Table of Contents

Advertisement

Quick Links

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Description

General

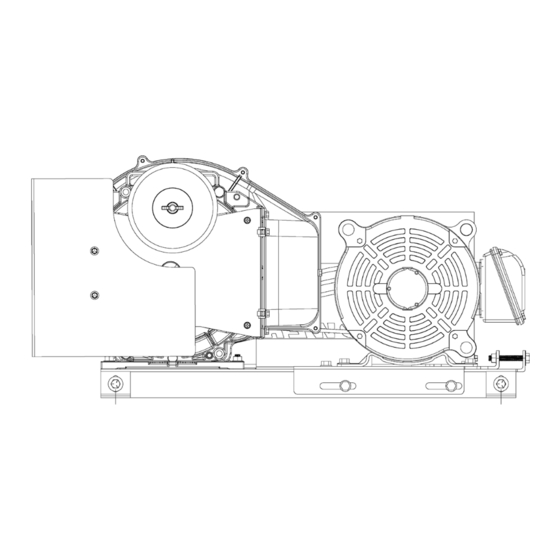

The Powerex Oil-less Rotary Scroll Air Compressor has advanced scroll

compressor technology through the development of a completely

oil-less unit. The Powerex Scroll Compressor offers a dynamically

balanced air end which insures vibration-free operation. The rotary

design permits a continuous 100% duty cycle. No oil separation, oil

filtration, or inlet valves are required on the Powerex Scroll unit.

Base mount assemblies are intended for use as replacements on

original Powerex Scroll systems and are not suitable for use as is

to provide compressed air for most applications. In general, an air

receiver and appropriate piping and valves, along with electrical

controls (base mounts may be provided with controls by Powerex)

are needed to provide a functional system. Powerex tank mounted

units, simplex or duplex are complete and ready to use.

The base mount assemblies include the scroll pumps, with provision

for intake filters to be mounted on the pump. The scroll pump is belt

driven using a 2 pole three phase electric motor. The electric motor

is mounted on a slide base to facilitate adjusting belt tension. The

belt drive is covered by a sheet metal belt guard. The pump delivers

compressed air into the after cooler that uses the air from the pump

blower fan to bring the compressed air temperature near ambient.

A check valve is installed in Powerex Scroll systems after the after

cooler. Compressed air is routed to the receiver tank. A pressure relief

valve is installed on systems where there is a possibility of accidentally

closing a shut off valve between the compressor and air receiver.

Controls on Simplex systems respond to pressure demand and

engage the electric motor when pressure in the receiver tank drops

to the cut in setting. (Approximately 95 psig) The motor runs and the

pump delivers air until the cut off point is reached (Approximately

115 psig). On Duplex systems, the controls alternate which pump runs

to respond to the air demand. If air demand exceeds the ability of

one pump, the second, or lag, pump is engaged at the lag switch cut

in point. It runs until the lag switch cut off is achieved, while the lead

pump continues to run until the lead switch cut off is achieved.

The after cooler on Powerex Scroll systems is mounted on resilient

mounts to prevent damage to the cooler. Piping is designed to

accommodate temperature and vibration encountered in normal use.

Powerex Scroll systems can be provided with separately powered

electric timer controlled automatic tank drains to expel condensation

that accumulates in the compressor tank. Make sure the tank drain is

working properly by operating the manual drain regularly to check for

Powerex • 150 Production Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

7.5 & 10 HP Basemount & Tankmount Scroll Air Compressors

accumulated condensation. Optional tank lining can be provided to

assure minimal corrosion of the tank interior. Dispose of condensate

as required by applicable regulations.

Powerex Scroll systems can also be provided with dryers. Dryers must

be provided with electrical power from a separate source and cannot

be powered from the control system, as the controls are not designed

for this load. Dryers will also expel water and the condensate must be

disposed of according to applicable regulations.

SPECIFICATIONS

Product

Performance Specifications

California Ordinance 462

(L) (2)

Compression Cycle

Control Panel

Drive

Lubrication

Motor Overhead Protection

Operating Temperature

Operating Voltages

Outlet Air Connections

Overpressure Protection

Standard Pressure Settings

SBS, STS, and STD series

See Product Data Sheet

Tank Mount units meet the requirements

of this ordinance

Scroll

UL508A Listed (panels are optional)

2-3V Belts

Grease filled bearings

IEC Motor overload relay (optional)

34°F - 104°F (1°C - 40°C) at inlet

1Ø 208-230 Volts, 60 Hz

3Ø 208-230/460 Volts, 60 Hz

Model specific - see detail drawings

ASME safety valve factory set and sealed

Simplex: 95-115 psi

Duplex: 90-110 psi; 95-115 psi

IN594102AV • 03/2017

Page 1 of 16

Advertisement

Table of Contents

Summary of Contents for Powerex SBS Series

- Page 1 Powerex Scroll unit. Base mount assemblies are intended for use as replacements on original Powerex Scroll systems and are not suitable for use as is to provide compressed air for most applications. In general, an air receiver and appropriate piping and valves, along with electrical accumulated condensation.

-

Page 2: Hour Meter

Scroll Air Compressors Compression Cycle Safety Guidelines The Powerex Oil-less Rotary Scroll Air Compressor is based on the This manual contains information that is very important to know theory of scroll compression. A scroll is a free standing, intricate and understand. This information is provided for SAFETY and to spiral bounded on one side by a solid, flat plane or base. -

Page 3: Installation

3. Avoid connecting the safety valve with any tubing or piping. 4. Manually operate the safety valve every six months to avoid sticking or freezing. Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com... -

Page 4: Operation

(diagram is typical, actual pipe and connection size may vary) drops. Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com... -

Page 5: Pump Maintenance

4. See Compressor Pump Manuals for replacement or service procedures. Pump Maintenance See the detailed pump maintenance manual included in the manual set. Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com... - Page 6 45 to 50 pounds. Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com...

- Page 7 Pump Side After Cooler Mounting Bracket SL051400AV SL051400AV Heat Shield SL060300AV SL060300AV *Not visible in diagram Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 7 of 16...

- Page 8 SL300701AV Tank Pressure Gauge GA016701AV GA016701AV Tank Safety Valve V-215400AV V-215400AV *Not visible in diagram Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 8 of 16...

- Page 9 Control Assembly Complete - 460V 60Hz PSI20074AJ PSI200A4AJ Control Assembly Complete - 575V 60Hz PSI20077AJ PSI200B7AJ Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 9 of 16...

- Page 10 PE001004AV Lead Pressure Switch CW207591AV CW207591AV Lag Pressure Switch CW207591AV CW207591AV *Not visible in diagram Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 10 of 16...

- Page 11 7.5 and 10 HP Base Mount and Tank Mount Scroll Air Compressors Wiring Schematics Simplex Starter: Duplex Control: Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 11 of 16...

- Page 12 7.5 and 10 HP Base Mount and Tank Mount Scroll Air Compressors Notes Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 12 of 16...

- Page 13 7.5 and 10 HP Base Mount and Tank Mount Scroll Air Compressors Notes Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 13 of 16...

- Page 14 7.5 and 10 HP Base Mount and Tank Mount Scroll Air Compressors Notes Powerex • 150 Production Drive • Harrison, OH 45030 • USA IN594102AV • 03/2017 P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com Page 14 of 16...

- Page 15 Compressor Air- End and Vacuum Pump shall be free of Defects for a period of forty-two (42) months from the date of shipment by Powerex, or thirty-six (36) months from the documented date of startup, or ten thousand (10,000) hours of use, whichever occurs first. Supplier’s repair or replace- ment of any Product shall not extend the period of any warranty of any Product.

- Page 16 Powerex warrants that such replace- ment parts will be free from Defects for the first twelve (12) months from the date of shipment by Powerex. For other replacement parts be- sides motors, Air-End or Vacuum Pumps installed on a system or unit that was not manufactured by Powerex after any initial warranty period has expired or where another warranty does not apply for any reason, Powerex makes no warranties.

Need help?

Do you have a question about the SBS Series and is the answer not in the manual?

Questions and answers