Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

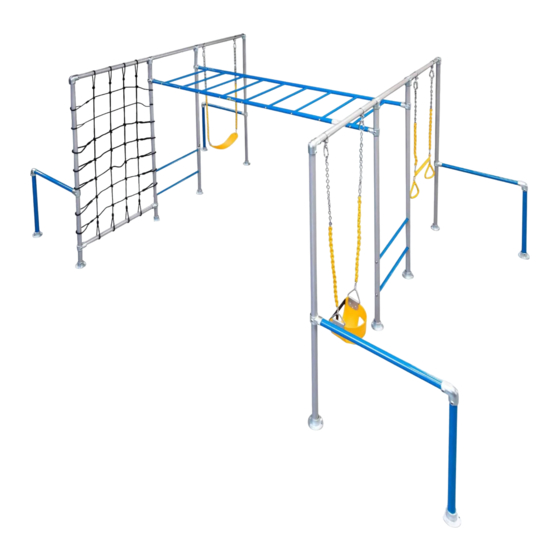

Summary of Contents for FUNKY MONKEY BARS THE GORILLA

- Page 1 THE GORILLA ASSEMBLY INSTRUCTIONS...

-

Page 2: Table Of Contents

Bars®, especially lower quality products that have not been approved by Funky Monkey Bars®. 15. Ensure the height of your Funky Monkey Bars® (horizontal ladder) are set at a level that is age appropriate. 16. DO NOT install your Funky Monkey Bars® over or near objects that could interfere with users in an unsafe way. - Page 3 Work on flat level surface. LOCATION A safe fall zone around your Funky Monkey Bars® is essential. A minimum distance of 1.5m to 2m (5 ft to 6.5ft) is recommended around the elevated hanging points of your Funky Monkey Bars®.

-

Page 4: Load Rating

QUALITY & INDEPENDENT TESTING At Funky Monkey Bars® we take the quality of our designs and safety very seriously. All Funky Monkey Bars® frames go through a stringent, independent structural testing process prior to being made available for release to our customers. -

Page 5: Dimensions

FUNKY MONKEY BARS ® THE GORILLA OVERALL DIMENSIONS A mimimum of 2.0 Metres clear fall zone is recommended around the elevated hanging points of your Funky Monkey Bars®. 5.05 Metres 2.0 Metres 2.0 Metres clear fall zone clear fall zone 2.0 Metres... -

Page 6: Assembly Tips

ASSEMBLY TIPS CORRECT INSERTION INTO FITTINGS - (indicative diagram shown) Gap. No gap. All tubes must be fully inserted until contact is made with adjoining tube. CORRECT TIGHTENING METHOD OF GRUB SCREWS - (indicative diagram shown) + 360 2. Using other end of the allen key do one full 1. - Page 7 ASSEMBLY TIPS (continued) IT IS CRITICAL YOUR MAIN FRAME IS 100% SQUARE AND LEVEL (indicative diagram shown) PLAN VIEW Check assembly is 100% level, square & straight. SIDE VIEW If your frame is not straight or level remove pegs, loosen grub screws, re-adjust re-tighten and re-peg the frame.

-

Page 8: Inventory

INVENTORY TOOLS REQUIRED FOR INSTALLATION Soft Hammer 17mm Rachet Spirit Level Tape Measure 8mm Allen key (Included) (Not included) (Not included) (Not included) (Not included) TUBES Rung Tube Twirly Tube Cargo Tube Swing Leg Tube Double Swing Tube Adj. Leg Tube Ladder Tube FITTINGS Short Tee... - Page 9 INVENTORY (continued) HARDWARE M10 Bolt Rung Insert Washer M10 Hex Nut Plastic End Cap Manufacture Sticker Height Sticker COMPONENTS (accessories if applicable) Trapeze Sling swing Toddler Swing Cargo Net Swing Hooks One of the best things about a Funky Monkey Bar is the ability to add new equipment and accessories as your child and family grows.

-

Page 10: Ladder Bar Assembly

ASSEMBLY INSTRUCTIONS - LADDER BAR ASSEMBLY RUNG ASSEMBLY (x13) Rung Tube 25Dia x 850mm 1. Assemble plastic rung inserts as shown above. 2. Push inserts into both ends of all rungs. MONKEY BAR LADDER ASSEMBLY M10 Bolts Washers Hand tighten all bolts. Assemble on flat surface. - Page 11 ATTACH SECOND LADDER TUBE Hand tighten all bolts Ladder Tube Washers 50Dia x 2950mm M10 Bolts FIRMLY TIGHTEN ALL RUNG BOLTS. See page 5 for correct tightening method. 3-4 turns Page 10...

- Page 12 ASSEMBLY INSTRUCTIONS - LEG ASSEMBLY LEG ASSEMBLY x 2 Insert plastic end caps into leg tubes. Adj. Leg Tube Dia 50 x 2300mm Plastic End Cap INSERT RUNGS M10 Bolts Washers Hand tighten all bolts. Assembled Rungs from step 1 ATTACH SECOND LEG AND CARGO NET 1.

- Page 13 ATTACH BASE PLATES AND 1x SHORT TEE (A) (cargo net side) Tighten all grub screws on base plates. Short Tee Leave short tee (A) loose. D-101 (Short tee (A) only with cargo net) Base Plate + 360 D-125 APPLY HEIGHT STICKERS Height Sticker Move net downwards to allow height sticker application.

- Page 14 SET LADDER BAR HEIGHT. 200mm Short Tee D-101 Good starting height is 100-200mm above reach. Position top short-tee at measured height. Push through cargo hoops if required. FIRMLY TIGHTEN ALL GRUB SCREWS AND RUNG BOLTS. Hand tighten grub screw A. (Temporary location).

-

Page 15: Leg Assembly

REPEAT STEPS 5-11 FOR 1x MORE SET OF LEGS. SAME PROCEDURE BUT WITHOUT CARGO NET AND ADDITIONAL SHORT TEE (A). SEE BELOW FOR DESIRED RESULT. LEG ASSEMBLY x 2. Standing up with top tees facing each other. Check all grub screws are fully tightened except on fitting A (hand tight only). -

Page 16: Twirly Whirly Bar Assembly

ASSEMBLY INSTRUCTIONS - TWIRLY WHIRLY BAR ASSEMBLY ASSEMBLE VERTICAL TWIRLY TUBE Elbow D-125 Tighten all grub screws. Insert Twirly Tube fully into Elbow. Twirly Tube 50Dia x 900mm Base Plate D-131 ATTACH HORIZONTAL TWIRLY TUBE Fully insert twirly tube then Twirly Tube firmly tighten all grub screws. -

Page 17: Main Monkey Bar Assembly

ASSEMBLY INSTRUCTIONS - MAIN MONKEY BAR ASSEMBLY FLIP LEGS 1 & 2 OVER For the following step the legs should be flipped over & attached one at a time. 180º 180º ATTACH 2x LEGS TO LADDER 1. Attach first set of legs 1 - tighten all grub screws. 2. - Page 18 FLIP ASSEMBLY OVER CRITICAL : ENSURE YOUR FRAME IS 100% SQUARE AND LEVEL (AS PER PAGE 6) BEFORE MOVING ONTO THE REST OF THE ASSEMBLY SECURE TO GROUND Select suitable location. Hammer in pegs x4. Pegs Page 17...

- Page 19 ASSEMBLY INSTRUCTIONS - SWING BAR ASSEMBLY SWING BAR ASSEMBLY x2. Slide on all fittings. Leave short tees and swing hooks hand tight only for assembly adjustment later, see below for spacing. Swing Hooks Short Tee D-101 Double Swing Tube 50Dia. x 2950mm Short Tee D-101 Swing Hooks...

- Page 20 ATTACH 2x SWING BAR ASSEMBLY. Cargo Net Side Attach the short tees (on the swing bars) to the main monkey bar ladder legs. The cargo net side will need to be threaded through the top cargo net hoops before attaching. Fully tighten all grub screws.

- Page 21 ASSEMBLY INSTRUCTIONS - SWING LEG ASSEMBLY ATTACH CARGO TUBE 1. Ensure the cargo net gap is 1040mm apart between legs. You may need to loosen top grub screws D & E to slide the swing bar along. Retighten before continuing. 2.

-

Page 22: Swing Bar Assembly

ATTACH LEGS x3 Swing bar. Slide legs onto swing bars. Fully tighten elbow grub screws. Fully tighten all elbow grub screws. Leg assemblies 1-3 from step 27. + 360 SECURE TO GROUND Pegs Page 21... - Page 23 ATTACH TWIRLY WHIRLY BARS x4 Adjust height of short tees to align with horizontal twirly whirly bar. Tighten all grub screws fixing twirly whirlys to legs. Tighten all grub screws. 4x Twirly whirly bars from step 18. + 360 CHECK ALL FITTING GRUB SCREWS ARE FULLY TIGHTENED + 360 1.

-

Page 24: Swing Leg Assembly

ASSEMBLY INSTRUCTIONS - LOAD TWIRLY WHIRLY BARS LOAD YOUR TWIRLY WHIRLY BARS x4 To reduce movement in your frame load your twirly whirly bars as follows. . Loosen the grub screw fixing the short tee to the swing leg. Swing leg Twirly Whirly . - Page 25 ATTACH ACCESSORIES (if applicable) Gorilla supplied accessory: (sling swing shown) Attach new accessories in desired position (if applicable)and tighten swing hook bolts with rachet. Gorilla supplied accessory: (trapeze swing shown) Gorilla supplied accessory: (toddler swing shown) REFER TO SEPARATE ACCESSORIES INSTRUCTIONS IF APPLICABLE Page 24...

-

Page 26: Sticker Placement Guide

ABN: 72 164 496 520 9 Cutting Way, Yangebup 6164 Telephone 1300 912 198 Year or Manufacture: 2020 This Funky Monkey Bars® has been designed and manufactured in accordance (where applicable) with: Australian Standards AS4685-1 ASTM Global Standards F1148 Playgrounds Equipment Standard EN1176... -

Page 27: Maintenance

FINAL CHECKS 1. Ensure frame is square and level. 2. Firmly tighten all grub screws and bolts. 3. All base plates are pegged down. MAINTENANCE. At the beginning of each heavy play session (especially a party) and twice a month during play season ensure; 1. - Page 28 72 164 496 520 1300 912 198 info@funkymonkeybars.com www.funkymonkeybars.com ® AUSTRALIAN MADE 9 Cutting Way, we are social monkeys AND OWNED Yangebup WA 6164 All Funky Monkey Bars® designs are registered and protected under IP Australian certification. IP Australia...

Need help?

Do you have a question about the THE GORILLA and is the answer not in the manual?

Questions and answers