Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Atlanta SFERA

- Page 1 SFERA 安装,保养及操作手册 中文 INSTALLATION, USE AND MAINTENANCE MANUAL 号码 依照原始文件翻译手册,请仔细阅 12000009455 读手册并保留以备将来参考 Code 版本 Revision Traslation of the original text Please, read this user's manual carefully and keep it for future reference.

- Page 2 Documento riservato ai termini di legge con DIVIETO di riproduzione o di renderlo noto a terzi senza esplicita autorizzazione del Costruttore. Le descrizioni e le illustrazioni fornite nella presente pubblicazione non sono impegnative. Il Costruttore si riserva il diritto di apportare tutte le modifiche che riterrà opportune. This document is legally protected and may NOT be reproduced or disclosed to third parties without the express authorisation of the Manufacturer.

-

Page 3: Table Of Contents

目录 CONTENTS 前言 ..............5 FOREWORD ..........5 阅读和使用操作手册 ........5 How to read and use the instruction 1.1.1 操作手册的重要性 .......... 5 manual ............5... 1.1.1 Importance of the manual ......5 1.1.2 妥善保管操作手册 .......... 5 1.1.2 Safekeeping of the manual ...... - Page 4 开始使用机器 ..........34 STARTING UP THE MACHINE ....34 触控操作面板 ..........34 6.1 Control panel ..........34 6.1.1 控制面板功能 ..........38 6.1.1 Control panel functions ......38 6.1.2 Description of operating modes cycles. .. 41 6.1.2 包装行程操作模式说明 ........ 41 Product reading arm adjustment ....43 导向轮调整...

-

Page 5: 阅读和使用操作手册

FOREWORD 前言 HOW TO READ AND USE THE 阅读和使用操作手册 INSTRUCTION MANUAL 1.1.1 操作手册的重要性 1.1.1 THE IMPORTANCE OF THE MANUAL The instruction manual is to be considered as an 这份手册被视为这部机器的一部份;妥善保管并仔 integral part of the product; keep it and look after it 细阅读。转交给其他相关的人员或接手机器的使用... -

Page 6: 图像和内容信息

1.1.5 图像和内容信息 1.1.5 INFORMATION ON THE IMAGES AND CONTENTS The illustrations in this manual have been included solely 手册内包括有图文部份清楚描述,制造商可在不 by way of example for better understanding of what is 通知的情况下,根据需要做修正。机器的安全使 described. This document may be subject to change by 用部份仍是被保障的。 the Manufacturer. -

Page 7: 谁该详阅操作手册

谁该详阅操作手册 1.2 WHO THE MANUAL IS FOR 机器操作员:经过培训后的操作员可进行大部份简 MACHINE OPERATOR: Trained operator who after an appropriate training course 易的机器调整。 on use of the machine will be able to carry out the most simple machine adjustments. 机械维修工程师: 合格的技师可以进行零组件的 MECHANICAL MAINTENANCE TECHNICIAN: Qualified technician able to operate the machine like 更换调整,维护与修... -

Page 8: 安全和事故预防

安全和事故预防 SAFETY AND ACCIDENT PREVENTION 一般的安全规章 GENERAL SAFETY INSTRUCTIONS • 开始工作前,机器操作员必须完全地熟悉机 器的操作方式。每天需检查所有机器的安全 • Before starting work, the operator must be perfectly 装置。 familiar with the position and operation of all the controls and machine features. Check all the safety devices on the machine on a daily basis. •... - Page 9 在 机器 维护 、修 理或 调整 , 需按 下紧 急停 DURING ALL MAINTENANCE, REPAIR 止按钮并拆除电池的电源供应。在机器贴上: OR ADjUSTMENT OPERATIONS, IT IS 警告!“机器维护中” OBLIGATORY TO PRESS THE EMERGENCY BUTTON AND TO DISCONNECT THE POWER SUPPLY TO THE BATTERIES. IT IS ADVISABLE TO POST A WARNING SIGN CLOSE TO THE MACHINE WITH THE 在机器运转中不要拆除固定保护装置。做完...

-

Page 10: 安全标志

安全标志 SAFETY SIGNS 手册内的安全标志(图 1.1), 位于机器硬件结构的各 The safety signs (Fig. 1.1) described in this manual, 个部位。 are located on the machine structure at suitable points and warn of the likelihood of danger due to residual 自黏贴纸,有着黄与黑框线,告示操作者危险区域并 risks. 在张贴。 The adhesive stickers, distinguished by yellow and black bands, warn of areas of risk for operators and so maximum care must be taken where these signs are 贴纸的区域要非常的小心。请保持贴纸的干净与可... -

Page 11: 其他危险的警示

1.2.1 其他危险的警 示 1.2.1 WARNINGS REGARDING RESIDUAL 机器本身的设计与建造已经考虑了操作员的安全 , RISkS 用安全设备,减少可能发生的危险。但是仍无法避 The machine has been designed and constructed in 免表列(图 1.2)的危险,是机器运转时本身会产生的。 such a way as to allow the operator to use it safely, eliminating or cutting down to the minimum the pos- sible residual risks by the adoption of safety devices. -

Page 12: 安全装置

安全装置 SAFETY DEVICES THE MACHINE HAS BEEN DESIGNED AND CONSTRUCTED TO ALLOW SAFE 机器的设计与制造可让操作员在所有情形下 USE IN ALL THE CONDITIONS INTENDED 操作,采用安全防护装置,当有危险发生时 BY THE MANUFACTURER, ISOLATING 可中断机器。 THE MOVING PARTS AND LIVE COMPO- 制造商已减少安全装置导致对人员与动物, NENTS BY THE USE OF SAFETY GUARDS AND SAFETY DEVICES TO STOP THE 障碍物的可能伤害。... -

Page 13: 技术协助

- Approximate number of service hours - 详细描述机器的操作情形或已发现的问题 - Detailed indications regarding a specific operation to be carried out or the fault found. TECHNICALASSISTANCE TECHNICALASSISTANCE ATLANTA STRETCH ATLANTA STRETCH TEL. +39 0541 627145 TEL. +39 0541 FAX +39 0541 627220 627145 info@atlantastretch.com... -

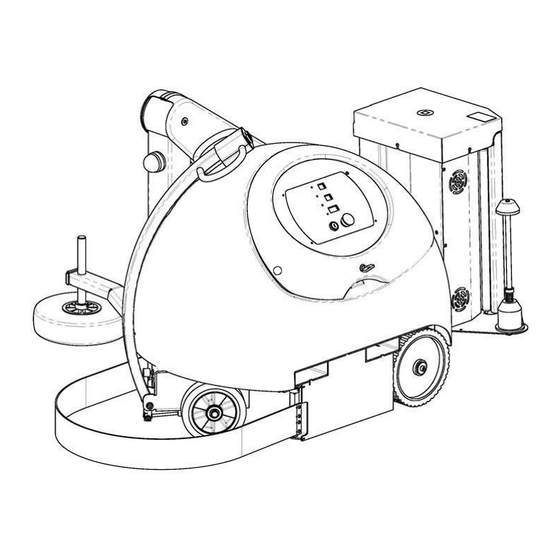

Page 14: 机器总述

机器总述 MACHINE DESCRIPTION 制造商与机器铭牌识别 MANUFACTURER AND MACHINE IDENTIFICATION DATA ATLANTA STRETCH S.p.A. ATLANTA STRETCH S.p.A. Via Chiesa di Camerano, 30 Via Chiesa di Camerano, 30 47828 - Poggio Berni - RN - ITALIA 47828 - Poggio Berni - RN - ITALIA TEL. -

Page 15: 一般数据

The control 参数。 简易版机型可做简易调 整,而升级版机 panel is used to control the machine and to set the 型可做程序设定,快速设定包装方式与多功能 wrapping parameters. The Sfera version allows simple adjustments while the Advanced version al- 方式。 lows programs and wrapping methods to be used in a quick and versatile manner. - Page 16 导向轮:连接有侧臂(7),紧靠着包装货物的栈板包装, 6 The Feeler wheel, connected to the side arm (7), is 主要的目的是确保产品与机器维持一定距离。 placed up against the pallet on which the product to be wrapped stands and its purpose is to guarantee a more or less constant distance between the product and the machine.

- Page 17 机器可以安装以下四种胶膜架: The machine can be fitted with one of the following four wrapping carriages: FM - FE - PRS and PS (Fig. 2.4). FM - FE - PRS - PS ( Fig. 2.4). 机械式的剎车,用来调整胶膜的束紧 FM 胶膜架: FM carriage: delivers film during wrapping and adjusts 力。在胶膜架上的一个旋钮可手动调整。...

-

Page 18: 正确的使用

正确的使用 INTENDED USE - PROPER USE - PURPOSE 这款自走式缠绕膜机的设计与制造适用于任何尺寸, The wrapping machine, designed to be anchored to 形状,重量的栈板货物,可以让货物在运送过程/ the ground, has been designed and constructed ted for 储藏过程中做到防潮与防尘作用。机器由导向轮带 wrapping various types of products stacked on pallets of any shape and weight with stretch film, in order to 动与包装栈板以一定距离顺时钟方向转动行走。... -

Page 19: 不正确的使用机器

不正确的使用机器 UNINTENDED AND UNAUTHORISED USE - FORESEEABLE AND UN- FORESEEABLE IMPROPER USE 不正确的使用或没有定期维护机器,会导致机器 Use of the pallet wrapping machine for unauthorised purposes, its improper use and lack of maintenance 操作员及暴露在现场的人员受到严重伤害的危险, can lead to the risk of serious danger to health and 影响工作效率及机器的安全性。... - Page 20 噪音 Noise Inaccordancewith annex 1 of machinedirective 2006/42/ 依据 2006/42/EC 的标准, 机器所发出的噪音低 EC, the manufacturer declares that the noise emitted 于 70dB(A). by the machine at the operator position is less than 70 dB(A). H = 2000 mm 2200 2050 2050 1000 1850...

-

Page 21: 机器工作行走范围

机器工作行走范围 WORk AND CONTROL STATIONS 区域 A - (图 2.7) 显示了最大的行走距离尺寸概 AREA A - The machine work area extends to a perimeter distance of 1.5 m from the package. 况和操作区域。工作中,这个范围内不能有任 Work area A (Fig. 2.7) inside which the machine operates 何的障碍物及人员。... -

Page 22: 胶膜架型式

胶膜架型式 ROLL-HOLDER CARRIAGES FM 型式胶膜架 FM roll-holder carriage 这款胶模架(图 2.8)可以调整胶膜作用在包装物上的 With this carriage version, the application tension of the 束紧力。 film on the pallet can be adjusted. 包括一个橡胶面的滚筒(1)和滚筒(2),一个机械煞车。 The carriage FM is composed of a rubber-coated roller 手轮(3)是用来调整机械煞车的动作,进而控制胶 (1) and a roller (2) with mechanical brake. The knob (3) is used to adjust the action of the brake 膜的束紧力。... - Page 23 FE 型式胶膜架 FE roll-holder carriage 这款胶模架(图 2.9)可以调整胶膜作用在包装物上的 With this carriage version, the application tension of the 束紧力。 film on the pallet can be adjusted. The FE carriage (Fig. 2.9) comprises a rubber-coated roller roller (1), an electromagnetic brake, and idle 包括一个橡胶面的滚筒(1)和滚筒(2),...

- Page 24 PRS 型式胶膜架 PRS roll-holder carriage 这款胶膜架(图 2.10)可以调整胶膜作用在包装物上的 束紧力。此胶膜架可以预延伸胶膜,根据固定可互 With this carriage version (Fig. 2.10), the application tension of the film on the pallet . 换的齿轮比例确定。 This carriage can pre-stretch the film according to fixed 预延伸比率是: ratios determined by interchangeable gears. The pre-stretch ratios are: -150% (长度...

- Page 25 Fig. 2.10...

- Page 26 PS 型式胶膜架 PS roll-holder carriage 这款胶膜架(图 2.11)可以调整胶膜作用在包装物上的 With this carriage version (Fig. 2.11), the tension with which the film is applied to the pallet.. This carriage 束紧力。此胶膜架可以预拉伸胶膜.预拉伸比率可以 allows pre-stretching the film. The pre-stretch value is 调整。 adjusted. 胶膜架装有: The carriage is fitted with: a sensor (4), connected to the outfeed roller, which 此胶膜架结合传感器(4),连接出膜的滚筒,再...

- Page 27 Fig. 2.11...

-

Page 28: 运输,装载,存放

TRANSPORT-HANDLING- 运输,装载,存放 STORAGE 包装和拆箱 PACkING AND UNPACkING 依照运送条件, 机器可以以不同方式运送。 The machine may be shipped in different ways depending 机器用透明的塑料膜包裹。. on the transport requirements: 机器放置在木头栈板上并由透明塑料膜包 Unpacked machine protected by transparent plastic wrapping. 装。 Machine on a wooden pallet and protected by transparent plastic wrapping. -

Page 29: 运送与处理未打开包装的机器

运送与处理未打开包装的机器 TRANSPORTING AND HANDLING THE PACkED MACHINE 使用适当的堆高机运送未打开包装的机器。 USE ONLY A FORk LIFT TRUCk OF 任何其他的处理方法而对机器造成损害,将 ADEQUATE CAPACITY TO LIFT AND 使保固的承诺失效。 TRANSPORT THE PACkED MACHINE. USING ANY OTHER SYSTEM WILL NULLIFY THE WARRANTY FOR ANY DAMAGE CAUSED TO THE MACHINE. 机器的重量标示在外包装上。... -

Page 30: 运送与处理已打开包装的机器

运送与处理已打开包装的机器 3.3 TRANSPORTING AND HANDLING THE UNPACkED MACHINE 从硬纸板外箱取出机器,如图(3.1) 所示。 抬高 Remove the machine from the cardboard box as shown 机器 A (图 3.2) 到组装区。 in (Fig. 3.1). Lift the machine A (Fig. 3.2) and move it to the installation area. -

Page 31: 储放未打开包装和已打开包装的机器

储放未打开包装和已打开包装的机器 STORAGE OF PACkED AND UNPACkED MACHINE 长时间未使用,使用者需将机器依照包装的条 In the event of long periods of inactivity, the customer must check the place where the machine is positioned 件(木条箱,木箱容器)放置合适的地点。 and depending on the type of packaging (crate, container, etc.), ensure that the storage conditions are suitable. 如机器未照技术规范储放,零件会遭污损。需... -

Page 32: 机器安装

机器安装 INSTALLATION 机器工作区域要求 WORkPLACE REQUIREMENTS • 气候条件:该机器能够正常大气条件下,在温 • Atmospheric conditions: 度为 40℃,相对 湿度不大于 50%和 90%,在 The machine is able to function correctlyin atmospheric 温度不大于 20℃(无结露)。如果大气条件不适合 conditions with relative humidity no greater than 50% 机器操作,制造商可以根据要求,提供解决方 at a temperature of 40° C and 90% at a temperature 案,以解决这个问题(如空调... -

Page 33: 零配件安装

零配件安装 4.2 FITTING THE UNITS 仅需要有机械维修人员或专业技师一名,执行任何 Any operations that need to be carried out with some 操作。 of the safety devices disabled, must be performed by a MECHANICAL MAINTENANCE TECHNICIAN OR A SPECIALISED TECHNICIAN. These operations must be carried out by one person only. DURING ALL MAINTENANCE, REPAIR OR 在进行所有的机器维护,修理或调整操... -

Page 34: 开始使用机器

CONTROL PANEL TOUCH SCREEN 触控操作面板 START STOP... - Page 35 A Icon START programmed cycle (press and hold 启动键(按下超过3秒) for more than 3 seconds) B 2-digit display, indicates the selected program 2位数显示屏,显示包装程式选择 (Note: the display flashes when a parameter has been modified); (修改时会闪烁) C 2-digit display, indicates the functions (parame- 2位数显示屏,显示功能参数选择...

- Page 36 参数载入:选择所需的参数图示自动载入至显示 Loading of parameters: takes place automatically by selecting the desired programme 屏"F"。 Saving of parameters: if the LED right of the display 参数储存:显示屏F右边LED指示灯正常是熄灭。 F is turned off, press the SAVE key for more than 4 seconds. This LED will start to flash rapidly to indicate 当按SAVE键超过4秒时。LED指示灯开始...

- Page 37 信号 Signals LED right of the display F indicates the writing LED显示屏F显示选定包装程式的写入保护状态。 protection status of the selected programme. If turned 如果打开将不可覆写修改的参数,如果需要覆写功 on, it is not possible to rewrite the modified parameters. 能F00参数值需设定1,然后按住复位键RESET至少 It is necessary to select the parameter F00 on the same 3秒。这时候所修改的参数将被储存,之后的储存...

-

Page 38: 控制面板功能

5.1.1 控制面板功能 5.1.1 CONTROL PANEL FUNCTIONS F00 This parameter is used to prevent cycle pa- F00 参数输入锁定,无法修改参数。 rameters from being overwritten. F01 包装行程选择: 01 双行程包装(上及下) 02 单行 F01 Set cycle:01 ascent and descent; 02 ascent or de- scent (see par. 5.2.3) 程包装(上或下) (参阅... - Page 39 F21 长形物包装(周长 m) – (默认值= 4.0m) F21 Product perimeter (m) - (default value =4.0 m) F22 Cycle with pause: enabled 1 or disabled 0 F22 顶部覆膜包装,1=使用 0=不使用 F23 Carriage descent position with F22 =1 F24 Thickness of film being used: 10 ÷ 35 micron F23 覆膜时胶膜架下降距离...

- Page 40 显示屏 DISPLAY F= AA Alarms DISPLAY F= AA The display V is used to signal the alarms displayed 显示屏V显示故障码,同时复位键旁边或显示 屏F右边(触控面板型式)的LED灯会闪烁。 RESET button or the right LED of the display F in the models with touch screen. E01:防撞条被撞击 E01: emergency bumper pressed E02:启动失败(机器不能动作) E02: failed starting (the machine does not turn) E03:机器断电或急停之后需按复位键E重启动...

-

Page 41: 包装行程操作模式说明

5.1.2 包装行程操作模式说明 5.1.2 DESCRIPTION OF OPERATING MODES/ CYCLES 机器以全自动模式操作。设定好包装参数(行走速 The machine works in AUTOMATIC operating mode. 度及胶膜包装圈数,按下开 始键(M),即可开始包 Operations can begin when the machine is turned on 装行程。 and in a safe condition by pressing the START button (M) after setting the wrapping parameters (speed and number of extra wraps, etc.). - Page 42 F12 – 手动设定胶膜架上升停止高度自动包装行程 F12 - DIFFERENT FROM 50 CYCLE WITH ALTIMETER 从栈板底部开始往上缠绕到预设的高度(由功能 F12 Automatic cycle that wraps the pallet starting from the 设定)后, 再从顶部往下缠绕到底部 bottom to reach a preset height (which is set with the F12 function) and then back to the bottom again. F21 - 长形物包装(周长...

-

Page 43: 导向轮调整

导向轮调整 5.2 PRODUCT READING ARM ADjUSTMENT DURING ALL MAINTENANCE, REPAIR OR 在进行所有的机器维护,修理或调整操作时, ADjUSTMENT OPERATIONS, EMERGENCY MUSHROOM BUTTON ON 急停按钮必须按下,并断开连接的电池. THE CONTROL PANEL MUST ALWAYS BE ACTIVATED AND THE BATTERY DISCON- NECTED. The reading arm, on which the wheel that follows the outline of the product to be wrapped is mounted, is sub- 此导向轮是靠在栈板边缘进行动作,可经由以下... -

Page 44: 手动移动机器

弹簧张力太大的影响: A more rigid spring results in: - 增加弹力; - Greater steering force - 手动移动机器增加拉的力量 - Greater steering arm rigidity during manual move- ments - 导致重量过轻栈板在地上滑动风险 弹簧张力太小 - The risk of lightweight pallets moving on slippery 的影响: flooring. - 减少弹力 - 手动移动机器减少拉的力量... -

Page 45: 安装胶膜

安装胶膜 LOADING A ROLL OF FILM 这是一个普遍的过程(参见图 5.6)。在手册中胶膜架 This is a general procedure (see fig. 5.6). Carriage-specific 介绍章节中有具体穿膜操作说明。 operations are described in the relative roll-holder car- riage manual. a) Lower the roll-holder carriage (1) to make it easier to load the roll; b) press the emergency button (2) in order to work in a) 降下胶膜架(1)方便放入胶膜. -

Page 46: 启动机器

启动机器 STARTING THE MACHINE BEFORE STARTING THE WORk CYCLE 工作周期开始之前,请确保机器绕行包装物的 MAkE SURE THAT THE AREA AND THE 区域和周围的地面是没有任何障碍 GROUND AROUND THE PRODUCT TO BE WRAPPED ARE FREE OF ALL OBSTRUC- TIONS AND THAT NO OBjECTS HAVE BEEN LEFT ON THE MACHINE. 机器开始动作后,操作员必须立即离开机器工... -

Page 47: 停止机器

5.6 停止包装 CYCLE STOP 在控制面板上按下停止键(D)停止包装行程。 Press STOP on the control panel to stop machine at the end of its current cycle. 5.7 紧急停止 EMERGENCY STOP 这机器配备了紧急停止按钮(9) (Fig. 5.8)。按下按钮 The machine is equipped with an emergency pushbutton 机器将立即停止。重新启动机器旋开紧急停止按钮 (9) (Fig. 5.8). Pressing the pushbutton, the machine will stop 并按下复归键按钮,重新启动控制面板。... -

Page 48: 保养维护

保养维护 MAINTENANCE 一般注意事项 GENERAL PRECAUTIONS 6.1.1 机器断电 6.1.1 MACHINE DISCONNECTION 进行保养维护或修理时, 机器需拆除与电源的连 Before performing any maintenanceor repairoperations, 接。 disconnect the machine from all the power sources. Make sure that the battery charger is not connected to the mains supply and unplug the batteries. 要确定电池充电器没有连接到主电源,并要拔除... -

Page 49: 每周例行保养

AFTER ANY WORk CARRIED OUT INSIDE THE CENTRE COMPARTMENT OF THE 打 开机器内部进行任何作业,不要把工具或物品 MACHINE, MAkE SURE THAT NO OBjECTS 遗放在机器内部,另外要把电池盖盖回去。 OR TOOLS HAVE BEEN LEFT INSIDE AND PUT THE CAPS BACk ON THE BATTERY TERMINALS. 6.2.1 每周例行保养 6.2.1 WEEkLY MAINTENANCE 清洁。使用湿布沾水或酒精擦拭,完全清洁机器... -

Page 50: 电池充电

电池充电 CHARGING THE BATTERY THE MACHINE USES A SEALED GAS 机器所使用的电池是由 AGM 科技公司所制造生 RECOMBINATION BATTERY, REGULATED 产,采用的是密封气体再化合电池,保证有高等 WITH A SAFETY VALVE MANUFACTURED 级的安全使用标准,不得替换原厂所使用的不同 USI NG AG M T ECHNO L O G Y W HI CH 电池。 GUARANTEES A HIGH LEVEL OF SAFETY IN USE. - Page 51 USE ONLY THE BATTERY CHARGER BUILT INTO THE MACHINE, SPECIFICALLY 内建式的电池充电器,特别设计符合机 DESIGNED FOR THE BATTERIES FITTED. 器的使用。如使用不同品牌的电池充电 USING A DIFFERENT BATTERY CHARGER CAN CAUSE DAMAGE TO THE BATTERY 器,可能会造成电池的损坏,并有毒物 AND THE RISk OF TOXIC SUBSTANCES 质的释放。 BEING GIVEN OFF. FOR MORE INFORMATION ON USE AND MAINTENANCE OF THE BATTERIES AND BATTERY CHARGER, READ CAREFULLY THE INSTRUCTIONS ENCLOSED WITH THE...

-

Page 52: 机器停止使用

机器停止使用 OUT OF SERVICE 拆解,报废和出售 DISMANTLING, SCRAPPING AND DISPOSAL 如果机器或零件已经停产,或因为破损,磨 IF THE MACHINE OR ITS COMPONENTS 损或到了他们的使用年限不能再维修了,就 ARE FOUND TO BE NO LONGER SERVICE- 必须将机器设备替换掉。 ABLE OR REPAIRABLE BECAUSE THEY ARE BROkEN, WORN OR HAVE COME TO THE END OF THEIR WORkING LIFE, THEY MUST BE DEMOLISHED. -

Page 53: 零件目录

零件目录 SPARE PARTS CATALOGUE BASE UNIT 基本主体组件 Base 10010012501 Base 10010012501 Chassis 10010011999 ChassIs 10010011999 Carter 10010012117 Carter 10010012117 Idle wheel 10010001076 Idle wheel 10010001076 Steering arm 10010001084 Steering arm 10010001084 Safety bumper 10010000410 Safety bumper 10010000410 Arm column h=2000 10010001717 Arm column h=2000 10010001717... - Page 75 ATLANTA STRETCH S.p.A. Via Chiesa di Camerano, 30 47828 Poggio Berni (RIMINI) ITALIA TEL. +39 0541.627145 FAX +39 0541.627220 www.atlantastretch.com info@atlantastretch.com...

Need help?

Do you have a question about the SFERA and is the answer not in the manual?

Questions and answers

Como sanar o E02?