Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Encore RAGE ER48FX730VL

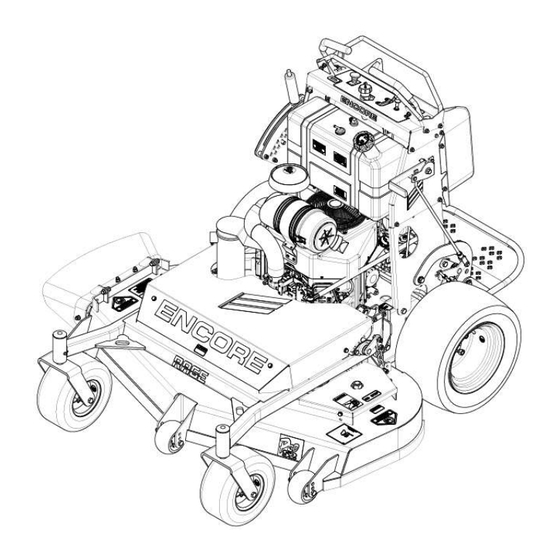

- Page 1 ER48FX730VL ER48FX730VLCA ER52FX730VL ER52FX730VLCA OPERATORS MANUAL...

- Page 2 ENCORE MANUFACTURING A DIVISION OF WORLDLAWN POWER EQUIPMENT, INC. ENCOREEQUIPMENT.COM 2415 ASHLAND AVE BEATRICE, NE 68310 800-267-4255 FAX – 402-223-4103...

-

Page 3: Table Of Contents

Contents SAFETY ................................6 Safety Alert Symbol ............................6 TRAINING ..............................6 PREPARATION ............................. 6 OPERATION ..............................8 SLOPE OPERATION ............................. 9 MAINTENANCE AND STORAGE ........................ 10 SAFETY AND INSTRUCTIONAL DECALS ....................12 SPECIFICATIONS ............................14 MODEL NUMBER ............................14 ENGINE ............................... - Page 4 DRIVING IN REVERSE ..........................18 OPERATING THE PLATFORM ........................ 18 OPERATING THE MACHINE WITH THE PLATFORM UP ............... 19 OPERATING THE MACHINE WITH THE PLATFORM DOWN ..............19 ADJUSTING THE CUTTING HEIGHT ...................... 19 TRANSPORTING ............................20 TRANSPORTING A UNIT ........................20 LOADING A UNIT.............................

- Page 5 PARK BRAKE ADJUSTMENT ........................30 FORWARD TRACKING ADJUSTMENT ....................30 NEUTRAL ADJUSTMENT ........................30 CASTER PIVOT BEARINGS PRE-LOAD ADJUSTMENT ................ 30 CLEANING ..............................31 CLEAN ALL DEBRIS FROM ENGINE AND EXHAUST SYSTEM AREA..........31 CLEAN DUST AND DIRT FROM CYLINDER HEAD FINS............... 31 CLEAN DEBRIS FROM MACHINE ......................

-

Page 6: Safety

WARNING, CAUTION. properly and safely perform the job. Use only accessories and attachments approved by ENCORE DANGER: White lettering/Red background. The use of personal protective equipment, such Indicates failure to observe the safety instructions as (but not limited to) safety glasses, hearing will result in death or serious injury. - Page 7 functioning properly. Do Not operate unless DANGER they function properly. In certain conditions during fueling, static electricity can be released causing gasoline DANGER vapors to ignite. In certain conditions gasoline is extremely A fire or explosion from gasoline can burn you, flammable and highly explosive.

-

Page 8: Operation

o Before dumping the grass catcher OPERATION o Before making height adjustments Although hazard control and accident prevention Park machine on level ground. Stop engine, are partially dependent upon the design and wait for all moving parts to stop, remove key configuration of the equipment, these factors are and engage parking brake: also dependent upon the awareness, concern and... -

Page 9: Slope Operation

WARNING DANGER Hands, feet, hair, clothing, or accessories can Mowing on wet grass or steep slopes can cause become entangled in rotating parts. Contact sliding and loss of control. with rotating parts can cause traumatic When mowing ditches or slopes recommended amputation or severe lacerations. -

Page 10: Maintenance And Storage

MAINTENANCE AND STORAGE DANGER Before any maintenance, disengage drives, lower implement, set parking brake, stop engine Charging or jump starting the battery may and remove key or disconnect spark plug wire. produce explosive gasses. Battery gases Wait for all moving parts to stop before can explode causing serious injury. - Page 11 Hydraulic fluid escaping under pressure can CAUTION penetrate skin and cause injury. Fluid accidentally injected into the skin must be If the ignition is in the “ON” position there surgically removed within a few hours by a is potential for sparks and engagement of doctor familiar with this form of injury or components.

-

Page 12: Safety And Instructional Decals

SAFETY AND INSTRUCTIONAL New safety signs may be obtained from DECALS your authorized Encore equipment dealer. Keep all safety signs legible. Remove all Safety signs may be affixed by peeling off grease, dirt and debris from safety signs the backing to expose the adhesive and instructional labels. - Page 13 CONSOLE DECAL – 463103 CONSOLE GRAPHICS CLUTCH ON CLUTCH OFF FAST SLOW NEUTRAL REVERSE PARK BRAKE CHOKE...

-

Page 14: Specifications

TRANSMISSION SPECIFICATIONS Two Hydro Gear® variable displacement pumps with two, Parker® Wheel Drive motors MODEL NUMBER Hydraulic Oil: 15w-50 Synthetic Speed: 0-8.0 mph Fwd ER48FX730VL 0-5.0 mph Reverse ER48FX730VLCA ER52FX730VL CUTTING DECK ER52FX730VLCA Cutting Width: 52” Discharge: Side WEIGHT &... -

Page 15: Operation

PARK BRAKE LEVER OPERATION Located on left side of unit OPERATOR CONTROLS To engage the brake, pull the lever rearward. Steering and Motion Control: To release, push the lever forward. The motion control levers control the forward and reverse rotation of the respective tire. When parking on a steep slope, the wheels Speed is proportional to amount the levers are must be chocked or blocked in addition to the... -

Page 16: Drive Wheel Release Valves

DRIVE WHEEL RELEASE VALVES PRE-START Located on the right front corner of the Fill fuel tank on level ground. For best results hydrostatic pumps. use only clean, fresh regular grade unleaded Drive wheel release valves are used to release gasoline with an octane rating of 87 or higher. the hydrostatic drive system to allow the IMPORTANT: Never use methanol, gasoline machine to be moved by hand without the... -

Page 17: Operating Instructions

BLADE ENGAGEMENT OPERATING DANGER INSTRUCTIONS The rotating blades under the mower deck STARTING THE ENGINE are dangerous. Blade contact can cause 1. Move both control levers to the neutral serious injury or kill you. position. Do Not put hands or feet under the mower 2. -

Page 18: Disengaging The Blades

DISENGAGING THE BLADES DRIVING FORWARD 1. Set the throttle midway between the 1. Move one motion control lever into the “SLOW” and “FAST” positions. neutral operate position. 2. Push down on the PTO switch to disengage 2. Release the parking brake. the blades. -

Page 19: Operating The Machine With The Platform Up

OPERATING THE MACHINE WITH THE WARNING PLATFORM DOWN Operating the machine with the platform down The operator platform is heavy and may is recommended when: cause injury when lowering and raising the operator platform. The platform may Mowing most areas suddenly drop if not supported when the ... -

Page 20: Transporting

If individual ramps must be used, use TRANSPORTING enough ramps to create an unbroken ramp surface wider than the unit. TRANSPORTING A UNIT Do Not exceed a 20 degree angle Use a heavy-duty trailer or truck to transport the between ramp and ground or between machine. -

Page 21: Maintenance

MAINTENANCE Note: The left and right side of the machine is determined by standing in the normal operator’s position. WARNING WARNING Remove the key from the ignition switch, Allow the engine to cool completely before engage parking brake, and pull the wire(s) service or making repairs around the engine off the spark plug(s) before you do any area. -

Page 22: Recommended Maintenance Schedule(S)

RECOMMENDED MAINTENANCE SCHEDULE(S) Maintenance Service Interval Maintenance Procedure Before each use or daily Check the engine oil level Check the mower blades Check the safety interlock system Check for loose hardware Check for belt obstructions ... -

Page 23: Check Engine Oil Level

Check the voltage of the battery with a digital CHECK ENGINE OIL LEVEL voltmeter. Locate the voltage reading of the battery Check the engine oil daily before starting the in the table and charge the battery for the engine otherwise shortage of the engine oil may recommended time interval to bring the charge up cause serious damage to the engine such as to a full charge of 12.6 volts or greater. -

Page 24: Release The Cushion For Rear Access

touch and that both electrical systems are off and at DANGER the same rated system voltage. These instructions are for negative ground systems only. Jump starting a weak battery that is cracked, frozen, has low electrolyte level, or an open/shorted battery cell, can cause an Connect the positive (+) cable to the positive explosion resulting in serious personal injury. -

Page 25: Check Safety Interlock System

2. Inspect blades and sharpen or replace as CHECK SAFETY INTERLOCK SYSTEM required. Service Interval: Before each use or daily 3. Reinstall the blades (if they were removed) in the following order: CAUTION A. Install blade bolt through blade with washer on bottom (grass) side of blade. -

Page 26: Check For Loose Hardware

10. With control levers in neutral position, release CHANGE ENGINE OIL park brake, engine should stop. Return park Service Interval: 100 hours brake to “ON” position. NOTE: Change oil and filter after first five 11. Restart engine. With control levers in neutral position, pull PTO switch to “ON”... -

Page 27: Check Hydraulic Oil Level

CHECK HYDRAULIC OIL LEVEL Service Interval: Every 40 hours Lubrication Chart 1. Stop engine, wait for all moving parts to stop NUMBER and remove key. Engage parking brake. FITTING INITIAL SERVICE LOCATIONS PUMPS INTERVAL 2. The oil fill is located in the center of the PLACES console. -

Page 28: Hydraulic System Air Purge

8. Fill reservoir as stated in Check Hydraulic Oil Air creates inefficiency because it has compression Level. and expansion rates that are higher than that of oil. 9. Raise the rear of machine up and support with Air trapped in the oil may cause the following jack stands (or equivalent support) just high symptoms: enough to allow drive wheels to turn freely. -

Page 29: Wheel Hub Nut Torque Specification

WHEEL HUB NUT TORQUE SPECIFICATION ADJUSTMENTS Service Interval: Every 500 hours thereafter Note: Disengage PTO, shut off engine, wait for all moving parts to stop, engage parking brake, and Torque the nut on the wheel motor tapered shaft to remove key before servicing, cleaning, or making 175-225 ft-lb (237-305 N-m) any adjustments to the unit. -

Page 30: Pump Drive Belt Tension

PUMP DRIVE BELT TENSION NEUTRAL ADJUSTMENT Self-tensioning – No adjustment necessary. The hydraulic pumps contain a return to neutral mechanism (RTN) which returns the hydraulic MOWER DECK DRIVE BELT TENSION pump to the neutral position when the operator Self-tensioning – No adjustment necessary. releases the control handles. -

Page 31: Cleaning

CLEAN DEBRIS FROM MACHINE CLEANING Service Interval: Before each use or daily Service Interval: Before each use or daily (May 1. Stop engine, wait for all moving parts to stop, be required more often in dry or dirty and remove key. Engage parking brake. conditions.) 2. -

Page 32: Troubleshooting

TROUBLESHOOTING IMPORTANT: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. When a problem occurs, do not overlook the simple causes. For example, starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble. -

Page 33: Wiring Schematics

WIRING SCHEMATICS... -

Page 34: Hydraulic Schematic

HYDRAULIC SCHEMATIC... -

Page 35: Evaporative Emission Control Warranty Statement

EVAPORATIVE EMISSION CONTROL WARRANTY STATEMENT CALIFORNIA EVAPORATIVE EMISSION CONTROL WARRANTY STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS The California Air Resources Board and Worldlawn Power Equipment is pleased to explain the evaporative emission control system's warranty on your 2014 model year lawn mower. In California, new equipment that use small off-road engines must be designed, built, and equipped to meet the State's stringent anti-smog standards. - Page 36 such part fails during the period of warranty coverage, it must be repaired or replaced by Worldlawn Power Equipment. Any such part repaired or replaced under the warranty must be warranted for a time not less than the remaining warranty period. (2) Any warranted part that is scheduled only for regular inspection in the written instructions must be warranted for the warranty period defined in subsection (b)-(2).

-

Page 37: Limited Warranty

Manufacturing, a Division of Worldlawn Power Equipment, Inc, (“Encore”) and is a limited warranty. Encore will warrant on the terms and conditions herein and applies to the original purchasers of new product from Encore Power Equipment or an authorized Encore dealer/retailer. Encore’s sole... - Page 40 ALL RIGHTS RESERVED RAGE OPERATORS MANUAL CONTENTS SUBJECT TO CHANGE STANDON 201601...

Need help?

Do you have a question about the RAGE ER48FX730VL and is the answer not in the manual?

Questions and answers