Subscribe to Our Youtube Channel

Summary of Contents for Parker GT Series

- Page 1 (217) 352-9330 | Click HERE Find the Parker / Compumotor Gemini GT6-L8 / GT6-L8-NK at our website:...

- Page 2 A – N . O B – A – B – 5 / 8 GT-U5 GT-L5 GT-U8 GT-L8 - L 5 Gemini GT Series Digital Stepper Drives Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 3 Since Parker Hannifin constantly strives to improve all of its products, we reserve the right to change this user guide and software and hardware mentioned therein at any time without notice.

- Page 4 Change Summary Gemini GT Hardware Installation Guide Revision B December 17, 1999 The following is a summary of the primary technical changes to this document since the previous version was released. This document, part number 88-017789-01B, supersedes 88-017789-01A. DRFLVL Command Removed from Configuration Steps (page 21) When you configure the drive, you no longer need to enter DRFLVLØ...

- Page 5 Product Type : Gemini Family of Drives, GTn and GVn Including, but not limited to : GT(6)-L5, GT(6)-L8, GT(6)-U5, GT(6)-U8 GV(6)-L3, GV(6)-U3, GV(6)-U6, GV(6)-U12 When installed in accordance with this installation guide, the above products have been demonstrated to be in compliance with the requirements of directives •...

-

Page 6: Table Of Contents

Table of Contents 1 – I ..........................7 HAPTER NTRODUCTION Gemini Products—Overview .............................. 8 Compatible Compumotor Products ........................... 10 2 – I ..........................11 HAPTER NSTALLATION Checking Your Shipment ..............................12 “Express Setup” Overview ..............................12 Step 1 – Connecting the Motor ............................15 Step 2 –... - Page 7 Gemini GT Hardware Installation Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 8: Chapter 1 - Introduction

C H A P T E R O N E Introduction IN THIS CHAPTER • Gemini Product Overview • Compatible Compumotor Products Chapter 1 – Introduction Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 9: Gemini Products-Overview

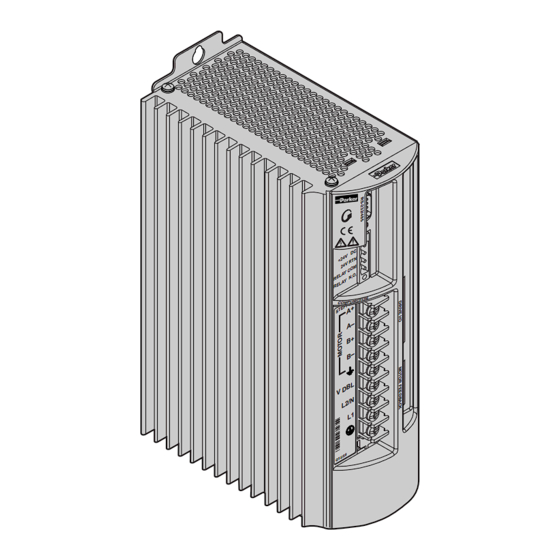

Gemini Products—Overview The Gemini Series is a family of high performance digital drives. The family contains drives for both stepper and servo motors. With many models and options available, the user can choose the precise level of power and control for the application’s motion requirements. - Page 10 Gemini Product Names The following table lists the meanings of letters and numbers in Gemini product names. Notice that “T” is associated with step motor products (“sTep”), and “V” is associated with servo motor products (“serVo”). Control Level: Step Motor Drives and Drive/Indexers Servo Motor Drives and Controller/Drives Step Motor Drive Servo Motor Drive...

-

Page 11: Compatible Compumotor Products

Compatible Compumotor Products GT-nn Stepper 6K or other Compumotor indexer GV-nnn Servo ±10V mode: 6K or other Compumotor controller Step/Direction mode: 6K or other Compumotor indexer Software Motion Planner Pocket Motion Planner (version 1.2 or higher) Note: Gemini drives are not compatible with ASCII communication programs such as Motion Architect or X Language software. -

Page 12: Chapter 2 - Installation

C H A P T E R T W O Installation IN THIS CHAPTER • Checking Your Shipment • Express Setup Chapter 2 – Installation Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 13: Checking Your Shipment

Checking Your Shipment Inspect your shipment carefully. You should have received one or more of the following: Gemini Drives GT-U5 GT-U8 GT-L5 GT-L8 Ship Kit Items The following ship with the drive: Part Part Number Gemini GT Quick Reference Guide 88-017777-01 Gemini GT Hardware Installation Guide 88-017789-01... - Page 14 In the express setup, we will give procedures for the following steps: Connecting the motor to the drive (without a load connected) Connecting AC power to the drive Establishing communications and configuring the drive for autorun Connecting a controller, enabling the drive, and observing the motor turn Information you may need for final installation will be presented in Chapter 3 Configuration, in Chapter 4 Special Features, in Appendix A Specifications, and in the separate Gemini Motor Reference Manual.

- Page 15 System Overview In this express setup procedure, we will give instructions for a Compumotor system—Gemini drive with Compumotor motor, Compumotor cables, and Compumotor 6K controller. If you use non-Compumotor equipment, try to follow along and perform the steps in the Express Setup procedure; consult Appendix A Specifications for additional information you may need.

-

Page 16: Step 1 - Connecting The Motor

Step 1 – Connecting the Motor The Gemini drive is compatible with 4, 6, or 8 lead step motors designed for use with a bipolar drive. Connecting the Motor Make sure power is off before you connect the motor. Wire your motor in series or parallel. For wiring diagrams, color codes, dimensions and speed/torque curves for Compumotor motors, consult the separate Gemini Motor Reference Manual . -

Page 17: Step 2 - Connecting Ac Power

Step 2 – Connecting AC Power GT-L5 and GT-L8 can be operated only at 120VAC. GT-U5 and GT-U8 can be operated at 120VAC or single phase 240VAC. Acceptable ranges of AC input voltage are listed below: Drive AC Input Range GT-L5 95VAC –... - Page 18 120VAC Operations: Connect power system’s safety earth to drive’s protective conductor terminal, marked with the symbol. Do not fuse the protective conductor terminal. Connect 120VAC, 50/60 Hz, single phase power line to drive’s L1 and N terminals. Reinstall the clear plastic terminal cover after you make connections. Connect jumper for 120VAC operations Fuses...

-

Page 19: Step 3 - Configuring The Drive

Step 3 – Configuring the Drive Gemini drives have no DIP switches or potentiometers for configuration. You will use software tools to communicate with the drive and configure drive settings. Configuration Software Two software programs are located on the Motion Planner CD-ROM. Motion Planner runs on a personal computer (PC). - Page 20 Configuring the Drive Choose one of the columns below, based upon which software program you are using—Motion Planner, or Pocket Motion Planner—and follow the procedure to configure your drive. NOTE: If this is not the first time the drive has been configured, issue an RFS command (Return to Factory Settings) from the terminal emulator, before performing the following procedures.

-

Page 21: Step 4 - Connecting The 6K Controller

Step 4 – Connecting the 6K Controller Connecting the 6K Controller and Enabling the Drive In this section of Express Setup, you will use the 6K to enable the Gemini drive. When you issue the DRIVE1 command in Step 7, the 6K will connect the Gemini’s enable input to ground, thus enabling the drive. - Page 22 Verifying Correct System Operations Choose one of the columns below, based upon which controller you are using—6K or non-6K—and follow the procedure to verify correct system operations. Verifying Correct System Operations Verifying Correct System Operations with a 6K Controller without a 6K Controller Verify that the drive is enabled.

-

Page 23: What's Next

What’s Next? This chapter has given you information and instructions for performing an Express Setup. The following list explains the steps you should take to complete your installation, and indicates where to find additional information for each of those steps. Mount the drive. -

Page 24: Chapter 3 - Configuration

C H A P T E R T H R E E Configuration IN THIS CHAPTER • Configuration • Damping Configuration • Stall Detect Configuration • Motor Matching Chapter 3 – Configuration Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 25: Configuration

Configuration You can configure the Gemini drive’s settings for optimum system performance. For most of these settings, configuration is optional—if you do nothing, the drive will use default values the very first time it powers up. If you change any settings, the new settings are automatically saved. -

Page 26: System Settings

DIGNC current loop gain DIGND current loop gain If you use a non-Compumotor motor, see Appendix B – Using Non-Compumotor Motors for additional instructions. System Settings The system settings configure the drive’s mode of operation, resolution, inertia ratio, and fault modes. Drive Settings Command Description Options:... -

Page 27: Communications Settings

Digital Outputs Command Description Options: OUTLVL output sense active high or active low (outputs 2, 3 and 4 can be set independently) Analog Monitors Command Description Options: DMONAV analog monitor A variable unused/turn off variable drive temperature velocity setpoint acceleration setpoint phase A commanded current phase A actual current phase B commanded current... -

Page 28: Procedure For Configuring Advanced Features

Damping These commands are used to configure the drive’s settings for damping. A procedure for adjusting damping settings is presented below. Relevant commands are: Command Description Options: DACTDP active damping gain you enter a number DDAMPA damping during acceleration can be turned on or off DELVIS electronic viscosity can be turned on or off... - Page 29 The default setting is disabled . (DABSD0) To turn ABS damping on , use the DABSD command. (DABSD1) If you use a Parker motor, the following parameters are automatically set when you use the configuration utilities (Motion Planner or Pocket Motion Planner) to select a motor.

-

Page 30: Configuring Stall Detect Settings

LJRAT system load-to-rotor inertia ratio If you use a Parker motor, the following parameters are automatically set when you use the configuration utilities (Motion Planner or Pocket Motion Planner) to select a motor. You do not need to enter values for them now. -

Page 31: Procedure For Motor Matching

Use the following procedures to configure the stall detect settings. Configuring Stall Detect The DSTALL command sets the sensitivity for the stall detection circuitry. The default setting is disabled . (DSTALL0) NOTE: Match the motor to the load (see the procedure on the following pages) before you configure stall detect settings. - Page 32 WARNING The following procedure causes the motor shaft to rotate. Setting Up Your System for the Motor Matching Procedure Before beginning the Motor Matching procedure, set up your system as follows: The Motor Matching procedure below is a bench top procedure—temporarily connect the drive, motor, indexer, and PC running Motion Planner (or a palm PC running Pocket Motion Planner), but do not permanently mount the components yet.

- Page 33 Gemini GT Hardware Installation Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 34: Chapter 4 - Special Features

C H A P T E R F O U R Special Features IN THIS CHAPTER • Relay Connections • +24VDC Keep Alive Power Connections • Multiple Drive Installations • RS-232/485 Communications • Updating the Drive’s Operating System Chapter 4 – Special Features Artisan Technology Group - Quality Instrumentation ... -

Page 35: Relay Connections (Optional)

Relay Connections (optional) To use the drive’s internal relay, connect your external circuit to the RELAY COM and RELAY N.O. terminals. The next drawing shows a typical application—connecting a motor brake to the relay terminals. GEMINI Drive User Supplied +24VDC +5VDC RELAY COM Motor Cable... -

Page 36: Multiple Drive Installations

DRIVE POWER SUPPLY VDC+ +24V DC 24V RTN VDC– RELAY COM RELAY N.O. Use twisted pair wiring +24VDC Power Input +24VDC Specifications: Input voltage range: 19.2 – 28.8 VDC Input current: 500 mA (maximum) Functions powered under +24VDC: position information (encoder or motor position counters in drive) communications diagnostics... -

Page 37: Rs-232/485 Communications

RS-232/485 Communications The Gemini drive has a single serial port marked, “ ,” on the front of the RS-232/485 unit. In the following this port will be referred to as the COM port. The Gemini drive uses a binary language for communication; it does not use ASCII. To enable 6000 ASCII level communication in a terminal mode, the Gemini uses a translator utility in Pocket Motion Planner and in the CommServer (for use with Motion Planner). -

Page 38: Configuring The Serial Port

Configuring the Serial Port The following commands can be used to configure the Gemini serial port and the terminals used by Motion Planner and Pocket Motion Planner. Complete descrip- tions of these commands can be found in the Gemini Programmer's Reference. Enable Serial Communication ECHO Enable Communication Echo... -

Page 39: Rs-232 Daisy-Chaining

RS-232 Daisy-Chaining Up to ninety-nine stand-alone Gemini drive products may be daisy-chained. Refer to the wiring diagrams for daisy-chain connections. Follow these steps to implement daisy-chaining: Step 1 To enable and disable communications on a particular drive unit in the chain, you must use the Daisy-Chain Address (ADDR) command to establish a unique device address for each unit. -

Page 40: Rs-485 Communications

Units with RS-232 disabled (EØ) will not respond to any commands, except E1; however, characters are still echoed to the next device in the daisy chain. Commands: 3_E0 ; Disable RS-232 on unit #3 DRES25000 ; Set resolution to 25000 on all other units 3_E1 ;... -

Page 41: Rs-485 Multi-Drop

RS-485 Multi-Drop Up to 99 Gemini drives may be multi-dropped. Refer to the diagrams in this section for daisy-chain connections. The ADDR command allows you to establish up to 99 unique addresses. To use the ADDR command, you must address each unit individually before it is con- nected on the multi drop. -

Page 42: Chapter 5 - Troubleshooting

C H A P T E R F I V E Troubleshooting IN THIS CHAPTER • LED Status • Software Commands for Troubleshooting • RS-232/485 Troubleshooting • System Problems Chapter 5 – Troubleshooting Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 43 Troubleshooting Guidelines If your system is not functioning properly, first try these steps. First Troubleshooting Steps: • Is the left LED illuminated? If not, look for problems with AC power. Also see System Problems at the end of this chapter. •...

- Page 44 Save the Configuration File Since further troubleshooting steps may change the drive configuration, you should upload the current drive configuration file and save it to your PC, in case you need it for future reference. Reconfigure the Drive To verify proper configuration, you may wish to reconfigure the drive. Pay particular attention to selecting proper configuration settings for the motor that you have installed, as motor configuration problems can cause a variety of errors.

- Page 45 TASX – Transfer Extended Axis Status The TASX command returns the axis status conditions. It reports more informa- tion than the TAS command, and is helpful for identifying which faults occurred. It returns a 32 bit response (1 = Yes; Ø = No). Note the positions of bits that are “1”...

- Page 46 RS-232/485 Communication Problems If you cannot establish RS-232 or RS-485 communications, the next sections give instructions for procedures to help isolate problems. Testing the COM Port Install and launch either Motion Planner or Pocket Motion Planner. See Chapter 2 Installation for information about using these software tools. RS-232 communications require that you use a null modem cable.

- Page 47 Testing the Cable Use the following two procedures to test your null modem cable, and verify that it is working properly. “Loop Back” Test Connect one end of your RS-232 cable to your PC, palm PC, or HPC. Disconnect the other end of the cable from the drive. Connect pin 2 to pin 3 on the drive end of the RS-232 cable.

- Page 48 System Problems If your Gemini drive is functioning properly, other parts of your system may be causing problems. It may be difficult to identify where the problem is coming from. To diagnose system problems, we recommend that you first have the drive perform its autorun function.

- Page 49 Motion Problems If problems occur during motion, check these possible causes: • Motor Sizing (ensure that the motor has enough torque to perform the move) • Excessive Acceleration or Deceleration • Excessive Velocity Electrical Noise Electrical noise on input or output lines can cause stop or kill inputs to activate unexpectedly.

-

Page 50: Appendixa - Specifications

A P P E N D I X A Specifications IN THIS APPENDIX • Gemini Drive Specifications • Input/Output Specifications • Dimensions • Protective Circuits • Cable Specifications Appendix A – Specifications Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 51: Power Specifications

Power Specifications Input Power Drive AC Input Range GT-L5 95VAC – 132VAC, 50/60 Hz, single phase GT-L8 95VAC – 132VAC, 50/60 Hz, single phase GT-U5 95VAC – 132VAC and 190VAC – 264VAC, 50/60 Hz, single phase GT-U8 95VAC – 132VAC and 190VAC – 264VAC, 50/60 Hz, single phase Connector Drive connector: #8 (M4) screw terminals. -

Page 52: Interface/Communication

Interface/Communication Connector Drive connector: 9 pin D-subminiature plug. Mating connector: 9 pin D-subminiature receptacle RS-232: RS-485:* Rx, Tx, Gnd 4-wire plus ground (Rx+, Rx-, Tx+, Tx-, Gnd) 9600 baud 9600 baud 8 data bits 8 data bits 1 stop bit 1 stop bit no parity no parity... -

Page 53: Inputs And Outputs

Standards UL, cUL 508C CE for LVD 72/23/EEC BS EN61010-1:1993/A2:1995 (ie includes 1995 amendment AMD 8961) Safety requirements for electrical equipment for measurement, control, and laboratory use Part 1. General requirements CE for EMC 89/336/EEC BS EN61800-3: 1997 Adjustable speed electric power drive systems Part 3. - Page 54 Command Input (required) The Gemini drive can accept several types of command input signals. Use the DMODE command to configure your drive to accept either a pulse input (step/ direction, clockwise/counterclockwise, or encoder), or ±10V velocity command. DRIVE I/O Connector Internal Connections 250 mA maximum source...

- Page 55 Enable Input (required) To enable the drive and energize the motor, you must connect the enable input (pin 1) to digital ground (pin 2). The next drawing shows the internal circuit. DRIVE I/O Connector Internal Connections Inputs internally pulled up to +24V, unless you connect an external 5 –...

- Page 56 Digital Inputs (optional) The Gemini drive has three digital inputs. Their functions are: Input 1 Positive Limit Input Input 2 Negative Limit Input Input 3 User Fault Input By default, these are +24VDC sourcing inputs. You can use VINref (pin 26) to change the switching voltage level.

- Page 57 Digital Outputs (optional) The Gemini drive has three digital outputs. Their functions are: Output 2* Drive Fault Output Output 3* At Limit Output 4* Position Error Output * For compatibility with other Compumotor products, the outputs are numbered 2, 3 and 4, rather than 1, 2 and 3.

- Page 58 Analog Monitor (optional) Two analog monitor outputs are available on pins 21 and 22. Use pin 25 as a ground reference for these monitors. Analog Monitor Specifications: Maximum Output: ±10V (scalable; use DMON command) Resolution: 8 bits peak to peak (for full scale signal) Internal Connections DRIVE I/O Connector 221 Ω...

-

Page 59: Dimensions

Dimensions Drive Dimensions 2.75 6.00 (70) (153.0) 3x clearance 1.38 for #8 or M4 (35) 5.40 mounting screws (138.0) (203.2) 7.75 (196.9) (177.8) Dimensions in inches (mm) 1.00 0.88 (25.4 ) (22.2) Fin Height Product Overall Width inches (mm) inches (mm) GT-L5 3.13 (79.4) 0.38 (9.5) - Page 60 2.75 6.00 (70) (153.0) 3x clearance 1.38 for #8 or M4 (35) 5.40 mounting screws (138.0) (251.5) 9.63 (244.5) (226.1) Dimensions in inches (mm) 1.00 0.88 (25.4 ) (22.2) Fin Height Product Overall Width inches (mm) inches (mm) GT-U5 3.13 (79.4) 0.38 (9.5) GT-U8 3.75 (95.3)

- Page 61 Drive Mounting The Gemini drive is a vented product. Mount it under an overhang to prevent material spilling into the drive. Panel Layout Dimensions NOTE: Provide proper spacing to maintain minimum clearance between drives. 1.00 (25.4 ) MINIMUM CLEARANCE 1.00 (25.4 ) MINIMUM CLEARANCE...

-

Page 62: Protective Circuits

Protective Circuits Short Circuit Protection The Gemini drive has an internal circuit that protects it from short circuits between one motor terminal to another (phase to phase), or from any motor terminal to earth. A short circuit fault is a latched fault. Causes of Fault: Phase to phase short circuit Phase to earth short circuit... - Page 63 Undervoltage Protection The Gemini drive’s undervoltage protection circuit monitors AC input voltage. If input voltage falls below 75VAC while the drive is operating, the drive issues an undervoltage fault, and turns off power to the motor. Undervoltage protection has the following features: Threshold Voltage: Voltage falling below 75VAC trips fault Results of Fault:...

-

Page 64: Cable Specifications

Cable Specifications This section contains specifications for Compumotor cables and cabling accesso- ries you can use with Gemini drives. CE Cables Many Compumotor cables are CE Cables. If installed according to instructions in Appendix C Regulatory Compliance: UL and CE, these cables are designed to aid the user in gaining European Compliance, and are thus an integral part of a CE system solution. - Page 65 NOTE: If using Compumotor 6000 Series stepper products, connect Gemini VINref (pin 26) to +5VDC, such as Gemini ENCODER +5 (pin 4 or 5). Do not connect Gemini VINref to any voltage higher than +5VDC. Flying Lead Cable – Color Code The next drawing shows the color code for the 50 pin connector/flying lead cable.

- Page 66 Gemini GEM-VM50 – 50 Pin Breakout Module Use the 50 pin breakout module for access to individual terminals on the 50 pin DRIVE I/O connector. The GEM-VM50 includes the cable above. Description: Part Number: 50 pin Breakout Module (with Cable) GEM-VM50 50 pin Breakout Module (without cable) 01-016986-01...

- Page 67 Gemini GT Hardware Installation Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 68: Motors

A P P E N D I X B Using Non-Compumotor Motors IN THIS APPENDIX • Commands for Motor Configuration • Wiring and Connections: 4-, 6-, and 8-lead motors • Setting Motor Current and Drive Gains Appendix B – Non-Compumotor Motors Artisan Technology Group - Quality Instrumentation ... - Page 69 Commands for Configuration If you use a non-Compumotor motor, you must configure the drive for your motor by setting values for all commands in the following table. Also see the Motor Parameters table on the Motion Planner CD-ROM for examples of recommended drive configuration settings for Compumotor motors.

- Page 70 Wiring Configurations Refer to the manufacturer’s motor specification document to determine the motor’s wiring configuration. You can also determine the wiring configuration with an ohmmeter using the procedures below (4-Lead Motor, 6-Lead Motor, 8- Lead Motor). Once you determine the correct motor wiring configuration, use the terminal connection diagram, shown at the end of this section, that applies to your configuration.

- Page 71 8-Lead Motor Because of the complexity involved in phasing an 8-lead motor, you must refer to the manufacturer’s motor specification document. Using the manufacturer’s specifications, label the motor leads as shown in the next drawing. Phase B Windings 8-Lead Motor – Labeling the Leads You can configure the 8-lead motor in series or parallel.

- Page 72 Terminal Connections After you determine the motor’s wiring configuration, connect the motor leads to the Gemini drive’s MOTOR connector according to the following figure. 4-Lead Motor 6-Lead Motor Gemini Gemini Terminals Terminals A-CT A– A– A– A– B– B– B-CT B–...

- Page 73 Direction of Motor Rotation The procedures above do not determine the direction of motor shaft rotation. To find out which direction the shaft turns, you must power up your system and command motion. If the shaft turns in the opposite direction than you desire, exchange the motor leads connected to A+ and A–...

- Page 74 8-Lead Motors Manufacturers generally use either a bipolar rating or a unipolar rating for motor current in 8-lead motors. Bipolar Rating: If the manufacturer specifies the motor current as a bipolar series rating: • If you wire the motor in series, use the DMTIC command directly. •...

- Page 75 Gemini GT Hardware Installation Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 76: Appendixc - Regulatory Compliance : Ul And Ce

A P P E N D I X C Regulatory Compliance: UL and CE IN THIS APPENDIX • Installation Instructions • Installation Guidelines • System Installation Techniques Appendix C – Regulatory Compliance: UL and CE Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 77 Regulatory Agencies The Gemini family of products is designed to meet the requirements of global regulatory agencies. Gemini products have shown compliance with the regulatory agencies in the following list. The list also shows additional steps users must take to ensure compliance.

- Page 78 89/336/EEC, the entire system must comply: motor, drive, cabling, and peripher- als. The installation of the product must include the following items. EMC Cabling For electromagnetic compatibility, you must use Parker Compumotor CE cables. EMC Motor For system CE compliance, you must use an EMC-ready motor, or a motor that has demonstrated acceptable EMC performance.

- Page 79 Installation Guidelines Gemini products are made available under “Restricted Distribution” for use in the “Second Environment” as described in EN 61800-3: 1996, page 9. Cabinet Mounting For Electromagnetic Compatibility, cabinet mounting is not required. However, Gemini drives have high voltage terminals—for safety purposes, the drive must not be user accessible during normal operation.

- Page 80 R-Clamp Remove outer jacket only. Do not cut braid. Bulkheak Clamshell Clamp Bulkheak Clamshell Clamp Enclosure Panel Enclosure Panel Cable Cable 360° Bonding Techniques The following clamps and clamp kits are available from Compumotor. Clamp Type: Compumotor Part Number: R-Clamp 58-016050-01 R-Clamp Kit (10 per) R CLAMP KIT...

- Page 81 System Installation The next figure shows a typical EMC installation. Limits Controller/ Gemini Indexer Drive Bond braid to earthed panel. Use R-clamp or bulkhead clamshell clamp. (See 360° bonding drawing.) RS-232/485 Cable Mount to earthed metal panel, paint VDC+ removed from mounting locations +24VDC VDC–...

-

Page 82: Index

Index Symbols communications 51 Compumotor 6200 63 +24VDC keep alive power 34, 50 GC-50 50 pin connector 65 Compumotor AT6n00 63 +24VDC power input 35 GEM-VM50 65 configuration 18, 24 ±10V command inputs 53 configuration status 44 360° bonding 79 connector 4-lead motor wiring 69 Drive I/O 52... - Page 83 naming system 9 serial port 37 non-Compumotor motor 68 ship kit 12 null modem cable shock 51 troubleshooting 46 short circuit protection 61 null-modem cable 65 software commands 43 numbering system 9 software for configuration 18 specifications 50 stall detect 29 standards 52 offset 30 step and direction 53, 56...

- Page 84 RS-232/485 Connector – Configuration Port: see page 36 LEDs – see page 42 To configure all drive parameters, connect a PC or HPC to this Green/Red Yellow/Green port. Use Motion Planner or Pocket Motion Planner for drive Gemini GT configuration. Stepper Drive RS-485 Connections LED Color:...

Need help?

Do you have a question about the GT Series and is the answer not in the manual?

Questions and answers