Table of Contents

Advertisement

KNF 121242-121509 04/20

OEM

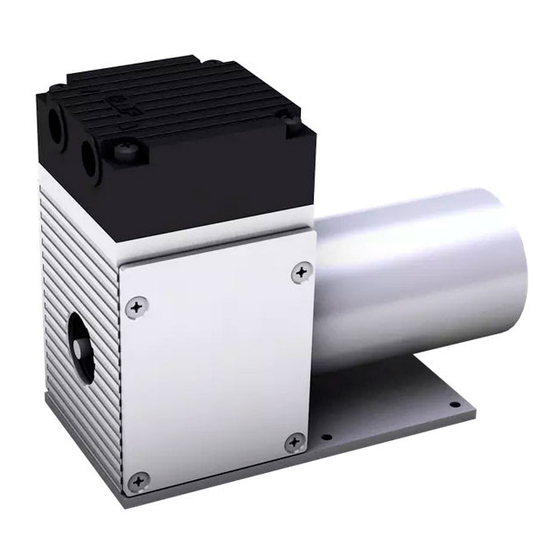

MINI DIAPHRAGM

VACUUM PUMP AND

COMPRESSORS

Note!

Before operating the pump and the accessories, please read the operating instructions on the web site

(www.knf.com/downloads) and pay attention to the safety precautions!

N 89 / N 811 / N 814 / N 815

TRANSLATION OF ORIGINAL OPERATING AND

INSTALLATION INSTRUCTIONS

ENGLISH

Advertisement

Table of Contents

Summary of Contents for KNF N 89

- Page 1 KNF 121242-121509 04/20 N 89 / N 811 / N 814 / N 815 TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTIONS ENGLISH MINI DIAPHRAGM VACUUM PUMP AND COMPRESSORS Note! Before operating the pump and the accessories, please read the operating instructions on the web site...

-

Page 2: Table Of Contents

KNF Neuberger GmbH Alter Weg 3 79112 Freiburg Contents Page Germany 1. About this document ..............3 Phone +49-(0)7664-5909-0 2. Use .................... 4 Fax +49-(0)7664-5909-99 3. Safety ..................6 4. Technical Data ................9 E-mail: info@knf.de 5. Design and function ..............12 www.knf.de... -

Page 3: About This Document

Diaphragm vacuum pump N 89/N 811/N 814/N 815 About this document 1.1. Using the Operating and Installation Instructions The Operating and Installation Instructions are part of the pump. Pass on the Operating and Installation Instructions to the next owner. -

Page 4: Use

Before using a medium, check the compatibility of the materials of the pump head, diaphragm and valves with the medium. Only transfer gases which remain stable under the pressures and temperatures occurring in the pump. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 5 The pumps are not suitable for transferring foodstuffs. The pumps are not suitable for use with aggressive media. Other pumps in the KNF product line are designed for use with aggres- sive media. Please contact us for more information. The pumps must not be used to create vacuum and overpressure simultaneously.

-

Page 6: Safety

This also applies for unusual operational situations. Note that the temperature of the medium increases when the pump compresses the medium (compressor operation). Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 7 In addition a protection against mechanical parts in motion and hot parts, if existing, has to be provided when mounting. The pumps conform to the Directive 2011/65/EU. The following harmonized standards have been used: Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 8 The pump is maintenance-free. But KNF recommends, checking repairs the pump regularly with regard to conspicuous changes in noise and vibrations. Only have repairs to the pumps carried out by the KNF Customer Service responsible. Housing with voltage-caring parts may be opened by technical personnel only.

-

Page 9: E-Mail: Info@Knf.de 4. Technical Data

FFPM Tab. 4 N 814 KN_ Assembly Material Pump head Wave diaphragm EPDM Valve Tab. 5 N 815 KN_ Assembly Material Pump head Wave diaphragm Valve EPDM Tab. 6 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 10 The pumps are fitted as standard with a thermal-switch to pro- tect against overloading. Project-specific pumps that are not fitted with a thermal switch must be protected by the user against the risk of overheating. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 11 N 815 K_DC Maximum permissible ambient 80% for temperatures up to relative humidity 31°C, decreasing linearly to 50% at 40°C. Max. altitude of site: 2000 [m above sea level] Tab. 11 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

-

Page 12: Www.knf.de 5. Design And Function

(1). The transfer chamber (3) is hermetically separated from the pump drive (7) by the diaphragm. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... -

Page 13: Installation And Connection

Install the pump so that accidental finger contact with the fan is impossible. Mounting dimensions See Fig. 3 and Fig. 4 (pump series N 89/ N 811), Fig. 5 and Fig. 6 (pump series N 814) and Fig. 7 and Fig. 8 (pump series N 815) for mounting dimensions. - Page 14 Installation and connection Diaphragm vacuum pump N 89/N 811/N 814/N 815 Fig. 4: Mounting dimensions pump series N 89/811 K_DC (All dimensional tolerances conform to DIN ISO 2768-1, Tolerance Class V) Fig. 5: Mounting dimensions pump series N 814 K_E (All dimensional...

- Page 15 DIN ISO 2768-1, Tolerance Class V) Fig. 7: Mounting dimensions pump series N 815 K_E (All dimensional tolerances conform to DIN ISO 2768-1, Tolerance Class V) Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 16 Protect the pump from dust. Protect the pump from vibrations and jolts. For pumps with fan: Install the pump so that accidental finger contact with the fan is impossible. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 17 Make sure that vibrations of the pump do not result in hazards associated with adjacent com- ponents. Foreign matter protection Protect the pump against contact and intrusion of foreign mat- ter. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 18 2. Open terminal box cover. 3. Connect the earth (ground) wire to the motor. With dc motors the wires must be connected to the correct polarity. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 19 (usual) A.C. /D.C. converter. The test is applicable for D.C. power inputs which are foreseen for a permanent connection to cables which are longer than 10m. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 20 3. Connect the suction line and pressure line (see Chapter 4, Tab. 11 for mounting dimensions). 4. Lay the suction and pressure line at a downward angle to pre- vent condensate from running into the pump. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

-

Page 21: Operation

If the air or gas quantity in the pressure line is throttled or regulated, make sure that the maxi- mum permissible operating pressure is not ex- ceeded. Ensure that the pump outlet is not closed or constricted. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 22 (see Chapter 8.2.1) to increase the service life of the diaphragm. Switching off the pump / Restore the system to normal atmospheric pressure (release removing from operation pneumatic pressure in pump). Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

-

Page 23: Servicing

As far as possible, clean the parts with a dry cloth. Solvent should be used for cleaning only if the head materials are not corroded (ensure compatibility of the material). If compressed air is available, blow out the parts. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 24 Tab. 13 *according to spare part list, Chapter 10 Tool and Material Quantity Tool/Material Phillips screwdriver No. 1 (N 89, N 811, N 814) Phillips screwdriver No. 2 ( N 815) Felt-tip pen Tab. 14 *according to accessories, Chapter 10...

- Page 25 Valve plate/sealing Diaphragm Diaphragm support (N 814/ N 815) 10 Diaphragm spacer(s) 11 Disc spring (N 815) 12 Connection rod 13 Counter weight Fig. 10: Cross-section view N 89/811 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 26 Servicing Diaphragm vacuum pump N 89/N 811/N 814/N 815 Fig. 11: Cross-section view N 815 Fig. 12: Cross-section view N 814 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

- Page 27 Change valve plates/sealings d) Refit pump head Proceed as follows (see Fig. 9 and Fig. 10 for type ranges N 89 / N 811, Fig. 9 and Fig. 12 for type ranges N 814, or Fig. 9 and Fig.

- Page 28 6. Turn the fan again to bring the diaphragm to top dead center. 7. Now tighten screws (4) firmly. If you have any questions about servicing call our technical adviser (contact data: see www.knf.com). Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

-

Page 29: Troubleshooting

Pump head components are Clean head components. soiled. Diaphragm or valve Replace diaphragm and valve plates/sealings (see plates/sealings are worn or de- Chapter 8.3). fective. Tab. 16 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 30 3. Clean the pump (see Chapter 8.2.2). 4. Send the pump, together with completed Health and Safety Clearance and Decontamination Form, to KNF stating the na- ture of the transferred medium. Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

-

Page 31: Spare Parts And Accessories

N 814 KTE, N814 113950 KTDC Diaphragm N 814 KNE, N814 043262 KNDC Diaphragm N 814 KTE, N814 043261 KTDC Tab. 19 *according to Fig. 9 and Fig. 12 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20... - Page 32 N 815 Accessories Order No. Silencer G 1/8 000346 Hose connection PA, G 1/8 000360 90° Hose connection PA, G 1/8 001858 Hose connection PVDF, G 1/8 014052 Tab. 22 Translation of original Operating and Installation Instructions, english, KNF 121242-121509 04/20...

-

Page 33: 11. Returns

Prerequisite for repairing a pump by KNF is a completed Decon- tamination Form. This is made available on the KNF website as a download. To find the form, select your country on the overview page (www.knf.com). You can find the Decontamination Form in the download area. - Page 36 KNF worldwide Find your local KNF partner on www.knf.com...

Need help?

Do you have a question about the N 89 and is the answer not in the manual?

Questions and answers