Nordic W Series Product Application, Installation And Service Manual

Water-to-water heat pumps

Hide thumbs

Also See for W Series:

- Installation and service manual (57 pages) ,

- Application, installation & selection manual (110 pages) ,

- Product application, installation and service manual (126 pages)

Table of Contents

Advertisement

Quick Links

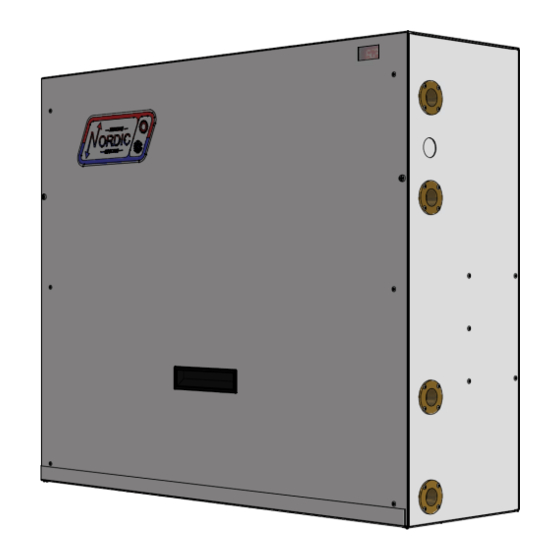

Application, Installation, & Service Manual

W/WH-25/45/55

W/WH-65/75/80

Maritime Geothermal Ltd.

P.O. Box 2555, 170 Plantation Road

Petitcodiac, NB E4Z 6H4

(506) 756-8135

ISSUE 04: 23-Sep-2022

Water-to-Water Heat Pumps:

W-Series (Standard Range),

WH-Series (High Temperature),

Model Sizes 25-80 (Heating/Cooling)

Model Sizes 45-80 (Pool Heating)

Model Size 85 (Domestic Hot Water)

WP-45/55/65/75/80

Page 1

ISSUE 04: 23-Sep-2022

WP-Series (Pool Heating)

WH-85-H (DHW)

info@nordicghp.com

www.nordicghp.com

002500MAN-01

002500MAN-01

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Nordic W Series

- Page 1 Application, Installation, & Service Manual Water-to-Water Heat Pumps: W-Series (Standard Range), WH-Series (High Temperature), WP-Series (Pool Heating) W/WH-25/45/55 Model Sizes 25-80 (Heating/Cooling) Model Sizes 45-80 (Pool Heating) Model Size 85 (Domestic Hot Water) WH-85-H (DHW) W/WH-65/75/80 WP-45/55/65/75/80 Maritime Geothermal Ltd. info@nordicghp.com P.O.

- Page 2 SAFETY PRECAUTIONS WARNING: Ensure all access panels are in place and properly secured before applying power to the unit. Failure to do so may cause electrical shock. WARNING: Before performing service or maintenance on the heat pump system, ensure all power sources are DISCONNECTED.

- Page 3 APPLICATION TABLE: W-SERIES OUTDOOR INDOOR MODEL FUNCTION REFRIGERANT VOLTAGE COMPRESOR REVISIONS COIL COIL W-25 HACW W-45 HACW W-55 HACW W-65 HACW W-75 HACW W-80 HACW This manual applies only to the models and revisions listed in this table APPLICATION TABLE - FIRMWARE AND PC APP Firmware Version* Associated PC APP...

- Page 4 APPLICATION TABLE: WH-SERIES OUTDOOR INDOOR SIZE FUNCTION REFRIGERANT VOLTAGE COMPRESSOR REVISIONS COIL COIL WH-25 HACW WH-45 WH-55 WH-65 HACW WH-75 HACW WH-80 HACW WH-85 This manual applies only to the models and revisions listed in this table APPLICATION TABLE - FIRMWARE AND PC APP Firmware Version* Associated PC APP...

- Page 5 APPLICATION TABLE: WP-SERIES OUTDOOR INDOOR MODEL FUNCTION REFRIGERANT VOLTAGE COMPRESOR REVISIONS COIL COIL WP-45 WP-55 WP-65 WP-75 WP-80 This manual applies only to the models and revisions listed in this table APPLICATION TABLE - FIRMWARE AND PC APP Firmware Version* Associated PC APP Version MGT GEN2 Bootload Firmware...

-

Page 6: Table Of Contents

Table of Contents Documents Ground Loop Installations ................7 ..........38 Circulator Pump Module ............38 Tables ................... 8 Flushing & Purging ............... 38 Series System Description Antifreeze Solution ..............39 ..........9 Initial Pressurization .............. 39 W-series .................. 9 Pipe Insulation .............. -

Page 7: Documents

Performance Tables: W-25 ............ 99 WH-Series Dimensions ............118 Performance Tables: W-45 ..........100 Model Specific Information: WP-Series ....119 Performance Tables: W-55 ..........101 WP-Series Refrigerant Charge ........... 119 Performance Tables: W-65 ..........102 WP-Series Shipping Information ......... 119 Performance Tables: W-75 .......... -

Page 8: Tables

Tables Table 1 - Heat Pump Size vs. Heated Area ................... 11 Table 2 - Heat Pump Size vs. Heated Area ................... 11 Table 3 - Auxiliary Heat Sizing ....................... 11 Table 4 - Power Supply Connections ..................... 14 Table 5 - Indoor & Outdoor Circulator Connections ................14 Table 6 - BACnet Connections ...................... -

Page 9: Series System Description

Reversing units (-HAC/HACW) There are several types of NORDIC water to water heat pumps: can also chill water for hydronic cooling applications. W-series Being a water source, ’geoexchange’, or ‘geothermal’ heat... -

Page 10: One Or Two Buffer Tanks

One or Two Buffer Tanks? This is an important design choice that needs to be made when planning an installation. These systems are described more fully in the following chapters. Single Buffer Tank Systems By far, this is how most systems are config- ured. -

Page 11: Sizing For Space Heating/Cooling

Sizing for Space Heating/Cooling W/WH-Series Heat Pump Sizing heat pump sizing, choose a heat pump with a standard capacity rating that matches or just slightly exceeds the calculated heat Table 1 shows the above grade size of building that can load. -

Page 12: Sizing For Pool Heating

Difference between desired pool temperature and outdoor age to the building envelope. temperature during coldest month of use A NORDIC PC-series indoor pool room dehumidifier re- · Wind exposure jects its heat into the pool room air or pool water, and can pro- ·... -

Page 13: Installation Basics

Installation Basics Unpacking the Unit heat pump and circulator pump module in one location. The hydronic layout may make a particular location ideal for the unit When the heat pump reaches its destination it should be installation. unpacked to determine if any damage has occurred during Looking at the side of the heat pump where the pipes shipment. -

Page 14: Wiring

Wiring Power Supply Connections per the voltage of the circulator pump module. Ground wire should be connected to the ground lug in the electrical box. Power supply for the heat pump from the breaker panel is Ensure that the total current draw does not exceed the value supplied to the unit via concentric 1.093”... -

Page 15: Bacnet Connections

BACnet Connections Both D1-D2 and D2-C default to ON and so must be used with an auxiliary heating device that has a HIGH TEMPERATURE LIMITER to If using BACnet for external control of heating/cooling de- avoid a serious safety hazard. mand and/or monitoring of status, use a shielded twisted pair to the connector at the bottom left of control board. -

Page 16: 002241Cdg - Typ. Gen2 Aux. Heat & Circulator Wiring

ISSUE 04: 23-Sep-2022 Page 16 002500MAN-01... -

Page 17: 002375Qss - Altsource Tanks: Getting Started

ISSUE 04: 23-Sep-2022 Page 17 002500MAN-01... -

Page 18: 002067Cdg - Typ. Heating Only Zone Wiring (Setpoint)

ISSUE 04: 23-Sep-2022 Page 18 002500MAN-01... -

Page 19: 002068Cdg - Typ. Htg/Cooling Zone Wiring (Setpoint)

ISSUE 04: 23-Sep-2022 Page 19 002500MAN-01... -

Page 20: 002069Cdg - Typ. Heating Only Zone Wiring (Signals)

ISSUE 04: 23-Sep-2022 Page 20 002500MAN-01... -

Page 21: 002070Cdg - Typ. Htg/Cooling Zone Wiring (Signals)

ISSUE 04: 23-Sep-2022 Page 21 002500MAN-01... -

Page 22: Piping

Piping W/WH-Series: Number of Tanks with the recommended size. The recommended size will mini- mize the number of starts per hour and provide longer runtimes All W/WH-series systems will require at least one buffer for improved efficiency. tank. If there is one buffer tank, it will contain the heated or Outdoor Loop chilled water. -

Page 23: Wh-Hac: Modulating Water Valve

WP-Series Pool Piping Connections WH-HAC: Modulating Water Valve WP-series connections for the outdoor loop are the A high temperature heat pump may typically be heating same type as W/WH series: 1” brass female NPT. They are the indoor loop to 130-160°F (54-71°C) using a cold (outdoor) labelled OUTDOOR IN and OUTDOOR OUT. -

Page 24: 002287Pdg - Typical Piping Connections - W/Wh 25-80

ISSUE 04: 23-Sep-2022 Page 24 002500MAN-01... -

Page 25: 002366Pdg - Recommended Buffer Tank Piping

ISSUE 04: 23-Sep-2022 Page 25 002500MAN-01... -

Page 26: 002367Pdg - Auxiliary Boiler Piping

ISSUE 04: 23-Sep-2022 Page 26 002500MAN-01... -

Page 27: 002528Pdg - Buffer Tank Piping - Multiple Units

ISSUE 04: 23-Sep-2022 Page 27 002500MAN-01... -

Page 28: 002240Pdg - Dhw With Single Wall Condenser

ISSUE 04: 23-Sep-2022 Page 28 002500MAN-01... -

Page 29: 002545Pdg - Tank Piping For Direct Dhw Heating

ISSUE 04: 23-Sep-2022 Page 29 002500MAN-01... -

Page 30: 002252Pdg - Two Tank Piping With A Rev. Heat Pump

ISSUE 04: 23-Sep-2022 Page 30 002500MAN-01... -

Page 31: 002527Pdg - 2 Tank Piping W/Multiple Rev. Heat Pumps

ISSUE 04: 23-Sep-2022 Page 31 002500MAN-01... -

Page 32: 002288Pdg - Two Tank Simultaneous Heating/Cooling

ISSUE 04: 23-Sep-2022 Page 32 002500MAN-01... -

Page 33: 001680Pdg - Two Tank Simultaneous (Diverting)

ISSUE 04: 23-Sep-2022 Page 33 002500MAN-01... -

Page 34: 000530Pdg - Typical Zone Types

ISSUE 04: 23-Sep-2022 Page 34 002500MAN-01... -

Page 35: 002286Pdg - Snow Melt W/Ground Loop Re-Heating

ISSUE 04: 23-Sep-2022 Page 35 002500MAN-01... -

Page 36: 000970Pdg - Desup. Connection To Dhw Pre-Heat Tank

ISSUE 04: 23-Sep-2022 Page 36 002500MAN-01... -

Page 37: 002384Pdg - Desup. Connection - Multiple Units

ISSUE 04: 23-Sep-2022 Page 37 002500MAN-01... -

Page 38: Ground Loop Installations

Ground Loop Installations When satisfied that all connections are leak free, release WARNING: The R134a WH-series requires a the air pressure and connect a purge cart (see Figure 1) to the source fluid temperature of 45°F (7°C) or great- er. Therefore, the WH series may not use a flushing access ports at the pump module (refer to drawing ground loop except in suitably warm climates. -

Page 39: Antifreeze Solution

Adjust the circulator pump module valves to connect the TABLE 12 - Volume of fluid per 100 ft. of pipe purge cart to the ground loop. Begin pumping water through the ground loop, ensuring that the intake of the pump stays Volume /100ft. -

Page 40: 000608Inf - Typical Horiz. Ground Loop Configuration

ISSUE 04: 23-Sep-2022 Page 40 002500MAN-01... -

Page 41: 000609Inf - Typical Vert. Ground Loop Configuration

ISSUE 04: 23-Sep-2022 Page 41 002500MAN-01... -

Page 42: 000906Cdg - Circulator Pump Module Installation

ISSUE 04: 23-Sep-2022 Page 42 002500MAN-01... -

Page 43: 001823Cdg - Dual Flow Pump Module Installation

ISSUE 04: 23-Sep-2022 Page 43 002500MAN-01... -

Page 44: 000629Pdg - Pump Module Inst - 2 Units On 1 Loop

ISSUE 04: 23-Sep-2022 Page 44 002500MAN-01... -

Page 45: Open Loop Installations

Open Loop Installations WARNING: The R134a WH-series absolutely It is best to flow the well for as long as possible (e.g. 12 requires a source water temperature of 45°F hours) at the flow rate required by the proposed heat pump size. (7°C) or greater. -

Page 46: Water Valve

A return well should be a minimum of 80 ft. from the supply Figure 3: Open Loop Accessories & Tools well for residential applications. The water returned to the well will not necessarily be pumped into the same aquifer, depend- Cumulative Water ing on underground conditions. -

Page 47: Water Flow Control

act as the water valve and an additional valve is not required. to satisfy the heating demand as quickly as possible and mini- The closed loop jumper plug can be left in place for WH-series. mize run time. For the same reason, slightly oversizing the heat pump is acceptable on open loop applications, although this will require higher water flow. -

Page 48: 000907Cdg - Typical Open Loop Installation

ISSUE 04: 23-Sep-2022 Page 48 002500MAN-01... -

Page 49: 001822Cdg - Dual Flow Open Loop Installation

ISSUE 04: 23-Sep-2022 Page 49 002500MAN-01... -

Page 50: 000619Inf - Ground Water Disposal Methods

ISSUE 04: 23-Sep-2022 Page 50 002500MAN-01... -

Page 51: Operation

Operation 1. BACnet Control 3. Setpoint Control If using BACnet Control, the heat pump will turn the com- One of the features of the heat pump’s GEN2 Control pressor on and off and activate cooling mode when it is told to Board is built in temperature control functionality called by the building control system. -

Page 52: Typical Temperature Setpoints

Setpoint Control window looks like this for Method 1 TABLE 15 - WP-series Typical Temp. Setpoints (Indoor Loop - ICR): Stage 1 Stage 2 (Aux) HEATING °F °C °F °C Setpoint Delta Activation * Delay 10 minutes Setpoint Delta RED—heating Activation * BLUE—cooling Delay... -

Page 53: Outdoor Reset

Outdoor Reset Then enable the outdoor sensor in the Tools --> Configu- ration window or LCD interface: As mentioned earlier, lower heating setpoints will translate directly into a higher COP (efficiency). When Control Source HYD is set to Setpoints, an op- PC APP: Tools-->Configuration tional Outdoor Reset control algorithm is available for heating... -

Page 54: Setpoint Control Method 2 - Indoor Loop (Icr), 2 Tanks

Setpoint Control Method 2 - Indoor Loop (ICR) Two Tanks It is possible to use all of the Setpoint Control Method 1 However, it is suggested to use Method 4 (External HTS/ settings, and operate two buffer tanks: one for heated water and CTS with two tanks) for this purpose. -

Page 55: Setpoint Control Method 3 - External Hts/Cts, One Tank

Setpoint Control Method 3 - External (HTS/CTS) One Tank right corner of the PC App’s Tools-->Configuration window or a) HTS/CTS w/ One Tank - Heat Pump Mode use the LCD interface and select SYSTEM ENABLE. Most of the time, water heating/cooling heat pumps turn on See below, and also the PC Application (PC App) section... -

Page 56: B) Chiller Mode

Setpoint Control window looks like this for Method 3b b) HTS/CTS w/ One Tank - Chiller Mode (External HTS/CTS with One Tank, Chiller Mode): For non-reversing models only (H/HW), Chiller Mode allows the heat pump to be controlled from the Outdoor Loop (cold side) rather than the... -

Page 57: Setpoint Control Method 4 - External Hts/Cts, 2 Tanks

Setpoint Control Method 4 - External (HTS/CTS) Two Tanks *REVERSING MODELS ONLY (HAC/HACW) Setpoint Control window looks like this for Method 4 PC APP: (External HTS/CTS with Two Tanks): Tools-->Configuration LCD Interface: Configuration Like with Method 3, when this method is used no indoor circulator control for temperature sampling will occur. -

Page 58: Pc Application (Pc App)

PC Application (PC App) NOTE: Before using the PC Application, refer to Appendices for installation instructions for the PC Application and USB driver for the COM port. Both must be installed in order to run the PC App and communicate with the control board. Connect a USB cable between the PC and the control board USB connector located at the bottom center of the board. - Page 59 View Menu: This menu handles all of the operational viewing screens. Clicking on the View submenus will open the page in the PC APP’s frame. The next few pages of the manual show screenshots of each of the pages along with some descriptions of what is on each page. View-->Control Panel: The main control panel window will open, shown below.

- Page 60 View-->Alarms, Limits and Faults (ALARMS Tab): NOTE: Greyed out Alarms in the PC APP are not applicable to the system setup and are not monitored by the control board. NOTE: Refer to Alarms and Faults screenshot below to see which alarms have a count. Alarms without a count: These alarms only occur one time at which point they immediately create a Permanent Alarm.

- Page 61 View-->Alarms, Limits and Faults (ALARMS LIST Tab): This tab show a history of alarms that have occurred since the PC APP was connected to the control board. This list will be lost when the PC APP is disconnected. Each alarm that occurs while This button will erase the the PC APP is connected to alarm events in the Alarm List.

- Page 62 View-->Alarms, Limits and Faults (FAULTS tab): This tab shows hardware faults that could occur. If one of these faults occurs there may be a problem with the control board hard- ware, with LCD Display and buttons, or with a sensor. If a fault occurs, some things to try: ·...

- Page 63 View-->Set Stage 2 Delay Sets the Stage 1 run time after which stage 2 will be forced ON. Set to 0:00 to disable. (Applicable to R410a heat pumps with 2- stage compressors only.) View-->Water Lines Shows the water line temperatures. View-->Digital Inputs Shows the digital inputs and their individual status (ON/OFF).

- Page 64 Graphs Menu: This menu is a list of the available graphs. Graphs are real-time and show a time stamp of when the recording started as well as a current time which will show up if the graph is screen captured. Each graph has a CLEAR button which will erase the stored data and restart the graph.

- Page 65 Tools Menu: This is where various tools for system setup and monitoring are located. Tools-->Configuration (System Configuration tab): This is where the system setup is done. Settings should only be changed by a person who has a good understanding of sys- tem operation.

- Page 66 Tools-->Configuration (Alarms and Delays tab): Click on the UP/DOWN arrows to change the value, noting that values have both a low and high limit. The number of minutes before the The minimum off unit can start again after various time when switching Count Reduce Time is alarm shutdowns between heating and...

- Page 67 Tools-->Calibration: Generally there is no need for calibration. The suction and discharge pressures may be calibrated in increments of 1 psi if there is a discrepancy in the readings when compared to a known good reference. Temperature sensors may be adjusted in increments of 0.1°F. There is an AUTO CALIBRATION routine in the program that continu- ally calibrates the temperatures sensors against an on board reference resistor by applying an offset to the temperature sensors.

- Page 68 Tools-->Datalogging (Datalog tab): A log will be automatically recorded at the following rates: · SYSTEM DISABLED: every 10 minutes · SYSTEM ENABLED: logging frequency set via the dropdown box at the top right of the PC App main window · ALARM: logging frequency automatically set to 10 seconds, for 2 hours ·...

- Page 69 Tools-->Parameters: WARNING! The Parameters page is for advanced use only. Changing parameter values can cause the system to stop functioning properly. The parameters page shows all configurable memory spaces with their name and current value and allows them to be edited directly. To change a parameter value type in the new value and press ENTER.

-

Page 70: Lcd Interface & Menus

LCD Interface & Menus These are examples of the unit status and operating data displayed when at the message display level (top level). Pressing ENTER will enter into the menu levels beginning with the Main Menu. 2x16 LCD ENTER button: UP button: DOWN button: OK/EXIT button:... - Page 71 Main Menu Tree Continued ENTER ENTER ENTER ENTER Description (From Main) (First Press) (Second Press) (Third Press) Summer Setback — Enable Setback? — Enable Enable summer setback. (only if using — Disable Disable summer setback. Setpoint Control) System EN/DIS — Enable System? —...

-

Page 72: Bacnet Interface

BACnet Interface The BACnet interface is an MS/TP connection via RS-485 twisted pair. BACnet IP is not available. Recommended wire: 22-24 AWG single twisted pair, 100-120 Ohms impedance, 17pF/ft or lower capacitance, with braided or alumi- num foil shield, such as Belden 9841 or 89841. The connector on the control board is a three wire removable screw connector. -

Page 73: Table 21 - Bacnet Objects - Data (Read Only)

TABLE 21 - BACnet OBJECTS - DATA (Read Only) Name Property Units Description AI0 (Comp1_Current) Present Value Amps Compressor current draw (AI0) - requires accessory AI1 (Comp2_Current) Present Value User User defined (0-5VDC or 4-20mA) Present Value User User defined (0-5VDC or 4-20mA) Present Value User User defined (0-5VDC or 4-20mA) -

Page 74: Table 22 - Bacnet Objects - Alarm Descriptions (Read Only)

TABLE 22 - BACnet OBJECTS - ALARM Descriptions (Read Only) Name Data Type Description AI0 (Comp1 Current) Analog Input Status alarm (Start / Stop Failure) - requires current sensor accessory AI1 (Comp2 Current) Analog Input LPS1 Analog Input Low pressure alarm HPS1 Analog Input High pressure alarm... -

Page 75: Table 23 - Bacnet Objects - Fault Descriptions (Read Only)

TABLE 23 - BACnet OBJECTS - FAULT Descriptions (Read Only) Name Data Type Description AI4 (Cold Tank) Analog Input Cold tank temperature sensor faulty or disconnected - requires accessory Hot tank temperature sensor faulty or disconnected - requires accessory AI5 (Hot Tank) Analog Input LPS1 Analog Input... -

Page 76: Startup Procedure

Startup Procedure The W/WH-Series Startup Record located in this manual is used in conjunction with this startup procedure to provide a detailed record of the installation. A completed copy should be left on site, a copy kept on file by the installer, and a copy should be sent to Maritime Geothermal Ltd. - Page 77 Unit Startup The unit is now ready to be started. The steps below outline the procedure for starting the unit and verifying proper operation of the unit. It is recommended that safety glasses be worn during the following procedures. IMPORTANT NOTE: The unit is shipped with the SYSTEM DISABLED in order to prevent the unit from starting when the power is first turned on.

-

Page 78: Startup Record

Startup Record Startup Date Installation Site Installer City Company Check boxes unless Province Model asked to record data. Country Serial # Circle data units. Customer Name Customer Phone # PRE-START INSPECTION Indoor Loop All shut-off valve are open (full flow available) (Hydronic) Loop is full and purged of air Antifreeze type, if any... -

Page 79: Routine Maintenance

Routine Maintenance MAINTENANCE SCHEDULE Item Interval Procedure Compressor 1 year Inspect for pitted or burned points. Contactor Replace if necessary. LCD Interface or When heat pump Check for alarms and faults (only necessary if alarms PC App problem is suspected not reported through a BACnet system). -

Page 80: Troubleshooting Guide

Troubleshooting Guide The following steps are for troubleshooting the heat pump. Repair procedures and reference refrigeration circuit diagrams can be found later in this manual. STEP 1: Verify that the LCD screen is functioning . If it is not, proceed to POWER SUPPLY TROUBLE SHOOTING, otherwise pro- ceed to STEP 2. - Page 81 ALARM TROUBLESHOOTING Alarm/Fault Description Recommended Action The data logging function of the GEN2 Control Board is a very useful tool for troubleshooting alarms. It provides a histo- ry of the unit operation up to and including the time at which the alarm(s) occurred. Note that some alarms require ac- cessory components.

- Page 82 FAULT TROUBLESHOOTING Alarm/Fault Description Recommended Action Digital Inputs Digital Outputs Analog Inputs Cycle the power a few times; if the A failure has occurred and the indicated section of the fault persists replace the control control board may no longer work properly. MODBUS Comms board.

- Page 83 COMPRESSOR TROUBLESHOOTING Fault Possible Cause Verification Recommended Action Compressor will Faulty control board. No 24vac output on STAGE1 when Replace control board. not start compressor should be operating. Faulty run capacitor. Check value with capacitance meter. Replace if faulty. (Single phase only) Should match label on capacitor.

- Page 84 OPERATION TROUBLESHOOTING - HEATING MODE Fault Possible Cause Verification Recommended Action High or low suc- Faulty sensor Compare pressure sensor reading Check wiring, replace sensor. If tion or discharge against a known reference such as a problem persists, replace control pressure new refrigeration manifold set.

- Page 85 OPERATION TROUBLESHOOTING - HEATING MODE Fault Possible Cause Verification Recommended Action Low suction EEV stuck almost closed Manually adjusting the EEV does Go to EEV troubleshooting sec- pressure or partially blocked by for- not affect the superheat or the suc- tion.

- Page 86 OPERATION TROUBLESHOOTING - COOLING MODE (HACW / HAC models only) Fault Possible Cause Verification Recommended Action Heating instead Zone thermostat intercon- Verify that there is 24VAC across O Correct setup. of cooling nection or zone controller and C of the terminal strip when not set up properly.

- Page 87 OPERATION TROUBLESHOOTING - COOLING MODE (HACW / HAC models only) Fault Possible Cause Verification Recommended Action High suction EEV stuck open Manually adjusting the EEV does Go to EEV troubleshooting section. pressure not affect the superheat or the suc- (may appear to tion pressure.

- Page 88 EEV TROUBLESHOOTING If there is a refrigeration problem such as low charge, plugged filter-dryer, EEV stuck, or any other kind of restriction in the refrigeration system, the apparent EEV position will work its way towards 100% (full open). High superheat is also a symptom.

- Page 89 DOMESTIC HOT WATER (DESUPERHEATER) TROUBLESHOOTING (HACW / HW models only) Fault Possible Cause Verification Recommended Action Insufficient hot Thermostat on hot water Visually inspect the setting. Adjust the setting. water (tank tank set too low. Should problem) be set at 120°F to 140°F. Breaker tripped, or fuse Check both line and load sides of Correct problem, and replace...

-

Page 90: Repair Procedures

Repair Procedures Pumpdown Procedure 1. Place the unit in SERVICE mode via the PC App or LCD interface; this will open the EEVs and start the indoor circu- lator (as long that circulator is powered and controlled by the heat pump). DO NOT turn off electrical power at the breaker panel, since the coaxial coils must have full water flow during refrigerant recovery. -

Page 91: Compressor Replacement Procedure

Compressor Replacement Procedure 1. Pump down the unit as per the Pumpdown Procedure above. If there was a compressor burn out (motor failure), the refrigerant cannot be reused and must be disposed of according to local codes. 2. Disconnect piping. 3. -

Page 92: Control Board Replacement Procedure

Control Board Replacement Procedure 1. Turn the power off to the unit. 2. Take a picture of the control board and connectors for reference. The picture in Appendix A may also be helpful. 3. Carefully remove all green terminal strips on the left side, the right side and the bottom of the control board. They pull straight off the board, with no need to disconnect wires from their screw terminals. -

Page 93: Lcd Interface (Display) Board Replacement Procedure

LCD Interface (Display) Board Replacement Procedure 1. Turn the power off to the unit. 2. Remove the display board cable connector from the control board. 3. Using a sharp utility knife with a long blade, slice each of the display board standoff heads off, taking care to not damage the lexan cover. -

Page 94: Model Specific Information: W-Series

Model Specific Information: W-Series Table 24 - W-Series Refrigerant Charge Table 25 - W-Series Shipping Information MODEL Refrigerant Oil Type WEIGHT DIMENSIONS in (cm) MODEL W-25 R410a lb. (kg) W-45 R410a W-25 305 (138) 34 (86) 34 (86) 35 (89) W-55 R410a W-45... -

Page 95: W-Series Pressure Drop Data

Table 29: W-Series Pressure INDOOR OUTDOOR OUTDOOR OUTDOOR Drop Data (water 104°F) (water 50°F) (15% methanol 32°F) (35% prop. glycol 32°F) 0.25 0.32 0.38 0.44 0.50 W-25 0.57 0.63 0.69 0.76 0.82 10.1 0.38 0.44 0.50 0.57 0.63 W-45 0.69 0.76 0.82 0.88... - Page 96 Table 29: W-Series Pressure INDOOR OUTDOOR OUTDOOR OUTDOOR (cont’d) Drop Data (water 104°F) (water 50°F) (15% methanol 32°F) (35% prop. glycol 32° 0.50 0.57 0.63 0.69 W-65 0.76 0.82 0.88 0.95 1.01 0.50 0.57 0.63 0.69 0.76 W-75 0.82 0.88 0.95 1.01 1.07...

-

Page 97: W-Series: Standard Capacity Ratings - Closed Loop

W-series: Standard Capacity Ratings - Closed Loop Standards ARI/ISO/CSA 13256-2 Table 30 - Standard Capacity Ratings - Ground Loop Heating* 60Hz STAGE 1 - ELT 41°F (5°C) EWT 104°F (40°C) *15% Methanol by Weight Ground Loop Fluid STAGE 2 - ELT 32°F (0°C) Liquid Flow Input Capacity... -

Page 98: W-Series: Standard Capacity Ratings - Open Loop

W-series: Standard Capacity Ratings - Open Loop Standards ARI/ISO/CSA 13256-2 Table 32 - Standard Capacity Ratings - Ground Water Heating 60Hz EWT 104°F (40°C) EWT 104°F (40°C) ELT 50°F (10°C) Liquid Flow Input Capacity (Outdoor & Indoor) Energy Model Mode Watts Btu/hr Stage 1... -

Page 99: Performance Tables: W-25

Performance Tables W-25-HACW-P-1T R410a, 60 Hz, ZPS20K6E-PFV OUTDOOR LOOP (15% Methanol) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) -

Page 100: Performance Tables: W-45

Performance Tables W-45-HACW-P-1T R410a, 60 Hz, ZPS30K6E-PFV OUTDOOR LOOP (15% Methanol) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) -

Page 101: Performance Tables: W-55

Performance Tables W-55-HACW-P-1T R410a, 60 Hz, ZPS40K6E-PFV OUTDOOR LOOP (15% Methanol) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) -

Page 102: Performance Tables: W-65

Performance Tables W-65-HACW-P-1T R410a, 60 Hz, ZPS51K6E-PFV OUTDOOR LOOP (15% Methanol) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) -

Page 103: Performance Tables: W-75

Performance Tables W-75-HACW-P-1T R410a, 60 Hz, ZPS60K6E-PFV OUTDOOR LOOP (15% Methanol) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) -

Page 104: Performance Tables: W-80

Performance Tables W-80-HACW-P-1T R410a, 60 Hz, ZP72KCE-PFV OUTDOOR LOOP (15% Methanol) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) -

Page 105: W-Series Electrical Specifications

W-Series Electrical Specifications * equipped with K6E compressors where available Max. Min. TABLE Power Supply Compressor Circulators Breaker Wire Code V-ø-Hz Max. A Amps Amps Amps 208/230-1-60 10.9 16.7 19.4 #10-2* 208-3-60 12.3 13.9 #12-3* 460-3-60 #14-3 W-25 220-1-50 15.0 17.3 #10-2 380-3-50... -

Page 106: W-Series Dimensions

Dimensions: W-25/45/55 All dimensions in inches. RECOMMENDED LEFT SIDE RECOMMENDED FRONT CLEARANCE: CLEARANCE RIGHT SIDE CLEARANCE: 2 FT OPTIONAL 2 FT NO BACK CLEARANCE REQUIRED Dimensions: W-65/75/80 LEFT SIDE RECOMMENDED RECOMMENDED CLEARANCE FRONT CLEARANCE: RIGHT SIDE CLEARANCE: 2 FT 2 FT OPTIONAL NO BACK CLEARANCE REQUIRED ISSUE 04: 23-Sep-2022... -

Page 107: Model Specific Information: Wh-Series

Model Specific Information: WH-Series Table 35 - WH-Series Refrigerant Charge Table 36 - WH-Series Shipping Information MODEL Refrigerant Oil Type WEIGHT DIMENSIONS in (cm) MODEL lb. (kg) WH-25 R134a WH-45 R134a WH-25 285 (129) 34 (86) 34 (86) 35 (89) WH-55 R134a WH-45... -

Page 108: Wh-Series Pressure Drop Data

Table 40: WH-Series Pressure INDOOR OUTDOOR Drop Data (water 104°F) (water 50°F) 0.25 0.32 0.38 0.44 0.50 WH-25 0.57 0.63 0.69 0.76 0.82 0.38 0.44 0.50 0.57 0.63 WH-45 0.69 0.76 0.82 0.88 0.95 0.38 0.44 0.50 0.57 0.63 WH-55 0.69 0.76 0.82... - Page 109 Table 40: WH-Series Pressure INDOOR OUTDOOR (cont’d) Drop Data (water 104°F) (water 50°F) 0.50 0.57 0.63 0.69 WH-65 0.76 0.82 0.88 0.95 1.01 0.50 0.57 0.63 0.69 0.76 WH-75 0.82 0.88 0.95 1.01 1.07 0.57 0.63 0.69 0.76 0.82 WH-80 0.88 0.95 1.01...

-

Page 110: Performance Tables: Wh-25

Performance Tables Performance Tables WH-25-H***-B-1S R134a, 60 Hz, ZR21K5E-PFV OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. -

Page 111: Performance Tables: Wh-45

Performance Tables WH-45-H***-B-1S R134a, 60 Hz, ZR32K5E-PFV OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) (Btu/hr) -

Page 112: Performance Tables: Wh-55

Performance Tables WH-55-H***-B-1S R134a, 60 Hz, ZR42K5E-PFV OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) (Btu/hr) -

Page 113: Performance Tables: Wh-65

Performance Tables WH-65-H***-B-1S R134a, 60 Hz, ZR54K5E-PFV OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) (Btu/hr) -

Page 114: Performance Tables: Wh-75

Performance Tables WH-75-H***-B-1S R134a, 60 Hz, ZR61K5E-PFV OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) (Btu/hr) -

Page 115: Performance Tables: Wh-80

Performance Tables WH-80-H***-B-1S R134a, 60 Hz, ZR68KCE-PFV OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A) Power (W) (°F) Temp. (gpm) (°F) (°F) (Btu/hr) -

Page 116: Performance Tables: Wh-85

Performance Tables WH-85-H-B-2S R134a, 60 Hz, ZR94KCE-TF5 OUTDOOR LOOP (Water) ELECTRICAL INDOOR LOOP (Water) Evap. Flow Delta T Heat Abs. Compressor Input Cond. Flow Delta T Heating (°F) Temp. (gpm) (°F) (°F) (Btu/hr) Current (A)* Power (W) (°F) Temp. (gpm) (°F) (°F) (Btu/hr) -

Page 117: Wh-Series Electrical Specifications

WH-Series Electrical Specifications Max. Min. TABLE Power Supply Compressor Circulators Breaker Wire Code V-ø-Hz Max. A Amps Amps Amps 208/230-1-60 10.8 16.0 18.7 #10-2* 208-3-60 12.9 14.8 #12-3* 460-3-60 #14-3 WH-25 220-1-50 14.5 16.8 #10-2 380-3-50 10.0 #14-4** 230-1-60 15.4 20.6 24.5 #8-2*... -

Page 118: Wh-Series Dimensions

Dimensions: WH-25/45/55 All dimensions in inches. RECOMMENDED LEFT SIDE RECOMMENDED FRONT CLEARANCE: CLEARANCE RIGHT SIDE CLEARANCE: 2 FT OPTIONAL 2 FT NO BACK CLEARANCE REQUIRED Dimensions: WH-65/75/80 CLEARANCES: AS ABOVE Dimensions: WH-85 CLEARANCES: AS ABOVE ISSUE 04: 23-Sep-2022 Page 118 002500MAN-01... -

Page 119: Model Specific Information: Wp-Series Wp-Series Refrigerant Charge

Model Specific Information: WP-Series Table 42 - WP-Series Refrigerant Charge Table 43 - WP-Series Shipping Information MODEL Refrigerant Oil Type WEIGHT DIMENSIONS in (cm) MODEL WP-45 R410a lb. (kg) WP-55 R410a WP-45 320 (145) 48 (122) 37 (94) 37 (94) WP-65 R410a WP-55... -

Page 120: Wp-Series Outdoor Loop Water Pressure Drop

Table 48: WP Outdoor Loop OUTDOOR OUTDOOR OUTDOOR Pressure Drop (water 50°F) (15% methanol 32°F) (35% prop. glycol 32°F) 0.38 0.44 0.50 0.57 0.63 WP-45 0.69 0.76 0.82 0.88 11.3 0.95 12.5 0.38 0.44 0.50 0.57 0.63 WP-55 0.69 0.76 0.82 0.88 0.95... -

Page 121: Wp-Series Capacity Ratings

WP-Series Capacity Ratings The tables show the heat pump performance when heating a pool to 80°F (27°C), or a hot tub to 104°F (40°C). All data is for 60 Hz operation with water as the pool loop fluid. METRIC Table 49 - Standard Capacity Ratings: HEATING Table 49a - Standard Capacity Ratings: HEATING... -

Page 122: Wp-Series Electrical Specifications

WP-Series Electrical Specifications Max. Min. TABLE Power Supply Compressor Circulators Breaker Wire Code V-ø-Hz Max. A Amps Amps Amps 208/230-1-60 15.4 20.6 24.5 #8-2* 208-3-60 10.4 15.6 18.2 #10-3* 460-3-60 #14-3 WP-45 575-3-60 #14-3 220-1-50 13.5 18.7 22.1 #10-2 380-3-50 10.6 12.0 #14-3*... -

Page 123: W/Wh/Wp Wiring Diagrams & Electrical Box Layouts

W/WH/WP-Series Wiring Diagram (208/230-1-60) ISSUE 04: 23-Sep-2022 Page 123 002500MAN-01... -

Page 124: 001890Elb - W/Wh/Wp-**-H***-*-1*-** Electrical Box Diagram

W/WH/WP-Series Electrical Box Layout (208/230-1-60) ISSUE 04: 23-Sep-2022 Page 124 002500MAN-01... -

Page 125: 001934Sch - W/Wh/Wp-**-H***-*-2*-** Schematic Diagram

W/WH/WP-Series Wiring Diagram (208-3-60) ISSUE 04: 23-Sep-2022 Page 125 002500MAN-01... -

Page 126: 001935Elb - W/Wh/Wp-**-H***-*-2*-** Electrical Box Diagram

W/WH/WP-Series Electrical Box Layout (208-3-60) ISSUE 04: 23-Sep-2022 Page 126 002500MAN-01... -

Page 127: 001936Sch - W/Wh/Wp-**-H***-*-4*-** Schematic Diagram

W/WH/WP-Series Wiring Diagram (460-3-60) ISSUE 04: 23-Sep-2022 Page 127 002500MAN-01... -

Page 128: 001937Elb - W/Wh/Wp-**-H***-*-4*-** Electrical Box Diagram

W/WH/WP-Series Electrical Box Layout (460-3-60) ISSUE 04: 23-Sep-2022 Page 128 002500MAN-01... -

Page 129: 001938Sch - W/Wh/Wp-**-H***-*-5*-** Schematic Diagram

W/WH/WP-Series Wiring Diagram (575-3-60) ISSUE 04: 23-Sep-2022 Page 129 002500MAN-01... -

Page 130: 001939Elb - W/Wh/Wp-**-H***-*-5*-** Electrical Box Diagram

W/WH/WP-Series Electrical Box Layout (575-3-60) ISSUE 04: 23-Sep-2022 Page 130 002500MAN-01... -

Page 131: 001940Sch - W/Wh/Wp-**-H***-*-6*-** Schematic Diagram

W/WH/WP-Series Wiring Diagram (220-1-50) ISSUE 04: 23-Sep-2022 Page 131 002500MAN-01... -

Page 132: 001941Elb - W/Wh/Wp-**-H***-*-6*-** Electrical Box Diagram

W/WH/WP-Series Electrical Box Layout (220-1-50) ISSUE 04: 23-Sep-2022 Page 132 002500MAN-01... -

Page 133: 001942Sch - W/Wh/Wp-**-H***-*-7*-** Schematic Diagram

W/WH/WP-Series Wiring Diagram (380-3-50) ISSUE 04: 23-Sep-2022 Page 133 002500MAN-01... -

Page 134: 001943Elb - W/Wh/Wp-**-H***-*-7*-** Electrical Box Diagram

W/WH/WP-Series Electrical Box Layout (380-3-50) ISSUE 04: 23-Sep-2022 Page 134 002500MAN-01... -

Page 135: Refrigeration Circuit Diagrams

Refrigeration Circuit Diagram: Sizes 25 to 80, Reversing ISSUE 04: 23-Sep-2022 Page 135 002500MAN-01... -

Page 136: 001877Rcd - W/Wh/Wp-H Refrigeration Circuit Diagram (Non-Reversing)

Refrigeration Circuit Diagram: Sizes 25 to 80, Non-Reversing ISSUE 04: 23-Sep-2022 Page 136 002500MAN-01... -

Page 137: 001674Rcd - Wh-85 Domestic Hot Water Heating Refrigeration Circuit Diagram

Refrigeration Circuit Diagram: WH-85 (DHW) ISSUE 04: 23-Sep-2022 Page 137 002500MAN-01... -

Page 138: Appendix A: Control Board Description

Appendix A: Gen2 Control Board Description The picture below shows the locations of the connectors and LED indicators of the control board. The control board offers many fea- tures such as short circuit protection on all digital outputs, Real Time Clock with super capacitor for backup power, WiFi capability, relay outputs for plenum heater control (if equipped), USB port, PIC32 microcontroller, etc. -

Page 139: Table A1 - Control Board Connector Descriptions (Top)

The tables describe the connections starting with the top of the board and working around the board counter clock-wise. TABLE A1 - Control Board Connector Descriptions (Top) Name Description HPS1/HI1 High Pressure Sensor 1 Measures discharge pressure. LPS1/LO1 Low Pressure Sensor 1 Measures suction pressure. -

Page 140: Table A3 - Control Board Connector Descriptions (Bottom)

TABLE A3 - Control Board Connector Descriptions (Bottom) Name Description BACnet MS/TP Ground for shield if required. BACnet MS/TP RS-485. BACnet MS/TP RS-485. STAGE1 Compressor Stage 1 Starts / stops the compressor. STAGE2 Compressor Stage 2 Unused. RV#1 Reversing Valve#1 Off in heating mode, on in cooling mode (reversing models only). -

Page 141: Table A4 - Control Board Connector Descriptions (Right Side)

TABLE A4 - Control Board Connector Descriptions (Right Side) Signal Description DI_1 Digital Input1 Unused. DI_0 Digital Input0 Low pressure select from open/closed loop harness (0=open loop, 1=closed loop) Phase Monitor2 Switch or dry contact from R to activate Summer Setback mode. Phase Monitor1 Accessory for 3 phase models. -

Page 142: Appendix B: Usb Driver Installation

Appendix B - USB Driver Installation 4. In the window that is displayed, click and hold down the The first step in connecting a Windows laptop computer to the mouse button on the folder name, and drag to your desktop: control board is to install the USB driver. -

Page 143: Appendix C: Pc App Installation

Appendix C - PC App Installation 4. In the window that is displayed, click and hold down the The PC App allows detailed interfacing with the control board mouse button on the folder name, and drag to your desktop: using a Windows laptop computer. Any Windows from XP and onwards should be compatible, but Windows 10 (as found on any recent laptop computer) is recommended. -

Page 144: Appendix D: Updating Firmware

Appendix D: Updating Firmware METHOD 1: Updating Firmware Using PC App This method can be used when updating post-2017 control 7. Click on YES. The following message box will appear: boards with bootloader version 2.0. This method will not work for older control boards with bootloader version 1.0 (approx. - Page 145 12. Click on Load Hex File. Select the 16. Close the PIC32 program. MGL_GEN2_V360.production.hex (or higher version num- ber) file, which is in the folder you created on the Desktop. 17. WAIT APPROXIMATELY 10 SECONDS. This gives the control board time to reset, initialize and re-connect to the PC USB port.

- Page 146 METHOD 2: Updating Firmware Using Jumper Pins This method should be used when updating older control boards 6. Turn the power back on. The control board is now in boot that have bootloader version 1.0, or where the PC App has trou- loader mode and is ready to be programmed.

-

Page 147: Warranty

Warranty: W-Series RESIDENTIAL LIMITED EXPRESS WARRANTY Unless a statement is specifically identified as a warranty, statements made by Maritime Geothermal Ltd. (“MG”) or its representatives relating to MG’s products, whether oral, written or contained in any sales literature, catalogue or agreement, are not express warranties and do not form a part of the basis of the bargain, but are merely MG’s opinion or commendation of MG’s products. - Page 148 Warranty: WH/WP-Series COMMERCIAL LIMITED EXPRESS WARRANTY Unless a statement is specifically identified as a warranty, statements made by Maritime Geothermal Ltd. (“MG”) or its representatives relating to MG’s products, whether oral, written or contained in any sales literature, catalogue or agreement, are not express warranties and do not form a part of the basis of the bargain, but are merely MG’s opinion or commendation of MG’s products.

Need help?

Do you have a question about the W Series and is the answer not in the manual?

Questions and answers