Summary of Contents for Unverferth NutriMax EQUALIZER

- Page 1 NutriMax Liquid Applicator ® EQUALIZER TRACK SYSTEM ® Serial Number B41600100 and Higher Part No. 415700...

- Page 2 — Introduction NutriMax Equalizer Track System Foreward This symbol identifies important safety messages. When you see it, read the message that follows and be alert to the possibility of personal injury. Remember, safety instructions stated in this manual are for your protection.

- Page 3 The information, specifications, and illustrations in the manual are based on information available at the time it was written. Due to continuing improvements in the design and manufacture of Unverferth products, all specifications and information contained herein are subject to change without notice.

-

Page 4: Table Of Contents

— Introduction NutriMax Equalizer Track System Table of Contents Section I Safety General Hazard Information ......................1-2 Following Safety Instructions ......................1-3 Before Operating or Servicing ......................1-3 During Operation ..........................1-4 Before Transporting ......................... 1-4 During Transport ..........................1-4 Preparing for Emergencies...................... - Page 5 — Introduction NutriMax Equalizer Track System Table of Contents Section III Parts Track Belt, Idler Wheels & Midrollers .................... 3-2 Track Frame Components ....................... 3-4 Front Idler Pivot Components ......................3-6 Rear Idler Pivot Components ......................3-8...

- Page 6 — Introduction NutriMax Equalizer Track System Notes...

- Page 7 — Safety NutriMax Equalizer Track System Section I Safety General Hazard Information ......................1-2 Following Safety Instructions ......................1-3 Before Operating or Servicing ......................1-3 During Operation ..........................1-4 Before Transporting ......................... 1-4 During Transport ..........................1-4 Preparing for Emergencies......................1-5...

-

Page 8: Safety

It is said that, “the best kind of a safety device is a careful operator.” We, at Unverferth Mfg. Co., Inc. ask that you be that kind of operator. -

Page 9: Following Safety Instructions

— Safety NutriMax Equalizer Track System Following Safety Instructions • Read and understand this operator’s manual before operating. • All machinery should be operated only by trained and authorized personnel. • To prevent machine damage, use only attachments and service parts approved by the manufacturer. -

Page 10: During Operation

— Safety NutriMax Equalizer Track System During Operation • Regulate speed to field conditions. Maintain complete control at all times. • Never lubricate equipment when in operation. • Use extreme care when operating close to ditches, fences, or on hillsides. -

Page 11: Preparing For Emergencies

— Safety NutriMax Equalizer Track System Preparing for Emergencies • Keep a first aid kit and properly rated fire extinguisher nearby. • Keep emergency numbers for fire, rescue, and poison control personnel near the phone. Wearing Protective Equipment • Wear clothing and personal protective equipment appropriate for the job. - Page 12 — Safety NutriMax Equalizer Track System Notes...

-

Page 13: Operation & Maintenance

— Operation & Maintenance NutriMax Equalizer Track System Section II Operation & Maintenance Track Operation ..........................2-2 Belt Conditioning ..........................2-2 “Condition” Track Prior to Initial Usage .................. 2-2 Belt “Conditioning” Procedures ....................2-3 Alignment ............................2-4 Maintenance ............................ 2-7 Track Tensioning &... -

Page 14: Track Operation

— Operation & Maintenance NutriMax Equalizer Track System Track Operation FIG. 2-1 The unit is not equipped with brakes. Ensure that the towing vehicle has adequate weight and braking capacity to tow this implement. Regulate speed to conditions. Maximum speed should never exceed 15 m.p.h. -

Page 15: Belt Conditioning Procedures

— Operation & Maintenance NutriMax Equalizer Track System Belt Conditioning (continued) Belt Conditioning Procedures • Road transport weight, distance and speed will affect the belt life. Before loading the unit, use the following recommendations to maximize the belt life: 1. Prior to transporting, apply generous amounts of clean dry dirt to the inside face, between the idler and bogie wheels, of the track. -

Page 16: Alignment

— Operation & Maintenance NutriMax Equalizer Track System Alignment • ENTANGLEMENT WITH MOVING PARTS CAN CAUSE SERIOUS INJURY OR DEATH. USE EXTREME CARE WHEN INSPECTING AND ADJUSTING BELT TRACKING. AVOID PER- SONAL ATTIRE SUCH AS LOOSE FITTING CLOTHING, SHOESTRINGS, DRAWSTRINGS, PANTS CUFF, LONG HAIR, ETC., THAT MAY BECOME ENTANGLED IN MOVING PARTS. - Page 17 — Operation & Maintenance NutriMax Equalizer Track System Alignment (continued) 3. Remove the adjustment bolt retaining hard- FIG. 2-3 ware. (FIG. 2-3) Adjustment Bolt Remove Front of track shown less belt and wheels for illustration purposes only 4. Clockwise rotation of adjustment bolt will steer idler as shown in FIG. 2-4.

- Page 18 — Operation & Maintenance NutriMax Equalizer Track System Alignment (continued) 5. Reinstall the adjustment bolt retaining FIG. 2-5 hardware. (FIG. 2-5) Use supplied spacer washers to properly space the adjustment Adjustment bolt locking plate to ensure hex of the bolt Bolt head is fully engaged in the locking plate.

-

Page 19: Maintenance

— Operation & Maintenance NutriMax Equalizer Track System Maintenance Track Tensioning & Detensioning • ENTANGLEMENT WITH MOVING PARTS CAN CAUSE SERIOUS INJURY OR DEATH. USE EXTREME CARE WHEN INSPECTING AND ADJUSTING BELT TRACKING. AVOID PER- SONAL ATTIRE SUCH AS LOOSE FITTING CLOTHING, SHOESTRINGS, DRAWSTRINGS, PANTS CUFF, LONG HAIR, ETC., THAT MAY BECOME ENTANGLED IN MOVING PARTS. -

Page 20: Detensioning

— Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) Detensioning 1. Park the unit on a firm, level surface. Set Hex Jam Nut 1 1/4-7UNC FIG. 2-8 the towing vehicle’s parking brake, shut off (9395-024) engine and remove key before adjusting. -

Page 21: Hub Seal Installation

— Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) Hub Seal Installation When installing the seal, make sure the spring on the inside of the seal is facing towards the outside of the hub, closest to the seal guard. - Page 22 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) Trunnion Replacement 2. Using a 16,000 lbs. safe lifting device, raise FIG. 2-10 one side of the unit. Place equally rated safe lifting devices under the axle nearest Remove to the track that will be removed.

- Page 23 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) 5. Using fork lift rated for 3,000 lbs., support the track assembly using the support tubes in the track frame. Remove all the outside idler wheels (111109B) and midrollers (111110B).

- Page 24 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) 7. Remove the front, inside idler wheel (111109B) and midroller (111110B). (FIG. 2-13) FIG. 2-13 Flange Nut Idler Wheel 5/8"-18UNF (111109B) (9007744) Capscrew 3/4"-10UNC x 1 3/4" (9390-144) Lockwasher (9404-033) Flat Washer 3/4"...

- Page 25 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) 10. Remove the track trunnion pin (409137) and retaining hardware as shown in FIG. 2-14. FIG. 2-14 Trunnion Pin (409137) Cross Pin (409140) Snap Ring (9003810) Grease Fitting (9006817) Bushing (9003230)

- Page 26 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) 15. Using safe lifting device rated at 400 lbs., install the front idler pivot assembly. (FIG. 2-15) Install the idler pivot pin (412331) and retaining hardware as shown in FIG. 2-15. Jam nut with setscrew (9005290), snug tighten the jam nut against the idler pivot plate and tighten the setscrew.

- Page 27 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) 17. Install the track belt (FIG. 2-16). FIG. 2-16 Install Rubber Track Belt (9006748) 18. Attach all the outside idler wheels (111109B) and midrollers (111110B). (FIG. 2-17) Torque 5/8”-18UNF wheel flange nuts (9007744) to 240 Ft.-Lbs.

- Page 28 — Operation & Maintenance NutriMax Equalizer Track System Maintenance (continued) 19. Tension track using procedure in MAINTENANCE section of this manual. 20. Install the track pivot pin and retaining hardware. Torque hardware accordingly. (FIG. 2-18) Torque To 220 Ft.-Lbs. Torque To 220 Ft.-Lbs.

-

Page 29: Lubrication

— Operation & Maintenance NutriMax Equalizer Track System Lubrication Track Idler Wheel & Midroller Hubs Track Idler Wheel & Midroller Hubs POINTS LUBRICANT HOURS DESCRIPTION 2 Shots 20 Hours Track Idler Wheel & 8 per Track EP-2 Midroller Hubs Repack... - Page 30 — Operation & Maintenance NutriMax Equalizer Track System Lubrication 9002479 DESCRIPTION PART NO. QTY. NOTES Swivel Pipe Adapter 9002479 Hose, 3/16 x 24 - Grease 3250PSI 9007857 Hose, 3/16 x 20 - Grease 3250PSI 9007858 Hose, 3/16 x 36 - Grease 3250PSI...

-

Page 31: Storage

— Operation & Maintenance NutriMax Equalizer Track System Storage 1. Avoid storing in sunlight. 2. Avoid excessive moisture. Ideally, rubber tracks should be stored indoors, in a draft-free area. If tracks must be stored outdoors, a tarpaulin or other covering should be used to protect them from the weather. - Page 32 — Operation & Maintenance NutriMax Equalizer Track System Complete Torque Chart Capscrews - Grade 5 NOTE: • Grade 5 capscrews can be identified by three radial dashes on the head. • For wheel torque requirements, refer to Wheels and Tires.

- Page 33 — Parts NutriMax Equalizer Track System Section III Parts Please visit www.unverferth.com/parts/ for the most current parts listing. Track Belt, Idler Wheels & Midrollers .................... 3-2 Track Frame Components ....................... 3-4 Front Idler Pivot Components ......................3-6 Rear Idler Pivot Components ......................3-8...

-

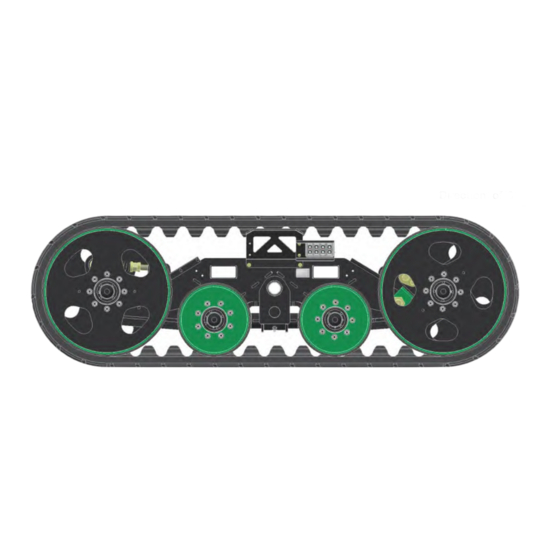

Page 34: Track Belt, Idler Wheels & Midrollers

— Parts NutriMax Equalizer Track System Track Belt, Idler Wheels, & Midrollers Please visit www.unverferth.com/parts/ for the most current parts listing. - Page 35 — Parts NutriMax Equalizer Track System Track Belt, Idler Wheels, & Midrollers Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Flange Nut 5/8-18UNF 9007744 Grade 8 Track Belt - 252” x 16” 9009116...

-

Page 36: Track Frame Components

— Parts NutriMax Equalizer Track System Track Frame Components Please visit www.unverferth.com/parts/ for the most current parts listing. Tension Arm Pivot Trunnion Pivot Idler Arm Inside Pivot Idler Arm Outside Pivot Track Fork Inside Pivot Track Fork Outside Pivot Idler Arm Inside Pivot... - Page 37 — Parts NutriMax Equalizer Track System Track Frame Components Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Track Frame Weldment 409127B Tension Spring Bushing 9007695 Track Trunnion Weldment 408982B Split Bushing 9003230 Track Trunnion Pin Weldment 409137 90°...

-

Page 38: Front Idler Pivot Components

— Parts NutriMax Equalizer Track System Front Idler Pivot Components Please visit www.unverferth.com/parts/ for the most current parts listing. - Page 39 — Parts NutriMax Equalizer Track System Front Idler Pivot Components Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Front Left-Hand Idler Pivot Assembly Includes Items 2A & 3 through 34 Front Right-Hand Idler Pivot Assembly Includes Items 2B &...

-

Page 40: Rear Idler Pivot Components

— Parts NutriMax Equalizer Track System Rear Idler Pivot Components Please visit www.unverferth.com/parts/ for the most current parts listing. - Page 41 — Parts NutriMax Equalizer Track System Rear Idler Pivot Components Please visit www.unverferth.com/parts/ for the most current parts listing. ITEM DESCRIPTION PART NO. QTY. NOTES Idler Pivot Assembly (Rear) Includes Items 2 through 38 Idler Pivot Weldment 411709B Pivot Pin Weldment...

- Page 42 MANUALS\\415700///December 2021-0...

Need help?

Do you have a question about the NutriMax EQUALIZER and is the answer not in the manual?

Questions and answers