or chains) is not supplied by MDB The operator must wear the following personal protective equipment: Safety footwear ›... -

Page 48: Lifting With A Forklift

MP100 Plus 4 - UNPACKING, LIFTING AND TRANSPORT 4.2.2 LIFTING WITH A FORKLIFT CAUTION The forklift must be suitably sized for the weight of the machine The operator must wear the following personal protective equipment: Safety footwear › Protective gloves ›... -

Page 49: Transport

MP100 Plus 4 - UNPACKING, LIFTING AND TRANSPORT TRANSPORT If necessary, the machine can be transported on a means of transport. The means of transport and ascent/descent ramps must be suitably sized for CAUTION the weight of the machine. The operator must wear the following personal protective equipment: Safety footwear ›... - Page 50 MP100 Plus 4 - UNPACKING, LIFTING AND TRANSPORT Unload the machine as follows: Release the machine from the vehicle, removing the ropes from the eyelets 2. › Start the machine (see chapter 5 for the procedure). › Position the bucket in the down position (see chapter 5 for the procedure).

-

Page 51: Operation And Use

MP100 Plus 5 - OPERATION AND USE OPERATION AND USE Before commissioning the machine, carefully read the following descriptions NOTICE and follow the given instructions scrupulously. CONTROL PANEL The control panel 1, positioned as shown in the figure, consists of: Display 2 ›... -

Page 52: Display

MP100 Plus 5 - OPERATION AND USE 5.1.1 DISPLAY On startup, the display shows the initial logo for a few seconds, after which it switches to the main screen, as shown in the figure. The following parameters are displayed: Engine rpm: indicates the engine speed detected by the alternator signal. - Page 53 MP100 Plus 5 - OPERATION AND USE PARAMETERS The following parameters are monitored by the control panel for the running engine: Engine rpm above set threshold › Alternator voltage above set threshold › Engine oil pressure switch open › The parameters monitored by the control panel for alarm signals are: High engine temperature ›...

- Page 54 When the engine is started, this light indicates faulty battery charging. Battery voltage Check the alternator belts and, if necessary, contact the MDB support service (see chapter 2). This light indicates that the engine temperature is higher than the permitted Engine temperature value.

-

Page 55: Programming Menu

› The basic menu is used by the operator to change some control panel parameters. The advanced menu is reserved for MDB service technicians, and is therefore password protected. BASIC MENU Press and hold buttons P1 and P2 simultaneously for five seconds. “000” will appear on the display. - Page 56 MP100 Plus 5 - OPERATION AND USE The following pages are configurable: Icon Page Description Enter this page to change the display contrast setting. Display contrast This is a useful function in ambient conditions where the display is too light or too dark.

-

Page 57: Alarms

MP100 Plus 5 - OPERATION AND USE 5.1.3 ALARMS Number Identification Description Alarm Low engine oil pressure Digital pressure switch activated (for engines with a digital sensor). Indicates low oil alarm pressure. Check that the oil level is correct High engine cooling Engine temperature above set threshold. -

Page 58: Remote Control

MP100 Plus 5 - OPERATION AND USE REMOTE CONTROL The remote control allows you to pilot the machine from a specific distance (see paragraph “3.4.1 Operator position”), and control its various working functions. The transmission frequency automatically changes to avoid sending the signals on channels already used by other devices. - Page 59 MP100 Plus 5 - OPERATION AND USE MDB004AEN_05...

-

Page 60: Remote Control Leds

MP100 Plus 5 - OPERATION AND USE 5.2.2 REMOTE CONTROL LEDS The remote control features LEDs that signal various information to the operator concerning: Machine operating states › Operating problems › Type of faults › Diagnostic functions › Battery charge level ›... -

Page 61: Controls On The Machine

MP100 Plus 5 - OPERATION AND USE CONTROLS ON THE MACHINE Control Description Arm up - Arm down Tilt bucket upwards - Tilt bucket downwards AUX1 Auxiliary control [used for tools (if present)] AUX2 Auxiliary control [used for tools (if present)]... -

Page 62: Pre-Start Checks

MP100 Plus 5 - OPERATION AND USE PRE-START CHECKS The machine is delivered in variable conditions depending on the regulations in force in the country of use. NOTICE For this reason, some of the operations listed in the following paragraphs may be unnecessary, as they have already been carried out before shipping. -

Page 63: Refuelling

MP100 Plus 5 - OPERATION AND USE 5.4.1 REFUELLING Handle fuel with extreme care because it is highly flammable. In the event of combustion, explosions and fires can occur with the risk of serious injuries. All fuel types are flammable. Do not burn or puncture the containers. -

Page 64: Engine Oil Refill

MP100 Plus 5 - OPERATION AND USE 5.4.2 ENGINE OIL REFILL Proceed as follows: Check the engine oil level and top up if necessary, as indicated in chapter 6. › 5.4.3 COOLANT REFILL Proceed as follows: Check the coolant level and top it up, if necessary, as indicated in chapter 6. -

Page 65: Start-Up

The starting operation can be repeated for a maximum of twenty consecutive seconds. Then, if the engine does not start, wait one minute NOTICE before repeating the operation. If the engine does not start after two attempts, contact MDB service. 5-15 MDB004AEN_05... -

Page 66: Remote Control Start

The starting operation can be repeated for a maximum of twenty consecutive seconds. Then, if the engine does not start, wait one minute NOTICE before repeating the operation. If the engine does not start after two attempts, contact MDB service. 5-16 MDB004AEN_05... -

Page 67: Use

MP100 Plus 5 - OPERATION AND USE The procedures described below are intended to illustrate the main controls necessary for the correct operation of the machine. NOTICE In order to perform the operations correctly and in complete safety, you must fully understand the following procedures. - Page 68 MP100 Plus 5 - OPERATION AND USE With the remote control: Move lever J5 in the direction › indicated by the arrow to tilt the bucket downwards With the controls on the machine: Move lever B in the direction ›...

- Page 69 MP100 Plus 5 - OPERATION AND USE Press switch S1 in the direction indicated by the arrow (ON), to turn on the › lights. Press switch S1 in the direction indicated by the arrow (OFF), to turn off the ›...

- Page 70 MP100 Plus 5 - OPERATION AND USE The adjustment allows the machine › to move always in alignment with Turn control knob S8 in the the direction of travel, allowing › the operator to correct the traction direction indicated by the arrow...

-

Page 71: Safety Guidelines For Use

MP100 Plus 5 - OPERATION AND USE 5.6.2 SAFETY GUIDELINES FOR USE POSITIONING THE LOAD ON THE BLADE The positioning of the load on the bucket determines the weight of the load to be lifted. For the maximum load weight to be lifted (capacity), see the details given NOTICE on the inside front cover of this manual. - Page 72 MP100 Plus 5 - OPERATION AND USE TRANSPORTING THE LOAD During transport, keep the load about 20 cm from the ground, as shown in the figure. Before starting to move, make sure that the bucket is in a tilted position, as shown in the figure.

- Page 73 MP100 Plus 5 - OPERATION AND USE Always proceed slowly, never exceeding a speed that may affect the stability of the load. DANGER Avoid starting, braking and steering abruptly. In the event of an emergency, it may be necessary to slow down in a way that may affect load stability.

-

Page 74: Picking Up And Depositing The Load

MP100 Plus 5 - OPERATION AND USE 5.6.3 PICKING UP AND DEPOSITING THE LOAD The load can be picked up/deposited either from the ground or from material transport vehicles. During lifting, the hydraulic self-levelling system keeps the bucket NOTICE positioned horizontally in relation to the ground, regardless of the position of the arm. - Page 75 MP100 Plus 5 - OPERATION AND USE PICKING UP FROM THE GROUND Approach the zone where the load is be lifted slowly, with the › bucket positioned horizontally 20 cm from the ground. 20 cm Lower the bucket towards the ground and pick up the load to be ›...

- Page 76 MP100 Plus 5 - OPERATION AND USE DEPOSITING ON THE GROUND Approach the zone where the load is be deposited slowly, with the › load 20 cm from the ground. 20 cm Raise the load and position it at an appropriate height for the ›...

-

Page 77: Parking

MP100 Plus 5 - OPERATION AND USE PARKING Proceed as follows: Identify the machine parking zone. › Move the machine to the prepared zone (using the controls indicated in the previous paragraphs). › If the bucket has to be disassembled and/or assembled, proceed as indicated NOTICE in paragraph “5.8 Removing/fitting the blade”, otherwise proceed as... -

Page 78: Removing The Blade

MP100 Plus 5 - OPERATION AND USE REMOVING/FITTING THE BLADE The procedures explained in the following paragraphs can only be carried NOTICE out with the remote control. 5.8.1 REMOVING THE BLADE Move switch S20 in the direction › indicated by the arrow. -

Page 79: Fitting The Blade

MP100 Plus 5 - OPERATION AND USE 5.8.2 FITTING THE BLADE Move lever J1 in the direction › indicated by the arrow. The plate 4 moves in the › direction indicated by the arrow, and moves towards the bucket 2. -

Page 80: Shutdown

MP100 Plus 5 - OPERATION AND USE SHUTDOWN The machine can be shut down in two different ways: Manual shutdown. › Shutdown by remote control › At the end of the work shift, the operator must check that there are no leaks NOTICE of liquids (fuel, coolant or hydraulic oil). -

Page 81: Shutdown By Remote Control

MP100 Plus 5 - OPERATION AND USE 5.9.2 SHUTDOWN BY REMOTE CONTROL Proceed as follows. Press the engine shutdown button S16. › The engine stops. › Press button S5 on the remote control to turn off the remote control. ›... -

Page 82: Hydraulic Connection Of Tools

Tools can be installed on the machine for various types of use. These tools must be connected to the machine hydraulically, using the fittings 1-2. For the types of tools that can be used (if any), contact the MDB support NOTICE service (see chapter 2), and/or see Annex E. -

Page 83: Maintenance

If parts need to be replaced, this must be done exclusively with original MDB replacement parts. MDB assumes no responsibility for damage to the machine or for accidents due to the use of non-original parts. Use of non-original parts leads to immediate forfeiture of the warranty. -

Page 84: Arm Raised Position Safety Bracket - Engine Compartment Bonnet

MP100 Plus 6 - MAINTENANCE 6.1.1 ARM RAISED POSITION SAFETY BRACKET - ENGINE COMPARTMENT BONNET Some types of maintenance require the following operations: Positioning of the safety bracket A in arm raised position. › Opening the engine compartment bonnet B . -

Page 85: Equipment Supplied

› Grease (see chapter 3 for the type of grease) › Replacement fuse kit › Fuse pliers › All maintenance equipment not expressly mentioned above is not supplied NOTICE by MDB, but is the responsibility of the end user. MDB004AEN_06... - Page 86 MP100 Plus 6 - MAINTENANCE SCHEDULED MAINTENANCE TABLE The information necessary for determining when the machine needs maintenance is given below. Carry out maintenance work in accordance with the time intervals, the indications of the hour meter (see chapter 5) and the table below.

-

Page 87: Check List

MP100 Plus 6 - MAINTENANCE 6.3.1 CHECK LIST Symbols used Description Symbol ● General indication Functional test Replacement Visual check Screw tightness check Cleaning Maintenance intervals Type of maintenance 1000 4000 General machine cleaning Checking engine oil Checking coolant Hydraulic oil level check... - Page 88 MP100 Plus 6 - MAINTENANCE Maintenance intervals Type of maintenance 1000 4000 Cooling system check Hydraulic system check Electrical system check General checks Changing the engine oil and replacing the oil filter Fuel filter check Hydraulic oil filter check Changing the engine oil and replacing the oil...

-

Page 89: Routine Maintenance

MP100 Plus 6 - MAINTENANCE ROUTINE MAINTENANCE Maintenance must only be carried out by a qualified and authorised person, referred to as the maintenance technician. The maintenance technician must be sufficiently skilled and experienced NOTICE to assess the condition of the machine and the effectiveness of personal protective equipment, based on technical norms. -

Page 90: Checking Engine Oil

Change the oil and filter after the first 50 hours of work. Subsequent oil changes and filter replacements should be carried out every 200 working hours. This operation must only be carried out by MDB service centre technicians. NOTICE For this reason, contact the MDB support service (see chapter 2). -

Page 91: Checking Coolant

MP100 Plus 6 - MAINTENANCE 6.4.6 CHECKING COOLANT Carry out this check every 8 working hours. WARNING BURN HAZARD The operator must wear the following personal protective equipment: Safety footwear › Heat resistant gloves › Protective clothing › Safety goggles ›... -

Page 92: Topping Up Coolant

Check the coolant level again as indicated in the previous paragraph, and top up it further if necessary. › 6.4.8 COOLANT CHANGE The coolant should be changed every 4,000 working hours. This operation must only be carried out by MDB service centre technicians. NOTICE For this reason, contact the MDB support service (see chapter 2). 6-10... -

Page 93: Hydraulic Oil Level Check

MP100 Plus 6 - MAINTENANCE 6.4.9 HYDRAULIC OIL LEVEL CHECK Carry out this check every 8 working hours. CAUTION The operator must wear the following personal protective equipment: Protective clothing › Safety footwear › Proceed as follows: Visually check the oil level in tank 1 using the level indicator 2. -

Page 94: Topping Up Hydraulic Oil

› 6.4.11 HYDRAULIC OIL CHANGE The hydraulic oil should be changed every 1000 working hours. This operation must only be carried out by MDB service centre technicians. NOTICE For this reason, contact the MDB support service (see chapter 2). 6-12... -

Page 95: Air Filter Check

MP100 Plus 6 - MAINTENANCE 6.4.12 AIR FILTER CHECK Carry out this check every 8 working hours. CAUTION The operator must wear the following personal protective equipment: Safety footwear › Gloves › Protective clothing › Safety goggles › Proceed as follows: Raise the arm (use the controls shown in chapter 5). -

Page 96: Cleaning The Air Filters

› 6.4.14 REPLACING THE AIR FILTERS The air filters should be changed every 1000 working hours. This operation must only be carried out by MDB service centre technicians. NOTICE For this reason, contact the MDB support service (see chapter 2). -

Page 97: Hydraulic Oil Filter Check

6.4.16 REPLACING THE HYDRAULIC OIL FILTER The hydraulic oil filter should be replaced every 1000 working hours. This operation must only be carried out by MDB service centre technicians. NOTICE For this reason, contact the MDB support service (see chapter 2). -

Page 98: Fuel Filter Check

› 6.4.19 REPLACING THE FUEL FILTERS The fuel filters should be changed every 200 working hours. This operation must only be carried out by MDB service centre technicians. NOTICE For this reason, contact the MDB support service (see chapter 2). -

Page 99: Track Check And Tensioning

MP100 Plus 6 - MAINTENANCE 6.4.20 TRACK CHECK AND TENSIONING Carry out this check every 8 working hours. CAUTION The operator must wear the following personal protective equipment: Safety footwear › Gloves › Protective clothing › Proceed as follows: Connect the tube 1 to the pump 2. -

Page 100: Periodic Lubrication

MP100 Plus 6 - MAINTENANCE 6.4.21 PERIODIC LUBRICATION Lubricate the points indicated in the figure every 8 working hours. CAUTION The operator must wear the following personal protective equipment: Safety footwear › Gloves › Protective clothing › Proceed as follows: Connect the tube 1 to the pump 2. -

Page 101: Checking Tightening Elements

NOTICE These replacements must only be carried out by MDB service centre technicians. For this reason, contact the MDB support service (see chapter 2). 6.4.24 COOLING SYSTEM CHECK Carry out the following checks every 8 working hours. Check that all tubes are in a good state of preservation. - Page 102 MP100 Plus 6 - MAINTENANCE FUSE REPLACEMENT The machine’s fuses are located in three different zones A-B-C. WARNING Short circuits can cause fires. Do not use the machine if it has loose, bent and/or damaged cables or wires. For the fuses in zone A proceed as follows: Loosen the screws 1.

- Page 103 MP100 Plus 6 - MAINTENANCE For the fuses in zone B proceed as follows: Loosen the screws 3. › Remove the casing 4. › Identify the damaged fuse and replace it, using the replacement fuse kit. › Fuse Description Amperage...

-

Page 104: Special Maintenance

NOTICE to assess the condition of the machine and the effectiveness of personal protective equipment, based on technical norms. Special maintenance must be carried out by specialised MDB technicians or authorised personnel. 6.5.1 TRACK REPLACEMENT The tracks must be replaced when the tread thickness is between 5 mm and 6 mm. - Page 105 MP100 Plus 6 - MAINTENANCE Lift the machine, leaving a gap of 150 mm between the track and the ground. › Position the safety stands under the chassis in zones 2. › 150 mm Unscrew the grease nipple 3. ›...

-

Page 106: Periodic Check And Inspection Log

MP100 Plus 6 - MAINTENANCE PERIODIC CHECK AND INSPECTION LOG Hours of Stamp and Date Work description Person in charge service signature 6-24 MDB004AEN_06... - Page 107 MP100 Plus 6 - MAINTENANCE Hours of Stamp and Date Work description Person in charge service signature 6-25 MDB004AEN_06...

- Page 108 MP100 Plus 6 - MAINTENANCE 6-26 MDB004AEN_06...

-

Page 109: Troubleshooting

The following paragraphs list possible faults or anomalies and identify a correct solution to quickly resolve the problem. In the event that the problem or its cause is not covered by the cases NOTICE indicated, contact the authorised MDB dealer. For the resolution of some problems, see chapter 6. 7.1.1... -

Page 110: Engine

Move forward and backward repeatedly until Brakes locked / hydraulic oil cold the brakes release Pump or engine problem Contact the authorised MDB dealer The engine starts but the Speed control knob on remote control Turn the speed control knob to the desired... -

Page 111: Tracks

Insufficient track tension Tension the track Worn track rubber Tension the track Track slow Insufficient track tension Damage to the track tensioning system Contact the authorised MDB dealer 7.1.4 AUDIBLE SIGNAL DEVICE Problem Cause Solution Fuel low Refill the tank... -

Page 112: Movement Devices

MOVEMENT DEVICES Problem Cause Solution The machine moves but the Auxiliary pump and/or distributor Contact the authorised MDB dealer arm does not move damaged and/or defective Remote control speed regulator set to Turn the remote control speed regulator to minimum maximum. - Page 113 MP100 Plus 8 - DISMANTLING DISMANTLING The work on the machine must be carried out by competent personnel CAUTION trained in the correct intervention and handling methods. TEMPORARY DECOMMISSIONING In the event that the machine will not be used for an extensive period, it must be made inoperative and stored in a special environment, as follows.

-

Page 114: Dismantling

MP100 Plus 8 - DISMANTLING MDB004AEN_08...

Need help?

Do you have a question about the MP100 Plus and is the answer not in the manual?

Questions and answers