Table of Contents

Subscribe to Our Youtube Channel

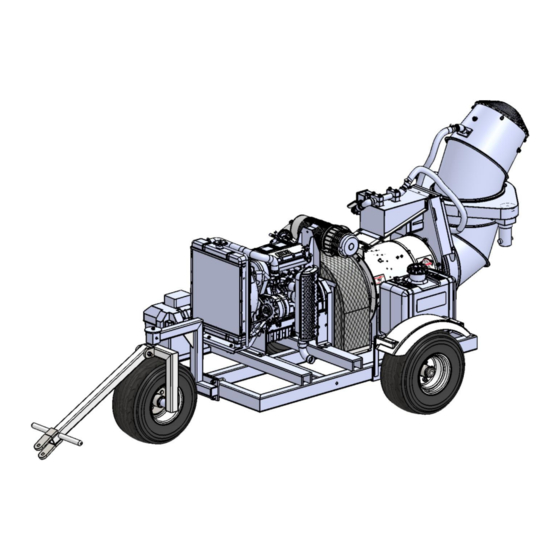

Summary of Contents for BUFFALO TURBINE BT-MDC2

- Page 1 BUFFALO TURBINE 180 Zoar Valley Road Springville, NY 14141 TEL: 716 592 2700 FAX: 716 592 2460 EMAIL: info@buffaloturbine.com WEBSITE: www.buffaloturbine.com BUFFALO TURBINE'S BT-MDC2 ORIGINAL INSTRUCTIONS AND PARTS MANUAL 06/20 -BT MAN...

-

Page 2: Table Of Contents

Maintenance Safety Fluids Service Checklist Declaration of Conformity Morflex Coupling Parts Morflex Coupling Installation BT-MDC2 Parts Reference (After serial # 24663) Oscillation Attachment Kit Parts Diagram Oscillation Attachment Kit Parts Reference BT-MDC2 Sub Assemblies 20-21 Gyratory Atomizing Nozzle parts breakdown... -

Page 3: Introduction

This Manual covers the BT-MDC2 Turbine Monsoon. Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your Buffalo Turbine dealer or distributor if you need assistance, information, or additional copies of the manuals. -

Page 4: Safety

YOU are responsible for the SAFE operation and maintenance of your Buffalo Turbine Monsoon. YOU must ensure that you and anyone else, who is going to operate, maintain or work around the Buffalo Turbine Monsoon be familiar with the operating and maintenance procedures and related SAFETY information contained in this manual. This manual will take you step-by-step through your working day and alerts you to all good safety practice while operating the Monsoon. -

Page 5: Safety Decals

SAFETY DECALS The types of decals on the blower unit are shown below. Good safety requires that you familiarize yourself with the various Safety Decals, the type of warning and the area, or particular function related to that area that requires your SAFETY AWARENESS.* THINK SAFETY! WORK SAFELY! !ATTENTION! KEEP HANDS, FEET AND CLOTHING AWAY FROM POWER DRIVEN PARTS. -

Page 6: Transport Safety

DOT Approved trailer for Highway Use and for speeds exceeding 15 MPH (24KPH). Make sure you are in compliant with all local DOT regulations regarding transporting Buffalo Turbine equipment on public roads and highways. The MDC2 can be made into a Skid Model by removing the trailer package and can easily be transported and operated in the bed of a standard pick-up truck or utility vehicle. -

Page 7: Warranty Information

Obligation under this warranty shall extend for a period of 10 years from date of purchase and, at the option of Buffalo Turbine, replacement of any parts found, upon inspection by Buffalo Turbine, to be defective. -

Page 8: 3.1 Warranty Registration Form

WARRANTY REGISTRATION FORM & INSPECTION REPORT Any units not registered with Buffalo Turbine are not eligible for warranty claims This form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery Dealer’s Name... -

Page 9: Operations

TO THE NEW OPERATOR OR OWNER Buffalo Turbine Monsoon are designed to spray a fine mist of water particles to control dust. The material is conveyed on a stream of high volume and velocity of air and water to remove it from the area of concern. -

Page 10: Model Bt-Mdc2 Assembly Instructions

MODEL BT-MDC2 Assembly Instructions 1. Fill engine oil to proper level. (overseas shipments) 2. (See Ref # 1) Attach 3 Wheel bracket (part# 3299) with 2 U-bolts each (part# 1707 and part #1180). Center (Part # 3299) with the center frame support. Tighten Nyloc nuts (part # 1180) 3. - Page 11 6. Attach 2 axle weldments (part# 3155) with 2 bolts/nuts each (part# 1137/1180). Torque to 45-50 Ft/Lbs. NEVER USE AN IMPACT GUN TO TIGHTEN NUTS / BOLTS! (SEE REF#4) 7. Install Tire (part # 2019) with lug nuts (part # 1576). Torque lug nuts to 80 Ft/Lbs (SEE REF #4) 8.

-

Page 12: Field Operation

Do not allow children to play around the stored unit. TROUBLE SHOOTING The Buffalo Turbine Monsoon uses a high volume and velocity of air to move material from one place to another. The system is simple and reliable requiring minimal maintenance. -

Page 13: Machine Specification

Machine Specifications Model MDC2 Series 136.5” with wheels and handle Length: 104.5” with wheels and handle (turned to side for transport) 88” with wheels and handle removed 55” with wheels Width: 36.5” without wheels 54”with wheels Height: 46” without wheels Weight: 975 lbs Electrical System:... -

Page 14: Maintenance

MAINTENANCE SECTION Maintenance Safety Set Blower on a level surface, stop engine, set park brake, remove ignition key and wait for all moving parts to stop before dismounting to service, adjust or repair. Reinstall and secure all guards removed for servicing before starting to use machine again. *We recommend wearing gloves when removing or installing the guard to avoid getting cut* Securely support machine with blocks or safety stands when changing tires or working beneath it. -

Page 15: Declaration Of Conformity

Declaration of Conformity According to EC Machinery Directive 2006/42/EC, Annex II B We, Buffalo Turbine of Springville, New York, USA herewith declare, that the following described machine/machinery part is to be incorporated into a(n) machine/assembly with other machinery to make... -

Page 16: Morflex Coupling Parts

INSTALLATION INSTRUCTIONS & PARTS FOR THE MOREFLEX COUPLING PART # 1746 – COUPLING COMPLETE, KOHLER ENGINE Includes PN 1110(1pc), 1111(1pc), 1112(4pc), 1113(4pc), 1114(1pc), 1115(1pc), 1256(1pc), 2869(4pc) ALIGNMENT OF TURBINE SHAFT WITH SHAFT OF ENGINE IS CRITICAL Install keys in both shafts. Slide coupling flanges on both shafts (engine and turbine shafts) Place Morflex coupling CENTER SECTION between coupling flanges and secure with 4 bolts and TOPLOC nuts. -

Page 17: Morflex Coupling Installation

MOUNTING BLOWER ASSEMBLY ONTO FRAME AND ALIGNMENT RECOMMENDATIONS Install blower assembly onto frame and tighten all of the bolts. Remove all burrs and oil from the shafts and keyways (engine and blower shafts). Using the supplied gauge, align the shafts parallel to each other (very important). Check in four places around the shafts at 90... -

Page 24: Bill Of Materials For Bt-Mdc2

BILL OF MATERIALS FOR BT-MDC2 DESCRIPTION 1100 3/8-24 X 1-1/4 HHCS ZINC GR 5 1101 3/8-24 X 1-1/2 HHCS ZINC GRADE 5 1104 3/8-24 X 2 HHCS ZINC GRADE 5 1105 3/8-24 HEX NUT ZINC PLATED GRADE 5 1106 SPACER-3/8 X 3/16 THICK WASHER... -

Page 25: Bt-Mdc2 Wireless Remote System Manual

If a valid code from an already registered TX is received, the receiver will go directly into normal operating mode. This is to speed up the startup time. NOTE: Breaking any warranty seal will void the equipment’s warranty, consult with Buffalo Turbine at 716-592-2700 before proceeding. -

Page 26: Wiring Schematic For Wireless Remote System

Receiver (Part # 3239) Wire color Function Terminal number Yellow +12VDC Black -0VDC, Ground Gray Nozzle 1 White Nozzle 1 Purple Throttle Relay Green Throttle Relay Future models will have all black wires sequentially numbered 1-12 and matching terminal numbers above. -

Page 27: Wireless System Warranty Information

Repairs and maintenance must be authorized by Buffalo Turbine. Use spare parts from Buffalo Turbine only. Contact Buffalo Turbine at 716-592-2700 if you require service or other assistance. Keep the product in a dry, clean place. Keep contacts and antennas clean. Wipe off dust using a slightly damp, clean cloth. Never use... -

Page 28: Wireless Remote System Diagnostic Tests

Troubleshooting For MDC2 Remote / Receiver Symptom – Does not throttle up properly. 1. Disconnect grey plug connected to the receiver. Grey plug must be removed by compressing the side tabs and pulling straight out as shown in Ref #1. Check to ensure that each wire is securely attached to the grey connector plug (see Ref #2). - Page 29 Step 4. If proper voltage has not been verified contact Buffalo Turbine for further instructions. 4. The engine should be off for the following tests. Apply power to the throttle actuator directly.

- Page 30 Troubleshooting For MDC2 Remote / Receiver Symptom: Nozzle will not rotate properly. 1. Disconnect grey plug connected to the receiver. Grey plug must be removed by compressing the side tabs and pulling straight out as shown in Ref #1. Check to ensure that each wire is securely attached to the grey connector plug (see Ref #2).

- Page 31 If rotation motor rotates in both directions, the motor is ok. If rotation motor will not rotate in either direction with power applied contact Buffalo Turbine. If rotation motor rotates in one direction but the other, contact Buffalo Turbine.

Need help?

Do you have a question about the BT-MDC2 and is the answer not in the manual?

Questions and answers

looking to purchase part#3513