Table of Contents

Advertisement

Quick Links

G G

X X

G

X

G G

F F

G

F

M M

u u

M

u

INSTRUCTION MANUAL

GX-M series

GX-8202M / GX-8202MD / GX-10202M / GX-12001M

GX-22001M /GX-32001M / GX-32001MD

GF-M series

GF-8202M / GF-8202MD / GF-10202M / GF-12001M

GF-22001M / GF-32001M / GF-32001MD

1WMPD4003846

- -

M M

S S

-

M

S

- -

M M

S S

-

M

S

l l

t t

i i

- -

F F

u u

n n

c c

l

t

i

-

F

u

n

c

E E

R R

E

R

E E

R R

E

R

t t

i i

o o

n n

B B

a a

t

i

o

n

B

a

I I

E E

S S

I

E

S

I I

E E

S S

I

E

S

l l

a a

n n

c c

e e

l

a

n

c

e

Advertisement

Table of Contents

Summary of Contents for AND GX-M Series

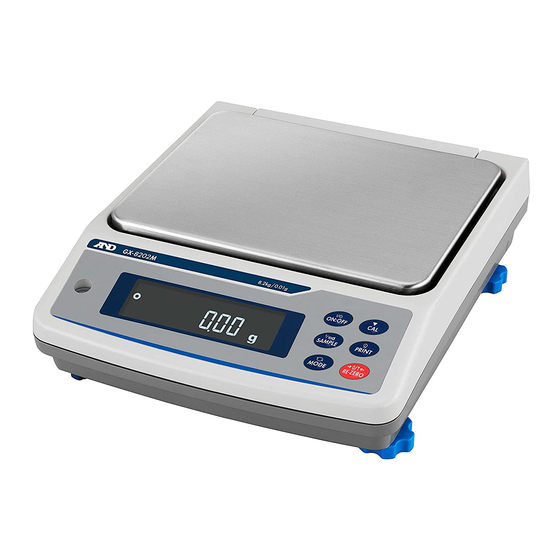

- Page 1 INSTRUCTION MANUAL GX-M series GX-8202M / GX-8202MD / GX-10202M / GX-12001M GX-22001M /GX-32001M / GX-32001MD GF-M series GF-8202M / GF-8202MD / GF-10202M / GF-12001M GF-22001M / GF-32001M / GF-32001MD 1WMPD4003846...

- Page 2 A&D Company Ltd. The contents of this manual and the specifications of the instrument covered by this manual are subject to change for improvement without notice.

-

Page 3: Table Of Contents

9-5 How to set the External Weight Value ....................41 9-6 Correcting The Internal Mass Value Of The GX-M series ..............42 9-7 Correcting The Internal Mass Value Of The GX-M series (Auto) .............. 43 10. Function Switch And Initialization ................44... - Page 4 13. Data Memory ......................78 13-1 Data Memory For Weighing Data ....................... 78 13-2 Data Memory For Calibration And Calibration Test ................82 13-3 Data Memory for Unit Mass in the Counting Mode ................85 13-4 Data Memory for Comparator Settings ....................88 13-5 Data Memory for Tare Value .......................

- Page 5 21-5 Changing Password ......................... 129 21-6 How To Delete The Password(U5ER 01~10) ................. 130 21-7 Missing Password ..........................130 22. Repeatability Check Function (GX-M series only) ..........131 23. Interface Specification(Standard) ................ 132 24. Maintenance ......................132 24-1 Treatment Of The Balance....................... 132 25.

-

Page 6: Introduction

1. Introduction This manual describes how the GX-M/GF-M series balance works and how to get the most out of it in terms of performance. Read this manual thoroughly before using the balance and keep it at hand for future reference. -

Page 7: About The Models

GX-32001M / GX-32001MD GF-32001M / GF-32001MD □ For the GX-M series, a weight for sensitivity adjustment is built in. It is possible to use functions such as calibration and auto calibration using the internal mass. □ For the GF-M series, sensitivity adjustment weights are not built-in. When calibrating, it is necessary to prepare an external weight. -

Page 8: About Communication Manual

1-4 About Communication Manual About the contents of the communication, download "Communication manual" from our website (https://www.aandd.jp/) and refer to it. -

Page 9: Unpacking The Balance

AC adapter labels AC adapter plug Note AX-TB248 Please confirm that the AC adapter type is correct for your local voltage and receptacle type. USB cable Breeze beak provided for (approx. 1.8m) GX-8202M, GX-8202MD, GX-10202M, GF-8202M, GF-8202MD, GF-10202M. AC adapter labels... -

Page 10: Installing The Balance

2-1 Installing The Balance Install the balance as follows: 1 Refer to "3. Precautions" for installing the balance. Bubble sprit level 2 Install the pan support, weighing pan and draft gate. Good No good Refer to the previous page. 3 Adjust the leveling feet to level the balance. -

Page 11: Precautions

The best operating temperature is about 20°C / 68°F at about 50% relative humidity. Install the balance where it is not exposed to direct sunlight and it is not affected by heaters or air conditioners. Install the balance where it is free of dust. -

Page 12: During Use

Take into consideration the affect of air buoyancy on a sample when more accuracy is required. Prevent foreign matter, such as powder, liquid and metal, from invading the area around the weighing pan. Use the "breeze break" for a precision weighing. -

Page 13: Power Supply

Do not allow the balance to be immersed in water. Even though the balance complies with IP code, the balance will not withstand being completely immersed in water. The weighing pan, pan support and draft gate can be removed to clean the balance. Clean by splashing with water. -

Page 14: Display Symbols And Key Operation

4.Display Symbols And Key Operation Display symbols Number of statistical data (Statistical calculation mode) Displays the weight data relative to the weighing capacity, in percentage, in the weighing mode (Capacity indicator) Preset tare mark Response indicators Gross mark Comparator indicators... - Page 15 ・ Enters mode for reading density number in flow measurement. Sets the display to zero. * When the "Gross net tare function" is selected, the display is turned off by pressing and holding (for 2 seconds). Please refer to "16.Gross Net Tare Function".

-

Page 16: Smart Range Function

"precision range" of a higher resolution and "standard range" of normal resolution. The range is switched automatically depending on the value displayed. Placing a heavy container on the weighing pan and pressing the RE-ZERO key allows the balance to weigh in the precision range. (Smart range function) The range can be fixed to the standard range, by pressing the SAMPLE key. -

Page 17: Weighing Units

“19.Programmable-Unit”.) A unit or mode can be selected and stored in the function table as described on page 47. If a weighing mode (or unit of weight) has been turned off, that mode or unit will be missing in the sequence. - Page 18 Note: The blinking processing indicator with “g” indicates that the density mode is selected. The tables below indicate the weighing capacity and the minimum display for each unit, depending on the balance model. GX-8202M GX-10202M GX/GF-M GF-8202M GF-10202M minimum Unit...

- Page 19 GX-12001M GX-22001M GX-32001M GX/GF-M GF-12001M GF-22001M GF-32001M Minimum Unit Capacity Capacity Capacity display Gram 12200 22200 32200 Kiloram 12.2 22.20 32.20 0.0001 Once(Avoir) 1136 0.005 Pound 26.9 48.9 71.0 0.0005 Pound/Once L oz 26L 14.3oz 48L 15oz 70L 15.8oz 0.01 Troy Once 1035 0.005...

- Page 20 GX-8202MD GX/GF-M GF-8202MD Standard range Precision range Minimum Minimum Unit Capacity Capacity display display Gram 8200 2200 0.01 Kiloram 8.20 0.0001 2.20 0.0001 Once(Avoir) 0.005 77.6 0.0005 Pound 18.1 0.0005 4.85 0.00005 Pound/Once L oz 18L 1.2oz 0.01 4L 13.6oz 0.001 Troy Once 0.005...

- Page 21 GX-32001MD GX/GF-M GF-32001MD Standard range Precision range Unit Minimum Minimum Capacity Capacity display display Gram 32200 6200 Kiloram 32.2 0.001 6.20 0.0001 Once(Avoir) 1136 0.05 0.005 Pound 71.0 0.005 13.7 0.0005 Pound/Once L oz 70L 15oz 13L 10.6oz 0.01 Troy Once 1035 0.05 0.005...

-

Page 22: Storing Units

5-2 Storing Units The units or modes can be selected and stored in the function table. The sequence of displaying the units or modes can be arranged to fit the frequency of use. The units stored are maintained in non-volatile memory, even if the AC adapter is removed. - Page 23 Unit setting example The example below sets the units in the order with g (gram) as the first unit followed by pcs (counting mode). 1. Press and hold the SAMPLE key (for 2 seconds) until ba5fnc the function table is displayed, then Press and hold release the key.

-

Page 24: Weighing

Data Memory”. Remove the sample □ When the ON:OFF key is pressed with a container placed on the weighing pan and weighing is started, the balance automatically cancels the weight (tare) and displays 0. 0 0 g. (Display off) Weighing Container... - Page 25 RE-ZERO key will automatically determine whether zero or tare operation is performed. The condition for determining which is used is "zero range", and when zero range is exceeded, the tare subtraction operation is performed. About measurement range For the balance, the range that can be weighed is determined by model.

-

Page 26: Counting Mode(Pcs

When the unit mass is stored correctly, the balance proceeds to the counting mode. * If the balance judges that the mass of the samples is too light and lo . is not adequate to be used as the unit mass, it displays (The couting result) * Registered unit mass is remembered even when the power is turned off. - Page 27 Unit weight can be read by ″ UN:mm ″ command. (mm corresponds to P01 to P50 with 01 to 50.) The read unit mass can output by ″ ?UW ″ command and can be changed by ″ UW ″ command.

-

Page 28: Percent Mode (%)

6-3 Percent Mode (%) The percent mode displays the weighting value in percentage compared to a 100% reference mass and is used for target weighing or checking the sample variance. Selecting The Percent Mode 1. Press the key to select the unit (Percent mode). -

Page 29: Animal Weighing Mode(Hold Function

The hold function allows the average weight of the animal to be displayed. To use the hold function, set the function in the function table. Refer to "11. Function Table" and "11-3. Description Of The Class "Environment, Display" for details. -

Page 30: Impact Detection Function

7. Impact Detection Function The GX-M / GF-M series has a function to detect impact to the mass sensor section and to display the impact level. By lowering the impact level at the time of loading, it is possible not only to alleviate variation in the weighing value but also to reduce the risk of failure of the mass sensor section. -

Page 31: Recording Impact History

7-1 Recording Impact History Impacts of impact level 3 or higher are stored on the balance with data and time included (maximum 50 data instances). LOcK 1 or Lock2 When the password lock function is on ( ), the login user information is added when outputting the impact history. - Page 32 Impact history output example Date, time, impact level, login and login user information are output together on one line. The login user information varies by the setting of the login user and the setting of Function table LOcK when receiving impact.

-

Page 33: Response Adjustment / Self Check Function

8. Response Adjustment / Self Check Function This function stabilizes the weight value, reducing the influence on weighing that is caused by drafts and/or vibration at the place where the balance is installed. This function adjusts by automatically analyzing the environment or by hand-operation. -

Page 34: Self-Check-Function / Automatic Setting Of Minimum Weight Value

The self-check function can easily check about whether proper performances are satisfied for the balance by checking and displaying repeatability in addition to malfunction check. In addition, it can also display and store minimum weighing value (reference value) using data of the repeatability. - Page 35 Press and hold (for 2 seconds) Batch output Store minimum weighing value when MW-CP is set to 0, the balance automatically set it to 1 (except near zero) and enables comparing function of the minimum weighing value. 0.0057 g 0.00...

-

Page 36: Calibration

□ To output the data for GLP/GMP using the RS-232C interface, set "GLP/GMP output (info)" of "Data output (dout)". Refer to "11. Function Table". The time and date can be added to the GLP/GMP report. If the time or date is not correct, adjust them. Refer to "11-7 Clock and Calendar Function". -

Page 37: Automatic Self Calibration For The Gx-M Series

Interval time can be set from 0.5h to 24h with function setting Caution If something is on the weighing pan, the balance judges that it is in use and does not perform automatic self calibration. The criteria that the balance judges is in use are as follows. -

Page 38: One-Touch Calibration For The Gx-M Series

9-2 One-Touch Calibration For The GX-M Series This function calibrates the balance using the internal mass. 1. Connect the AC adapter and warm up the balance for at least 30 minutes with nothing on the weighing pan. 2. Press the CAL key. The balance displays Calin and performs calibration using the internal mass. -

Page 39: Calibration Using An External Weight

Displayed only on GX-M series) is displayed, then release the key. 1Calout 3. Make sure that nothing is on the weighing pan and press the PRINT key to weigh the zero point. Do not apply vibration, etc. Press and Hold (for 2 seconds) 4. -

Page 40: Calibration Test Using An External Weight

9-4 Calibration Test Using An External Weight This function tests the weighing accuracy using an external weight and outputs the result. This is available only when the GLP doutinfo1) output parameter is set to "( . (Calibration test does not perform calibration) -

Page 41: How To Set The External Weight Value

9-5 How to set the External Weight Value When calibrating the balance or performing a calibration test, the external weight you have on hand can be set. (Refer to "Usable calibration weight" on Page 37.) After Cal 0 is displayed, the external weight value can be set as shown in "9-3.Calibration Using An External weight". -

Page 42: Correcting The Internal Mass Value Of The Gx-M Series

Note □ Correction of internal mass value can not be executed at factory setting. Refer to "9. Function Switch And Initialization" or the following setting method, and enable changing of the function setting and correction the internal mass value. Setting procedure 1. -

Page 43: Correcting The Internal Mass Value Of The Gx-M Series (Auto)

9-7 Correcting The Internal Mass Value Of The GX-M series (Auto) Calibrate referring to "9-3. Calibration Using An External weight". This is method of correcting the internal mass weight value based on an external weight. After calibration with the external mass, the balance automatically loads and unloads the internal mass and corrects the internal mass value. -

Page 44: Function Switch And Initialization

"A function selection switch" is provided to protect those parameters and it can be used to select "change prohibited" or "changeable (usable)". By setting to "change prohibited", that function cannot be entered, so inadvertent change. - Page 45 Example of GX-M series The display shown left indicates the factory settings. Function table To inhibit changes to the function table. To permit changes to the function table. No function Calibration using an external weight To inhibit calibration using an external weight.

-

Page 46: Initializing The Balance

□ External calibration weight a n d h o l d i n g □ Function switch settings □ Density of a liquid and a water temperature at density mode Note Be sure to calibrate the balance after initialization. C l r Setting procedure 1. -

Page 47: Function Table

The function table reads or rewrites the parameters that are stored in the balance. These parameters are maintained in non-volatile memory, even if the AC adapter is removed. The function table menu consists of two layers. The first layer is the "Class" and the second layer is the "Item". - Page 48 Setting Example This example sets "Stores weighing data (dAtA 2)" for "Data memory (dAtA)" and "1 minute (int 5)" for "Interval time (int )". Step1 (for 2 seconds) Keep pressing and holding Step2 Press several times Classification item Step3 Setting item "Data memory function"...

-

Page 49: Details Of The Function Table

Factory setting Note: "Digit" is a unit of minimum weighing value. * A number shown in【 】is class number and output as identification sign when outputting the function setting information at once. Refer to “11-12 Outputting the function setting information”. - Page 50 Cp frd Comparison by flow rate value Flow measurement Comparison by weighing value Cp-b HI, OK and LO can be displayed largely at the Expanding Display weighing display when using comparator mode. Function Cp HH Cpin Displayed only when See 11-8 comparator Function"...

- Page 51 10 digit ap-b Difference between reference value and displayed value 100 digit Auto print difference 1000 digit Factory setting Note: "Digit" is a unit of minimum weighing value. For *1, download "Communication manual" from our website (http://www.aandd.jp/) and refer to it.

- Page 52 Refer to "13.Data Memory" Stores unit mass in counting mode Data memory Data output mode Stores the weighing data and calibration history Stores comparator setting values Stores tare values Interval time in the interval Every measurement memory mode when using...

- Page 53 Class Item Parameter Description All communication setting are possible. 【06】 can be selected. Printer Only Access point Serial interface External indicator 600bps 1200bps Baud rate 2400bps 4800bps 9600bps 19200bps 38400bps 7 bit EVEN btpr 7 bit ODD Data bit, parity bit 8 bit NONE Crlf CR: ASCII 0Dh code...

- Page 54 Class Class Item Item Parameter Parameter Description Description Normal weighing mode Normal weighing mode Refer to Capacity indicator Capacity indicator "11-11.Description Of ap fnc ap fnc Application" 【10】 Application Application Statistical calculation mode Statistical calculation mode mode mode Application Application Flow measurement mode Flow measurement mode function...

- Page 55 Setting temparature Setting time Calibration mode 【17】 Interval time Auto calibration Refer to " 9-1 Automatic Self calibration Setting time1 For The GX-M Series " Setting time2 Setting time3 Interval time C5in Refer to "9-7 Correcting The 【18】 Automatic input...

-

Page 56: Description Of The Class "Environment, Display

This function is used to weigh a moving object such as an animal. When the weighing data is over the weighing range from zero and the display fluctuation is within the stabilization range for a fixed period of averaging time, the processing indicator illuminates and the balance displays the average weight of the animal. -

Page 57: Description Of The Data Output

) Tare value record( After turning on the power supply, the display will not be automatically set to zero, and it will start from the previous weighing value. This is useful when a hopper, etc. is attached to the weighing pan and the power needs to be turned off while weighing discharge. -

Page 58: Clock And Calendar Function

Confirm the time key and go to "5". □ When the time is correct and the date is to be confirmed, press the SAMPLE key and go to "6". □ When the time is correct and the date does not need to be confirmed, press the CAL key and go to "8". - Page 59 Cp fnc The balance displays the next menu of the function table. Press the CAL key to exit the clock and calendar function and return to the weighing mode. Note Do not enter invalid values such as a non-existing date when setting the time and date.

-

Page 60: Comparator Function

11-8 Comparator Function The comparison of comparators can select 3-steps or 5-steps (Cp fnc , Cp-t), and it is set to 3-steps at the factory setting. When 3-step comparator is set, the results of the comparison are indicated by HI LO on the display. - Page 61 Selecting the comparator stage (3 stages/5 stages) 1. Press and hold the SAMPLE key (for 2 seconds) to display Press and hold bA5Fnc of function settings. (for 2 secons) bA5Fnc CP fnc 2. Press the SAMPLE key several times to display...

- Page 62 (Always compare except "near zero" ± 20 digits and digitally input reference Example1 value and scope.) Selecting a comparator mode (Input scope, comparison criteria and value.) Keep pressing and holding (for 2 seconds) 1. Press and hold the SAMPLE key (for 2 seconds) until 1ba5fnc of the function table is displayed, then release the key.

- Page 63 RE-ZERO key ··· Change the value of the digit selected. MODE key ······· Switch the polarity. PRINT key ······· Store the new setting and go to "15". CAL key ·········· Cancel the new setting and go to "15". When CP LMt is displayed, pressing the PRINT key will display the currently set value.

- Page 64 Example 2 (Continuous comparison, including "near zero", reference value and tolerance value.) Selecting a comparator mode 1. Press and hold the SAMPLE (for 2 seconds) key until 1ba5fnc of the function table is displayed, then release Keep pressing and holding the key.

- Page 65 Press the RE-ZERO key to enter the load input mode. 0 . 0 0g Press the RE-ZERO key, is displayed. Place a sample of the weight of the upper limit on the balance and press the PRINT key. (Register the upper limit value.) Cp lo When finished, is displayed.

-

Page 66: Adding The Comparison Results

Sound the built-in buzzer corresponding to the comparison result. 1 Press and hold the SAMPLE key (for 2 seconds) until ba5fnc of the function table is displayed. Press and Hold (for 2 seconds) 2 Press the SAMPLE key several times to display Cp beep . -

Page 67: Main Display Comparison Function

Note While the main display comparison function is in use, unit selection using the MODE key is not available. Setting the function table 2 Press and hold the SAMPLE key (for 2 seconds) until ba5fnc of the function table is Step displayed, then release the key. -

Page 68: Description Of Application

" that use the data memory function ( apf 2 Description of the statistical calculation mode This is a function to statistically calculate the weighing value and to display and output the result. Refer to "14.Statistical Calculation Mode " . -

Page 69: Outputting The Function Setting Information

4 Description of the gross net tare mode This is a function to operate the zero setting and taring separately and to output the data of Gross (total amount), Net (net amount) and Tare (tare quantity). Refer to "16.Gross Net Tare Function". - Page 70 【Output example】 Model name GX-10202M 123456789 Serial number LAB-0123 2019/01/22 Date Output a data and time for the balance Time ⓐ ⓑ ⓒ … ⓐ Class (2 characters) ⓑ Item (8 characters) ⓒ Parameter (1 character) or (12 characters) * Each one is divided using comma.

- Page 71 2. Install the WinCT to a PC to be used. Download WinCT software from A&D web site (http://www.aandd.jp/). 3. Start up RSCom and match communication settings such as COM port or baud rate to settings of the balance. Press the[Start]button to enable the communication.

-

Page 72: Id Number And Glp Report

・"Calibration test report" of the calibration test, using an external weight. ・"Title block" and "End block" for the weighing data. □ Calibration and calibration test data can be stored in memory to output several reports at the same time. Refer to "13. Data Memory" for details. - Page 73 Display correspondence table 11 Segment A B C D E F G H 0 1 2 3 4 5 6 7 8 9 J K L M N O P Q R S T U V W X Y Z Space 7 Segment A B C D E F G H...

-

Page 74: Glp Report

1), i f the time and date are not correct, set the correct time and date in "Clock ( CLAdJ )" of the function table. Calibration report using the internal mass This is the GLP report when the balance is calibrated using the internal mass. - Page 75 PC or printer can be used without using the clock data of the balance. Note □ Clock data output from external device is for devices that have a clock function and can receive date and time data by receiving <ETC>D, <ETC>T.(Ex. AD-8127 multi printer, RsCom winCT etc.)

- Page 76 Calibration report using an external weight This is the GLP report when the balance is calibrated using the external weight. Setting of info 1 Setting of info 1 Printer format (AD-8127) PC format (RsCom) <TERM> A & D Manufacturer A & D <TERM>...

- Page 77 Application / Operation As a method of managing weighing values, add "Heading" and "End" parts before and after the weighing value. By pressing and holding the PRINT key (for 2 seconds), "Heading" and "End" are output in turn. Note data 0 If the data memory function is used (except when ), heading and end cannot be output.

-

Page 78: Data Memory

PC for a long time. □ The data in memory can be displayed on the balance for confirmation. □ Data (ID number, data number, time and date) to be added to the output data can be selected in the function setting. - Page 79 Enabling data memory function 1. Press and hold the SAMPLE key (for 2 seconds) until Press and hold 1ba5fnc of the function table is displayed. (for 2 seconds) bA5Fnc Press several times 2. Press the SAMPLE key several times to display dout .

- Page 80 Confirm that the "Data memory (data)" parameter is set to " data 2". Left of the display 1. Press and hold the PRINT key (for 2 seconds) until is displayed, then release the key. When setting without clock / date The type of data appears in the upper left of the display as shown to the right "-d- or d-t"...

- Page 81 Press and hold Confirm that the "Serial interface (5if)" parameters are set properly. (for 2 seconds) Refer to "10. Function Table" and "Communication Manual " on the A&D website. RECALL 1. Press and hold the PRINT key (for 2 seconds) until displayed, then release the key.

-

Page 82: Data Memory For Calibration And Calibration Test

13-2 Data Memory For Calibration And Calibration Test Characteristic □ Calibration data (when and how it is performed) and calibration test data can be stored in memory. □ All the data in memory is available to be output at one time to a printer or Upper left of the display personal computer. - Page 83 If there is no calibration history, is displayed, Release and then the display returns to the weighing display. When there is no calibration history 2. Press the PRINT key to display 3. Change the with the RE-ZERO key.

- Page 84 Deleting data stored in memory 1. Press and hold the (for 2 seconds) until is displayed, then release the key. is displayed. Press and hold 2. Press the key to display SAMPLE (for 2 seconds) 3. Press the PRINT key to display 4.

-

Page 85: Data Memory For Unit Mass In The Counting Mode

To use the weighing input mode, press the SAMPLE key to enter the weighing input mode. Go to "Weighing input mode" on the next page. To use the digital input mode, press the SAMPLE key, then press and hold the MODE key to enter the digital input mode. Go to "Digital input mode" on the next page. - Page 86 CAL key ..... To return to the unit mass confirmation mode. Go to step 3 of the previous page. MODE key ..Press and hold (for 2 seconds) to go to the digital input mode. Digital input mode To use this mode, the sample unit mass must be known beforehand.

- Page 87 MODE key To decrease the unit mass by one. 3. Press the PRINT key to confirm the selection and to return to the weighing mode. To cancel the selection and return to the weighing mode, press Confirm the CAL key...

-

Page 88: Data Memory For Comparator Settings

The data memory function can store 20 sets of upper and lower limit values for the comparator mode. The reference value or tolerance value for the comparator mode can not be stored in memory. The upper and lower limit values in memory can be recalled easily using the MODE key and used for weighing. - Page 89 MODE key Press and hold (for 2 seconds) to go to the weighing input mode. Weighing input mode In the weighing input mode, a sample is placed on the pan to store the upper and lower limit values. Notes Pressing the...

- Page 90 Recalling the upper and lower limit values (Quick selection mode) The procedure below describes an easy way to recall the upper and lower limit values to be used for weighing. When the recalled upper and lower limit values are to be changed, refer to "Storing the upper and lower limit values".

-

Page 91: Data Memory For Tare Value

"Weighing input mode" on the next page. To use the digital input mode, press the SAMPLE key, then press and hold the MODE key (for 2 seconds) to enter the digital input mode. Go to "Digital input mode" on the next page. - Page 92 (step 3 in "Storing the tare value"). To go to the digital input mode, press and hold the MODE key. 1. The first display in the weighing input mode is the current weight value and the selected tare number with PT blinking.

- Page 93 Tare number 2. Press the MODE key to enter the quick selection mode. After entering quick selection mode, display shows tare value (blinking), “PT” mark and tare value Tare value number. A prior selected setting value is displayed. 3. Press the MODE key to select the value. Each time...

-

Page 94: Data Memory: Quick Selection Mode

13-6 Data Memory: Quick Selection Mode The data memory has a quick selection mode to recall data in memory quickly. Using the quick selection mode, the comparator settings or the tare value, whichever is selected in the function table, can be recalled, by a simple operation, using the MODE key. Note While the data memory function is in use, unit selection using the MODE key is not available. -

Page 95: Data Memory: Confirmation And Storage Mode

13-7 Data Memory: Confirmation and Storage Mode The confirmation and storage mode can change and store the recalled data. Of the three types of memory data listed below, one may be selected in the function table, and is available for changes using this mode. - Page 96 Two inputting modes are available for entering the value to be stored. Digital input mode Weighing input mode To switch the inputting mode, press and hold the MODE key (for 2 seconds). To cancel the operation and return to the weighing mode, press the CAL key.

-

Page 97: Statistical Calculation Mode

14.Statistical Calculation Mode The statistical calculation mode statistically calculates the weight data, and displays or outputs the results. To use the statistical calculation mode, set the "Application function (apf)" parameter of “Application (ap fnc)" in the function table to "2", as described below. To return to the normal weighing mode (factory setting), set "Application mode (apf)"... - Page 98 Note Selecting the unit using the MODE key is not available after the data is entered. In this case, clear the data as described on page 99 "Cleaning the statistical data" and select the unit using MODE key. When the unit used for the statistical calculation mode is to be enabled upon power-on, select...

- Page 99 RE-ZERO key ..Sets the display to zero in the weighing mode. PRINT key ....Outputs the data number and the weight data and includes the weight data to statistical calculation in the weighing mode. (Output is not in the data format specified in the function table because of the data number added.)

- Page 100 Delete the statistical data variation and relative error is displayed as - - - - - - - . □ When the average is 0, the coefficient of variation and relative error is displayed as - - - - - - - .

- Page 101 Clearing the statistical data All the statistical data will be deleted and the number of data will be 0 (zero). 1. In the weighing mode, press the MODE key several times, to display 2. Press the PRINT key to display 3.

-

Page 102: Statistical Calculation Mode (Example Of Use)

The mixing process is (for 2 seconds) recorded using the balance and the printer. In the example, the GX-10202M and the AD-8126 or AD-8127 are connected using the RS-232C serial interface. Press several times... - Page 103 1) Container(tare value) The weight value data is output when the peripheral ST,+00056.37 output equipment is connected. 4. Weigh formula 2 and press the PRINT key. 0.00 g The balance displays . (Storing the weight value Formula 1 of formula 2) The weight value data is output when the peripheral output equipment is connected.

-

Page 104: Flow Measurement

□ If the flow unit is set to mL/*, density can be registered. The maximum number of registrations is 10, and if density is set in advance, it can be selected according to the measurement sample. □ The flow rate value is calculated by the following formula. - Page 105 There are two ways to set flow calculation time Ct, either by automatic setting in the balance according to the flow rate value or by manually determining a fixed value. To switch between manual and automatic, please perform the following operation. From setting of flow rate unit In factory setting, flow calculation time Ct is set to manual input setting ( Ct AUto "oFF"...

- Page 106 How to set flow calculation time by manual setting The flow calculation time Ct can be set by the following procedure. 1. In weighing display, press and hold the MODE key (for 2 seconds) to display 2. Calculation time can be changed by following key operation.

- Page 107 MODE (-) key ········· Change the number of the blinking digit SAMPLE key ······· Move the blinking digit PRINT key ············ Store the set value and return to weighing display. CAL key ··············· Return to weighing display without storing the set value.

-

Page 108: Gross Net Tare Function

16-1 Preparation Of Gross Net Tare Function To use this function, enter the Function table as follow, and set "Application Function ap fnc " to "4 " in "Application mode apf ". To return the normal weighing mode (Factory settng), set " Application mode apf "... - Page 109 Key operation In case of setting, operate with the following keys. Function Operation Weighing value(gross) Update a zero point and clear a tare Within the zero range Zero setting value. (ZERO) Out of the zero range Do nothing Plus value...

-

Page 110: Example Of Using The Gross Net Tare Function

Output 1. Every time pressing the PRINT key, it will output in the order of "NET"(object), "GROSS"(total amount), "TARE"(tare). 2. Only A&D standard format, DP format and CSV format are available as output format. Output example (A&D standard format) ST, N ,+00 045.67 g NET(object) ST,G ,+0005 5.90 g... -

Page 111: Minimum Weighing Warning Function

If the amount of sample is too small, the proportion of the measurement error in the measured value increases accordingly, and the reliability of the analysis result may drop. By using the minimum weighing warning function, it is possible to judge at a glance whether the amount of sample meets the set minimum weight value. -

Page 112: Entering And Outputting The Minimum Weighing Value

Store a parameter and proceed to next stage. * In this time, when MW-CP is set to 0, the balance automatically set 0.00 it to 1 (except near zero) and enables comparing function of the minimum weighing value....CAL key Proceed to next stage without storing the setting value. - Page 113 8. Press the SAMPLE key to display EXT MA55 . EXT MA55 9. Press the PRINT key to proceed as order 5TART → READY → Weighing mode. And display requests a first load for repeatability as 5TART LOAD . READY 0.00...

- Page 114 Time out (when no operation is made for approx. 2 minutes) * After displaying Error, the repeatability measurement is forcibly finished and the balance returns to function settings. 17. Repeatability (5D) or minimum displaying value (MW) can be output by selecting them.

- Page 115 23.20 * In this time, when MW-CP is set to 0, the balance automatically set it to 1 (except near zero) and enables comparing function of the minimum weighing value. 21. Press the CAL key twice to proceed to weighing mode. Alarm function of minimum weighing value is started.

- Page 116 3. After finishing output at once, display shows End and returns to KEY in or Ext MA55 . 【Batch output example of minimum weighing value set currently】 A type of output vary depending on how to set minimum weighing value.

-

Page 117: Underhook

Step2 draft gate fall off, when turnig over the balance. Remove them first. Draft gate 1. Remove the draft gate. 2. Remove the weighing pan and pan support. 3. Turn over the balance. Step3 4. Remove the cover plates. Underhook 5. -

Page 118: Programmable-Unit

The coefficient must be within the range between the minimum and maximum shown below. If the coefficient set is beyond the range, an error is displayed and the balance returns to the coefficient setting mode, prompting to enter an appropriate value. A coefficient of 1 was set at the factory. -

Page 119: Density Measurement

Formula to obtain the density 1. Density of solid It can be obtained from the weight of the sample in air, the weight in the liquid, and the density of the liquid. A : Mass value of a sample in air ρ... - Page 120 4. Enter the density of the liquid Weight in liquid Refer to "(3) Entering the density of a liquid" and set the lights, lights density. Next, press the PRINT key to enter the density Set the density in liquid mode.

- Page 121 (9 is displayed after 0 ) SAMPLE key ....Move the blinking digit. PRINT key ....The key to store new water temperature and return to the density mode.(Proceed to Step 5) CAL key ....... The key to cancel the change and return to the density mode.

- Page 122 Place the float on the weighing pan in air RE-ZERO key to display zero. Weight in air Place the float on the pan in air and wait until the display is lights, blinks stabilized. Output If the weight value is stored or output, press the PRINT key to store it after a stable weight value is displayed.

- Page 123 (Next to 0 will be 9.) key .... Move the blinking digit. SAMPLE key ....The key to store the change and return to the density mode. (Proceed to Step PRINT CAL key ....The key to cancel the change and return to the density mode. (Proceed to Step...

-

Page 124: Password Lock Function

The function is effective for preventing alteration of date/time setting and preventing internal setting changes by the user. The password is set with four keys MODE , SAMPLE , PRINT and RE-ZERO keys in four digits (4 x 4 x 4 x 4 = 256 outcomes) . -

Page 125: Enable Password Lock Function

GUE5t 5 Response adjustment, settings of the minimum weighing value, confirmation of the repeatability using the internal weight, function switch and initialization and function table (date and time setting) 6 The administrator (ADMIN) can set this to prohibited as shown in "10-1 Permit Or Inhibit ". -

Page 126: How To Input The Password At The Start Of Weighing

In : U5ER times at the administrator level.) Password is incorrect If the password is incorrect, the buzzer sounds 3 times, fAIL FAiL will display and the display will turn off. Weighing display Display off In case of Lock 2 1. -

Page 127: How To Logout

Display the administrator level.) login level If the password is incorrect, the buzzer sounds 3 times in : ADM FAiL display and the display turns off. Password mismatch fAIL Display weighing Display off 21-3 How To Logout Turn off the display by pressing the ON:OFF key to log out. -

Page 128: Registering Password (Changing)

21-4 Registering Password (Changing) The password can be changed at "Password ( )" of the Function Table. 0.00 1. Press and hold the SAMPLE key (for 2 seconds) in the weighing mode. ba5fnc is displayed. Press and hold (for 2 seconds) 2. -

Page 129: Changing Password

21-5 Changing Password Refer to 1. Refer to "21-4. Registering Password (Changing)" and "21-4.Registering Password (Changing)" display the login level you want to change the password on. 2. Press the PRINT key to display the current password. At factory settings, the password is (the RE-ZERO key, 4 times) 3. -

Page 130: How To Delete The Password(U5Er 01~10

21-6 How To Delete The Password(U5ER 01~10) Refer to "21-5. Changing Password" and select the user Refer to "21-5.Changeing Password" (U5ER 01~10) and display the Password input screen. Hold down the CAL key (for 2 seconds) when setting the password and display (blink). -

Page 131: Repeatability Check Function

With the repeatability check function, the balance obtains 10 measurement data using the built-in weight and displays its standard deviation. By installing the balance and using this function, it is possible to check repeatability in the environment where the balance is installed. -

Page 132: Interface Specification(Standard

Do not use powerful water jets. Do not submerge the balance in water. Clean the balance with a lint free cloth that is moistened with warm water and a mild detergent. Do not use organic solvents to clean the balance. -

Page 133: Troubleshooting

The balance is a precision instrument. When the operating environment or the operating method is inadequate, correct weighing can not be performed. Place a sample on the pan and remove it, and repeat this several times. If the balance seems to have a problem with repeatability or to perform improperly, check as described below. -

Page 134: Error Codes

□ If this error continues to be displayed and can not be resolved, the internal sensor or the circuit may be damaged. Please contact your dealer. - Page 135 Clock battery error The clock backup battery has been depleted. Press any key and set the time and date. The clock and calendar function works normally as long as the AC adapter is connected to the balance. If this error appears frequently, contact the local A&D dealer.

- Page 136 Refer to "13.Data Memory" EC,E00 Communications error A protocol error occurred in communications. Confirm the format, baud rate and parity. EC,E01 Undefined command error An undefined command was received. Confirm the command.

-

Page 137: Other Display

25-4 Asking For Repair If the balance needs service or repair, contact your local A&D dealer. The balance is a precision instrument. Use much care when handling the balance and observe the following when transporting the balance. □ Use the original packing material for transportation. -

Page 138: Connection With Periphecal Device

26.Connection With Periphecal Device Download "Communication manual" from our website (https://www.aandd.jp/) and refer to it. 26-1 Command Download "Communication manual" from our website (https://www.aandd.jp/) and refer to it. 26-2 Key Lock Function This function restricts the key operation of the balance by sending a specified command to the balance. -

Page 139: Specifications

*1: The balance allows weighing using a precision range, even with a heavy tare placed on the pan. (Smart range function) *2: With GX-M series, accuracy right after calibration using the internal mass in good ambient conditions (within the temperature range of 10°C to 30°C (50°F to 86°F) with no abrupt changes in temperature or humidity, no drafts, no effect by magnetic fields or static electricity). - Page 140 300(W) x 355(D) x 111(H) mm Power consumption: Approx. 30VA (supplied to the AC adapter ) Power supply & AC adapter type Confirm that the adapter type is correct for the local voltage and power receptacle type. Weight Approx. 8.3kg Dust and water protection Complying with IP65 *1: The balance allows weighing using a precision range, even with a heavy tare placed on the pan.

-

Page 141: External Dimention

29. External Dimention Unit: mm... -

Page 142: Options And Peripheral Instruments

29-1 Options And Peripheral Instruments Options Name Description GXM-04 This option is equipped with relay and buzzer output, Comparator Output RS-232C interface and external key input terminal that can (Relay/ with a Buzzer) / operate “PRINT” and “RE-ZERO” externally. RS-232C / External key... - Page 143 Can transmit weighing data to a personal computer in real Quick USB Adapter time when connected to the RS-232C interface of the analyzer and to the computer using USB. Data transmission to any application such as Excel and Word. (Simplex) AX-USB-9P-EX Adds a COM port to a PC.

- Page 144 Others Name Description AD-1691 The analyzer can be used for diary check and analysis and Weighing proof of the cause of a weighing error. Environment Analyzer The analyzer can be used to deal with weighing errors. Quality control can be managed easily by using as a standalone analyzer (without using a computer).

- Page 145 MEMO...

- Page 146 MEMO...

- Page 148 3-23-14 Higashi-Ikebukuro, Toshima-ku, Tokyo 170-0013, JAPAN Telephone: [81] (3) 5391-6132 Fax: [81] (3) 5391-1566 A&D ENGINEERING, INC. 1756 Automation Parkway, San Jose, California 95131, U.S.A. Telephone: [1] (408) 263-5333 Fax: [1] (408)263-0119 A&D INSTRUMENTS LIMITED Unit 24/26 Blacklands Way, Abingdon Business Park, Abingdon, Oxfordshire OX14 1DY United Kingdom Telephone: [44] (1235) 550420 Fax: [44] (1235) 550485 A&D AUSTRALASIA PTY LTD...

Need help?

Do you have a question about the GX-M Series and is the answer not in the manual?

Questions and answers