Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Peak UM-NM300L

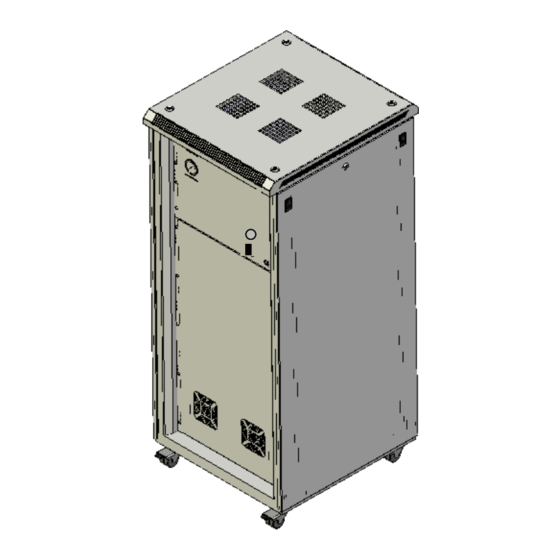

- Page 1 NM300L NITROGEN GAS GENERATOR USER MANUAL UM-NM300L -19”R- Dual Voltage...

-

Page 2: Table Of Contents

NM300L- Nitrogen Gas Generator UM – NM300L Contents Page No Document History Warranty Statement Safety Notice to Users Declaration of Conformity Air Connection Electrical Connection Principle of Operation Commissioning Maintenance Schedule Technical Specifications Pneumatic Diagram Electrical Diagram Over Dimension Maintenance Log Notes... -

Page 3: Document History

NM300L- Nitrogen Gas Generator UM – NM300L History Rev. No. Changed Initials Date Document Created S. Khan 18/05/10... -

Page 4: Warranty Statement

SAFETY NOTICE TO USERS These instructions must be read thoroughly and understood before installation and operation of your Peak Scientific NM300L. Use of the Generator in a manner not specified by Peak Scientific MAY impair the SAFETY provided by the equipment. -

Page 5: Declaration Of Conformity

NM300L- Nitrogen Gas Generator UM – NM300L Declaration of Conformity Declaration of Conformity... -

Page 6: Air Connection

NM300L- Nitrogen Gas Generator UM – NM300L AIR CONNECTION The Nitrogen Generator should be connected to a clean, dry, OIL - FREE source of compressed air. A minimum pressure of 125 psig is required for efficient operation of the Generator. Any doubts as to the suitability of your compressed air supply should be referred to the factory for advice. -

Page 7: Principle Of Operation

Principle of Operation Principle of Operation Peak Scientific Instruments Membrane Generators utilise Hollow Fibre Membrane Technology to efficiently separate Nitrogen from other gases present in ambient air. The membrane operates on the principle of selective permeation in that so-called “Fast” gases such as H O, CO &... -

Page 8: Commissioning

NM300L- Nitrogen Gas Generator UM – NM300L Commissioning Commissioning With the Generator installed as described earlier. Disconnect the Nitrogen Outlet connection to allow the generator to vent to atmosphere until the unit is stabilized then open the air supply. The Generator has been pre-set in the factory to give the specified output flow-rate and pressure. -

Page 9: Maintenance Schedule

NM300L- Nitrogen Gas Generator UM – NM300L Maintenance Schedule WARNING: Servicing and/or repair of the Generator should only be undertaken by a TECHNICALLY COMPETENT PERSON with the Generator in a safely isolated condition. Due to the simplicity of the design and the small number of moving parts the NM Series Nitrogen Generator will have a long and trouble free life. - Page 10 NM300L- Nitrogen Gas Generator UM – NM300L Maintenance Inlet Filter / Separator Elements These should be changed at intervals as indicated below. In addition filter bowls should be cleaned and, the operation of the auto-drains should be checked. The Air supply to Generator MUST be turned OFF and the Generator MUST be de-pressurised prior to attempting to remove ANY filter bowl.

- Page 11 NM300L- Nitrogen Gas Generator UM – NM300L Maintenance RAC Filter The Element is as shown, and should be changed at 12-month intervals. The Air supply to the Generator MUST be turned OFF and the Generator MUST be de-pressurised prior to attempting to remove ANY filter bowl. Failure to do this may cause injury.

-

Page 12: Technical Specifications

NM300L- Nitrogen Gas Generator UM – NM300L General Details Technical Data Minimum Operating Ambient Temperature C (41 Maximum Operating Ambient Conditions C (86 F) 70% RH(max) Inlet Conditions (Free of oil and bulk moisture) Minimum Air Inlet Pressure 125 psig (8.61 Barg) Maximum Air Inlet Pressure 145 psig (10.0 Barg) Minimum Air Inlet Flow Rate... -

Page 13: Pneumatic Diagram

NM300L- Nitrogen Gas Generator UM – NM300L Pneumatic... -

Page 14: Electrical Diagram

NM300L- Nitrogen Gas Generator UM – NM300L Electrical... -

Page 15: Over Dimension

NM300L- Nitrogen Gas Generator UM – NM300L Overall Dimensions Overall Dimensions... -

Page 16: Maintenance Log

NM300L- Nitrogen Gas Generator UM – NM300L Maintenance Log Maintenance log Model- NM300L Serial number Work Done Remarks Date Name... -

Page 17: Notes

NM300L- Nitrogen Gas Generator UM – NM300L Notes...

Need help?

Do you have a question about the UM-NM300L and is the answer not in the manual?

Questions and answers