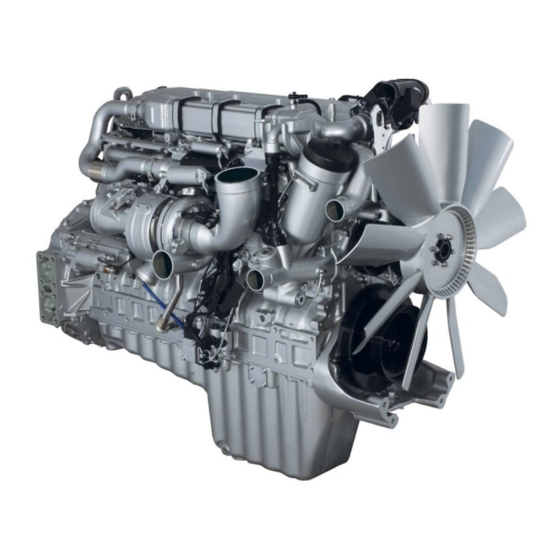

Detroit Diesel MBE4000 Inspection Procedure

Fuel system

Hide thumbs

Also See for MBE4000:

- Service manual (587 pages) ,

- Application and installation manual (224 pages) ,

- Service information (40 pages)

Table of Contents

Advertisement

Quick Links

TO:

All Distributors, U.S. and Canada

ATTN.

Service Managers

FROM:

Evandro Silva

SUBJECT:

MBE4000 – Fuel System – Inspection Procedure

The MBE 4000 service manual was released in June of 2002 to provide the field with important

technical information for MBE 4000 support.

Based upon our service experience over the past year, it has been determined that additional

material should be included to assist technicians servicing this engine. This information includes

both revised and additional material to current sections of the manual as well as new features that

will be added to the 2004 release of the engine.

The updated information will be sent in two formats, through Technical Service Letters and

Service Information Bulletins.

Attached to this letter is the first installment of the updated material: Fuel System – Inspection

Procedures.

cc:

Regional Vice Presidents, U.S. & Canada

Regional Product Support Managers, U.S. & Canada

Detroit Diesel Corporation 13400 Outer Drive, West / Detroit, Michigan 48239-4001 / Telephone: 313-592-5000

DA 1

Evandro Silva

Technical Service

DaimlerChrysler Powersystems

NO.: 03 TS - 24

May 28, 2003

Advertisement

Table of Contents

Summary of Contents for Detroit Diesel MBE4000

- Page 1 Attached to this letter is the first installment of the updated material: Fuel System – Inspection Procedures. Evandro Silva Technical Service Regional Vice Presidents, U.S. & Canada Regional Product Support Managers, U.S. & Canada Detroit Diesel Corporation 13400 Outer Drive, West / Detroit, Michigan 48239-4001 / Telephone: 313-592-5000 DaimlerChrysler Powersystems DA 1...

- Page 2 Do not smoke when refueling. NOTE: For additional safety precautions, refer to the MBE4000 Service Manual (6SE422) – General Information – page 15. 1 - Check fuel delivery lines looking for deformation or bent lines, creating restriction and/or obstruction of the flow.

- Page 3 b) Gauge Installation – setup 2: (before the fuel filter): 1 – Fuel filter housing 2 – Fuel outlet line 3 – Fuel Pump 4 – Fitting 5 – Mechanical gauge NOTE: The fitting applied in both setups is not a special tool and it is not included on the Mercedes-Benz kit or SPX kit.

- Page 4 Checking the fuel pump driven gear bolt torque This procedure describes how to check the fuel pump assembly looking for play/wear on the fuel pump shaft drive gear mounting bolt. Any play in this component has a big impact on the engine performance. Picture A Picture B 1.Fuel pump...

- Page 5 7 - Fuel System Test – Using Minidiag2 CAUTION To avoid injury when working near or on an operating engine, remove loose items of clothing, jewelry, and tie back or contain long hair that could be caught in any moving part causing injury CAUTION Diesel engine exhaust and some of its constituents are known to the state of California to cause cancer, birth defects, and other...

- Page 6 Step 2: Swap the suspect unit pump with one operating properly and run the test again - refer to the following sections of the MBE4000 Service Manual – 6SE412: 2.1.1 for unit pump removal and section 2.1.2 for unit pump installation. If the...

Need help?

Do you have a question about the MBE4000 and is the answer not in the manual?

Questions and answers