Table of Contents

Advertisement

Quick Links

Models:

____________________________________________________________________________

HS 116

S

HS 118

S

HS 121

S

HS 124

S

HS 130

S

HS 136

S

HS 142

S

Hydrus® Commercial Softening Systems

HS 116

OD

S

HS 118

OD

S

HS 121

OD

S

HS 124

OD

S

HS 130

OD

S

HS 136

OD

S

HS 142

OD

S

HS 216

OD

S

HS 218

OD

S

HS 221

OD

S

HS 224

OD

S

HS 230

OD

S

HS 236

OD

S

HS 242

OD

S

Owner's Manual

HS 316

OD

S

HS 318

OD

S

HS 321

OD

S

HS 324

OD

S

HS 330

OD

S

HS 336

OD

S

HS 342

OD

S

HS 416

OD

S

HS 418

OD

S

HS 421

OD

S

HS 424

OD

S

HS 430

OD

S

HS 436

OD

S

HS 442

OD

S

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for KineticoPRO Hydrus HS 116s

- Page 1 Owner’s Manual Hydrus® Commercial Softening Systems Models: ____________________________________________________________________________ HS 116 HS 116 HS 216 HS 316 HS 416 HS 118 HS 118 HS 218 HS 318 HS 418 HS 121 HS 121 HS 221 HS 321 HS 421 HS 124 HS 124 HS 224 HS 324...

-

Page 2: Table Of Contents

able of onTenTs ydrus eries ommerCial ofTeners How a Water Softener Works ........................................4 ......................................4 ydrus ofTener esign eaTures Automatic Operation ...........................................5 Countercurrent Regeneration ........................................5 Low Leakage ..............................................6 High Flow Rates ..............................................6 High Capacity ..............................................6 Low Maintenance Requirements .......................................6 System Sizing ..............................................7 peraTion Concepts ................................................ - Page 3 roubleshooTing Frequent Regeneration..........................................25 Hard Water ..............................................25 Hard Water Continued..........................................26 High Salt Consumption ..........................................26 Iron Bleed Through ............................................27 Leaks .................................................27 No Water to Service............................................27 Pressure Loss ..............................................28 Salty Treated Water ............................................28 Taste, Color and/or Odor .........................................28 Unit Sticks in Cycle ............................................29 Water Running to Drain ..........................................29 arTs Complete Systems, Tanks, Risers and Distribution ................................

-

Page 4: How A Water Softener Works

SOFT WATER Unlike other softeners, the KineticoPRO multiplex Hydrus systems regenerate with soft water. The multiplex systems also regenerate countercurrent to the service flow. Just as there are differences in cleaning with soft water, there are differences in regenerating with soft water. The system uses only clean, soft water to carry out the regeneration and to make the saturated brine solution in the salt storage tank. -

Page 5: Automatic Operation

HS Series Owner’s Manual uTomaTiC peraTion Once the Hydrus Softening System has been installed and set up, operation is completely automatic. The standard, most efficient configuration is to have a flow meter in line that monitors the total amount of water that is softened. -

Page 6: Low Leakage

Hydrus softeners can be configured to provide hardness less than 1.0 mg/L, as calcium carbonate. aTes KineticoPRO’s Hydrus Softening Systems are designed to accommodate the high flows demanded by today’s growing businesses. Despite its compact size, the system provides softened water when needed, on demand. -

Page 7: System Sizing

These values are obtained from water meter readings and water bills. The remaining factor used in properly sizing a KineticoPRO Hydrus system is the hardness of the water to be treated. Hardness is a measure of the calcium and magnesium salts dissolved in the water. The positively- charged portions of these salts, or cations, constitute the loading on the system used to soften the water. -

Page 8: Concepts

HS Series Owner’s Manual peraTion This section is provided to instruct on the operation of tanks, controls and bringing systems. KineticoPRO’s Hydrus Softening Systems are an assembly of five major sub-assemblies: media tank, remote meter, Smart Start Controller, the brining system and the Hydrus Valve itself. Together, they provide softened water efficiently, reliably and continuously. -

Page 9: Level 3-6 Assembly

The KineticoPRO Hydrus System has two basic configurations: simplex and multiplex. The simplex configuration is straightforward in its operation. As a single tank, the regeneration occurs without affecting any other tanks or sub-systems that may be present. Raw water is by-passed around the treatment system during a regeneration. -

Page 10: Plumbing

HS Series Owner’s Manual To provide the most efficient, productive regeneration, Hydrus multiplex systems use softened water for all four stages of the regeneration and to refill the brine tank. For a better understanding, a triplex Hydrus system is used in the following example. -

Page 11: Media Tanks

HS Series Owner’s Manual edia anks The media tanks are made up of several components: the tank itself, upper distributor, media, underbedding, lower distributor and riser. The raw water flows into the valve and through the upper distributor at the top of the tank just beneath the valve. -

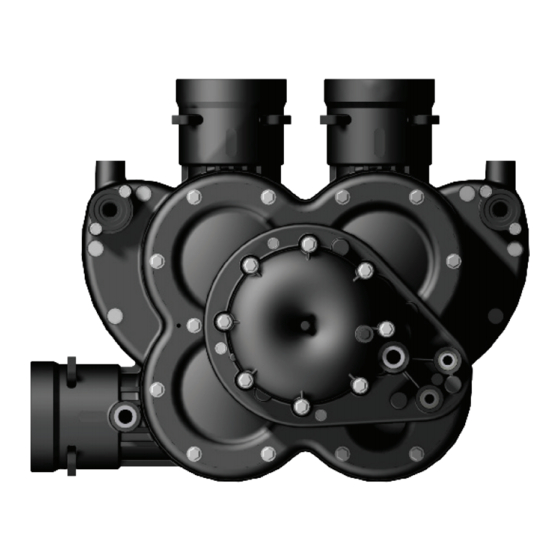

Page 12: Central Brining

Kinetico Incorporated. ydrus alVe The Hydrus Valve is at the heart of KineticoPRO’s commercial high-flow systems. It’s a multi-port valve that controls system flow through a single tank. It is designed to link to other Hydrus valves, making expansion to multi-tank configurations uncomplicated. -

Page 13: Sizing

Compliance must also be achieved in a modification of the original installation. Consult a KineticoPRO professional or the appropriate technical documentation if a modification or an alteration is planned or carried out. -

Page 14: Compensated Hardness Equation

HS Series Owner’s Manual Compensated Hardness Equation: mg/L Hardness, as + 3 mg/L iron + 5 mg/L manganese = Compensated Hardness, grain/gal as CaCO CaCO 17.1 The equation above is used to determine the compensated hardness. It provides a method for converting iron and manganese into an equivalent hardness. -

Page 15: Two Tank Systems (Maximum Capacity In Thousands Of Gallons)

HS Series Owner’s Manual Two Tank Systems (maximum capacity in thousands of gallons) HIGH EFFICIENCY Brine Dose (5 lb/ft Salt Setting) HIGH CAPACITY Brine Dose (7.5 lb/ft Salt Setting) HS 216s HS 218s HS 221s HS 224s HS 230s HS 236s HS 242s HS 216s HS 218s... -

Page 16: Three Tank Systems (Maximum Capacity In Thousands Of Gallons)

HS Series Owner’s Manual Three Tank Systems (maximum capacity in thousands of gallons) HIGH EFFICIENCY Brine Dose (5 lb/ft Salt Setting) HIGH CAPACITY Brine Dose (7.5 lb/ft Salt Setting) HS 316s HS 318s HS 321s HS 324s HS 330s HS 336s HS 342s HS 316s HS 318s... -

Page 17: Four Tank Systems (Maximum Capacity In Thousands Of Gallons)

HS Series Owner’s Manual Four Tank Systems (maximum capacity in thousands of gallons) HIGH EFFICIENCY Brine Dose (5 lb/ft Salt Setting) HIGH CAPACITY Brine Dose (7.5 lb/ft Salt Setting) HS 416s HS 418s HS 421s HS 424s HS 430s HS 436s HS 442s HS 416s HS 418s... -

Page 18: Brining System

HS Series Owner’s Manual rining ysTem Following the chart below, set the brine valve by raising or lowering the float cup: Float Setting (A) Brine Drum Size Salt Dose, Measure from cups center in lb 24 x 50 30 x 48 39 x 60 50 x 60 8.1”... -

Page 19: Central Brining

This central drum can contain salt and brine, or just brine from a separate salt saturator. Equipment and instructions for Hydrus softeners using central brine tanks are available separately from KineticoPRO Incorporated. 454 High Flow Brine Valve Today’s larger commercial brine valves demand higher brine draw and refill rates. -

Page 20: Backwash Flow Control

KineticoPRO offers two (2) Smart Start controller models: • Base Smart Start: uses mechanical actuation to measure water usage and initiate regeneration. KineticoPRO modifies the mechanical meter from its original configuration to allow it to interface with the Base Smart Start controller. -

Page 21: Brine Drums

HS Series Owner’s Manual Some features and benefits: Salt Fill Line • Uniquely shaped for extra hardness removal • Virtually 100% water soluble, minimizing brine tank clean out • Helps prevent mushing, bridging and channeling • Designed to keep softeners clean and trouble-free The frequency of salt replenishment is based upon usage and size brine tank in use. -

Page 22: Remote Meter

Slowly turn counter-clockwise until the actuator has advanced the “Indicator” arrow to the “BRINE” position, about 10°. At this point, the flow of water will be audible. This indicates a successful regeneration initiation has occurred. If water flow is not heard, contact a KineticoPRO professional . Override Actuator... -

Page 23: Battery Replacement

HS Series Owner’s Manual aTTery eplaCemenT Insert the battery pack into the mid-wall section to hold the batteries. Plug the keyed battery connector into the two-terminal port on the inside of the circuit board labeled “BAT+POWER.” Battery Pack Press into mid-wall section. Note: The fit is tight to keep the battery in place. -

Page 24: T Roubleshooting

If the problem is not shown below, a call to the local KineticoPRO professional should be helpful. KineticoPRO will try to assist over the phone and may send out a service professional. -

Page 25: Hard Water

HS Series Owner’s Manual Beginning with “Frequent Regeneration”, possible reasons for the complaint and the corresponding solutions. requenT egeneraTion Problem Reason Solution 1. The customer is not familiar p If customer previously owned n Explain to the customer how the Hydrus with Hydrus unit operation an electric unit with timer based softener works... -

Page 26: Hard Water Continued

HS Series Owner’s Manual aTer onTinued Problem Reason Solution 6. The by-pass is open p An open by-pass allows water to n Close the by-pass flow around the system without any treatment at all p All simplex units incorporate an internal n Sample during service for a simplex by-pass system, not regeneration... -

Page 27: Iron Bleed Through

HS Series Owner’s Manual leed hrough Problem Reason Solution 1. Customer plumbing p Previous iron buildup inside existing n Verify that customer plumbing is the plumbing after the water softener problem by testing the water quality at the brine fitting with water running 2. -

Page 28: Pressure Loss

HS Series Owner’s Manual ressure Problem Reason Solution 1. Reduced pressure entering the p The pre-filter is clogged n Replace the clogged prefilter unit 2. The upper and/or lower p Foreign matter from the input lines is n Clean the distributors distributors are plugged accumulating in the distributors n Add a prefilter to eliminate the foreign... -

Page 29: Unit Sticks In Cycle

HS Series Owner’s Manual TiCks in yCle Problem Reason Solution The unit sticks in regeneration or p The regeneration flow path is plugged n Clean the regeneration flow path backwash cycle at the regeneration nozzle or flow control p The regeneration drive pawl and/or n Replace the regeneration drive pawl spring is weak or broken p There is a damaged tooth on the... -

Page 30: Complete Systems, Tanks, Risers And Distribution

HS Series Owner’s Manual arTs ompleTe ysTems anks isers and isTribuTion Complete Softener Tank Assemblies Includes: Tank Distributor Valve Resin Underbedding Manual Diffuser Tank Size Simplex Multiplex 16” x 65” ......H15873 ........H15874 18” x 65” ......H12239 ........H12245 21”... -

Page 31: Complete Valves

HS Series Owner’s Manual Complete Valves Hydrus, Softener, Multi-tank, 16-24 ........ H12194 Hydrus, Softener, Multi-tank, 30-42 ......H12189 Hydrus, Softener, Simplex, 16-24 ........H12198 Hydrus, Softener, Simplex, 30-42 ........H12202 Includes Valve manual Level 1 / 2 Screws (#10x1.5”) (QTY 8 for Cap) ........10734 Filter, Single or Multi-tank ..........12216A Softener, Multi-tank, Countercurrent ....... -

Page 32: Level 3 - 5A

HS Series Owner’s Manual Level 3 - 5A Main Assembly Screw ............10946 Filter Disc, L-3 SS ..............11017A Level 3 ..................10902 Level 3 Seal ................10945 Radial Coupling with O-ring ..........12298 Level 4 (with retainers and quad rings).....10904A Level 5A Seal (simplex HWBP) .........10978 Level 5A Seal (Multi-tank NHWBP) ......... -

Page 33: Level 5B - Base

HS Series Owner’s Manual Level 5B - Base Level 5B (with inserts) ............12294A Base Seal ...................10932 Base (includes retainers and O-ring) ......10908A Riser Tube O-ring ..............10930 Upper Distributor Diffuser (used with filters) ..........10977 Distributor (used with softeners) ........10968 Upper Distributor Screw ............ -

Page 34: Miscellaneous

HS Series Owner’s Manual Miscellaneous Drain Flow Control 1.00 cc Lube Packet ........11319 (MED 420) Backwash Flow Control ..10919 (universal) O-ring (BWFC) ........10967 Hydrus System Service Kit ..........12316 Owners Manual ..............12223L Internal Valves Control Valve and Start Next Valve Valve Piston (with quad ring) ........... -

Page 35: Base Smart Start Controller

HS Series Owner’s Manual Base Smart Start Controller Complete Smart Start Controllers Smart Start Controller, No Box ...........12137 Enclosure Back Mounting Plate Enclosure .........12100 Midwall Enclosure ..............12101 Front Cover Enclosure ............12102 Electrical Timer Circuit with Coating (SS Base) ......12142 Two-Terminal Battery Pack ..........12106 Bi-Stable Solenoid, including fittings ......17309 Miscellaneous... -

Page 36: Meters - Remote Reset

HS Series Owner’s Manual Meters - Remote Reset Immediate Regeneration, 120 VAC 2” Meter, Plastic, 120V 50/60HZ, 3-150 gpm, 6,250-106,250 gallon range ..................16714 3” Meter, Stainless Steel, 120V 50/60HZ, STD, 7-300 gpm, 3,750-63,750 gallon range ............16712 3” Meter, Stainless Steel, 120V 50/60HZ, EXT, 7-300 gpm, 18,750-318,750 gallon range ............16713 Brining System Complete Brine Systems... -

Page 37: Miscellaneous Components

HS Series Owner’s Manual Miscellaneous Components Adapter Flange, 6” to 4” ...72868 (required on 36” and 42” tanks) 2” Flex Hose Connector ............... 13096 Vacuum Breaker 1” .................58547 Coarse Gravel .................. 1226A Fine Gravel ..................57580 Installation Kits Master Installation Kit Includes: Quantity Venturi Kit... - Page 38 HS Series Owner’s Manual oTes ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________ ______________________________________________________________________________...

- Page 40 ’ wner anual ydrus ommerCial ofTening ysTems ©2021, Kinetico Incorporated Corporate Headquarters 10845 Kinsman Road Newbury, Ohio 44065 www.KineticoPRO.com Product No. 12223M Rev. 12.20.2021...

Need help?

Do you have a question about the Hydrus HS 116s and is the answer not in the manual?

Questions and answers